The salient pole rotor is one type of rotor construction, the word “salient” means to project. A Salient pole rotor consists of poles projected from the surface of the rotor core. But let’s pause here. There is another type of rotor field, which is called a non-salient (cylindrical) rotor. Both the salient and non-salient (cylindrical) rotor have their specific parts. We will be describing the salient pole rotor, here at Linquip, its parts, design; and then we move to non-salient pole rotor details.

What is Salient Pole Rotor?

A salient pole rotor is made from steel laminations to minimize loss of electric current. This is because the rotor is subject to magnetic field changes. Poles with the same dimensions are assembled to the necessary length via stacking laminations. There is a non-uniform air gap in a salient pole rotor. The air gap under the centers of the poles is reduced and it is maximum between the poles.

Salient pole rotors have several poles, which are built for medium and low speeds. There is also a large diameter for a salient pole generator.

Spider

Spider, the first section of a salient pole rotor! It is made from cast iron allowing the magnetic flux to move easily. The shaft is held and the pole core and pole shoe are fixed to the outside wall.

Pole core and pole shoe

The second part of the salient pole rotor is pole core and pole shoe. This part is made of a laminated sheet of steel. The Pole Core makes the magnet field less reticence and the pole shoe distribute the field uniformly to create a sinusoidal wave around the periphery.

Field winding

The field winding is wound on the former and placed around the core of the pole. This is supplied with DC using slip rings. The magnetic field is generated when direct current flows through the field winding.

Damper winding

On the extreme outermost periphery, copper bars are inserted and the rings forming damper winding is cut on both sides.

Salient Pole Rotor Designs

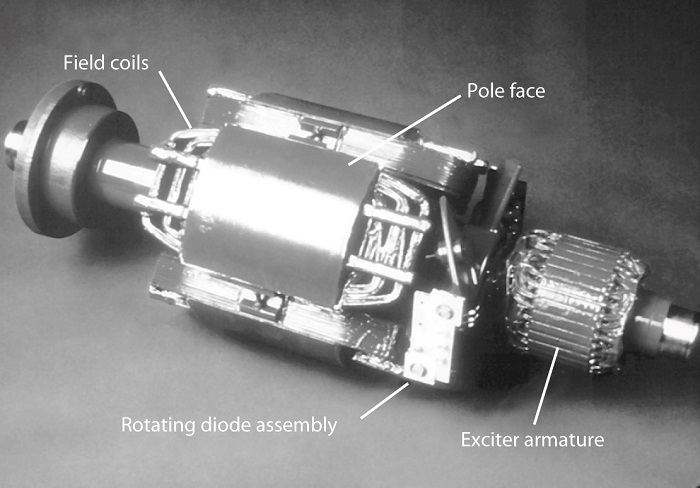

A salient pole rotor is usually found in large (many MW), low-speed, including hydrogen generators or higher-speed machines, up to 1-2 MW. It can be built up and subsequently assembled in pieces. Each pole is connected to a rotor shaft by its field-winding unit. Considering a four-pole salient pole rotor: each pole has a winding, mounted around a pole body with a “pole face” on top. The face of the pole will have a curvature different from the stator surface, which makes the resulting flux density sinusoidal. Salient pole devices are harder to build than round rotors. The torque and power characteristics of round rotor machines are different.

Characteristics of the salient pole rotor

A salient pole rotor has a wide diameter and short axial length. The Pole shoes cover 2/3 of the pitch. It is also applicable to hydraulic turbines or diesel engines. The average speed of a salient pole rotor is about 100 to 375 rpm. As the water-turbine speed is slow, more pole speeds are needed to achieve the frequency. So, the typical number of pole machines in a salient rotor is between 4 and 60. Regarding the cost, a salient pole rotor is cheaper for speeds below 1000rpm, which is in contrast with a non-salient (cylindrical) rotor machine. Moreover, there are severe losses of winding. flux distribution is not consistent in the salient pole rotor. Sp, emf waveform is not strong compared to a cylindrical machine.

Where is the salient pole rotor used?

About the salient pole rotor speed, it is mainly used for low- and medium-speed output because of its mechanical instability at higher speeds.

- It is used in hydropower plants.

- It is also used in water turbine-powered in low-speed generators.

What are the benefits of the Salient pole rotor?

In terms of efficiency, no weld is applied to ensure minimal core losses. A salient pole rotor is reliable since the core is clamped to provide rigidity under high uniform pressure. Salient pole rotors are safe; they have enhanced mechanical stability at low vibration levels. Considering the costs, they save toy money in that they minimize components that rotate and remove the element of sync. Space and weight do not matter in their production.

What is Non-salient pole (cylindrical) Rotor?

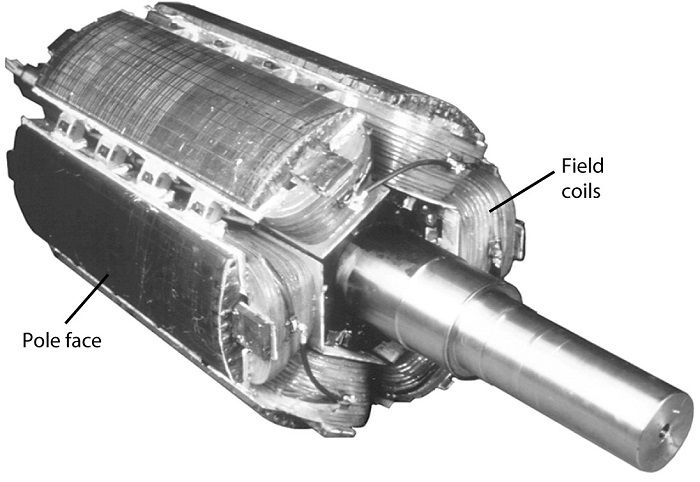

In contrast to the salient pole rotor, there is the non-salient pole (cylindrical) rotor which is another type of rotor field. A non-salient pole (cylindrical) rotor is for 2- or 4-pole machinery. Such a design offers a higher mechanical force and allows a more precise dynamic balance. Non-salient pole rotor is usually powered by steam or combustion turbines. It is made from solid steel. Also, non-salient pole rotors have parallel slots to position rotor windings in the cylindrical form. The winding is placed in rotary machine-built slots and held by metallic wings, typically made of aluminum or steel, against strong centrifugal forces. The holding rings contain the end part of the windings. The supporting rings are made from stainless steel for big devices.

What are the Non-salient (cylindrical) rotor parts?

The following parts are for non-salient pole type rotors.

Rotor core

The rotor core consists of stamping silicon steel. It is located on the shaft. Slots in which exciting coils are put are cut off on the external periphery.

Rotor or exciting winding

The rotor winding is placed on the rotor slots and the current is moved by the winding to form the poles needed.

Slip Rings

Slip rings provide DC supply to the rotor windings.

Field winding

The field winding is made by large electromagnets placed on the rotor. The rotor arrangement can be either round-rotor or non-salient or have a different air gap length.

Some important features of a Non-Salient pole Rotor:

- It has smaller diameters and a longer length of the axis.

- It is used for high-speed operations typically 1500 and 3000 rpm

- A non-salient rotor has less loss of winding

- It has a noiseless operation

- It has a stronger emf in the distribution of sinusoidal flux around the periphery.

What is the difference between a salient pole and a cylindrical pole?

A salient pole and a cylindrical pole, both, are the two main types of synchronous machines. Both of them are similar regarding the stator construction. Each has a stator that is spread over the internal periphery with a three-phase winding. But a question is raised here: What is the difference between a salient pole and a cylindrical pole? A salient pole and a cylindrical pole differ in different aspects. In high-speed machines, a cylindrical pole is useful. A cylindrical pole is also better in dynamic balance. Besides, there is no need to have damper windings, as the field poles serve as dampers themselves.

Up to now, we have provided information about the salient pole rotor, what its different sections are as well as its benefits and uses. We went further to give you info on another type which is the non-salient (cylindrical) rotor. So, you read about these issues, but you may want to know how the two types differ from each other in more detail. So, check our next article about the differences between the non-salient rotor and the salient pole rotor at Linquip. You will find exciting things about them.