Types of Ac Generators- AC generators or alternators convert mechanical energy into electric power, and the provided electric power is in the form of an Alternative Electromotive Force (EMF) or current. The usual form of output in these generators is sinusoidal alternating current, and the input mechanical energy is supplied by the steam, gas, or wind turbines and combustion engines.

AC Generators

This generator’s working principle is based on “electromagnetic induction” and Faraday’s law. Faraday’s law states that the EMF is produced in the current conductor that cuts the magnetic field. In AC generators, we have a static magnetic field and a rotary conducting coil or rotating magnetic field that includes a static conductor.

It is better to have a stationary coil due to the simple component and the ease of drawing induced alternating current from a stationary armature coil than a rotating coil. EMF depends on the magnetic field strength number of the armature coil and the rotating field’s speed. Most generators are working at a constant speed; therefore, the maximum voltage value is constant all the time. The frequency of the voltage is dependent on the number of field poles and the speed of operation:

F=\frac{NP}{120}

where:

P = number of poles

N = rotation speed (rpm)

f = frequency (Hz)

The number 120 appears because of converting rpm to the rotation per sec and the pair of poles to the total number of them.

AC Generators Parts

All types of AC generators have rotating and static parts that are connected by connections. This device consists of various components:

6 Parts of AC Generators are:

- Armature

- Field

- Prime Mover

- Slip Rings

- Rotor

- Stator

Armature

Armature produces the voltage in the AC generator and consists of coils of wire and can carry the generator’s full load current.

Field

Coils of conductors that converts the received voltage from the source to a magnetic flux are called the field. The magnetic flux cuts the armature to provide magnetic flux.

Prime Mover

Prime mover drives the AC generator and can be diesel engines, motors, or various types of turbines.

Slip Rings

Electrical connections used in the generators are called slip rings, and the purpose is to transfer power between components. Slip rings are designed to conduct the current from a stationary part to a rotating part.

Stator

The stationary part of an AC generator is the stator and can be an armature or a field. Stator would be the field if the EMF is generated there, and it can be the armature if the excitation of the field is there.

Rotor

The rotor is known as the rotating part of the generator, and the prime mover drives it. Armature or the field can be the rotor based on the generator type. The rotor would be the field if the excitation of the field is there, and it can be the armature if the EMF is generated there.

Types of AC Generators Based on the Application

AC generators can be categorized in many ways based on their applications, designs, or parts of them. Various types of AC generators based on the applications include:

- Diesel-electric locomotive alternators – they are used in locomotives that need electric and mechanical power at the same time.

- Brushless alternators – they are used in electrical power plants as the main source of power.

- Radio alternators – they are used for transmission of low band radio frequency.

- Automotive alternators – they are used in modern automobiles for generating electric power.

- Marine alternators – they are used in marine applications for the generation of demand power.

Types of AC Generators Based on the Speed

Alternators can be categorized based on the speed of rotation as the design of the system can vary based on the applications. The salient Pole Type is for low speed, and Smooth Cylindrical Type is designed for high-speed rotation as the application demands.

Salient Pole Type

These kinds of alternators are used for low or medium-speed applications. This AC generator has many poles with the bolted core to the heavy magnetic wheel, which is built from good magnetic quality steel or casted iron. They are known for their large diameter and short axial length and look like a wheel. Low-speed turbines such as hydel power plants are using these alternators. The summary of the salient pole type specification are:

- Poles are projecting.

- They don’t have a uniform air gap.

- They have a large diameter and small axial length.

- They are mechanically weak and work at lower speeds.

- Another name for this type is the projected pole type.

- They are Preferred to be used at high speeds ranging from 125 to 500 RPM.

- There have separate damper windings.

Smooth Cylindrical Type

The steam turbine rotates at high speed, and as a result, it needs a high-speed generator for its conversion. The rotor is a smooth forged steel cylinder with a certain number of slots placed in intervals along with the field coils’ outer edge. They are designed with 2 or 4 poles for 3600 and 1800 rpm, respectively. The summary of the smooth cylindrical type specification are:

- There do not have separate damper windings.

- They are Preferred to be used at high speeds ranging from 1500 to 300 RPM.

- Another name for this alternator is non-salient or non-projected.

- They use mechanically strong prime movers, the same as steam turbines.

- They have a small diameter and long axial length.

- Poles are non-projecting.

Types of AC generators based on the number of phases

Generally, AC generators can be classified as single-phase([/katex] 1\varphi[/katex] ) and three phases ([/katex] 3\varphi[/katex] ), and the only difference between them is the number of the armatures used in the generators. The basis of the operation is the same in these two types, while the three phases have more consistent voltage and include wye-connection or delta-connection.

Single-phase AC generators

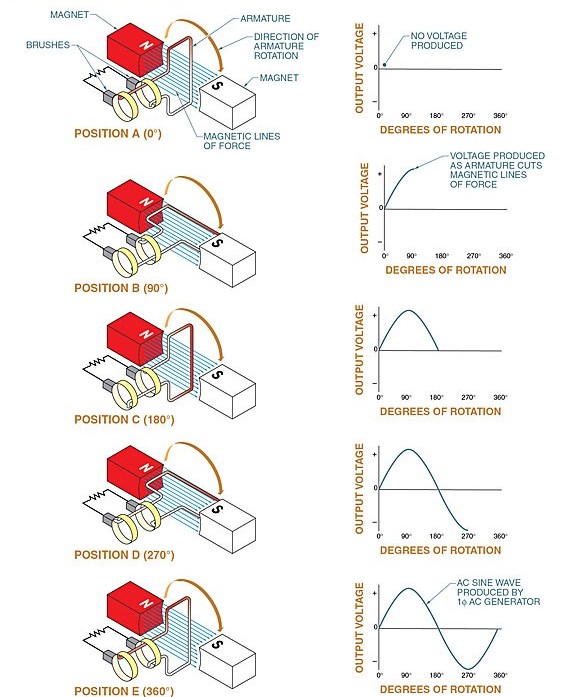

Every rotation in rotors provides a current cycle in the single-phase alternators, and the output is a single sinusoidal current or voltage. Figure 1 illustrates the operation of the single-phase AC generators.

We can Define position A as the 0 degrees and the beginning position, and clockwise as the rotation direction. In this position, there is no voltage or current due to the angle of the surface motion and the magnetic field and not cutting the magnetic field by the armature.

By rotation of the armature from A to B, the armature cuts across the magnetic lines and produces current in the circuit. The current increases in the sinusoidal form to the maximum value at 90 degrees, and a quarter of the one complete cycle is complete.

Rotation from B to C and D and finally E, which is the same angle as the A (360 and 0 degrees), completes one period, and each one is a quarter of the cycle. Current reaches its minimum by the rotation of -180 to 90 in the displacement B to D and two-quarters of the cycle.

Three-Phase AC Generators

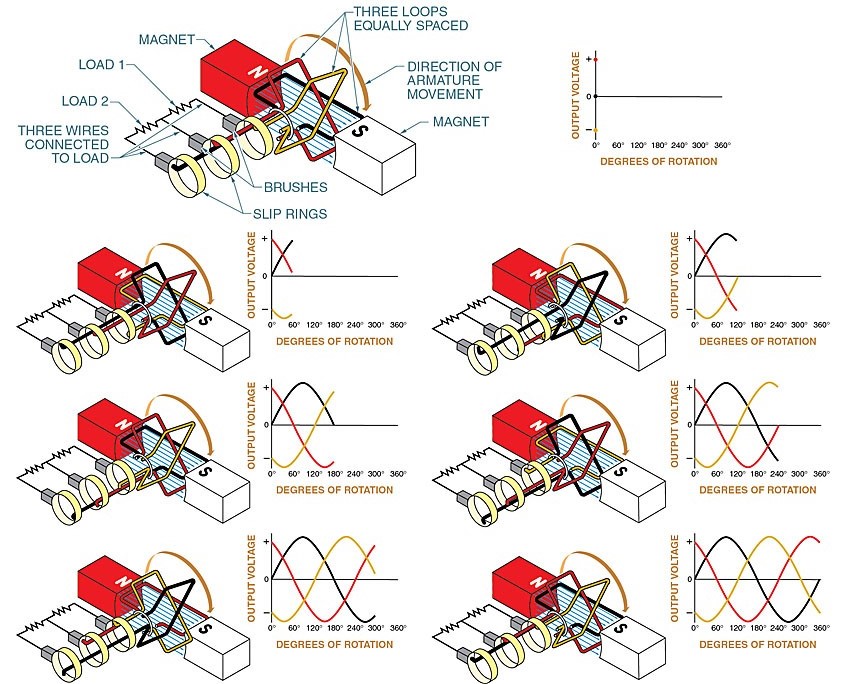

Single-phase and the three-phase AC generator have the same principle; however, a three-phase generator has three armature white 120-degree shifts in the rotation. Figure 2 illustrates the working steps one by one, and the voltage diagram is presented in each step.

Armatures are connected in the wye (Y) and or delta ( \Delta ) connection and it is the main characterization of the AC generator output.

Wye (Y) Connection AC Generators

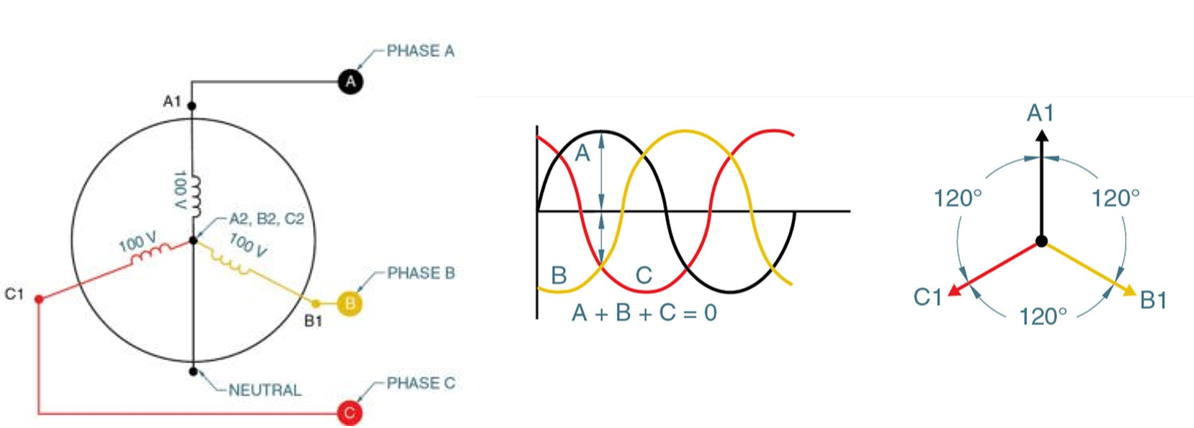

In Wye (Y) connection AC generators, all the coils are connected at one point, and the other end of each one is for external connection. All three wires can be connected to the neutral point as there is no difference in voltage between each. When A is at its maximum value, the B and C summation is exactly the opposite of A. Figure 3 illustrates this type of generator, and as it is shown, A2, B2, and C2 are ended together.

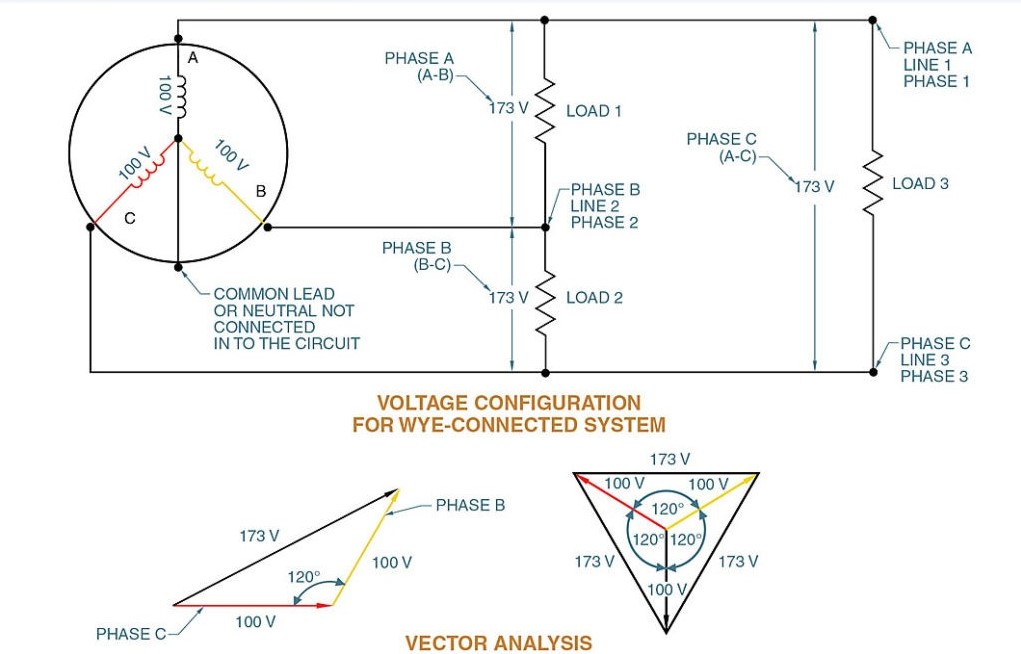

The simplest form of the wye connection is shown in Figure 4, and each load has a connection with two phases in series. The voltage for each load is \sqrt3 multiplied by phase voltage. For instance, if the maximum voltage is 100 for each of the phases, the voltage for the loads is 173. Vector summation for the voltage with the 120 phase difference is illustrated in Figure 4, and as is shown, the summation is equal to 173 for the voltage 100 in each phase.

The described three-phase generator is a balance system with equal voltage consumption for the loads, and in this circuit, the current is zero at the neutral point due to the current summation being zero. Large power systems are tried to be designed with balanced loads or closely equal. If there are unbalance loads in the system, the current flows to the neutral point, and usually, it is connected to the ground. In power plants, high voltage is supplied in the generator, and for 2400 and 7200 V in the phase-to-neutral, 4,152 and 12,456 V are created in the phase-to-phase connection, respectively.

Using a Wye connection, we can obtain higher phase-to-phase voltage, and it is better for the system because of the reduction in power loss. At higher voltage, power loss is much lower, and it is the benefit of using this connection. According to the P=E\times I and a given amount of power, increasing the voltage led to a reduction in the current. On the other hand, for the power reduction, we have P=R\times I^{2} , and reduction in the current decreases the power loss by the square of the current value.

Delta Connection AC Generators

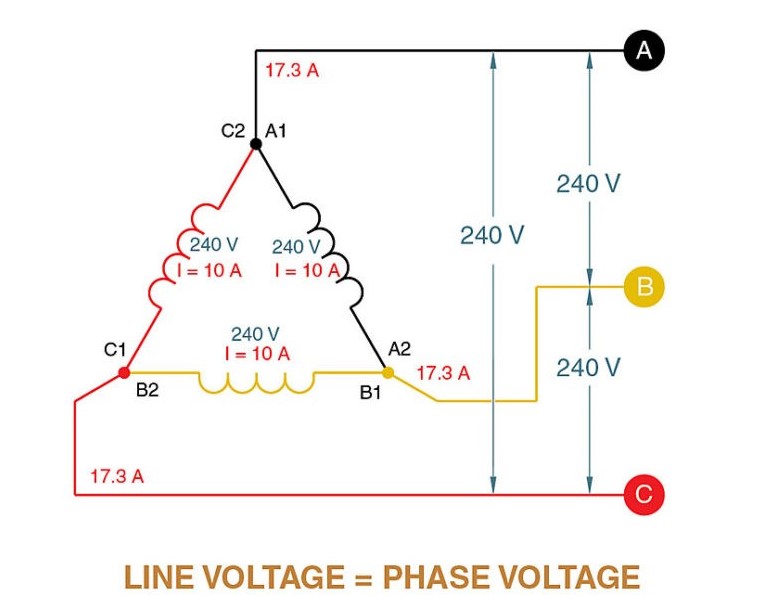

In a delta ( \Delta ), all the coils are connected and make a closed loop. Figure 5 shows the circuit of the delta connection.

The generated coil voltage and the voltage in the lines are the same in this connection and can be measured directly in both of them. Currents in the delta connection are 120 apart, and the summation of them is zero.

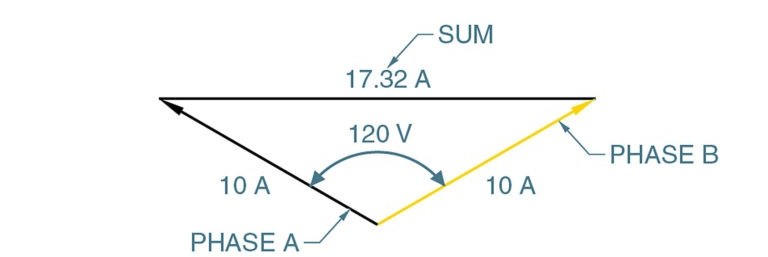

The current in each line comes from the two phases. Usually, we have a balanced current in the system, and the line current is 1.73 or \sqrt3 times the current in each of the coils as they are the same. For instance, the current is 17.3 in the lines while the current is 10 in the coils. The reason for the higher current in the line can be described by the current flowing in different windings at different times in the circuit.

There is always more than one path for the current flowing, and this makes the delta connection similar to the parallel connection. Currents are 120 degrees out of space, and the summation of the vectors can be calculated in Figure 6.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip