A 3 phase air compressor is used by many large companies because of it is durable and reliable. It also has several other advantages compared to single-phase air compressors.

You must understand how to select an air compressor that fulfills your requirements and delivers the outcomes you need while staying within your budget. An Essential Product of Using Industrial Tools Is a Three-Phase Air Compressor. 3 phase air compressors are provided by several suppliers and companies, different manufacturers, and a lot of Distributers and there are a lot of 3 phase air compressors for sale on Linquip.

There is a comprehensive list of air compressor services on the Linquip website that covers all OEM fleets. Linquip vendors can assist you with this. Please contact Linquip’s 3-Phase Air Compressor Experts to learn more about how to connect with a wide choice of service providers who consistently deliver the highest quality products.

Today, we are going to give a basic yet clear description of the 3 phase air compressor in this new article at Linquip. So, follow us to get more about it.

What Is a 3 Phase Compressor?

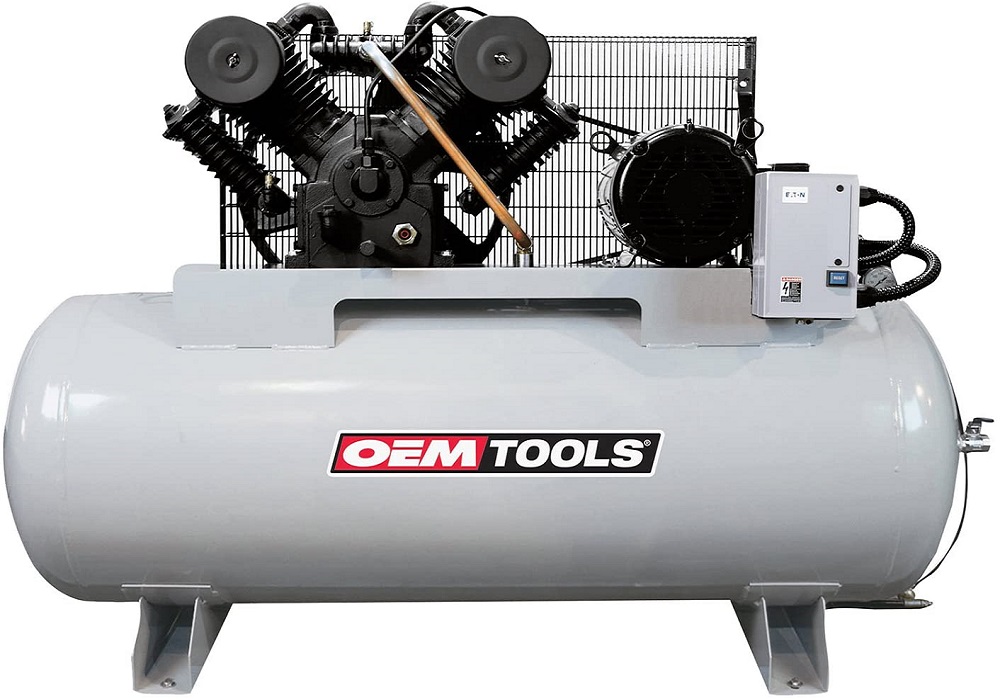

A 3 phase compressor is an air-conditioning machine that produces energy to attach air devices, such as grinders or nail weapons, in the storage tank. It has three different power windings inside one motor housing to create a steady power supply to the 3 phase air compressor. This specialized machine does not use a single, basic winding motor.

The compressors are supplied with the electrical alternating current (AC) for the motor, equivalent to power from a standard wall outlet; but a 3-phase compressor must have three electrical offset pulses for a specific AC supply. Three phases of electrical power supply continuous power supply to the compressor with the crests of three different electric pulses. The machine creates a steady power supply for the hard-working compressor motor which would come up against a single-phase motor.

The 3 phase air compressor function is simply similar to single-phase compressors. Until the storage tank is densely filled with air molecules, the engine forces the compressor into the machine outside the air. A user adds a compressed air to the unit and rushes it into the device for mechanical motion. Many enterprises use compressors because they can be used with different tools to ensure that employees don’t get tired of heavy instruments that require separate motors.

But there is a difference between the three phases and the single-phase air compressors. The main difference is primarily in the voltage provided by each wire form. Single-phase control is also referred to as “split-phase” power. Several methods are available to determine if a three-phase wire or single-phase wire is present.

A 3 phase air compressor has got several advantages and “Lifespan” is the main advantage. The steady moving power to the motor of the compressor ensures the system remains in a steady-state; as with single-phase control, the motor does not need to be turned on and off. This increases the longevity of the engine. Also, the three electric winding systems are less current; and this protects the operation of the winding to prevent premature failures and expensive repairs.

However, one problem with a 3 phase air compressor is the specific electrical supply. That is, the majority of home garages and smaller companies have normal one-stage power, and pulses withing each outlet received from the electrical company. Larger companies tend to have three-phase power, such as welders and generators. To operate this type of compressor, a home hobbyist or small business will have to install three-phase power systems in its working space.

As one type of 3 phase air compressor, the 3hp 3 phase air compressor is an advanced machine made to meet the ever-increasing requirements of the customers. A 3hp 3 phase air compressor can be used for industrial as well as commercial purposes.

3 phase air compressor to single phase

Switching of the 3 phase air compressor to a single-phase can provide the easiest, most cost-effective solution for one phase operation. For three-phase machinery operation on a single-phase, we offer various options.

The rotary phase converter is the most common. They are simple to install and reliable to supply machinery with three-phase power when only one phase source is usable. The phase conversion needs to be very conservative due to the high demand during the startup of air compressors and at full load.

Variable speed motor drives (VFDs) can be used as a good choice for smaller loads because they offer high reliability in a compact, low maintenance packag, high efficiency, and integration of motor protection. The problem is that it is more complicated to install and they tend to lose their cost-benefit above 5 HP.

Once the 3 phase air compressor is converted into operating systems with only single phased control, many customers tend to find a reliable solution at a reasonably low cost. But, for certain cases, a second-hand 3 phase air compressor may save considerably on its single-phase equivalent, but this benefit is lost when considering the comparatively large Rotary Phase Converter or VFD expense required to operate correctly.

3 phase air compressor wiring

The basic requirements for 3 phase air compressor wiring include adding a nameplate for each engine, usually on the side or end of the engine. The label details show the scale of the motor and electric demands. An electrical service then must have either three phase-230 volts or three phase-460 volts for the shop where the motor is to be mounted.

Then, an electrical service panel, like electric engines, should be fitted with a label that is either attached to the cover or inside the door. The label info will be specific to the production, models, and voltage rating of the electrical panel. An analysis of the main circuit breaker, which has the amperage ratings, such as on the breaker handle, is better known for its true amperage power.

Electrical Power for a 3 Phase air compressor needs three separate power lines that are produced by a three-phase electrical service panel without becoming too technical. A one-phase panel with 120/240-volt found in a shop or a home could only supply up to two separate power lines, so the power needed by a 3 phase engine could not be provided by such electric services.

Next: 3 Phase Motor Starters and Control Circuits

As mentioned above, 3 separate isolated wires for power and ground wire will be installed on the standard 3 phase motor circuit. For a 3 phase motor, a neutral cable is not required.

To summaries, about 3 phase air compressor wiring, it is required to identify the voltage and amperage required and determine the voltage and amperage capacity of the electrical service panel. Then, electric motors typically are attached to a motor controller or engine starter that is appropriately designed to protect the motor’s heat and thermal overload.

Ingersoll rand 3 phase air compressor

Ingersoll Rand 3 phase air compressor, as one of the other kinds of the 3 phase air compressor, offers a broad range of oil-free compressors, suitable for your industry and application. Ingersoll Rand assesses and recommends the best oil-free air compressor solution to meet the requirements – from processes that involve high flow volumes to industries with fluctuating demands that need to use the Nirvana oil-free VSD compressor. We are equipped with compressors without oil screws, centrifugal compressors, PET solutions, and many more.

The key benefits of Ingersoll rand 3 phase air compressors are:

- Our oil-free air compressors increase installation productivity with optimized compressed-air solutions tailored to suit your needs;

- zero danger of your final product being contaminated;

- These compressors are robust and reliable for harsh environments through the use of highest-quality materials by trusted and world-class suppliers.

The quality of the Ingersoll 3 phase air compressors has three features:

- Regulatory compliance: in several countries, the use of compressed air is subject to strict legislation in sensitive industries, for example in food and drink or pharmaceutical;

- Use of an oil-free air compressor certified in Class 0: this ensures contamination-free air

- Efficiency and productivity: High-quality air (oil-less 0 air class and -40 ° C PDP) safeguards secure, low maintenance and long-life downstream equipment.

Can I Run A 3 Phase Air Compressor on a Single Phase?

It is difficult to connect a three-phase air compressor wire to a single-phase panel since the two are incompatible. Rather, you may run a three-phase wire through a secondary system that converts your 120/240 system to the correct voltage.

How Do I Know If My Compressor Is 3 Phase?

From within the compressor, three electrical connections should be connected to the housing. The terminals of a three-phase compressor are labeled T1, T2, and T3. A single-phase compressor, on the other hand, will have three terminals labeled S, R, and C. (Start, Run, and Common).

In this article, we tried to provide a good understanding of the 3 phase air compressor. But you might want to know about other types and its sale procedure. With our team of experts, we are here to answer all your questions. So, register at Linquip for more information on 3 phase air compressor.

Read More on Linquip

- What is Air Compressors & How Does it Works?

- How an Air Conditioners Compressor Work?

- The Essential Guide to the 4 Types of Air Compressors

- The 7 Best Air Compressors

- The 8 Best Small Air Compressors

- Top Air Compressor Suppliers & Manufacturers In The World

- The 10 Best Air Compressor for Home Garage

- The 10 Highest CFM Air Compressors

- The 10 Best 12v Air Compressors

- Difference Between Air Compressor and Air Pump

- How Much Does It Cost to Replace A Compressor in An Air Conditioner?

I need 3phese electric motor with compressor and how much is it