According to international reports worldwide, 15-25% of heat loss from buildings is made happen by air leaking out of the building. Heat Recovery Ventilation (HRV) proposes a method to bring fresh air into your home without allowing the heat runaway. Air leakage makes homes more problematic to heat. Not only this is big trouble for the environment, but also heating an unsealed house needs more cost and time. The house heat recovery ventilation system operates without interruption to provide new, filtered air to inhabitable rooms and extracts stale air and moisture from wet rooms like bathrooms. As a result, heat recovery ventilation systems guaranty that the heat we generate on daily activity is not wasted.

Here at Linquip, you’ll find everything you need to know about heat recovery ventilation systems. We at Linquip strive to offer you a wide selection of the most efficient ventilation systems on the market. The Linquip’s “Ventilation” page provides information on what Linquip offers in terms of ventilation systems equipment and parts.

Searching for heat recovery ventilation system parts? Linquip’s website offers a free database of Ventilation Products. We also make it easy for you to request free quotes from different Ventilation Suppliers and Companies through Linquip.

What is Heat Recovery Ventilation, or What is the HRV system?

Modern buildings are normally constructed to far higher technological standards than homes made a few decades ago and have much more energy efficiency, mainly due to better heat sealing. We spend 90% of our time indoors approximately, so clean air is vital for optimum healthiness. Unfortunately, many businesses and homes have polluted air. However, the link between indoor air quality and health matters such as allergies, asthma, and respiratory ailments is popular research; the importance of indoor air state for cognitive performance is less known.

Recent workplace research has presented that indoor air state influences the ability to focus, condition, and worry, and more time disposal can even cause personality modifications, weakened memory, and slower cognitive performance. Of course, opening a window changes the stale air for new air. But this operation deactivates all the time and effort spent in sealing the home. Besides, opening a window chills a space too fast in the winter months. Now, we should consider some strategies to revise this matter.

There are many procedures to improve air quality to keep pollutants out and thin airborne contaminants with a ventilation system, however, a large number of them increase the heating and cooling costs while reducing comfortable internal situations. This is while HRV systems preserve energy and reduce utility bills. The exhaust air has heat that is conveyed to the entering air by a heat exchanger. Heat recovery ventilators are about 95% efficient, conserving energy. This also helps decrease the volume and size of the HVAC (Heating, Ventilation, and Air Conditioning) instruments needed due to the fact that it does not have to operate as hard to cool and heat when the intake air is desired by the HRV section.

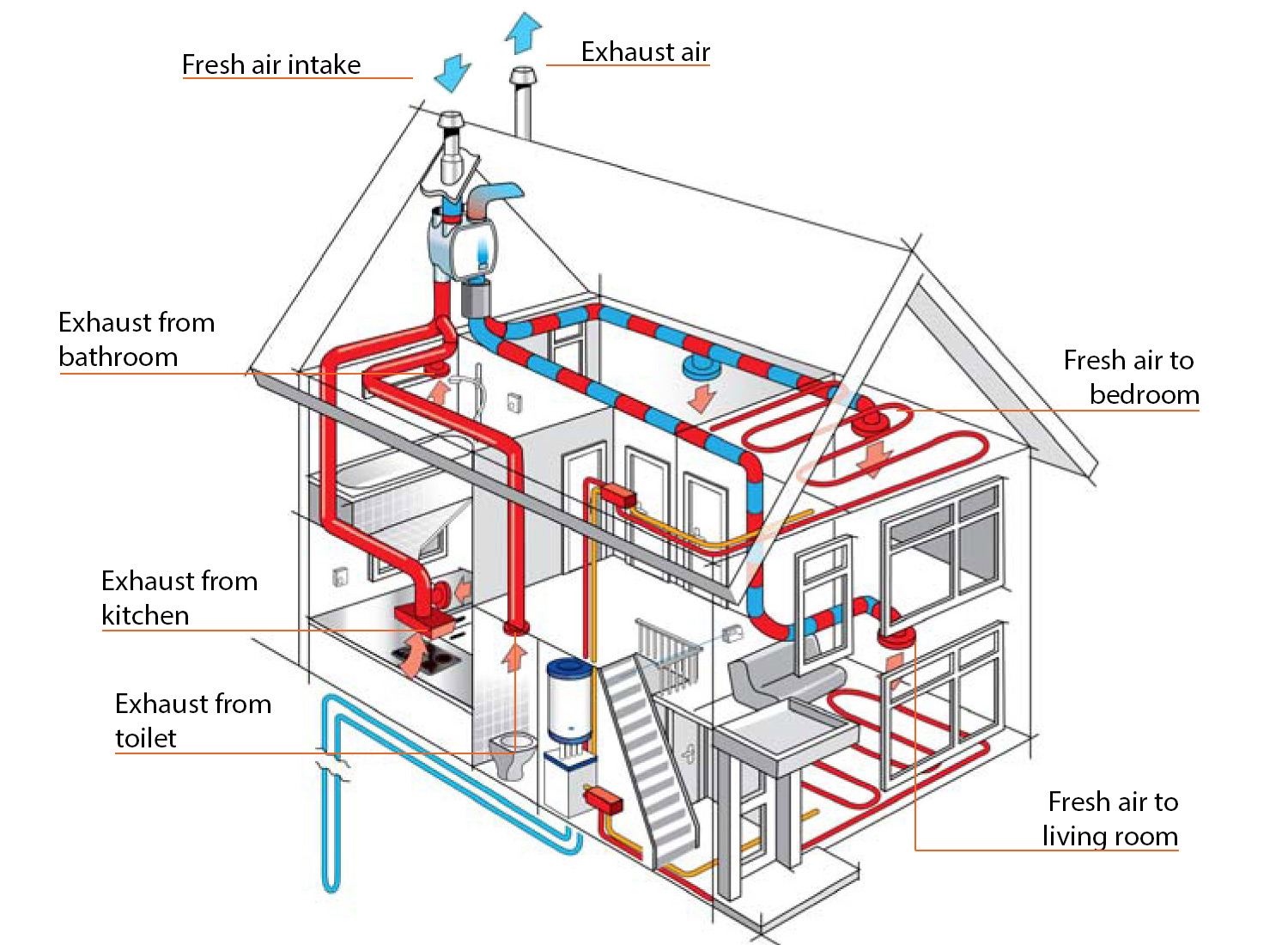

HRV systems utilize filters to take away many pollutants from the air prior to entering homes and business places. High-quality HRV filters can cease and remove even small toxin particles such as smoke, smog, pollen, bacteria, and mold spores, from entering your home or office. HRV devices are also modeled to exhaust stale air precisely from kitchens, bathrooms, and utility rooms, where most home contaminants such as fumes, particulates, and excessive humidity grow and originate. Click here to see what happened in the air quality of your home when you install an appropriate HRV system.

Toxins and other pollutants like smog, mold, pollen, fumes, radon gas, and odors all reduce the state of home air health. Internal air pollution can be particularly treating people who are compromised immune systems, have chronic illnesses or have chemical or mold sensitivity. HRV systems help prohibit mold growth by exiting excessive humidity made by cooking, washing dishes, showering, doing laundry, and occupying other household operations.

All molds generate allergens and irritants. Although disposal to mold outdoors hardly concerning, internal mold formation usually causes health issues in occupants. Instant or delayed allergic reactions can be done by breathing in this place or touching materials containing mold spores. These reactions consist of red eyes, an asthma attack, sneezing, a runny nose, and a weakened immune system. An HRV system supplies a constant reserve of newly filtered air for the home’s occupants. The HRV system can operate to obtain and recover warmth from spaces you may not even have thought of like the ground in your garden or the air outside. It permits us to be more efficient and can help decrease the amount we cost for our energy bills.

Heat Recovery Ventilator Types

Heat recovery ventilation systems have different types, but all include some form of the heat exchanger. The most efficient types of them are as follows:

Thermal Wheel Units

Thermal Wheel units are the biggest in size among HRV systems, so they have the largest air recovery efficiency of all the ventilation types. They have consisted of two large wheels using a honeycomb array, one half of which is drawing in stale air, the other half new air from outside the home. The wheels have rotations in opposite directions to each other, and the energy from the exhaust air is moved to the entering air, heating it up. The profit of the thermal wheel is that it is extremely efficient (up to a maximum of 80%) contrasted to other systems and is likely to prepare a fast return on investment if established appropriately.

Heat Pumps

Heat Pumps capture the heat from one section and move it to another location. They run in the same way as refrigeration devices and can be utilized for both warming and cooling the air like an HRV system. There are several different diversities, and they can extract heat from the external air as well as from the ground through the utilization of a network of pipes.

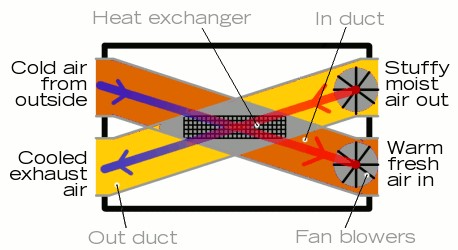

Plate Heat or Recuperator Technology

Plate Heat or Recuperator Technology is more usual than thermal wheel heat improvement according to the fact that it can be employed on a smaller scale than other types of HRV systems. It contains a box with a series of parallel surfaces constructed from plastic or metal, which permits the exhausted air to bypass the entering air, moving the energy and heating it up. The airflows are divided by the plates and have no contact with each other. So, one of the important factors in the efficiency of any system is how fine and conductive the individual surfaces are. Plate heat recovery devices usually have an efficiency near 70% at best.

Run Around Coil or Closed Loop Technology

Run Around Coil or Closed Loop Technology is an existing air monitoring system and normally contains two coils that are joined to each other by a pumped array of pipes. Water is typically utilized to charge the circuit, exhausting the heat from the external pipe and moving it to the reserve air coil. Heat recovery ventilation systems such as these are employed where the two airflows are not close enough for more efficient systems. It usually presents a maximum efficiency of up to 50%.

Heat pipes

Heat pipes need the lowest maintenance among all the heat recovery ventilation systems. They can, however, just be utilized where air monitoring is operated in one system. It employs a tube system with a refrigerant to exhaust the heat from the external air and bypass it to the reserve air. Vertical pipes utilize the evaporation of the refrigerant to move the heat; however, horizontal ones employ wicks with the pipework that also let the moving of refrigerant. Vertical networks are more efficient than horizontal ones, by about 25%.

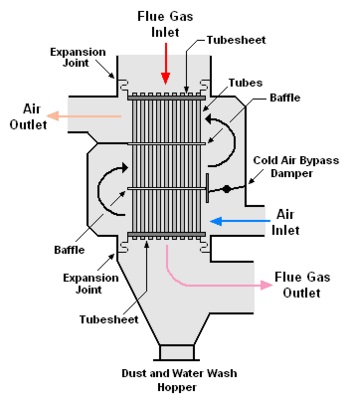

Boiler Flue Economizers

As HRV systems, Boiler Flue Economizers can now be introduced as a subject of course on new boilers. They can also be reassembled into older ones and catch the heated vapor, which can then be utilized in diverse ways to increase boiler efficiency. In most cases, efficiencies of 5 to 15% can be achieved by considering the matter of condensing or non-condensing gas-to-water systems.

Heat Recovery Ventilator Components and Working Principle

A Heat recovery ventilation System has some main parts as following, but it can consist of other components according to the required application.

- An entering vent in at least one room of the home.

- An air monitoring unit with heat recovery.

- A corresponding external vent for each entering vent.

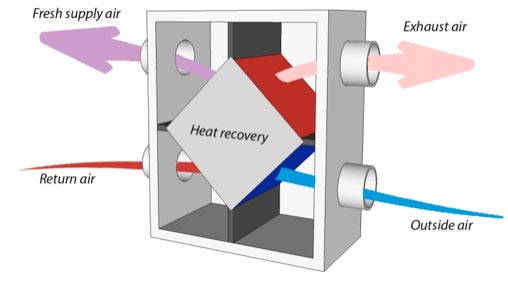

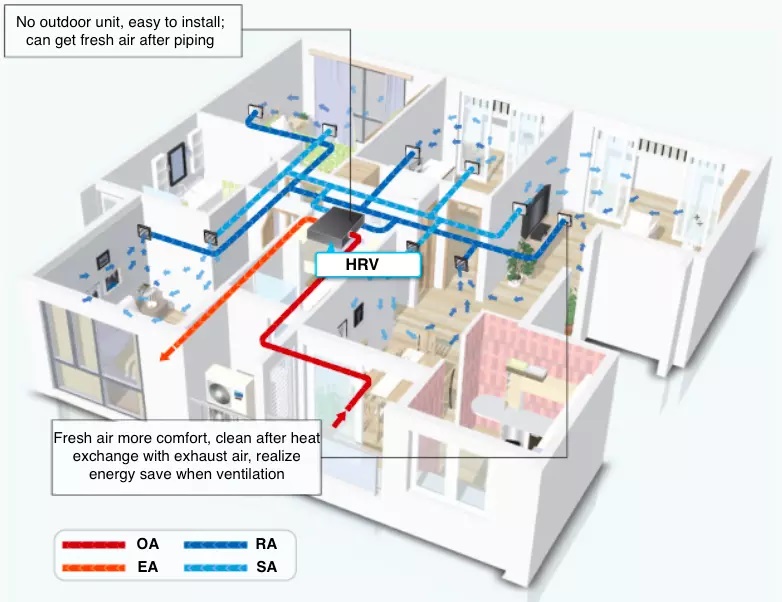

The entering vents bring in new air from out of the home. As the air enters through the roof, it passes within the heat exchanger. They include two ventilation channels operating near one another, moving between the inside and the outside of a home. One transfers fresh, cold air in; the other carries humid, old air out. The important matter is that the airflows operate through a system called a heat exchanger that permits the exhausted air to cross most of its heat to the entering air without the two airflows combining together. Typically, there’s a fan (blower) in each channel that can be turned down or up either automatically or manually or depending on the temperature and moisture rates. The entering air reserve may also have a bypass way assembled to it so that on summer months, when it’s cooler out than in, cold outside air can be moved straight into the home without mixing outgoing air.

Heat Recovery Ventilator Advantages

The advantages of HRV systems are multiple and various. HRVs have an obvious fascination: they give you a warm, well-ventilated home and stop you to cost more. In winter, they can help preserve your heating costs; in summer, they decrease the requirement for air conditioning. By keeping extra humidity out of your home, they’re better for your building, your instruments, and your healthiness.

The HRV systems help to keep the climate in your home in a more constant state. Normally, the HRV systems can maintain about two-thirds to three-quarters of the heat that would usually be lost from your building through ventilation, so they really do reserve energy. According to international environmental reports and calculations, HRV systems can safely cut the number of air modifications per hour in a house by about 50 percent, decreasing the energy loss through recovery ventilation up to 65 percent. Few amounts of this energy are utilized to power the electric fans in the HRV system (typically about 50–100 watts, and as high as 300 watts in some cases), but there’s still a noticeable energy saving.

However, HRVs are expensive to install at first, and they’re not guaranteed to pay back your costs soon. The most advantages of HRV are in harsh climates; where the difference between inside and outdoor temperatures is considerable in summer, winter, or both. Therefore, in moderate climates, the benefits are much decreased and may, in some cases, be not existing.

Energy Recovery Ventilator Installation and Sizing

Proper HRV system design, modeling, layout, sizing, and commissioning are important for the best HRV function and perdurability. It is vital that the heat recovery ventilation and HVAC systems are part and do not share the channels of ductwork. This certifies appropriate energy efficiency and airstream rates. You must employ ventilation experts to help you design the best system for a specific project, containing the sizing of the HRV system and running the ducts. They can propose technical assistance, making the systems easier and faster to set up, even for people who aren’t skilled in HRV installation. Click here to visit a patent of appropriate installation for HRV systems.

Properly designed and installed HRV systems are considerably more efficient in modifying air quality. Imbalanced systems can reduce the efficiency of an HRV from around 90 percent to around 60 percent, ensuing in four times more energy waste. Some of the HRV devices have semi-stiff tubing, which is perfect for long duct operations and can be bent over and under blocks, including joists and pipes. This removes the requirement for straight duct runs and reduces the number of joints, saving both money and time.

A Quick Guide for the Sizing of Ducts in HRV Systems

Ducting must permit the resistance of airflow. A larger ducting diameter presents better running of the airflow and lower noise. The average size of the duct is 200 mm. The ducting must have the following conditions:

- Have as flat as feasible inner surfaces to minimize the resistance to the airstream

- Have as few curves as practicable

- Where curves cannot be passed, allow them to have the largest diameter possible

- Not have extreme curves since this can cause resistance to the airstream

- Be protected by interposing material that prevents the loss of heat or the intrusion of sound

Energy Recovery Ventilator Cost

There are too many specific matters that require to be considered when trying to fix a price for any installation of heat recovery ventilation. This can contain the existing system and how difficult it is to approach pipework, the age of the building, as well as the level of insulation, and the extent of installation work needed. The price of heat recovery ventilation also differs from business to domestic installations, as you would anticipate. Generally, a domestic HRV system could cost between £2,000 and £7,000 according to the amount of work required and the size of the sections. The cost of the heat recovery ventilation unit is one sight, but the installation operation is usually complex and often harder than other renewable technologies.

Despite the variables included, it is feasible to give an approximate idea of how much you can anticipate costing. For a business or office building, the HRV system you can anticipate to cost around £7,000 to £12,000, although this cost may well be rather higher in the case of retrofit procedures given practical installation problems. This price will normally contain all sections (ducting, control panel, heat exchanger, etc.), installation, as well as the modeling of the device to fit your feature. The more effective rotational heat exchanger diversity of the system will cost rather more than this. It may cost between £6,000 and £8,000 for a boiler flue economizer for greater heating systems.

FAQs about Heat Recovery Ventilation

- What is the difference between an HRV and an ERV?

HRVs and ERVs share the function of providing fresh air to the home and exhausting stale air, while also recovering heat from the exhaust air. Both HRVs and ERVs transfer heat, but ERVs transfer heat and moisture simultaneously.

- What is the recommended CFM of an HRV?

In order to keep indoor air quality high, heat or energy recovery ventilators (HRV or ERV) must deliver 0.35 air changes per hour. In this calculation, the entire house volume must be taken into account. A rate of 5 CFM for every 100 square feet of floor area will make this calculation much easier.

Conclusion

This post was intended to provide the readers with an in-depth guide to heat recovery ventilation systems, including basic information, diagrams, types, components, costs, and pros and cons. Feel free to contact Linquip Ventilation Experts with any questions you may have about selecting the right HRV unit for your building, or about purchasing the right equipment and parts. Furthermore, Linquip offers a database of numerous HRV Service Providers so that you can easily find local service providers if you need maintenance or repairs on your HRV unit.

A video for the Heat Recovery Ventilation

The following video provides a visual overview of HRV systems. Complete your knowledge by watching it.

Download PDF for Heat Recovery Ventilation

This article is available as a PDF file and you can download it if you wish to read it later.

linquip.com-Heat Recovery Ventilation HRV Definition Advantages amp Installation