There are many things to consider when you decide to buy ball valve parts. You should know the ball valve well enough and for that, you need to learn each and every part and gain a deep understanding of ball valve replacement parts to find the right Valevs for your system. Linquip gathered around all the necessary information you need to know about ball valve parts in this article. So read on and enjoy effortless learning.

⇒ View a List of Ball Valves for Sale and Their Suppliers ⇐

Different ball valve parts

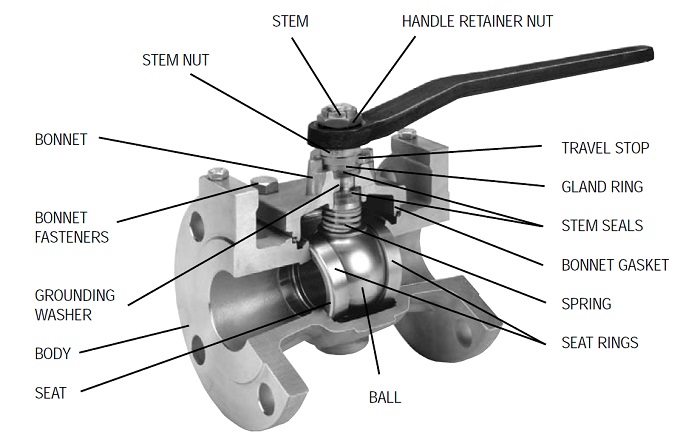

Let’s get into different ball valve parts to have an overall idea of how ball valve manufacturers put them together to help us control the flow inside a system.

Shell or Body

One of the main ball valve parts is its body. The shell or body is used to keep all the units of a ball valve together and help them stay in one place. Plus, it helps keeping all the units safe from outside threats and dangers to some extent. No matter what shape or type the ball valve is, it will always need a shell or a body to keep everything together. This framework also works as the pressure boundary of the ball valve when it comes to protecting the units inside, preventing the volume and the pressure of the liquid from damaging ball valve parts.

Bonnet

You’ll see the bonnet in the opening of the ball valve’s body. Bonnet is used to cover this opening and just like the body, it serves as a pressure boundary at the second stage. Bonnet holds the ball and the stem assembly in place and its cap is fastened to the body to do the task. By the right adjustment of this unit, you can achieve the right compression of the packing to supply the stem seal. Manufacturers usually make the bonnet with the same material as the shell or the body. This makes the valve more strong and firm since the bonnet is bolted and screwed with the body in many cases.

Watch Video about Ball Valve Parts

Ball

The ball is another one of the ball valve parts that shapes like a sphere and contains a flow path (also known as hole or tunnel) at its center. The ball has a connection point for a shaft which permits the rotation of the ball.

Actuator

The actuator works with the parts inside the Trim (don’t worry, you didn’t miss the trim! It’s the next one on our list!) Actuator runs the stem and the disk (two parts of the trim). There are different designs for actuators you can choose based on the operation you need. Different actuator designs include: handwheels, motors, levers, solenoids, pneumatic operators, or hydraulic arms. The most popular design is that the actuator will be mounted with the bonnet through a yoke.

Trim

Different ball valve parts together create the Trim. These parts are Disk, Sleeves, Seat (also known as seals ring), and Stem. Trim enables the ball valve to perform basic motions as well as providing flow control. The disk separately is considered as a pressure boundary at the third stage in many designs, just like the body that was the first stage and the bonnet as the second stage. The disk has pressure-retaining capacity, enabling it to prohibit or permit fluid flow.

In the Trim, the seat and the disk together help determining the performance of the ball valve system. The seat works like an interface, showing where the disk is seated and it is designed in two different ways. Manufacturers either forge the seat within the body, or welding it by machine. The seat shapes like a doughnut. This round unit contains discs that form a seal between the ball and the body.

Stems usually have a rectangular portion at the ball end. By turning the stem, the enlargement enables the rotation of the ball. The stem is not fastened to the ball in a ball valve. The stem is also responsible for connecting the disk and the actuator through welded joints and help positioning the disk.

Packing

The space between the bonnet and the valve stem needs something to help prevent leaks. That’s where packing comes in. The packing helps preventing leaks from this space. There are different materials enabling packing to seal the space between ball valve parts (the internal parts) and the outside environment of the valve. These materials can fibrous materials such as flax or Teflon that can make the packing the best choice for sealing. Since leaks can cause damage to the ball valve system and its environment, it’s important for the packing to be properly placed at the right space. It shouldn’t be too loose or too tight.

Popular materials for ball valve parts

Since ball valves work with pressure, they should be designed and created with durable materials that can endure different environmental parameters such as diverse temperature, different pressures, etc. There are some popular materials used to create ball valve parts such as: Stainless Steel, brass, bronze, chrome, titanium, PVC, CPVC, Teflon, flex, etc.

Advantages and disadvantages of ball valves

Ball valves are less expensive compared to other types of valves! Plus, they need less maintenance as well as low maintenance costs. Another advantage of the ball valves is that they are compact and provide tight sealing with low torque. Not to mention their quick quarter turn on / off operation. And they don’t need lubrication! But every good unit has disadvantages too… and so do ball valves. The conventional generations of ball valves have poor throttling characteristics and the seat quickly erodes due to the impingement of high velocity flow.

So that was all there’s to know about ball valve parts and their application within the system. Want to share your experience with different ball valve parts? Write to us in the comment section and let us know what you think about ball valve types and their different parts. If you have any questions and need an expert to help you out, feel free to sign up on our website and we’ll be right with you.

See All Safety & Relief Valve for Sale

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Valve Suppliers and Companies in United Kingdom

- Solenoid Valve Suppliers and Companies

- Regulating & Pressure Reducing Valve Suppliers and Companies

- Angle Valve Suppliers and Companies

- Ball Valve Suppliers and Companies in United States

- Flanged Control Valve V150 for Sale

- Fisher EZ Control Valve EZ for Sale

- Control Valve ET for Sale

- Ball Valve Manufacturers

- Needle Valve Manufacturers

- Air release valve Manufacturers

- Control Valve Manufacturers in United States

- Solenoid Valve Manufacturers

- Control Valve Parts: The Go-To Guide for beginners and experts

- globe valve vs ball valve; Which One Is the Best for You?

- Industrial Valves A Comprehensive Review on Parts, Types and its Usability

- Control Valve Types101: Different Classifications, Advantage and Disadvantages

- Ball valve types and their uses

- What is Pinch Valve

- What is Piston valve

- What is Plug Valve

- What is Pressure Reducing Valves

- What is Safety & Relief Valves

- Gate Valve vs Ball Valve

- Ball valve vs Plug valve

Very Informative article.

Thanks for visiting our website and leaving your comment! We hope to hear from you again in our other posts.