What is a Bleeder Valve? Working Principle & Function

A threaded bleed screw is often used to open or close a Bleeder Valve. These valves are typically used to vent pressure and release media. This is frequently required prior to doing maintenance on a line that contains pressurized liquids or gases. In hydraulic brake calipers, bleeder valves are placed to allow trapped air to escape. Heat air bleeder valves can also be used to remove hot air that has accumulated in industrial tools. Bleed valves can be used to route leaks into a safe containment system in addition to screening for leaks through the root isolation valve. The pressure in the pipe segment between the two block valves must be zero. When selecting this sort of valve, keep the following factors in mind: the valve's function, its quality and durability, the valve's handling and maintenance, and the cost.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Bleeder Valve

Top Devices in Bleeder Valve

What is Bleeder Valve?

A Bleed Valve is a screw-type valve that allows trapped vapor or liquid to escape from a system. These valves are typically found on blowout preventers, pipelines, storage tanks, and pumps and are modest in size. By venting gases and liquids, they ensure that pressure surges inside drilling equipment, pipes, and tanks are controlled or eliminated.

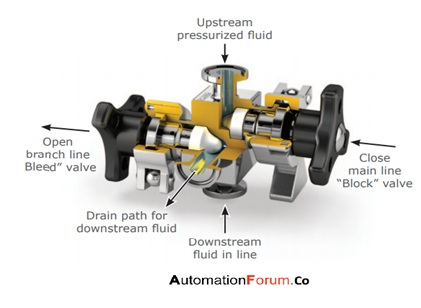

Automated bleed valves and manually operated bleed valves are the two types of bleed valves that can be categorized based on their operations. Bleed valves can be purchased as part of a complete system with block valves, or they can be purchased separately. When bleed valves and block valves are combined, block and bleed valves are formed. The block and bleed valve is primarily used to prevent oil or gas from flowing from one system while allowing oil or gas from another system to flow into the downstream network. It also relieves any built-up pressure in the system.

The Function of a Bleed Valve?

A bleed valve is a valve that is used to stop fluid or air from flowing. Many industrial applications, including piping systems and heavy-duty gas turbines, utilize bleed valves. The bleed valve's inlet will be tiny to prevent air or liquid from flowing through it. The bleed valve's primary function is isolation, but it can also interfere with the system's operation when it's needed. The bleed valve is designed to stay open at a specific pace. As a result, bleed valves can provide a tight shut-off or isolation.

For example, in some industrial processes, dangerous gases may be present, and bleed valves can keep the harmful gas from being released. Bleed valves are employed in gas turbines in various sectors, and they prevent the axial compressor from surging and stalling that might occur when the operation is started and stopped. Bleed valves are also used to transfer liquid or air from one system to another.

A combination of two ball valves and a needle valve makes up the double block bleed valve. Between the two ball valves, a needle valve will be placed. The use of double block bleed valves ensures that there is no leakage, allowing for quick maintenance and repair. As a result, twin block bleed valves are widely employed. Because this valve can ensure zero leakage, it is used in some fueling systems.

Working Principle of a Bleed Valve?

These valves are utilized in a variety of industrial applications to provide improved isolation while performing plant operations. Double block bleed valves are commonly employed in industrial systems that require sufficient isolation, and these valves are used in sensitive applications such as high-pressure systems and toxic gas industrial processes. These valves feature two seating surfaces and can block the valve on both the upstream and downstream sides.

Isolation is provided by these valves, which are commonly employed in pipelines and process systems. When the valve is closed, the individual seal is entirely isolating, preventing any flow from the downstream and upstream directions. Because of the thermal relief vent, the body cavity would bleed during an overpressure situation, isolating the downstream pipeline from the upstream pressure.

The process of isolating a section of the plant from the operational section is known as positive isolation. It can also be thought of as separating the operational part from the equipment, which could include pressure indications and level gauges. The valve with two blocks would be closed. The shutdown side and the bleed assembly would be drained. The bleed valve of the double-block and bleed assembly is used to release trapped fluid between two block valves.

You can find plenty of Bleeder valve Companies and Manufacturers in Linquip, along with expert Service Providers.

Parts of Bleed Valve

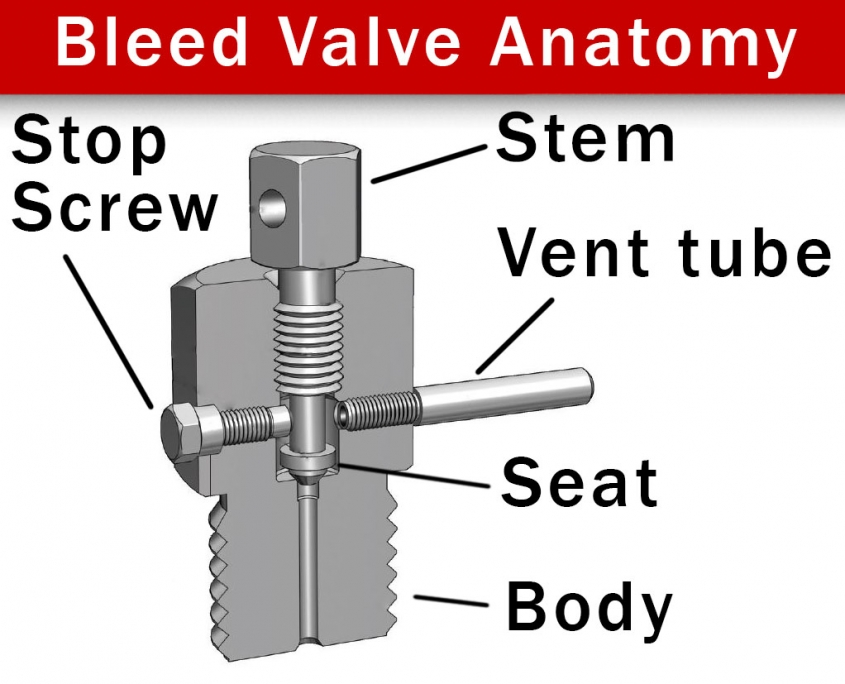

A bleed valve is a valve that opens and closes using a threaded bleed screw. Typically, these valves are used to release pressure or media from within a system. Before working on a line that carries pressurized liquids or gases, this is frequently required. Bleed valves are also used by system operators to discharge media for analysis or to calibrate other control systems. In the figure below, the various parts of a bleeding valve are shown.

Bleed valves are manually operated valves that are used to drain liquids or gases from a system or device. These valves also allow you to alter the direction of the outflow through the vent tube.

Instrumentation bleed valves can withstand higher temperatures and pressures than standard bleed valves. With a working pressure of 10,000 PSI at -65°F to roughly 6,085 PSI at 850°F, they can handle a larger range of pressures.

FAQ about Check Valve

- What does bleeder valve mean?

A bleed valve is a valve that allows liquid to be removed from a tank or tube or gas to be removed from a liquid. Bleed valves are used in hydraulic brake calipers to allow trapped air to be released. The manual bleed valve allows the air pressure in the tire to be released manually.

- What is a bleed valve on a radiator?

The bleeder valve is usually located towards the top of the radiator, but it can also be placed on the opposite end. It's spherical in shape, with two notches in the middle and a square section in the middle. The bleed key (or screwdriver) will be inserted here to drain the radiator and release the trapped air.

- What are double block and bleed?

The practice of closing in a segment of pipe on both sides of the valve rather than just one is known as double block and bleed (DBB). Close the ball valves to isolate both the upstream and downstream sides of your work area, then bleed any remaining pressure in the piping and valve.

Linquip offers a wide variety of Distributer, Experts, and Equipment for Sale of Bleeder valves.