Types of rotors fall into two categories. The ratio of rotating speed of the rotor and its frequency is connected to whether or not a rotor is marked as rigid or flexible. This article will present an understanding of types of rotors at Linquip as well as other rotor types in a helicopter, squirrel cage rotors and so on.

What are the types of rotors?

In general, types of rotors fall into two categories: rotors with a critical speed below 70 % are considered as “rigid and balanced”, and Rotors with a speed above 70 % bend or flex due to imbalance forces and are therefore referred to as “flexible rotors”.

When running at a different speed, a flexible rotor balanced at one running speed cannot be balanced. The reason is that the weight of the rotor is removed from the rotating centerline when the rotor curves or deflects to create a new unbalanced condition called “whip”. This new imbalance is re-equilibrated in the two end planes, but at slower speeds when no deflection is observed the rotor would be out of balance. A balance correcting in the real unbalanced planes is the only solution to ensure smooth operation at all speeds.

The Difference Between Stator and Rotor: The Ultimate Guide!

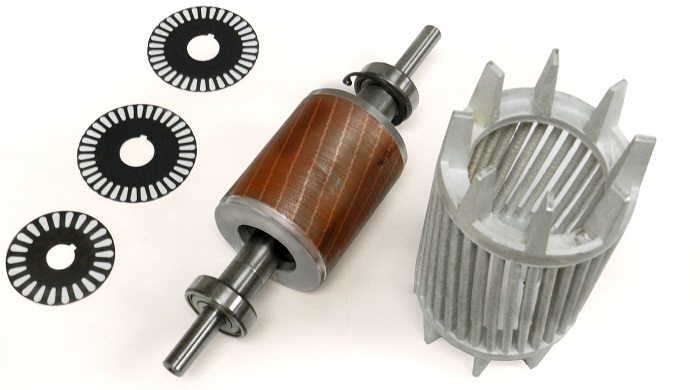

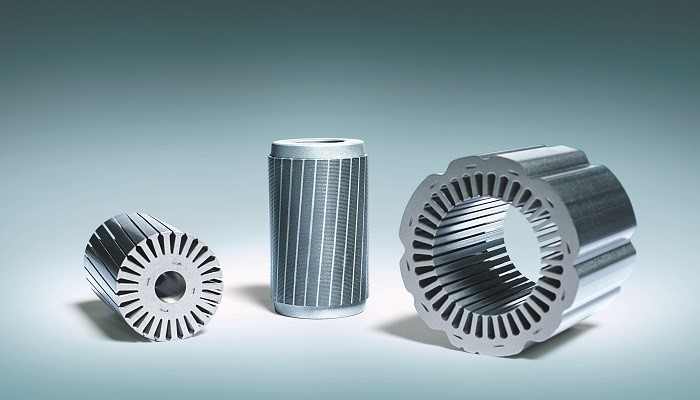

squirrel cage rotor

Besides the above types of rotors, “the Squirrel cage motor” also is another type that works on the Electromagnetism principle. It consists of rotor, stator, and other parts such as bearings, laminated cylindrical center, shaft, etc.

The purpose of cage rotor bearings is to reduce rotating and stationary friction in the unit. The engine rotor consists of a laminated cylindrical core with parallel slots to carry the rotor conductors. rotor conductors are not wiring, but thick bars of copper, aluminum, or alloy are used as rotor conductors. The shaft is used for mechanical energy transfer from or to the unit in the engine. The stator is the main engine stationary section.

Speaking of operation, squirrel cage engines optimize electromagnetic induction by using rotor bars to communicate with stator electromagnetic induction. This current changes in sync with alternates that alter the current direction of the wires. The wire stator usually contains windings that in turn contain an AC current. If the current oscillates, it will follow the generated EMF and rotate with a frequency similar to the AC frequency in certain arrangements. This turning EMF generates a counter voltage and EMF of the rotor bars, which pushes the rotor around and generates rotary movement.

This rotor (next to other types of rotors) does not spin at exactly the frequency of the AC current and, therefore, squirrel cage engines are considered asynchronous. Between the AC frequency and the spinning frequency of the shaft, there is always some loss or slip, and this is a result of the rotation of the rotor.

types of rotors for cars

Brake rotors are an important component of any vehicle’s braking system. There are four various types of rotors for cars:

- Blank & Smooth: these types of rotors are called blank and smooth rotors because they are what most passenger cars are equipped with and have a smooth, blank metal surface all around the rotor.

- Slotted rotors better dissipate heat and reduce the brake fade in hard-driving scenarios, like when you go downhill with a heavy vehicle or when on the race track.

- Drilled rotors are the third types of rotors for cars that have holes drilled in them and look like slotted rotors, for an enhanced brake cooling. They also allow water to better escape the braking surface and thus improve braking performance in the rain. This only matters on the race track.

- There are also drilled and slotted rotors that are filled with grooves and holes. While they can improve braking, many consumers want it because it looks cool.

zonal rotors

After mentioning the previous types of rotors like brake rotors and squirrel cage rotors, there is another type which is the zonal rotor. A zonal rotor is divided into four zones. At low speed, the density gradient medium is pumped to the areas. At high speed, a gradient with the same density in each area creates a range of concentric rings at the same radius. The molecules introduced into the rotor by the hub migrate to the radius where they have the same density as the gradient when the gradient is formed. The gradient distribution is photographed through the transparent rotor cover using reflected light.

types of centrifuge

The centrifuge consists of a rotor that houses the tubes where separation takes place. Two types of centrifuge rotors exist, fixed-angle and bucket swing. Fixed-angle rotors hold tubes with the axis of rotation at a stable angle (45 ° usually). When centripetal force is applied, a swinging-bucket rotor swings out and holds the cells at an angle of 90 ° relative to the rotation angle. Note that the centripetal force angle is divided by more dense material. So, the pelleted material forms at the bottom of the centrifuge tube in a swinging bucket rotor, while sedimentation is caused on the side by tubes being processed in a fixed-angle rotor. Unless the solids are trapped in the tube position, this can become troublesome.

In Swing-Bucket Rotors, usual samples range from 36 mL to 2.2 mL are assisted by a swing-bucket rotor. Two types of separations: rate-zonal and isopycnic are provided by swing buckets. For rate-zonal separation, swing buckets are preferred because the distance between outside the meniscus and outside the bottom of the tube is long enough to separate.

types of rotors in helicopter

A rotor helicopter system is the combination of several rotor blades and an aerodynamic control system that supports the helicopter’s weight and the pull that counteracts an aerodynamic thrust in a front. In contrast to a helicopter tail rotor which connects a combination of the drive shaft(s) and gearboxes in the tail boom, each principal rotor is mounted vertically above the helicopter. There are three main types of rotors in a helicopter as rigid, semi-rigid, and fully articulated.

Fully Articulated Rotor

A helicopter with more than two blades has an articulated rotor, allowing the rotation in three directions of each blade. Within this design, every blade can rotate around the pitch axis; every blade can move in the helicopter, lead and lag and flap up and down through a hinge independent of other blades.

Semi rigid Rotor

Semi rigid rotors are other types of rotors in a helicopter. On helicopters with two rotor blades, the semi rigid rotor configuration is found. The blades are so connected that the opposite blade flaps down when one blade flaps up.

Rigid Rotor

The rigid rotor system has a rare structure but offers both fully articulated and semi-rigid rotors the best features. The blade roots are rigidly mounted on the rotor hub in this design. There are no hinges on the blades for flapping or lead-lag. The blades are instead suitable for these movements with elastomeric bearings. Elastomeric bearings are rubber-like materials which are applied to the corresponding parts. They twist and flex to allow the correct movement of the latches instead of rotating like conventional bearings.

Stator and rotor in a generator

Stator and rotor are the main components of a generator. The important difference between the stator and stator in a generator is that rotor is the rotating part of the engine while the stator is the fixed part of the engine. A rotor is also known as “the alternator ‘s rotating magnetic core”. It has permanent magnets moving around the iron plate of the stator to generate an alternating current (AC). Rotors require current movement, so it will only work for a stator once the engine is running.

This article clarified different types of rotors. It then provided info on squirrel cage rotors and how they operate. To find more and possible answers to your questions, feel free to sign up and leave your comments on this article at Linquip on the types of rotors.