A Boiling Water Reactor (or BWR) is a class of light water nuclear reactors used for electrical power generation. After the Pressurized Water Reactor (or PWR), the boiling water reactor is the second most well-known type of electricity-generating nuclear reactor. Both types are light water nuclear reactors.

Linquip’s website has a wealth of information regarding reactors, and we strive to provide as much information as possible to help you find the right product for your application. To find answers to any questions you might have about boiling water reactors, Linquip is the best option. Please feel free to contact Linquip with any questions you may have regarding boiling water reactors. We recommend that you read Linquip’s article, “What is Thermal Power Plant?” if you do not have one already.

Linquip Expert registration is required to fully utilize the Linquip platform and access the full range of Linquip components. A Linquip account will allow you to demonstrate your skills related to industrial technologies in a way that is tailored to the industry’s specific needs. Would you be interested in writing a guest blog post for Linquip? Using the Guest Posting feature, your content can be added directly to Linquip’s site.

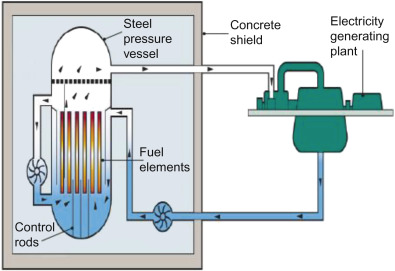

The principal difference between a boiling water reactor and a pressurized water reactor is that in the first reactor, the core heats water, converts it into steam, and then a steam turbine is driven. In the latter, the reactor core heats water without boiling. The hot water exchanges heat with a water system that is at a lower pressure. So, it turns to steam and runs the turbine.

The boiling water reactor was developed in the mid-1950s by the Argonne National Laboratory in the United States and General Electric (GE). GE Hitachi Nuclear Energy is now the main present manufacturer specializing in designing and building this type of reactor. Seventy-five boiling water reactors, including four advanced boiling water reactors, are in operation in Japan.

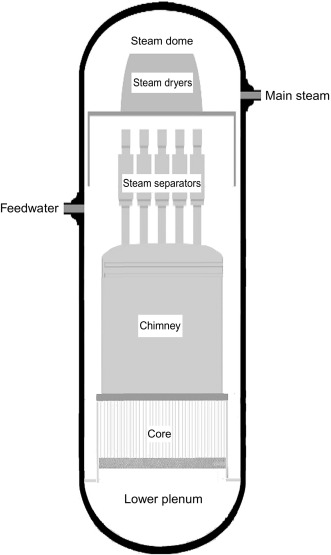

In a boiling water reactor, demineralized water is utilized as a coolant and neutron moderator. Heat is generated by nuclear fission in the reactor core, making the cooling water boil and the steam produced. The steam is directly applied to drive a turbine and then is cooled in a condenser and turned back to liquid water. This water is then sent to the reactor core to complete the loop.

The cooling water is held at a pressure of about 75 atm to boil in the core at a temperature of about 285 °C. In comparison, in a pressurized water reactor, no significant boiling occurs due to the high pressure in its primary loop which is about 158 atm. Per every 10,000 to 10,000,000 reactor years, one core damage accident is estimated.

Working Principle of Boiling Water Reactor

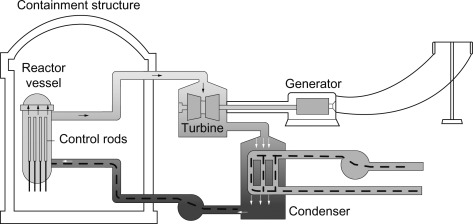

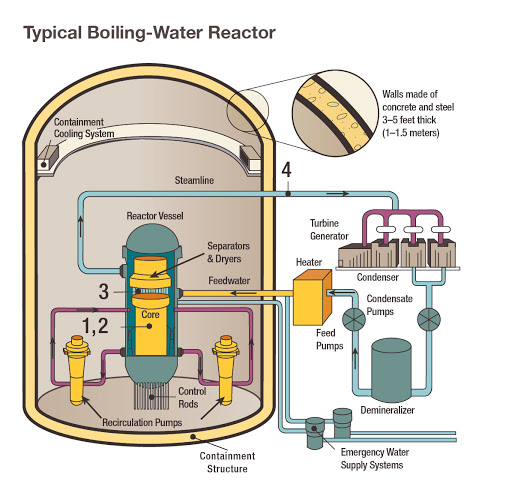

The concept of a commercial boiling water reactor design is based on the following steps:

1- The core within the reactor vessel generates heat.

2- When very pure water (reactor coolant) flows upwards through the core and absorbs the heat, a mixture of steam and water is created.

3- The mixture of steam and water leaves the upper part of the core. It then enters the two stages of moisture separation, in which water droplets are excluded before the steam enters the streamline.

4- The streamline delivers the steam to the turbine and causes the turbine to rotate the generator to produce electricity.

The following figure illustrates the components of a boiling water reactor, as well as the process of operation according to the above steps.

The remaining steam is depleted to the condenser to be converted into water. The water is pumped out of the condenser by a set of pumps and then reheated and pumped back again to the reactor vessel. The core of the reactor contains fuel equipment cooled by water circulated by electrically powered pumps.

The pumps and other operating parts in the plant get their power from the electrical grid. If off-site power is failed, other pumps can provide emergency cooling water, which can be supplied by on-site diesel generators. Other safety systems also require electric power. A boiling water reactor contains between 370-800 fuel assemblies.

The boiling water reactor applies ordinary water (light water) as its coolant and moderator. In the boiling water reactor, the water in the core of the reactor is allowed to boil under a pressure of 75 atm and a boiling point of 285°C. The generated steam is used directly to run a steam turbine. As the steam is exposed to the core, some radioactive pollution in the turbines arises. But this is short-lived, and the turbines can be driven soon after shutdown.

The boiling water reactor probably represents the simplest feasible configuration of a nuclear reactor because there is no need for further heat exchangers or steam generators. However, the internal structure is complicated. The pressure and temperature of the steam are relatively low compared to modern coal-fired power plants, and the steam turbine is typically huge. Boiling water reactors have capacities of up to 1400 MW and efficiencies of around 33%.

The boiling water reactor utilizes enriched uranium as fuel. This fuel is put into the reactor as uranium oxide pellets in zirconium alloy tubes. As much as 140 tonnes of fuel is located in 75,000 fuel rods. Refueling a boiling water reactor includes removing the upper part of the reactor. The core itself is maintained underwater. The water protects operators from radioactivity. Boron control rods enter the core from under the reactor.

Similar to all reactors, the fuel rods excluded from a boiling water reactor core are much more radioactive and continue to generate energy for some years. Therefore, at least before being shipped for reprocessing or final storage, they are usually kept in a discreetly controlled storage pool at the plant.

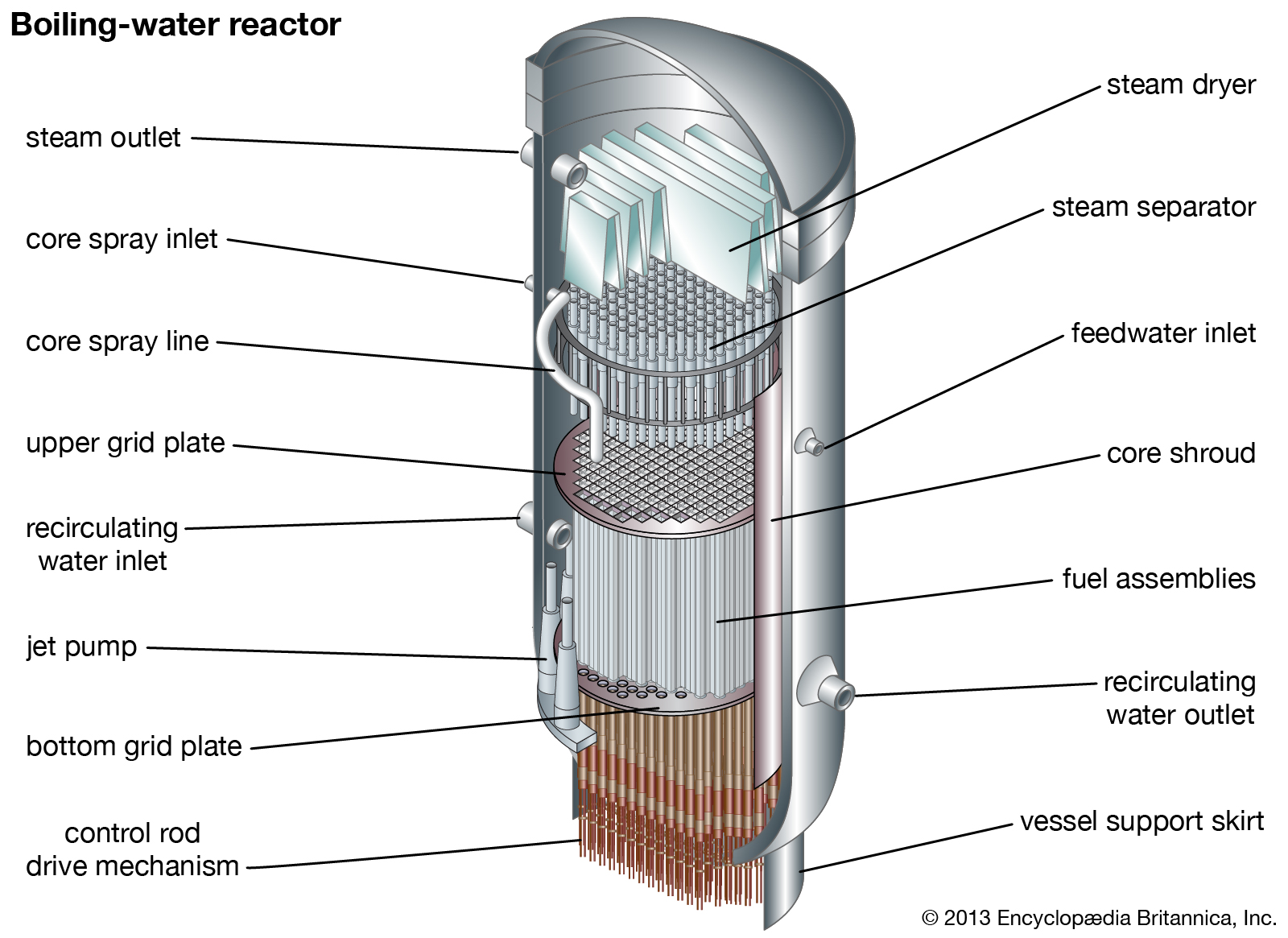

Components of Boiling Water Reactor

The operation of a boiling water reactor requires components that work together in an efficient set, as described in the previous section.

Condensate and Feedwater

The steam leaving the turbine moves into condensers installed under the low-pressure turbines, in which the steam is cooled and converted into liquid (condensate). Then, the condensate is pumped into feedwater heaters that increase its temperature utilizing extraction steam from different turbine stages. Feedwater coming from the feedwater heaters enters the pressure vessel through nozzles located on the vessel, above the upper part of the nuclear fuel assemblies that form the reactor core, but below the water level.

The feedwater enters the downcomer or annulus region and mixes with water, leaving the moisture separators. The feedwater helps subcool the saturated water exiting the moisture separators and flowing downwards. The water then passes through jet pumps or internal recirculation pumps that supply additional pumping power. The water then rotates 180 degrees and travels up into the nuclear core to be heated by the fuel elements. As a result, the water coming out from the fuel channels is saturated with a steam quality of nearly 15%.

The heat generated by the core produces a thermal head that helps the recirculation pumps recirculate the water inside the pressure vessel. A boiling water reactor can be designed without recirculation pumps and rely solely on the thermal head to recirculate the water inside the pressure vessel. However, the forced recirculation head by recirculation pumps is beneficial in controlling power and allows for reaching higher powers that are not possible in other ways.

The mixture of water and steam on top of the core enters the riser. The height of this area may be increased to raise the thermal natural recirculation pumping head. The moisture separator is located in the upper part of the riser area. The steam is separated using swirling the two-phase flow within cyclone separators and rises towards the steam dryer. The water moves horizontally out into the downcomer or annulus area, in which the water mixes with the feedwater to repeat the cycle.

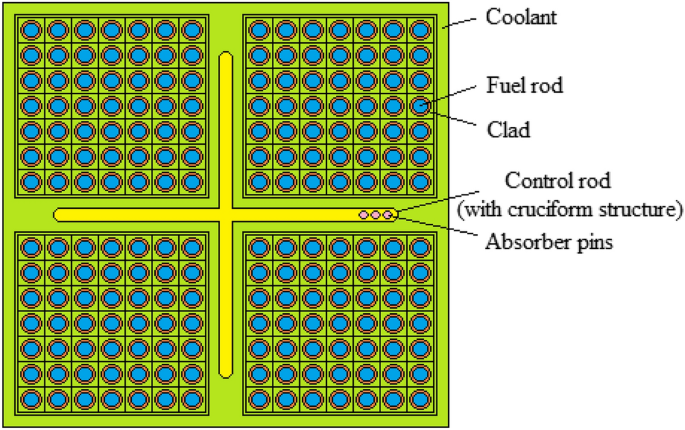

Reactor Core

A modern boiling water reactor fuel assembly includes 74 to 100 fuel rods. There are up to almost 800 assemblies in a reactor core, containing up to about 140 short tons of low-enriched uranium. The number of fuel assemblies in a particular reactor differs according to considerations of desired power output, core size, and power density of the reactor.

Steam Turbine

Steam generated in the reactor core moves through steam separators and dryer plates over the core and then is directly guided to the turbine as a part of the reactor circuit. Since the water around the reactor core is always polluted with fragments of radionuclides due to neutron capture by the water, the turbine must be protected during normal operation, and radiological shielding has to be provided during maintenance.

The increased cost of operation and maintenance of a boiling water reactor leads to balancing the savings because of the simpler design and higher thermal efficiency of a boiling water reactor than a pressurized water reactor.

Boiling water reactor steam turbines use a high-pressure turbine designed to control saturated steam, followed by multiple low-pressure turbines. The high-pressure turbine takes steam from the reactor. The high-pressure turbine exhaust travels through a steam reheater, superheating the steam to above 400 degrees Fahrenheit for the low-pressure turbines to utilize. The low-pressure turbine exhaust is delivered to the main condenser.

The reheaters take some of the steam of the turbine as a heating source to reheat which leaves the high-pressure turbine exhaust. The reheaters help improve the thermodynamic efficiency of the power plant.

Refueling System

The reactor fuel rods are sometimes replaced from the reactor pressure vessel to the spent fuel pool. A fuel cycle typically lasts from 18 to 24 months. Almost one-third of fuel assemblies are replaced during a refueling outage. However, the remaining fuel assemblies are moved to new core places to maximize the efficiency and power generated in the later fuel cycle.

They are hot due to both radioactivity and heat, and this would be performed using cranes and underwater. Thus, the spent fuel storage pools are installed above the reactor. They are stored in rigid arrays to avoid criticality. The fuel rods normally are kept enough cool in the reactor and spent fuel pools.

Control Systems

Some control systems are utilized to control the reactor power, reactor pressure, and reactor water level.

Reactor Power

Two systems control reactor power: positioning control rods, including inserting or withdrawing and adjusting the water flow within the reactor core.

Positioning Control Rods

Positioning control rods is the usual way to control power when starting up a boiling water reactor. As the control rods are withdrawn, absorption of neutrons decreases in the control material and raises in the fuel, thus increasing reactor power. By inserting control rods, neutron absorption decreases in the fuel and increases in the control material. Therefore, the reactor power decreases. The control rods in a boiling water reactor are inserted from below to provide a more homogeneous power distribution. In the upper part, the water density is lower due to the formation of vapor. This causes the neutron moderation less efficient and the chance of a fission event lower.

Water Flow Changing

Typically, the control rods are only utilized to supply a homogeneous power distribution and compensate for the fuel consumption. Thus, the power is controlled by the water flow in a normal operation.

Increasing or decreasing the water flow inside the core is the common method to control power from 30% to 100% reactor power. It can be done by varying the recirculation pump speeds or adjusting flow control valves.

When water flow increases through the core, steam bubbles leave from the core more quickly, the liquid water volume in the core and neutron moderation increase, more neutrons are slowed down to be absorbed by the fuel, and finally, reactor power increases.

Conversely, when the water flow decreases through the core, steam bubbles stay in the core for longer, the liquid water volume in the core and neutron moderation decrease, the fuel may absorb fewer neutrons to be slowed down, and subsequently, reactor power decreases.

Reactor Pressure

Reactor pressure in a boiling water reactor is controlled by the turbine or steam bypass valves. In a pressurized water reactor, the turbine steam demand is determined by the operators manually. But in a boiling water reactor, the turbine valves are adjusted to keep reactor pressure at a set point. With this controlling system, the turbine automatically follows reactor power changes.

The function of the main steam bypass/dump valves in offline or trip events is to be open to direct steam directly to the condenser. These bypass valves are adjusted automatically or manually if necessary to keep reactor pressure and control the heat up and cool down rates of the reactor while steaming is still going on.

Water Level

The main feedwater system controls the reactor water level. From about 0.5% to 100% power, feedwater automatically controls the water level in the reactor. Using the water injection and steam flows, the feed water control system can anticipate water level deviations quickly and respond to keep the water level within a few inches of the set point.

Safety System

A boiling water reactor continues to generate heat even after the fission reactions have ended, which could lead to possible core damage. The heat is generated by the radioactive decay of fission products and substances activated by neutron absorption. The boiling water reactor contains multiple safety systems to cool the core after an emergency shutdown.

Advantages of a Boiling Water Reactor

Some of the strengths of a boiling water reactor are listed below:

- The associated components work at a lower pressure of about 70–75 bars than about 155 bars in a pressurized water reactor.

- The pressure vessel does not become brittle with age.

- A boiling water reactor operates at a lower nuclear fuel temperature than in pressurized water reactor.

- Due to a lack of steam generators, a pressurized vessel, and the associated primary circuit pumps, there is a less large metal and fewer overall components. This also makes boiling water reactors simpler to operate.

- The water level measurement is the same for both regular and emergency operations, which leads to an easy assessment of emergency conditions.

- There is a lower risk of a rupture causing loss of coolant than in a pressurized water reactor. If such a rupture occurs, there is a lower risk of core damage. The reason is that there are fewer pipes and large-diameter pipes, fewer welds, and no steam generator tubes.

- A boiling water reactor can be designed to operate by only natural circulation to remove recirculation pumps entirely.

- A boiling water reactor does not use boric acid to regulate fission burn-up to avoid the generation of tritium and contamination of the turbines. It results in less possibility of corrosion in the reactor vessel and piping.

Disadvantages of a Boiling Water Reactor

In this section, we will describe some of the weaknesses of the boiling water reactor:

- Boiling water reactor needs more complex calculations for regulating nuclear fuel consumption during operation due to the two-phase fluid flow (water and steam) on top of the core. Also, more instrumentation in the reactor core is required.

- The pressure vessel of the boiling water reactor is larger than for a pressurized water reactor of similar power, and related costs are higher.

- Contamination of the turbine created by short-lived activation products is another drawback of the boiling water reactor. Therefore, during normal operations due to the radiation resulting from the steam coming directly from the reactor core, shielding and access control throughout the steam turbine are needed.

Different designs of Boiling Water Reactor

Advanced boiling water reactors and simplified boiling water reactors, as well as economically simplified boiling water reactors, are the design types of these reactors after the first series of production, which are briefly described below.

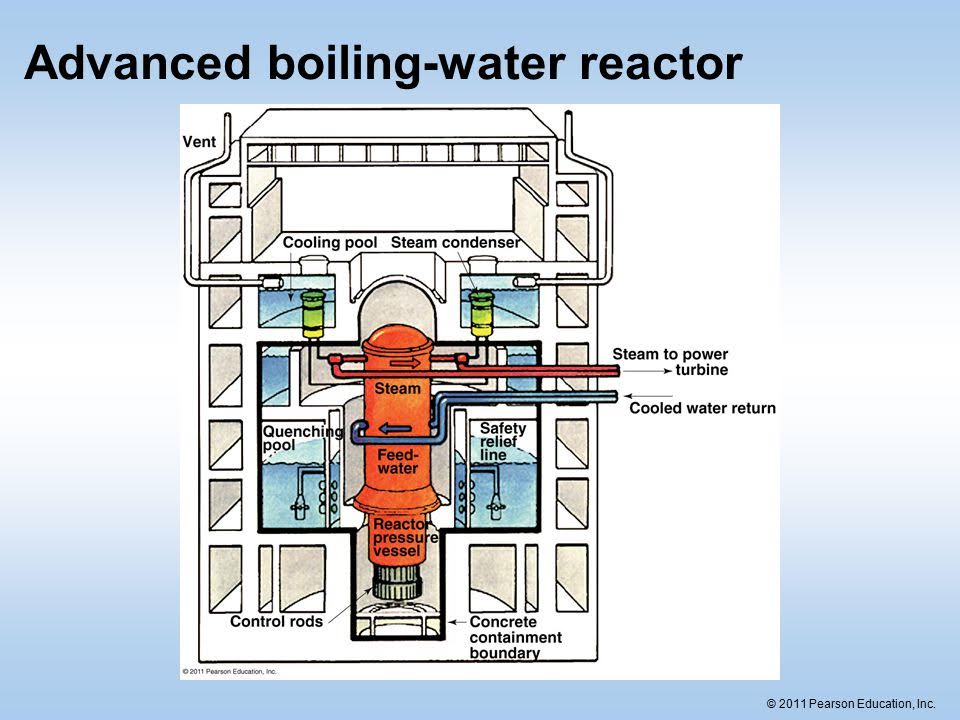

Advanced Boiling Water Reactor

The advanced boiling water reactor (or ABWR) is a newer design of a boiling water reactor. The advanced boiling water reactor originated in the late 1980s and early 1990s. It includes advanced technologies in the design, such as control, control rod removal, motion, plant automation, in-core pumping, and safety systems to propose enhancements over the primary series of boiling water reactors. It delivers a high power output of around 1350 MWe per reactor. The risk of core damage is significantly lowered.

Simplified Boiling Water Reactor

Parallel to developing the advanced boiling water reactor, a different concept known as the simplified boiling water reactor (or SBWR) was developed by General Electric. It is an advanced light water reactor working based on natural circulation.

This smaller 600 MWe reactor was remarkable for its establishment of the passive safety design concept. The principle of passive safety means that the reactor is designed to return to a safe mode only using natural forces instead of needing the intervention of active systems to keep the reactor at a safe margin, including emergency injection pumps.

For example, when the reactor became too hot, it creates a system releasing soluble neutron absorbers, or materials that, by absorbing neutrons, greatly disrupt a chain reaction in the reactor core. The tank holding the soluble neutron absorbers is installed on top of the reactor. Once the system is triggered, the absorption solution flows into the core by gravity force and almost stops the reaction.

Another example is that the simplified boiling water reactor designers use the thermal study to design the reactor core so that natural circulation, due to cold water falling and hot water rising, brings water to the core center to be boiled.

Economic Simplified Boiling Water Reactor

During a period from the late 1990s, GE proposed to merge the concepts of the advanced boiling water reactor and the simplified boiling water reactor designs. The resulting design had capacities to larger sizes of 1,600 MWe. Reportedly, it has been advertised that the plan had a probability of core damage of only 3×10−8 core damage events per year.

PWR or BWR: Which Is Safer?

PWRs are less prone to spreading radioactive materials owing to leaks since the working fluid loop is separate from the primary loop. As the same fluid is passed through both the reactor and turbine in BWR plants, any leak in the turbine can cause radioactive elements to spread into the atmosphere.

What Is the Number of Boiling Water Reactors in the World?

There are about 425 water-cooled reactors worldwide, ranging in size from 30 to 1660 MW.

Download Boiling Water Reactor PDF

It is possible to download the entire article in PDF format by clicking on the link provided below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In linquip

- What is Breeder Reactor? Types and Applications

- How Does a Nuclear Reactor Work? A Closer Look at the Working Principle of Nuclear Reactors

- Types of Nuclear Reactors: Differences and Operation Principles

- What is a Continuous Stirred-Tank Reactor? Application and Working Principles

- What is Heavy Water Reactor Used for? Formula & Application

- What is Thorium Salt Reactor? Thorium-Based Nuclear Power

- What Are the Components of a Nuclear Reactor?

- What is Shunt Reactor? Definition & Example

- What is Distributed Generation? (Clear Guide) + PDF

- How Does A Hydrogen Fuel Cell Work? (A Comprehensive Guide)

- Top 10 Solar Panel Companies and Manufacturers in the US in 2022

- What are the Negative Aspects of Renewable Energy? (2022 Guideline)

- Can Renewable Energies Solve the Grave Problem of Climate Change?