Cooling tower efficiency plays quite a significant role in improving the overall efficiency of commercial and industrial cooling systems. The cooling tower is an indispensable component of these systems, be it a commercial one intended for an office building or an industrial one for a refinery, and therefore, maintaining and further increasing its efficiency would be quite beneficial if not crucial.

There is a wealth of information available on Linquip’s website about cooling tower equipment and devices. Any cooling tower questions you may have can be answered by Linquip’s team of experts. Linquip has an excellent article, “What Is Cooling Tower?“, that you may find interesting.

See a list of Linquip’s Cooling Tower Products to discover a range of cooling tower devices & equipment. To take advantage of all of the features offered here, you can also register as a Linquip Cooling Tower Expert. Would you be interested in Guest Posting on Linquip? You can submit your content as a guest on the Linquip platform.

Cooling towers consist of different components with various functions whose proper performance corresponds to the overall performance of the cooling process. Aside from conditions of tower parts, the cooling tower efficiency would essentially depend on the climatic conditions, particularly the relative humidity of the ambient air and its wet-bulb temperature.

When a cooling tower is designed, some factors are taken into consideration. These factors include the wet-bulb temperature, cooling range, approach to the wet-bulb temperature, water circulation rate, air velocity through the tower’s air passageway(s) and of course tower height. These design parameters play an important role in the efficiency of the cooling tower.

Here at Linquip, we have arranged for our clients to conveniently choose from some of the best suppliers of cooling tower parts and products.

Stay put for more details on the factors that are used for efficiency calculations of the cooling towers, as well as increasing their efficiency.

⇒ View a List of Cooling Tower for Sale and Their Suppliers ⇐

First Thing to Know about the Cooling Tower Efficiency

There are two factors that are strong indicators of the cooling tower efficiency: makeup water quality and the cycles of concentration (COC). These factors will also help identify whether there is room for improving the efficiency of cooling tower.

Water used in the tower for the cooling process is cycled through the device for a number of times before being discharged, and COC is a number that quantifies how many cycles there could be. It is considered as the primary indicator of cooling tower efficiency.

The optimum value for the cycles of concentration is highly dependent on the local water quality. Therefore, it is important to know the makeup water compositions. This information can be extracted by conducting some chemical analysis of the water, which might be reported by the water supplying party, or through analysis by water treatment sections.

The impurities inside the makeup water lead to some scale formation, which alongside the water composition data could contribute to finding maximum COC.

By knowing about the recommended maximum COC, one can simply identify the existence of an opportunity for improving the efficiency of the cooling tower by comparing that optimum COC with the current one. Now, if the current COC is at the proximity of its optimum value, some water treatment technologies such as filtration systems and water softeners might be beneficial to increase the cycles of concentration even higher.

Now, let us proceed with some details about the scientific calculations concerning the cooling tower efficiency.

Cooling Tower Thermal Efficiency Calculations

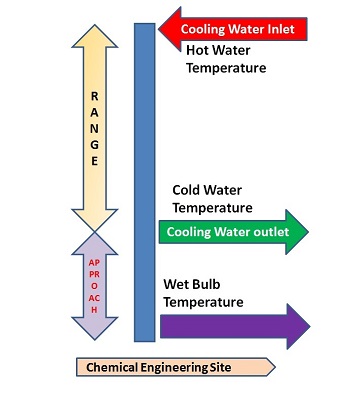

There are two factors that contribute to the calculation of cooling tower efficiency, namely the range and approach of the cooling tower. As was previously mentioned, the efficiency of the tower is highly related to the ambient wet-bulb temperature. The cold water temperature would ideally equal this wet-bulb temperature.

Of course nothing can be perfect in this word and in this case it is so because such an ideal situation can only be achieved by having a very large tower which is not only infeasible but also has its own problems such as large amounts of evaporation and windage (more on this in the upcoming sections).

Cooling Tower Approach

The cooling tower approach is the difference between the cold water temperature at the outlet of the tower and the ambient wet-bulb temperature. This measure is one of the important factors contributing to the cooling tower efficiency.

Approach = Cold Water Temperature – Wet Bulb Temperature

Cooling Tower Range

Another indicator of the cooling tower efficiency is the cooling tower range, which is calculated by subtracting the tower’s outlet water temperature from the hot water temperature at the inlet of the cooling tower.

Range = Hot Water Temperature – Cold Water Temperature

Tower Efficiency

By calculation of the cooling tower range and approach, one can easily arrive at the cooling tower efficiency. The efficiency of the tower is equal to the percentage of water temperature cool down against the difference between the hot water temperature and the ambient wet-bulb temperature. Therefore, it can be re-written as follows:

Cooling Tower Thermal Efficiency = Range/ (Range + Approach) x 100

As can be seen from the above equation, the efficiency of the cooling tower is negatively correlated with the wet-bulb temperature of its ambient. Since the wet-bulb temperature raises with temperature, hotter climates enforce lower cooling tower efficiencies, which is compatible with intuition.

Other Cooling Tower Efficiency-Related Calculations

Cycles of Concentration

As was mentioned before, water composition contributes to the maximum cycles of concentration for the cooling tower water. Therefore, COC is defined as a dimensionless number that represents the ratio of a parameter corresponding to some minerals in the cooling water to that parameter in the makeup water.

The cycles of concentration can be calculated by any of the following formulas.

COC = Silica in Cooling Water / Silica in Makeup Water

or

COC = Ca Hardness in the Cooling Water/ Ca Hardness in Makeup water

or

COC = Conductivity of Cooling Water / Conductivity of Makeup water

It is desirable to reduce the amount of makeup water in the tower, therefore higher values of COC are better. While that is true, higher COC for the same amount of makeup water means an increase of the chance of scaling and fouling of the heat transfer components. Therefore, the optimum COC is a compromise between the heat transfer quality and makeup water requirements.

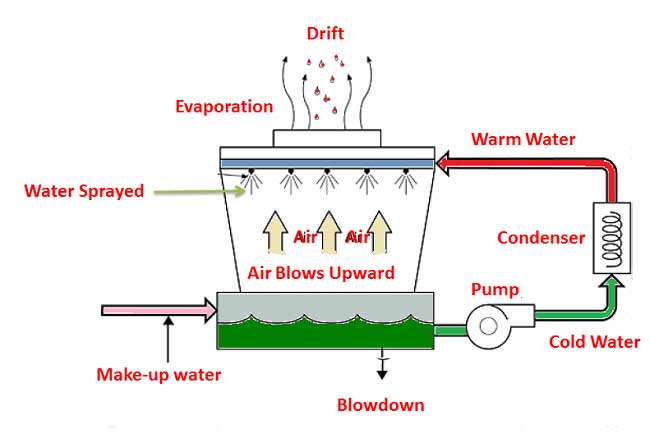

Evaporation Loss Calculation

The evaporation loss can be calculated from the formula below derived from the energy balance calculations across the tower:

Evaporation Loss = COC x Range x Cp / Hv

where

Hv = latent heat of vaporization of water = 2260 kJ / kg

Cp = specific heat of water = 4.184 kJ / (kg.°C)

or from below equation derived empirically:

Evaporation Loss = 0.00085 x 1.8 x Range x Circulating Water Flow

Bleed-off or Blowdown

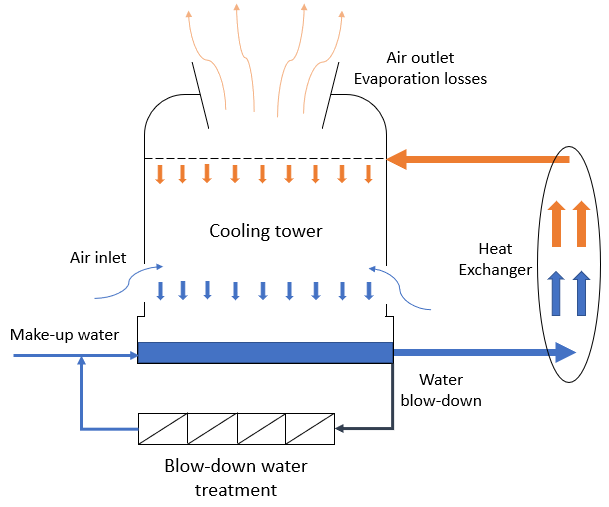

As the water in the cooling tower circulates in the system, some evaporates during the process, adding to the concentration of minerals dissolved in the remaining circulating water. When mineral concentrations pass the saturation point of the water, scale formation would be a natural result of the situation.

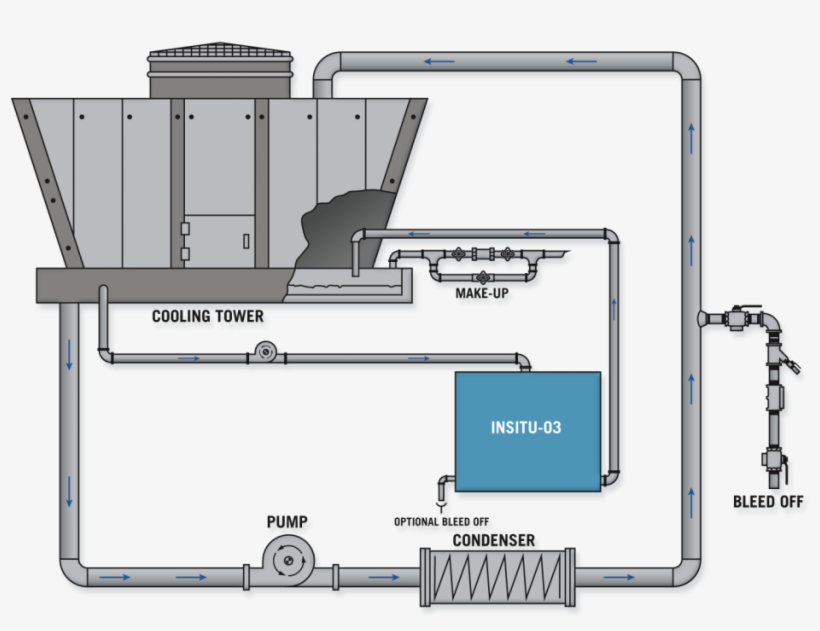

In order to address the issue of scale formation due to high mineral concentrations, a portion of the cooling tower system water that is highly concentrated with the minerals is flushed down the drain and is replaced with fresh water simultaneously in a process that is called cooling tower blowdown or bleed-off.

The formula for calculation of the amount of required blowdown is as follows:

As the cooling water circulates the cooling tower, part of water evaporates thereby increase the total dissolved solids in the remaining water. To control the Cycle of Concentration blowdown is given. Blowdown is the function of Cycle of concentration. Blow down can be calculated from the formula:

Blow Down = Evaporation Loss/ (COC-1)

Windage or Drift Loss Calculation

Windage or drift loss is the amount of tower water that is lost to the airflow through the tower. This value is normally provided by the manufacturer of the cooling tower, but in case no such information is provided, the following can be assumed for its amount:

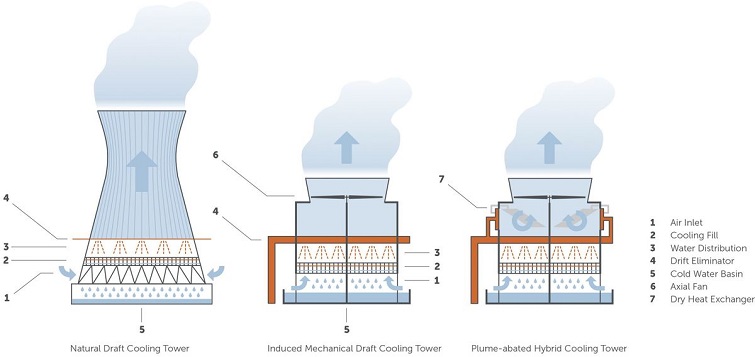

- Windage = 0.3 to 1.0 percent of the circulating water for a natural draft cooling tower without drift eliminators

- Windage = 0.1 to 0.3 percent of the circulating water for an induced draft cooling tower without drift eliminators

- Windage = about 0.005 percent of the circulating water (or less) if the cooling tower has drift eliminators

- Windage = about 0.0005 percent of the circulating water (or less) if the cooling tower has drift eliminators and uses sea water as make-up water.

Cooling Tower Makeup Water Requirement

By performing a mass balance across the cooling tower and using the aforementioned measures, the requirement for the makeup water would be the summation of the blowdown, evaporation loss, and drift loss.

Makeup Water = Blowdown + Evaporation Loss + Drift Loss

Increasing Cooling Tower Efficiency

There are some factors to look for when we seek ways to increase cooling tower efficiency. Nonetheless, how could someone quantify the effect of applied changes to the system and track them once the areas for improvement have been identified?

The truth is that measuring this improvement can only be done through some other measurements! Water flow meters and conductivity meters, for example, should be installed to monitor and track makeup water and blowdown conductivity to see how COC is changing. Therefore, it is essential to consider some reference values to evaluate the extent to which changes have contributed to the system’s performance.

Now, let us explore some ways to help with increasing cooling tower efficiency:

Mitigation of Blowdown

Blowdown limits the performance of the cooling system and mitigating its adverse effects is something that we need to address when increasing cooling tower efficiency is desired. The question here then would be how?

As was discussed in our other article on cooling tower efficiency, to which you can find the link in the beginning of this article, the goal is to minimize blowdown in order to have higher values of COC, which would result in increasing cooling tower efficiency.

Of course by lowering blowdown, the amount of discharged chemical waste would be reduced that is good news for both the environment and the economical status of the operator. Some stream filtration could also be arranged to control the amount of solid debris discharged to the environment.

Water Savings for Increasing Cooling Tower Efficiency

One of the most important economical and environmental considerations of the cooling towers is to minimize water consumption for the system. Therefore, water saving strategies could be considered as essential steps towards increasing cooling tower efficiency.

An optimum operation is when the cycles of concentration is at its highest possible value, and any COC lower than that maximum indicates that there is room for increasing the cooling tower efficiency through raising COC and hence resulting in more water savings.

Re-using Wastewater Streams

Some wastewater steams of the facility could be used as the cooling water makeup in order to minimize the amount of freshwater use. Such water streams could be pre-treated and employed as a source of makeup water without inflicting any damage to the equipment or deterioration of the performance.

Such reusable wastewater sources vary from one facility to another, but treated waste water from water treatment plants, boiler blowdown, facility equipment and floor washdowns, filter backwash, etc. could be considered as such.

Cooling Tower Water Treatment

Other than reusing treated water from other waste streams to increase water savings, there is also the possibility and necessity to treat the cooling tower’s own water for increasing cooling tower efficiency. What needs to be considered here is the concentration of minerals in the cooling process water.

The water for the cooling tower could be taken from surface water resources, such as lakes or rivers, or groundwater. Apart from that, as water moves throughout the passages to carry out its cooling duties, it takes with itself some impurities from the contact surfaces along the way. It is clear that such impurities will result in corrosion and scale formation that reduce the service life of the equipment.

Cooling tower water treatment will help eliminate the chance of scaling, fouling, and deterioration of the equipment as well as preventing malfunctioning of heat transfer surfaces. Increasing cooling tower efficiency can therefore be achieved through enhancing the quality of treated cooling tower water through more advanced water treatment technologies.

Static vs. Dynamic Driver Speeds

In case of using a mechanical draft cooling tower, there is the need for using a motor to drive the fan for heat removal. Moreover, every water pump in the cooling tower that pushes the cool water through the system has a motor as its driver. It can be understood that the motor speed plays a significant role while increasing cooling tower efficiency is intended.

Old cooling tower motors could only operate at a specified speed, i.e. its full load rating, which does not seems to be an efficient way of operation, due to the fact that there are situations in which there is no need for full power operation of the motors. This kind of motors are called static drivers.

In order to solve the issue of static driver speed, cooling towers are not equipped with dynamic drivers that use enhanced technologies that would not only assist with increasing cooling tower efficiency, but also contribute to lower noise emissions and higher reliability and safety.

New cooling tower equipment utilizing improved motor drive technology can increase overall efficiency, while also improving noise reduction, reliability and safety. Such dynamic drivers commonly come in the form of VFD or RVSS that will be discussed shortly in the following. This comes in two forms of cooling tower frequency drives — Variable Frequency Drive (VFD) and the Reduced Voltage Soft Starter (RVSS).

Reduced Voltage Soft Starter (RVSS)

Soft starters reduce motor speed during the start up in order to eliminate the danger of high initial torque. They share many benefits with VFDs, but they are cheaper and require less space. Nonetheless, motor voltage modulation cannot be done with soft starters; they are only solving the issue of motor startup as can also be inferred from the name. Therefore, the control over these drivers is lower compared to VFDs.

Variable Frequency Drive (VFD)

VFDs start stably at lower speeds that help minimize the oscillation and noise during motor startup. This means that the chance for component malfunction or failure due to full power startup of static drivers is almost zero and as a result a high level of torque exerted on stationary components is eliminated. Their speed is then adjusted based on load demand, and all this results in a much more efficient motor operation and power consumption as well as more service life of the equipment.

Despite the fact that these drivers are much more expensive than the static ones, the amount of money saved in the long term completely balances out this initial cost and results in even higher savings due to reduced water and electricity use, and low maintenance costs.

You may read here to have a better understanding of the difference between these two dynamic driver types and where to use which one in order to make a better decision for increasing cooling tower efficiency.

Additional Benefits of Increasing Cooling Tower Efficiency

Now that we have seen how some actions could result in higher efficiency of the cooling tower, we might also see how they could benefit the facility in general.

As already mentioned, better water treatment lowers the amount of scale buildup in the corresponding tower sections that guarantees higher heat transfer rates lowers the workload on the compressor.

Considering this as an example, increasing cooling tower efficiency not only yields better a performing component performance, but also leads to better performance of all the other components of the system that work together interactively, resulting in lower operation costs, maintenance costs, and watching over the environment.

Which Cooling Tower Is the Most Efficient?

Hot water is distributed perpendicularly to the air flow in crossflow (forced draft) towers while directly into the air flow in counterflow towers. Induced draft systems (counterflow) are deemed to be more efficient.

More on Cooling Tower Efficiency

More details on the ways and considerations of increasing cooling tower efficiency can be found here.

For some tips on maintenance of the cooling towers to improve energy savings click here.

To find out more about the calculations regarding tower efficiency read our post here. You may also refer to here to know some other efficiency considerations of the cooling tower.

Download Cooling Tower Efficiency PDF

You can download this article as a PDF so that you can access it whenever you like.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- How to Calculate the Efficiency of Heat Exchangers?

- Cooling Tower Approach: Basic Elements of Efficiency in Cooling Towers

- Transformer Efficiency: Essential Things You Should Know

- Cooling Tower Partsand Functions: A Concise 10,000-Foot yet Essential View

- The Counterflow Cooling Tower: A Quick Intro

- What is HVAC? Types, Parts & Diagram

- How an Air Conditioners Compressor Work?

- Crossflow vs Counterflow Cooling Towers: Which to Use Where

- The Counterflow Cooling Tower: A Quick Intro

- Top Air Conditioner Manufacturers and Companies in the US

- 5 Best Electric Boilers: A Practical Guide

- How to Choose the Best AC Repair Service

- Common Problems with Solar Air Conditioners

- Benefits of Installing Lennox Air Conditioning

- Difference Between Air-Cooled vs Water-Cooled Compressor

- Advantages of Air Conditioner: Everything You Need to Know

- What Are Air Source Heat Pumps? A Complete Guide

- 5 Types of Ventilation and All We Should Know About

- The Essential Guide to the 4 Types of Air Compressors

- Can I Use Water Instead of Coolant in an Emergency?

- A General Overview of Heat Pump Problems

- At What Temperature is a Heat Pump Not Effective? Easy Answer

- What Is a Condenser; Parts, Functions and types

- Easy Introduction to HVAC Maintenance and Services ( Heating and Cooling Repair )

- Cooling Tower Parts and Functions: A Concise 10,000-Foot yet Essential View

- How an Air Conditioners Compressor Work?

Senior technician in hvac 17 years of experience in the field, I am looking for a new opportunity

Dear Ait Ali

You Can Join to our Linquip Platforms

excellent

Thank you so much

Hi

Thanks for your comment and opinion about this article

Very Informative, Thanks….!

Happy to hear that!

It is very helpful and informative for people like me working in thermal power station

Glad we could help.

very useful thanks …

Good info for cooling tower

Good technical information

Thanks for sharing your experience with us, Sham! You can also visit our industrial directories, where you can find thousands of various industrial equipment based on your application and demand.

ange of FRP Axial Flow Fans

Cooling tower Fanx Fans Range

Available Sizes: 2 Feet to 40 feet (600 mm to 12,000 mm)

Number of Blades: 4 to 16

Static Pressure: Up to 1 inch of WG(25 mm)

Air Flow: Up to 30,00,000 CFM (1420 m^3 / sec)

Fan RPM: Up to 1440

Operating Temperature Range: – 40ºC to 120ºC