Gate Valve vs Ball Valve – The valves in a functioning plumbing system are one of the most crucial parts. Valves control the flow of liquid by allowing it to start and stop, and they must operate adequately to avoid leaks and unwanted flow. While there are many other types of valves available, the ball valve and the gate valve are two of the most prevalent. The function of both ball and gate valves is essentially the same. Their structural characteristics, however, are noticeably different. Here is everything you need to know about these two types of valves.

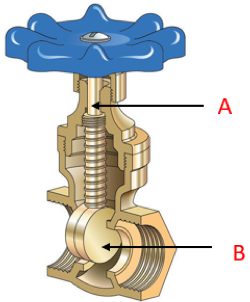

What Is Gate Valve?

The gate valve is the most prevalent valve for water supply systems. It is a linear-motion isolation valve with the ability to either stop or allow flow. These valves should not be used to regulate flow; they should be used to entirely open or completely close, as the partial opening will cause harm. The name “gate valve” comes from the closure part sliding into the flowing fluid to produce shut-off and therefore acting as a gate. Gate valves are used to isolate specific parts of the water supply network for maintenance, repair, and new installation operations, as well as to reroute water flow throughout the pipeline.

Gate valves are commonly used with larger pipe diameters, ranging from 2″ to the largest pipelines, because they are less complex to construct than other large-size valves. Gate valves are available in a variety of sizes, materials, temperature, and pressure ratings, as well as gate and bonnet designs, among other things. There are electric and pneumatic actuator gate valves available, however manual gate valves are more cost-effective due to their infrequent use.

A gate valve is among the most frequent valves in use today because of its simple design and ability to be used in a variety of low-pressure-drop applications. Gate valves are full-port valves by design. This indicates that the valve port is the same size as the connecting pipe’s inner diameter. A full-bore gate valve allows fluid to flow without being obstructed and without causing a pressure drop in the pipeline. This also enables the use of a cleaning pig to clean the pipe.

For more information about Gate Valves visit this link.

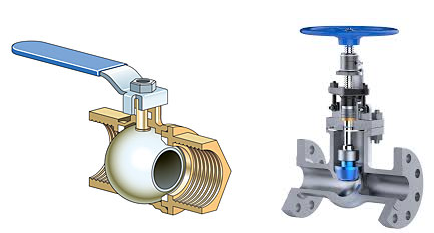

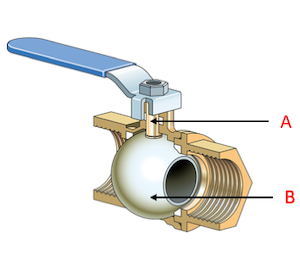

What Is Ball Valve?

Ball valves, as the name implies, use a rotatable ball with a bore to control the flow of liquid and gases from one opening to the next. The medium can flow through or be stopped by turning the ball a quarter turn (90 degrees) around its axis. These valves regulate the flow by permitting the opening to be open, blocked, or partially open. Ball valves are the best choice for use with gases since they have a stronger seal. They can withstand pressures of up to 700 bar and temperatures of up to 350°C, and their sizes typically range from 0.5 cm to 30 cm. Because they have a simple structure, they are simple to use and repair.

Ball valves are reliable, closing securely even after prolonged periods of rest, and durable, working well after many cycles. They have a higher resistance to contaminated media than most other valve types and ensure a good seal even when the medium is unclean. These characteristics make them a great choice for shutoff and control applications, where gates and globe valves are frequently chosen, but they lack the fine control of those alternatives in throttling applications.

For more information about Ball Valves visit this link.

Read More on Linquip

- Gate Valve vs Butterfly Valve

- Parts of Gate Valve

- Ball Valve Types and Their Uses

- Ball valve vs Plug valve

- Difference between gate valve and globe valve

- Ball valve parts : An easy-to-understand Guide to know ball valves better

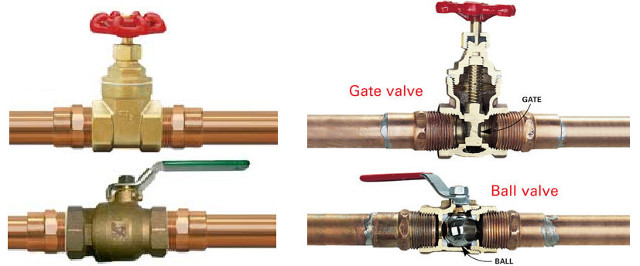

Gate Valve vs Ball Valve

Working Mechanism

A gate valve employs a gate to control the medium flow. Gate is a solid disk that is connected to a stem, acting as a barrier. Gate valves are commonly operated by an actuator, e.g. handwheel. The actuator is connected to a valve stem and transmits rotational energy to it. This energy turns the threads of the valve stem into the gate when the gate valve is opened and vice versa when the gate valve is closed. Hence, the gate is moved upward or downward by this energy. Because it requires more than a 360° turn to fully open or close this valve, it is also known as a multi-turn valve. The valve is opened by lifting the gate out of the flow path. As the gate is lowered to its original position, the bore is sealed, and the valve is totally closed.

The relationship between the vertical movement of a gate valve and flow rate is nonlinear, with the biggest fluctuations occurring near shutoff. The comparably high velocity of the flow during partial opening causes gate and seat wear, as well as possible gate vibrations, lowering the valve’s service life when used to control flow.

Gate valves are typically positioned in locations of a pipeline where they will longer remain open or closed, as they require time to move between these two states. Motorized gate valves are utilized when the valve needs to be operated frequently or even remotely (i.e. equipped with an electric actuator).

A ball valve employs a rotary ball with a hole inside it to control the flow of media. The ball is attached to the valve stem. When the handle on the stem is turned, the ball rotates, opening or closing the valve. Because the handle only needs to be turned 90 degrees (quarter turn) to allow or stop the medium flow, this valve is also known as a quarter turn valve. In the case of manual operation, when the valve is open, the handle is flat in line with the flow, and when it is closed, it is perpendicular to it, allowing for easy visual confirmation of the valve’s status. The 1/4 turn in the closed position can be done in either a clockwise or counter-clockwise direction.

General Features

The main difference between gate valves and ball valves is in their operation, which is discussed above in detail. Some other important differences between these two types of valves can be understood through their general features, which are addressed as follows:

- Shut off mechanism: Gate valve closes the valve slowly because it requires more than a 360° turn to close it. In comparison, the ball valve provides a quick shut-off in a quarter turn.

- Visual detection: The position of the handle can be used to visually detect whether the ball valve is open or closed, whereas it is difficult to determine if the gate valve is open or closed.

- Durability: Ball valves are more durable and less prone to damage. They have a high level of consistency after numerous cycles, as well as reliability and the ability to close securely even after extended periods of rest. While using the gate valves, the stem may corrode, making the valve less durable.

- Leakage: Gate valves leak more easily than ball valves. The ball valves maintain a tight seal, leading to 100% shut off characteristics even when utilized after a lengthy period of time.

- Water hammer: When the flow is abruptly stopped by quickly closing the valve, pressure builds up due to the momentum of the moving medium, resulting in a short pressure surge. The pressure surge produces a noise like a hammer striking the pipes. A powerful water hammer might lead to a system rupture or leak. In the gate valves, this phenomenon is reduced since they open and close slowly. But the quick opening and closing of the ball valves may increase the risk of water hammer.

- Port: A gate valve has two ports, but a ball valve might have several.

- Size: Gate valves are typically employed with larger pipe diameters, ranging from 2″ to the largest pipelines; while, bore sizes under 2″ are better suited for the ball valves.

- Flow capacity: Because gate valves are often available in bigger diameters than ball valves, they can give more flow capacity.

- Installation space: A quarter turn handle of the ball valve necessitates more installation space than a gate valve.

- Cost: In most cases, a ball valve is more expensive than a gate valve with the same specs.

The main advantages and disadvantages of gate valves can be listed as below:

Advantages of gate valves

- Low fluid resistance; gate valve’s body is a straight-through design that does not change the direction of the flow, allowing fluid to pass through the valve (when fully open) with minimal resistance.

- Superior sealing performance; Shut-off valves do not give as good a seal as gate valves. The opening and closing mechanisms of the gate valve are faster and more convenient than the other shut-off valves.

- Being bidirectional; Gate valves can flow in both directions. They are not restricted to one-way flow and are not affected by the medium’s flow directions. As a result, gate valves are appropriate for use in pipelines with varying flow directions.

- With a wide range of applications; Gate valves are incredibly adaptable, and they can be utilized with a variety of media, including steam, oil, and other liquids. In addition, gate valves can be employed in media with granular materials and high viscosity. It can also be utilized as a low-vacuum system valve and a venting valve.

Disadvantages of gate valves

- Opening and closing slowly, the valve gate must be elevated to the upper portion of the valve chamber during the opening procedure and must fall into the valve seat during the closing one. Hence, the valve gate must move a considerable distance to open or close, resulting in a lengthy opening and closing time.

- Prone to Scratches; excessive friction can be created during the opening and closing cases between the gate and the two sealing surfaces of the valve seat, resulting in scratches on the sealing surface. These scratches may appear insignificant at first, but they eventually have an impact on the sealing performance and service life.

While the major advantages and disadvantages of ball valves are as follows:

Advantages of ball valves

- Efficient sealing performance; ball valves have a good sealing performance with no leakage among other types of valves.

- Strong; to be able to withstand high pressure up to 700 bar even more. They also can withstand high temperatures up to 350°C.

- Easy to use; Available in flange type, welding type, thread type, double union type, tri-clamp, wafer thin type. It’s simple to set up and use.

- Easy for repair and maintenance to extend lifespan.

- Affordability; cost-effective valves for any desired application.

- Multi-function; Available in 2 way and 3-way ball valve to transfer, divert, and conflux the medium.

Disadvantages of ball valves

- Wear and tear; if suspended particles are present in the medium, the valve body and ball valve will wear down, and the valve may be struck.

- Limited size variety; typically, it is 8 inches. However, the larger size can be fabricated as customized at a higher price.

Common Application

Ball valves and gate valves are both extensively utilized in residential and industrial applications. However, these two types have differences in their usage:

- A ball valve is better suited for applications that require rapid opening and closing speeds or during crises due to its quarter-turn on/off function. A gate valve takes longer to operate than a ball valve since it requires more than a 360° turn.

- Gate valves are commonly found in older plumbing systems that do not require frequent shutoffs. They are used in large water supply systems because of their direct flow path and lack of flow constraints, whereas ball valves are increasingly being employed in new plumbing systems that require frequent shutoffs.

- Low-pressure applications are suited for both ball and gate valves. A gate valve, on the other hand, is better suited to high-pressure applications. This is due to the ball valve’s rapid opening and closing, which can create a water hammer.

- Since gate valves are easier to clean and maintain, they are commonly employed with slurries and viscous media while ball valves are not ideal for this end; because they are hard to clean and slurry particles can harm the rotary ball.

- Ball valves are frequently utilized in fire suppression and marine applications. Ball valves are hard to clean and may cause contamination, thus they are best avoided in food, beverage, and pharmaceutical applications.

- Gate valves are utilized in high-temperature, high-pressure settings such as power plants, mining, and water treatment.

Read More o Linquip

- Ball Valve Manufacturers

- Gate Valve Manufacturers

- Needle Valve Manufacturers

- Air release valve Manufacturers

- Valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers