A solenoid valve is a crucial component of any fluid control system. It is an electro-mechanical valve that is commonly employed to control the flow of liquid or gas which as a result, eradicates the need for an engineer to manually control the valve, saving time and money. Usually, solenoid valves are used whenever the flow of media has to be controlled automatically. An increasing amount of plants are taking advantage of the solenoid valve, as a variety of different designs are available, enabling the valve to be selected to suit the application in question. But how does a solenoid valve work? In this article, Linquip explains the solenoid valves working principle. Stay tuned to find out more.

Solenoid Valves Working Principle

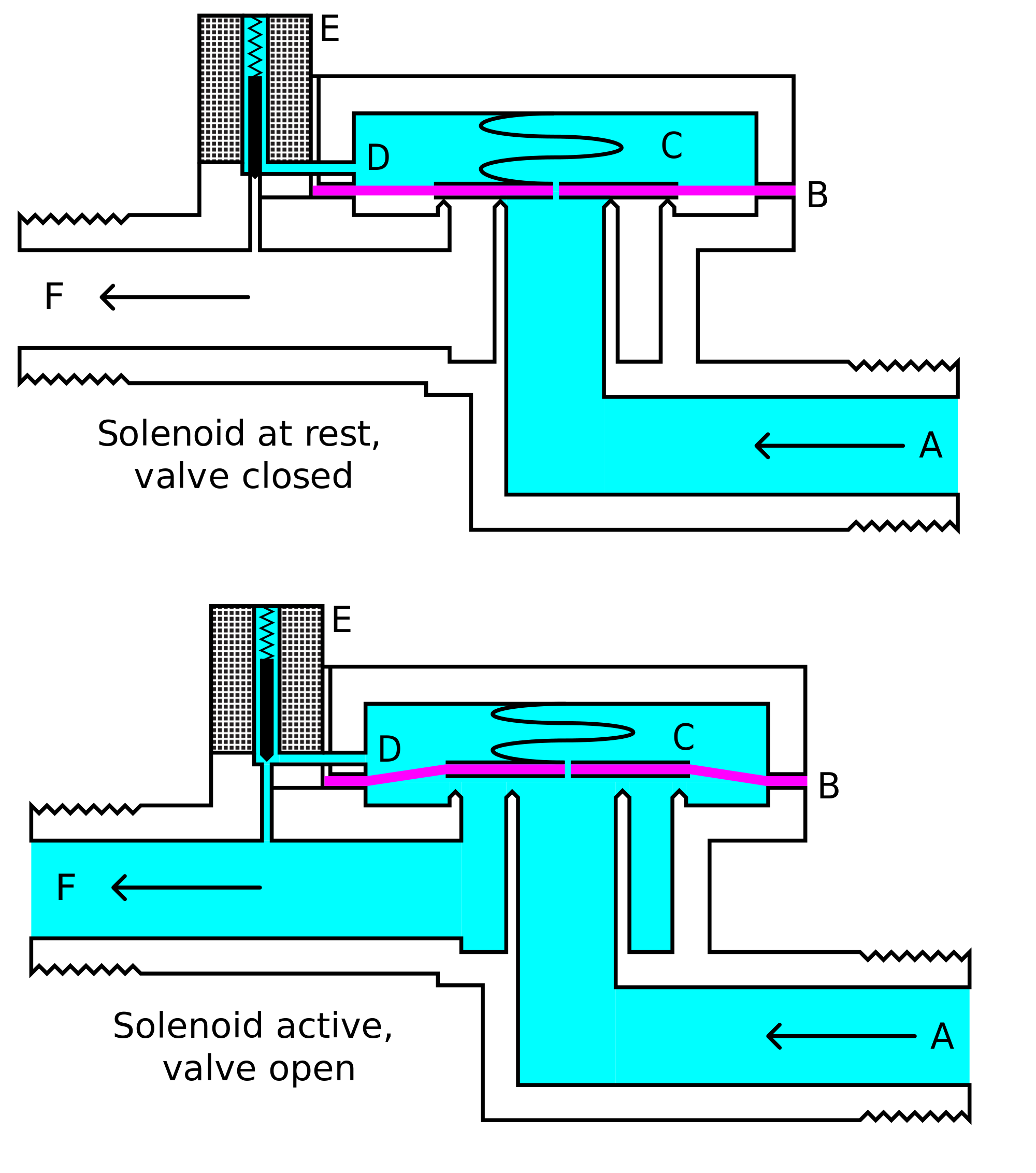

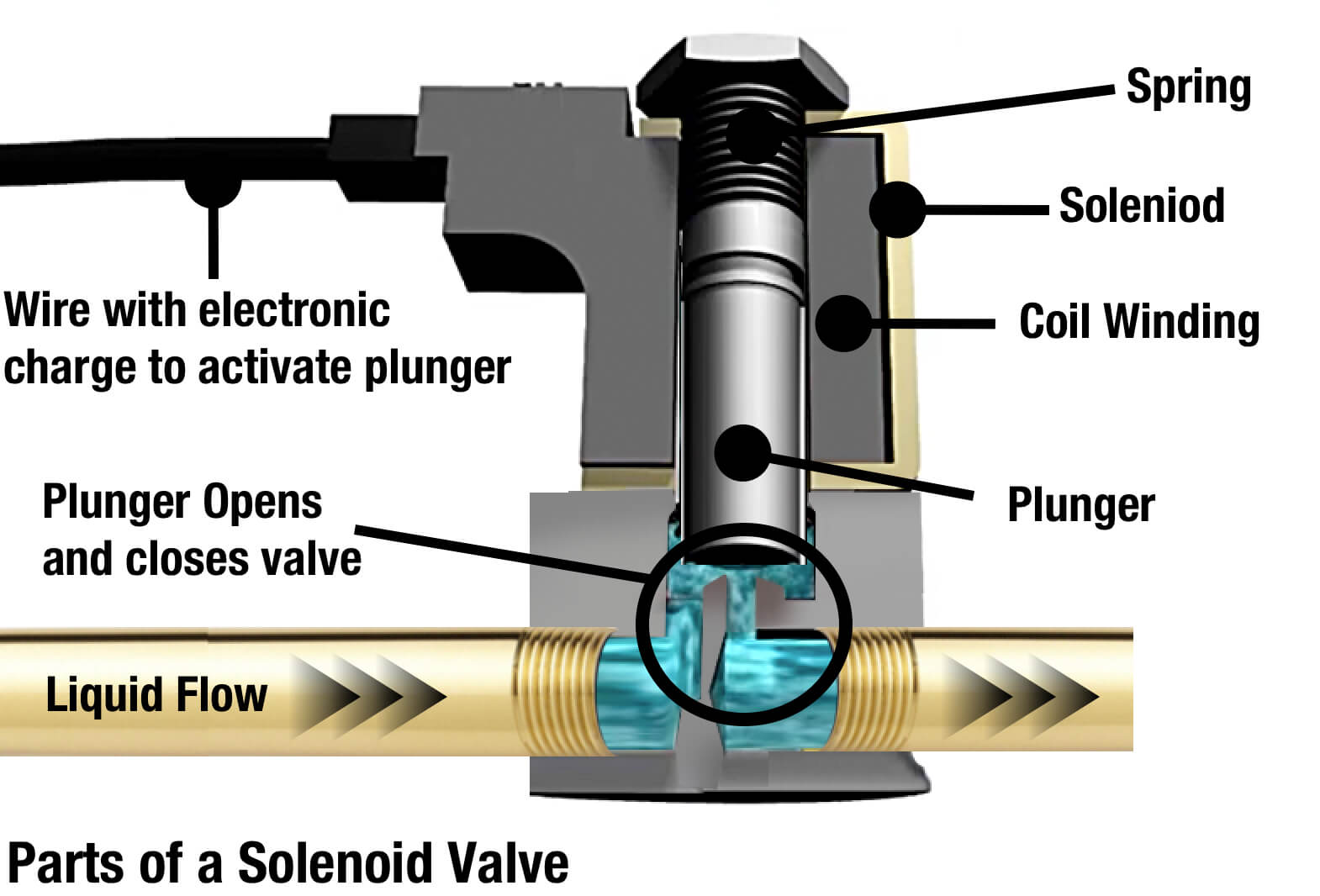

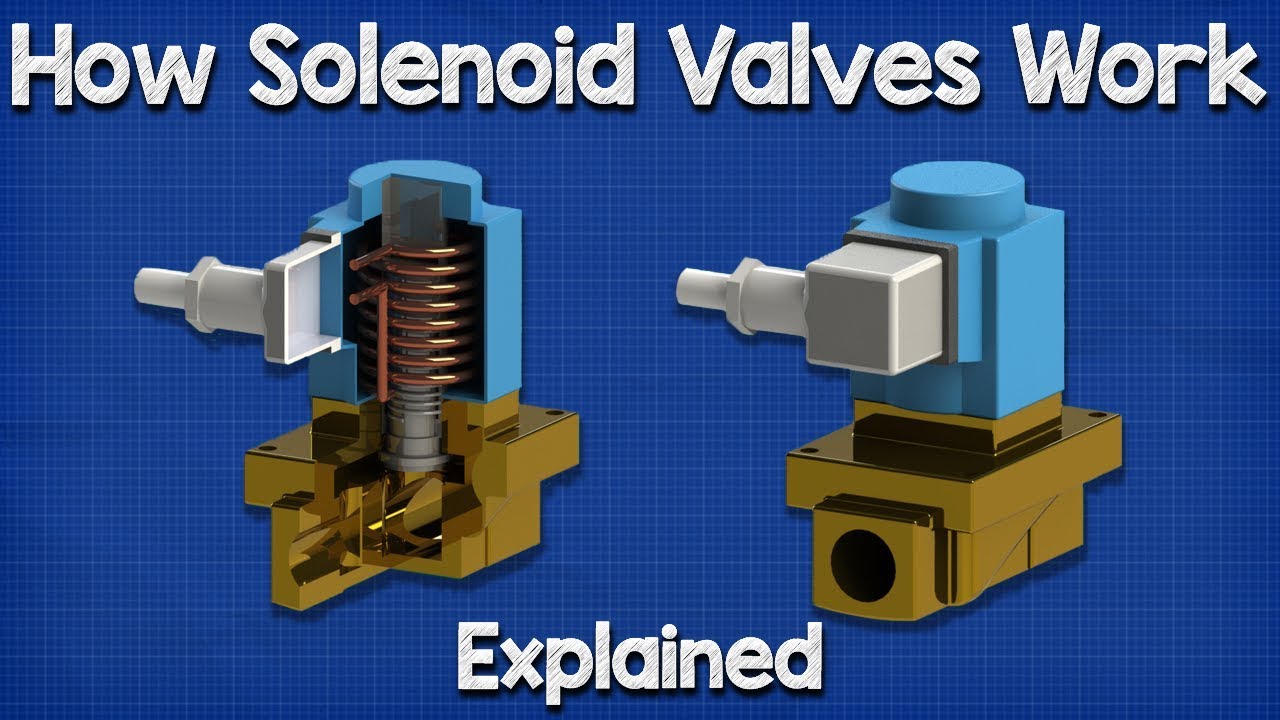

A solenoid valve consists of two basic units: an assembly of the solenoid (the electromagnet) and plunger (the core), and a valve containing an orifice (opening) in which a disc or plug is positioned to control the flow of fluid.

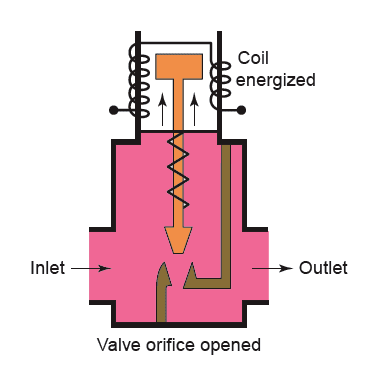

- The valve is opened or closed by the movement of the magnetic plunger.

- When the coil is energized, the plunger is drawn into the solenoid (electromagnet), and flow through the orifice is allowed.

The valve returns automatically to its original position when the current ceases due to the pressure of spring and flow through the orifice is restricted.

- The valve body is usually a special brass forging that is carefully checked and tested to ensure that there will be no leakage due to porosities. The armature, or plunger, is made from high-grade stainless steel.

- The effects of residual magnetism are eliminated by the use of a kickoff pin and spring, which prevent armature from sticking.

- A shading coil ensures that the armature will make a complete seal with the flat surface above it to eliminate noise and vibration.

- To ensure that the valve will always seat properly the strainers should be used to prevent grit or dirt from lodging in the orifice. Dirt in these locations will cause leakage.

- The inlet and outlet connections of the valve must not be reversed. The tightness of the valve depends to a degree on the pressure acting downward on the sealing disc. This pressure is possible only when the inlet is connected to the proper point as indicated on the valve.

Below you will learn about the working principle of two main types of solenoid valves.

Read More on Linquip

- Facts About The Flow Control Valve Function

- Everything You Need To Know About Check Valve Function

- How Valves Work in an Engine

Pilot Operated Solenoid Valves Working Principle

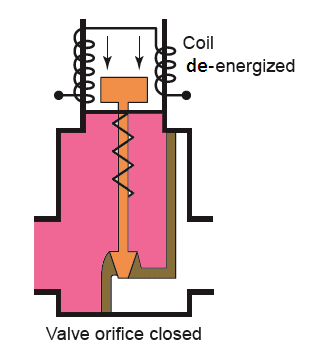

- Two Way Pilot Operated Solenoid Valves have two chambers separated by a diaphragm. The upper chamber is connected to upstream through a pilot hole in either the cover or diaphragm. The media exerts a pressure that acts on the upper side of the diaphragm and keeps the valve closed. When the coil is charged the core lifts off the orifice seat allowing the operating chamber to de-pressurize. The thrust of the upstream pressure under the diaphragm continues, lifting the diaphragm and opening the valve.

- Pilot operated solenoid valves only operate with a suitable upstream pressure differential and do not operate at zero pressure. Also a minimum pressure differential across the valve is required to keep them open or closed. Pilot operated solenoid valves can provide high flow rates at high pressures with lower power consumption.

Direct Acting Solenoid Valves Working Principle

- Direct-acting solenoid valves do not use a diaphragm, their seal is part of the moving core. Two Way Normally Closed Direct Acting Solenoid Valves have a spring that holds the core against the seal. When the coil is charged the spring is overcome and the seal is lifted from the orifice seat thus opening the valve and allowing the media to pass through the valve.

- Two Way Normally Open Direct Acting Solenoid Valves have a fixed core which is usually in the bottom section of the armature tube. The armature is located in the upper part of the valve. A stem passes through the fixed core and is coupled to the seal. This is held off the seal by means of a spring and makes a seal when the coil is energized, thus closing the valve.

- Three-Way Direct Acting Solenoid Valves work in almost the same way as a two way direct acting solenoid valve. The fixed core has an exhaust orifice running through it. The plunger has an upper seal and lower seal allowing flow to or from either the body seat or exhaust.

- Direct-acting solenoid valves are used when there is no line pressure applied. Typical applications would include a cleaning line when a pump supplies bursts of water through the line. A direct operated solenoid valve would remain closed, even when no pressure is being applied. This is in contrast to a pilot operated valve, which requires some pressure for the valve to stay closed.

So, this was everything you needed to know about solenoid valves working principle. If you enjoy this article, let us know what you think by leaving a reply in the comment section. We will be more than glad to have your viewpoint on the article. Is there any question we can help you through? Feel free to sign up on Linquip where our experts are prepared to provide you with the most professional advice.

Read More on Linquip

- Solenoid Valve Manufacturers

- Angle Valve Manufacturers

- Pinch Valve Manufacturers

- Gate Valve Manufacturers

- Air release valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

The valve returns automatically to its original position when the current ceases due to the pressure of spring and flow through the orifice is restricted.

The valve returns automatically to its original position when the current ceases due to the pressure of spring and flow through the orifice is restricted.

Nice

Anaa, thank you for the information! A solenoid valve is a control mechanism that turns electrical energy into mechanical work. These devices consist of a plunger, a coil, and a plunger and sleeve assembly. When electrically charged or de-powered, solenoid valves regulate or stop the flow of fluids in the system.

Thanks for sharing your experience with us, Amanda! You can also visit our industrial directories, where you can find thousands of various industrial equipment based on your application and demand.