The invention of control valves and different control valve parts had a huge effect on the industry and on our day to day life. They enable us to control the pressure and the flow of fluids and eliminate some of the boring manual tasks. In this article from Linquip, you’ll read all about different control valve parts and their functionality in the whole system. Plus, you’ll also read about which parts of the Valve are considered as its main parts and which ones differ based on design.

⇒ View a List of Control Valves for Sale and Their Suppliers ⇐

What are control valves?

Control valves are the element controlling the pressure and the flow inside a system or within a process. These mechanical devices are there to control liquids, gasses, vapors, slurry, and so on. Some of the control valves are manual but automatic control valves are also available when the condition and environmental condition is suitable for such units.

What are different control valve parts?

Depending on the control valve characteristics and its design, some parts differ within the control valve, but the rest is pretty much the same. Control valve positioner, trim, body, etc. are all there within control valves as their basic components. Examples of different control valve types are Gate, Globe, Check, Plug, diaphragm, Ball, Butterfly, pressure relief, etc. Each type has multiple models and each model has different parts with different features and functionalities.

The main goals of different control valve parts:

- Controlling the flow direction

- Relieving the system from specific pressures

- Increasing or decrease the flow

- Turning the flow on or off

- Regulating the flow or process pressure

What are the main control valve parts?

Control valves, regardless of the type, have some main parts including: The body, Actuator, Packing, Bonnet, and Trim.

See All Bleeder Valve for Sale

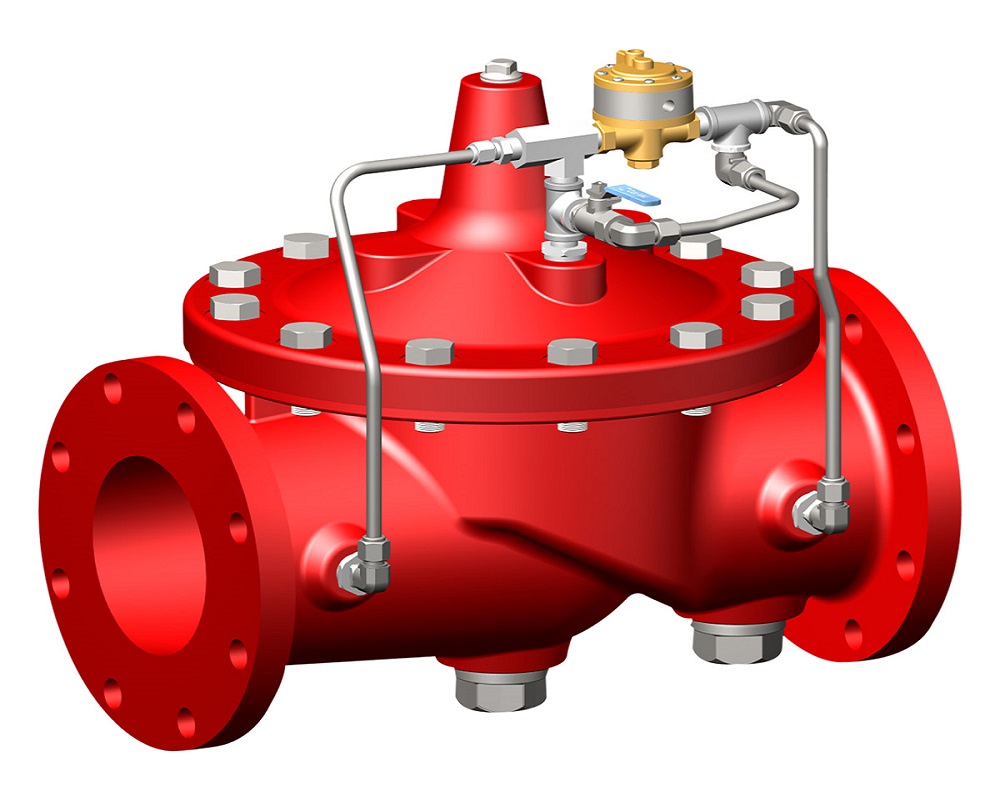

A. The body

One of the main control valve parts is its body which is also known as the shell. Working as a framework, the valve body is considered as the main unit in the valve assembly and the main boundary of a pressure valve. It enables the whole system to seat in one place and never falls apart.

The bodies of the valves are forged or cast in multiple shapes for multiple functions with relevant materials enduring the provided environment.

Threaded, welded, or bolted joints in the body enable it to receive inlet and outlet piping, and resist the fluid pressure loads as well. Different connections connect different control valve parts together and different designs enable the application of diverse nozzles and connection types suitable for specific needs.

Read More on Linquip

- What is Butterfly Valve

- What is Check Valve

- What is Control Valve

- What is Diaphragm Valve

- What is Flap Valve

- Working Principle of Control Valve

- Top Control Valve Suppliers in the USA

B. Bonnet

Bonnet in control valves covers the opening in the body. They are also an important part of the system since like valve body, they work as a boundary of a pressure valve. They, too, have different models and designs.

Bonnets are connected to the valve body with a welded, bolted, or threaded joint. They are the last part installed after the internal parts are placed inside the valve body. Bonnet then closes the body and covers the opening to hold the whole unit together. The materials used to forge or cast the bonnet are the same as the ones used in the valve body. Since they are a potential source for leakage, the manufacturing process and materials must be of good qualities.

Read More on Linquip

- Control Valve Types 101: Different classifications, advantage, and disadvantages

- Control Valves 101: The ultimate guide to understand control valves and how they operate

- Flow control valve types and functions

- Control valve positioner: an easy-to-understand guide to know them better

C. Trim

Trims are considered as the internal parts of the valves that can be replaced or removed and are in contact with the flow medium. Seat, guides, glands, disc, bushings, spacers, and internal springs are all considered as trim. But keep in mind that although bonnet, valve body, and packing are in contact with the flow medium, they are not considered as valve trim.

Different materials are used to construct the trim control valve parts each specifically designed for the different characteristics and environmental phenomena they need to withstand. For example, disc and seats experience different forces that packing glands, resulting in the difference of the used materials.

Trims enable basic motions and flow control. But their performance will be determined by the relation of the disk position to the seat and their interface.

-

Valve Disc

Depending on the position of the disc, stopping the flow or throttles are made possible. This part is also considered as a pressure boundary unit since the closing of the valve results in the full system pressure across the disc. In many cases, the design of the disc is what the valves are named after; like in a ball valve, the disc is also named ball.

-

Valve Seat(s)

Some control valves have one seat, like a globe valve or swing-check valve; but others have multiple seats. The disc, as well as the seats, creates a seal to stop the flow. The ones with two seats are designed with one seat on the upstream side and the other on the downstream side, each providing the seating surface for the disk.

Read More on Linquip

- Gate Valve Suppliers and Companies

- Other Valves Suppliers and Companies

- Hydraulic Valve Suppliers and Companies

- Knife gate valve Suppliers and Companies

- Globe Valve Suppliers and Companies

- Control Valve Suppliers and Companies

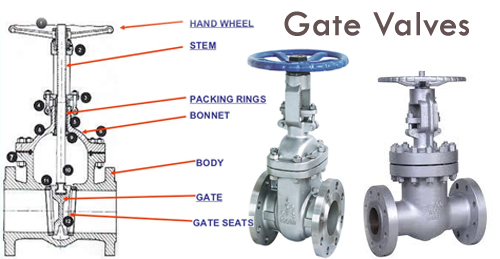

D. Stem

The stem is connected to the handwheel or the actuator from one side. The other side is connected to the disc. The stem is among the control valve parts that provide the movement to the plug, or the disc, resulting in the opening or closing the valve. The stem is also in control of the proper disc positioning.

Stems are usually available in 5 types, including rising stem with inside screw, rising stem with outside screw and yoke, non-rising stem with inside screw, rotary stem, and sliding stem.

In rotary valves, the disc would rotate, while in the linear ones, the motion of the disc is linear to open or close the valve.

E. Yoke and Yoke Nut

The yoke nut is placed at the top of the yoke to pass the valve stem through the yoke. The yoke is the connector of the bonnet or the valve body with the actuating mechanism.

F. Actuator

The valve actuator is one of the important control valve parts, used to fully open or fully close the valve. Actuators receive a positioning signal for controlling or regulating valves. They have different types such as gear actuators, electric motor actuators, pneumatic actuators, solenoid actuators, and hydraulic actuators.

Manual valves contain a handwheel that is attached to the stem or yoke nut and is rotated to open or close the valve. The manual quarter-turn valves have a lever that actuates the valve. The valves that are not suitable for manual applications are equipped with an actuator to produce rotary or linear motion of a source of power under the action of a control source.

See All Solenoid Valve for Sale

G. Packing

Packing is among control valve parts made from fibrous materials that are used to prevent leakage in some control valves. It is used for the leakage in the space between the bonnet and the stem.

Now you know all there is to know about different control valve parts and their use within the system. Don’t hesitate to read related articles on Linquip about control valves to get a better understanding of this subject. And feel free to sign up on our website to have an expert answer all your related questions and help you expand your knowledge even further.

Read More on Linquip

- Control Valve Manufacturers in United States

- Needle Valve Manufacturers

- Check Valve Manufacturers

- Pinch Valve Manufacturers

- Ball Valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

I’m very much interesting of knowing about all the components of valves parts and their functions. Thanks.

Dear Victor

Thanks for your attention.