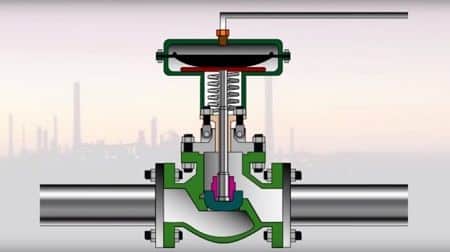

The working principle of control valve is opening or closing internal passages in order to regulate the flow of a liquid or gas. Control valves are part of a control loop that controls a process. Control valves adjust internal openings in response to instructions from the controller.

The control valve is the last control component that is used the most frequently in process control sectors. To counteract the load disturbance and maintain the regulated process variable as close to the intended set point as feasible, the control valve modifies a flowing fluid, such as gas, steam, water, or chemical compounds. There are multiple Control Valves for Sale on Linquip, and control valves are offered by a range of Suppliers & Businesses, manufacturers, and Distributors.

There is a complete list of valve services on the Linquip platform that covers all OEM fleets. Please call Control Valve Experts in Linquip to learn more about how to connect with a diverse group of Service Providers who consistently deliver high-quality products.

Basics of Control Valves

The control valve is used for controlling fluid flow by changing the size of the flow passage according to the controller and enabling direct control over the flow rate. This results in controlling process quantities such as liquid level, temperature, and pressure. In automatic control terminology, it is called the final control element. Based on controller input, control valves are able to control fluid flow rates.

Control valves can be used to regulate pressure and/or flow rate automatically, no matter which pressure is used. In some cases (as determined by design), different plant systems may operate at pressure and temperature combinations that require Class 300 valves, so all control valves are usually Class 300 for interchangeability. As long as the system does not exceed the rating for the Class 150 valves, this is not necessary.

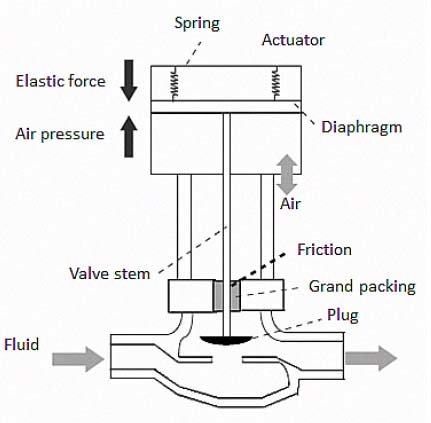

Control valves are normally globe valves whose ends are flanged to facilitate maintenance. Depending on the type of supply, the disk can be moved by hydraulic, pneumatic, mechanical, or electrical actuators. A valve modulates flow by moving a valve plug in relation to the valve body’s port(s). Valve plugs are attached to valve stems, which, in turn, are attached to actuators.

What Is the Application of Control Valve?

A control valve is one that, as the name suggests, is used to control something. Controlling flow, temperature, pressure, or liquid level is a typical application for control valves. A control signal, which might be hydraulic, electric, or pneumatic, opens and closes the control valve.

Operation of Control Valves

The process control industry includes control valves as the final control element. Control valves manipulate fluids, such as water, gas, steam, or chemical compounds, to compensate for load disturbances, keeping the regulated process variable as close to the desired set point as possible.

Typically, automatic control valves are opened or closed by electrical, hydraulic, or pneumatic actuators. When a modulating valve can be set anywhere between fully closed and fully open, valve positioners are normally used to ensure that the valve achieves the desired degree of opening.

The simplicity of air-actuated valves makes them popular, as they are only powered by compressed air, as opposed to electrically-operated valves, which require additional cabling and switch gear, and hydraulically-actuated valves, which require high-pressure fluid supply and return lines.

Control signals for pneumatic systems are typically based on a pressure range of 3 to 15 psi (0.2 to 1.0 bar) or, typically, on a 4-20mA electrical signal for industry or a 0-10V signal for HVAC systems. Today, electrical control often includes a smart communication signal that can be superimposed over the 4-20mA control signal, allowing the controller to monitor and signal valve health and position back to the controller.

One of the most important but also most neglected parts of a control loop is the control valve. Most of the problem comes from instrument engineers’ limited knowledge of facets, terminologies, and areas of engineering disciplines such as metallurgy, fluid mechanics, noise control, and plumbing, as well as vessel design, which may be involved depending on the severity of the service requirements.

Control loops usually consist of a process condition sensor, a transmitter, and a controller that compares the received “process variable” to the “set point,” i.e. desired process condition. The controller, in turn, transmits a corrective signal to the “final control element,” the last component of the loop and also the “muscle” of the process control system.

A control loop is considered to be made of three parts, the eyes, which are sensors of the process variables; the brain, which is the controller; and the hands, which are the final control element. Consequently, it is the most vital, but sometimes least understood, component of an automatic control system. In part, this occurs since we are so enamored with electronic components that we neglect to fully understand and utilize all-important hardware elements.

What Are the Characteristics of Control Valve?

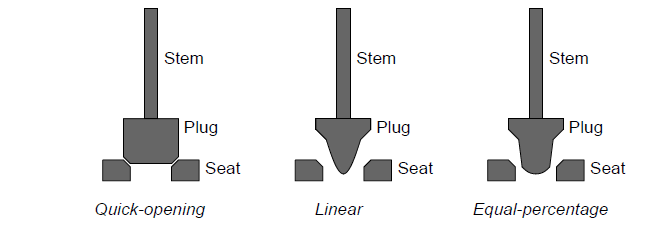

Although certain other intrinsic valve features, including parabolic, modified linear, or hyperbolic, are occasionally employed, quick opening, linear, and equal proportion valves are the most often manufactured. Each application’s installation will have a special feature that links fluid flow to heat demand.

Arrangement of Control Valves

The following image illustrates how the flow rate in a line can be controlled using a control valve. A “controller” receives pressure signals and compares them with the desired flow. If the actual flow varies from the desired flow, the control valve adjusts to overcome the difference. It is possible to control any one of a number of process variables in a similar manner. The most commonly controlled variables are temperature, pressure, level, and flow rate.

Control Valve Problems

It is possible that control valves fail to regulate the parameter they are controlling properly. Quality issues arise when the process is not controlled.

- There is a possibility of oversizing control valves. When fine adjustments are needed, an overly large control valve is insensitive and wastes money. The control valve is usually one or two lines smaller than the pipe.

- Control valves can experience excessive lag (react too late) if the sensor is installed too far away.

- There may be a low air supply at the actuator or air leaks away, which results in less force being available to move the stem.

- It is possible for the stem of a control valve to become sticky if the packing is too tight or if there is a leak in the product.

Control Action

Using an air-operated valve as an example, there are two control actions available:

“Air or current to open”: As the control signal value increases, the flow restriction lowers.

“Air or current to close”: The flow restriction rises as the control signal value increases.

Failure to safety modes can also occur:

Failure of an air or control signal to close “- If the compressed air supply to the actuator fails, the valve closes under spring pressure or with backup power.

Failure of an air or control signal to open “- If the compressed air to the actuator fails, the valve opens by spring pressure or by backup power.

The types of failure operation are required by the plant’s failure to safety process control specification. In the case of the cooling water, it may fail open, whereas it may fail closed in the event of chemical delivery.

Control Valve Tuning

Tuning the controller determines how the valve reacts to a changing process parameter. Tuning determines the valve response speed and intensity when it detects a need for a correction. The controller contains internal logic which produces a predetermined amount of movement in response to an input.

Tuning the controller determines how the valve reacts to a changing process parameter. Tuning determines the valve response speed and intensity when it detects a need for a correction. The controller contains internal logic which produces a predetermined amount of movement in response to an input. The logic considers some items:

- The magnitude of the discrepancy between the controlled parameter’s value and its setpoint (Proportional);

- Duration of the discrepancy (Integral);

- The speed of changes in the discrepancy (Derivative).

After that, it determines how fast and how far the stem should move.

Once the trim position has been altered, the controller waits for the next measurement from the sensing element to determine the remaining difference to the set point. Valve stems are moved, and the flow is altered until there is no difference between the setpoint and the actual value of the controlled parameter.

Tuning a control valve can be compared to adjusting the taps under a shower to get the water temperature right. If hot water is turned on first, the control valve will become the cold water tap. Temperature is sensed by your body. The cold water tap is opened if the water gets too hot. The effects of increasing the cold water flow take a while to feel (the time lag). Temperature is adjusted up or down until the desired temperature is achieved from the combined flows. After the valves are at the right temperature, the temperature remains steady.

If something changes, such as someone doing their laundry with cold water, the cold water flow to the shower drops, and the water temperature rises. A change in temperature is again sensed, and adjustments are made. In response, taps are opened further for cold water or closed for hot water. Temperature measurement and a valve position adjustment are carried out until the parameter under control (temperature) stabilizes. The same applies to control valves.

Parts of Control Valves

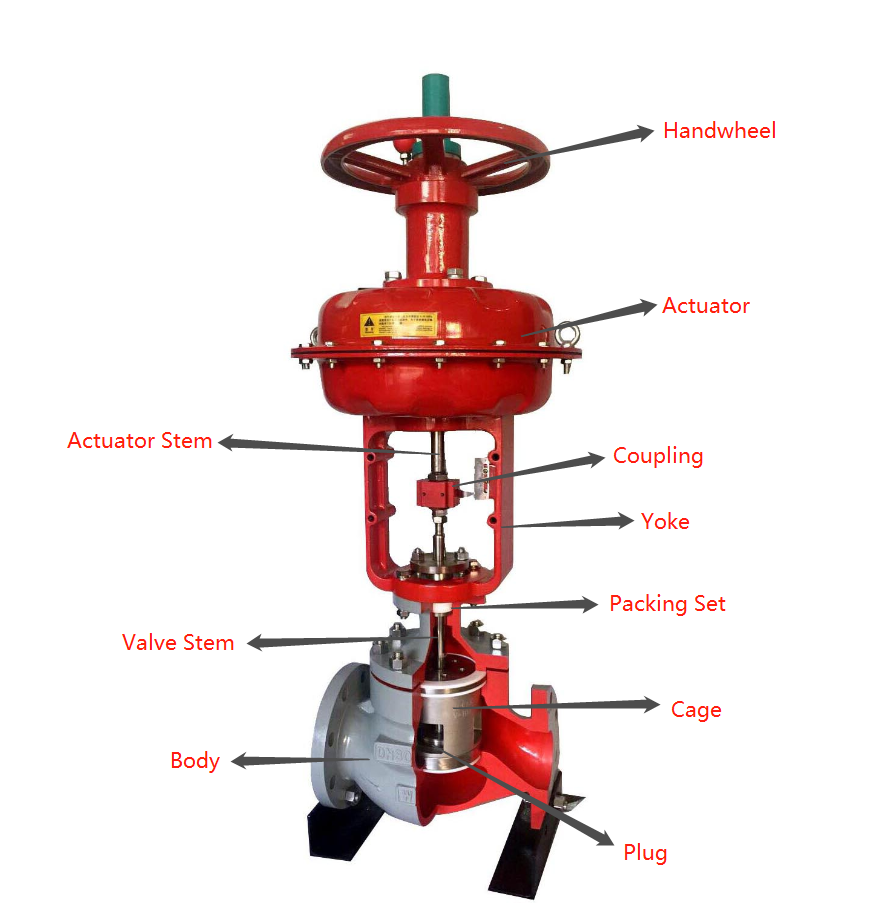

In general, a control valve consists of three parts, each of which exists in several types and designs:

Valve Actuator

Valves have actuators that move the modulating elements, such as balls or butterflies.

Valve Positioner

This device ensures that the valve has been opened to the desired degree. Friction and wear problems are thus eliminated. Positioners have the function of delivering pressurized air to the valve actuator to set the valve’s stem or shaft corresponding to a set point in the control system. A positioner is typically used when throttling is required.

Positioners are designed to take position feedback from the stem or shaft of a valve and deliver the pneumatic pressure to an actuator to open and close the valve. This positioner must be attached to or close to the control valve assembly.

Positioners are categorized according to types of control signals, diagnostic capabilities, and communication protocols, including pneumatic, electric, electro-pneumatic, and digital.

Pneumatic Valve Positioner

A pneumatic device sends and receives pneumatic signals. It is intrinsically safe and can close valves with a lot of force.

Using a single-acting valve actuator with range springs, a single-action (or a three-way) pneumatic positioner sends air to and exhausts air from only one side of the valve. However, double-acting or four-way pneumatic positioners can move air on both sides of the actuator.

Electric Valve Positioner

Electrical signals are sent and received by electric valve positioners. Electric motors can be either single-phase or three-phase run on alternating current (AC) or direct current (DC).

Electro-pneumatic Valve Positioner

Current control signals are converted into pneumatic equivalents by electro-pneumatic valve positioners.

Digital Valve Positioner

Digital or smart devices control and record data and position the valve actuator with the help of a microprocessor. This type of positioner is highly accurate, uses less air than analog positioners, and allows for online digital diagnostics.

A digital valve controller performs two additional functions in addition to controlling the valve’s position: diagnostics and two-way digital communication. As a result, smart positioners provide the following advantages when used on control valves:

- Calibration and configuration of the positioner automatically.

- A real-time diagnostics system.

- Reduced installation and calibration costs for loop commissioning.

- Maintaining loop performance with diagnostics.

- Reduced process variability through improved process control accuracy.

Valve Body

A valve body contains the modulating element, such as a plug, globe, ball, or butterfly. There are two basic types of valves; plug and seat valves, where the plug is closed against the seat, or quarter-turn valves that have a disc, ball, or cone turning against the seat.

It is the valve trim that is responsible for regulating the flow of water. There is a fixed-in-place seat along with a moveable plug, disc, ball, or cone. Various passage shapes can be created using the trim, which manages the flow in a deliberate manner.

There are three main types of control valve trim:

Snap Trim (also known as Quick-Opening Trim)

Snap Valve Trims open quickly and are used for on/off operation. Among the common applications are liquid dumps, pressure reliefs, and metering. Zirconia seats are also available for erosive applications.

Nominal Trim (also known as Linear Trim)

Typically, nominal valve trim is used to throttle liquids, control liquid level, and prevent water hammering.

Equal Percentage Trim

The equal percentage valve trim is used in throttling applications to control the flow or the pressure of gas and vapor.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Download Working Principle of Control valve PDF

Read More on Linquip

- Control Valves 101: The Ultimate Guide to Understand Control Valves and How They Operate

- Control Valve Parts: The Go-To Guide for beginners and experts

- Control Valve Types 101: Different Classifications, Advantage and Disadvantages

- How Valves Work in an Engine

- Top Control Valve Suppliers in the USA

- Diaphragm Valve Manufacturers

- Control Valve Manufacturers

- Gate Valve Manufacturers

- Solenoid Valve Manufacturers

- Valve Manufacturers

- Facts About The Flow Control Valve Function

- Flow control valve types and functions

- Backwater Valves Installation, Costs and Maintenance in 2022

- How to Repair a Gate Valve? (Clear Guide)

- Backflow Valve Installation, Costs and Maintenance in 2022

- How to Install a Thermostatic Mixing Valve? (Costs and Maintenance in 2022)

- How to Install a Water Pressure Reducing Valve? (Costs and Maintenance in 2022)

- Check Valve Installation Costs and Maintenance in 2022

- The 10 Best Water Shut off Valves of 2022

- What is Drain Valve? Working Principle, Types & Applications

- What are Coaxial Valves? Working Principles and Type

- What is Isolation Valve? Working Principle & Types