DC Generator Repair- All of your industrial AC & DC electric motor and generator repairs can be handled by several service providers; this includes anything from assets weighing 145 tons and rated to 15kV to small, fractional HP, low-voltage devices (690V).

A thorough list of DC generator services for all OEM fleets is available on Linquip’s website. Linquip vendors can assist you with this. Please get in touch with DC Generators Experts to find out more about how to find a wide range of service providers who continuously deliver high-quality goods.

A DC generator needs MMF to create flux in its magnetic circuit. The MMF is necessary to establish flux in a DC generator’s magnetic circuit is obtained through field excitation. A DC voltage applied to the field windings of a DC generator causes current to flow through the windings, producing a steady magnetic field. This phenomenon is known as field excitation. Manufacturers, distributors, and suppliers from a wide range of industries, as well as Linquip, who has a big assortment of DC Generators for Sale, are all able to provide DC generators.

A DC generator can only be evaluated through testing. Your emergency DC generator system will function and you will be prepared for a power outage if you test it frequently. If you work for a business that has a commercial-sized generator, please learn more about full-load bank testing services.

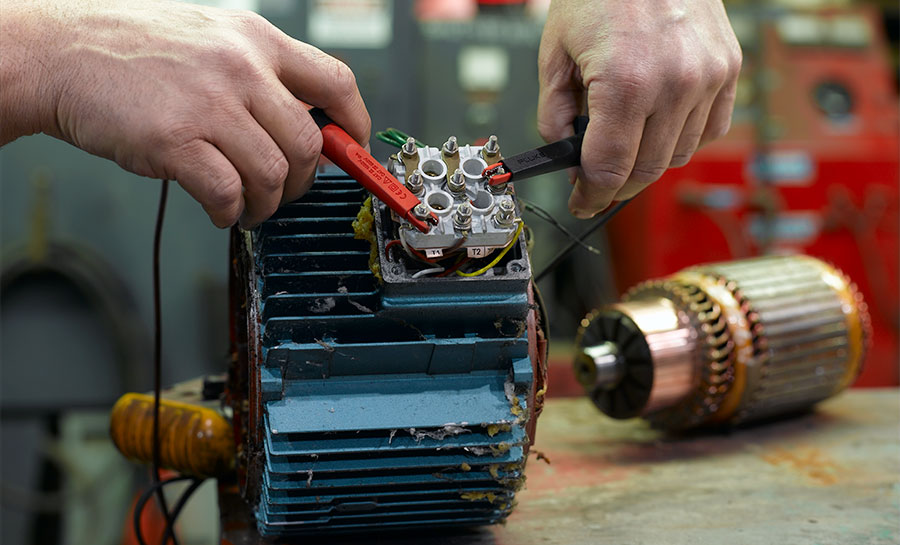

What is DC Generator Repair?

It’s time to schedule generator repair if you observe any of the following symptoms:

- Your generator’s electrical components are broken: Be careful to pay attention to the wiring, buttons, and other parts of your generator when inspecting it. Your generator certainly needs to be fixed if they show any signs of corrosion or wear. Wet weather has the potential to significantly damage these parts, which could lead to a power outage.

- Your generator leaks fuel: Leaks are more likely to occur in a generator that is beginning to age. These leaks can be coolant leaks, fuel leaks, or oil leaks, and they all work to keep your generator from overheating while it’s in operation. Make sure to thoroughly inspect the generator because leaks can happen practically everywhere. Pay particular attention to any puddles that have developed by the generator because they usually signal a leak. Be cautious if you discover any leaks because any substance that escapes could be dangerous.

- Your generator starts up slowly: Your generator shouldn’t start up slowly. Your generator needs to be serviced if it seems to be taking longer to start up than it used to. The battery is most likely the problem because it can discharge after extended periods of inactivity.

- Your generator is physically damaged: Look for any damage such as cracks, dents, or frayed wires. You would not think that a little scratch on your generator’s surface should cause much trouble, but it might have impacted the interior wiring. The performance of the generator could be impacted by even little dents or cracks.

Linquip’s DC Generator Services provide the essential load-bank testing for commercial and industrial generators. This series of demanding tests are designed to put your generator through its paces and evaluate its performance. If there is even the slightest problem, your generator could operate poorly or perhaps stop functioning altogether in an emergency. DC Generator Experts at Linquip can carry out these thorough examinations and resolve any problems that can prevent you from producing your maximum power.

At Linquip, we can provide a lot of services for your DC generator. To track the operation of your DC generator, we can install monitoring equipment. When your generator takes action or has a problem, these gadgets send you a text message and/or email to let you know. DC Generator Installation, DC Generator Repair & Maintenance, DC Generator Inspection, and several other services can be provided by Linquip. To learn more about our 100% customizable notifications, get in touch with us today!

DC Generator Maintenance

An inspection, testing, cleaning, replacement, and lubrication plan are all included in a DC generator maintenance program, which is a preventative and corrective maintenance schedule that ensures the proper operation of D.C. motors and related equipment. Creating and implementing a maintenance program is quite simple. When routine maintenance checks are added to a shop’s work schedule, they quickly become apparent and produce cost savings that much outweigh the time and material costs incurred in maintaining them.

Maintenance Guide Summary

This maintenance manual will go through typical maintenance practices for the majority of DC generators. Before performing maintenance, the maintenance technician should consult the manufacturer’s technical documentation to ascertain the maintenance needs of a specific device. The following subsections comprise this section:

- Noise and Vibration Inspections

- Reviewing the Service History

- Windings Tests

- Visual Inspection

- Bearings and Lubrication

- Brush and Commutator Maintenance

Noise and Vibration Inspections

A noise and vibration inspection should be done before disconnecting the item and taking it to the shop or a repair facility for maintenance. For this, the motor must be activated, attached to its driving load, and used regularly (if possible). Mechanical noises or vibrations may be a sign of some issues, including electrical and/or mechanical imbalances, misalignments, brush chattering, bad bearings, bent shafts, mechanically loose windings (shaken loose by excessive vibrations, for example), a loose cooling fan, or something stuck in the vents or shroud. After it has been taken apart, inspect the lead and insulation for damage if the windings are loose. Excessive heat and brush sparking may also be caused by vibrations.

Electrical imbalances like open or shorted windings or unequal air gaps can produce noises or vibrations in addition to mechanical issues or imbalances. Power up the motor first, then cut power, to distinguish an electrical imbalance from a mechanical one. If the noise or vibration continues when the power is turned off, the issue is mechanical; if it stops when the power is turned back on, the issue is typically electrical.

Visual Inspections

Consult the manufacturer’s technical literature for suggestions on suggested inspection tests or procedures before disassembly. The information in this paper will help perform visual inspections.

Visual inspections are used to spot and document irregularities in a motor’s physical state while it is de-energized. A motor that looks dusty, rusted, or “beaten up” was likely used in a harsh environment and may be more problematic than typical. The “smell” test should be part of this assessment. Does the burning smell emanate from the motor windings? The insulation varnish on the motor windings is where the burnt smell is coming from. If so, there may be a problem with excessive heat. Under these circumstances, motor winding damage is probable, hence winding tests should be performed.

Overheating issues may not always be caused by the motor itself; instead, they may be the result of mechanical overloads like jams in the driven load or cold oil being pumped by a motor drive, running the motor at low speeds so that insufficient cooling airflow is present, electrical noise from DC drives heating the windings, or it may simply be the result of a dirty environment.

Since heat damage is the weakness of typical motor operation, dirt works as a heat insulator. Make sure that the cooling fan is working properly and that there are no obstructions in the channels. With a rag, wipe off all surfaces. Use a shop vac to blow out or vacuum the channels. Motor windings may be harmed by corrosion, which can also result in high-resistance wiring connections. If the winding tests show that winding damage has occurred, a motor rewind may be justified if the corrosion is persistent. It could also be necessary to re-plug the terminals on the motor connection box.

How to Test Your DC Generator

Do not be alarmed by a generator system. It is simple to perform periodic testing. In contrast to a portable generator, a home generator is directly attached to a power supply. The generator is then joined to the mainline circuit breaker. This main utility line may be located in a box outside, in the basement, or in the garage when it enters your property.

- The incoming utility line will lose power when the main utility disconnect is flipped, requiring the generator to start.

- For distributing electricity throughout the home from an incoming utility or generated power, the transfer switch is the installation that is used the most frequently. The generator may run for a few seconds to a minute until the transfer switch clicks and power is distributed. This is because the transfer switch needs to verify that the generated electricity flowing in is stable.

- Give your generator some time to “work out” and “warm up.” It’s a good idea to check that the electricity has been fully restored by taking a walk around your home right now.

- Make sure to activate the mainline breaker after performing a test, then wait for the transfer switch to click and for the generator to restart.

Types of DC Generator Testing and Monitoring

If your building has an emergency generator, you should abide by these guidelines to maintain it operating properly. The following is a list of the standby generator testing requirements for each month and each year:

Monthly Type

A monthly test is performed on Level 1 and Level 2 generators. A generator classified as Level 1 is one whose failure could result in fatalities or serious injuries. A level 2 generator is one whose failure wouldn’t put lives in danger. During testing, a generator should run with the available load for at least 30 minutes. Successful testing occurs when the generator:

Reaches the minimum exhaust gas temperature necessary for the owner’s manual’s recommended monthly testing or operates at a minimum of 30% of the nameplate kilowatt rating while ordinarily operating.

A generator should only be tested for a brief period until its water and oil pressures have stabilized to avoid prolonging its downtime.

Yearly Type

If a generator fails the monthly test, it must be tested annually with a load provided by a load bank for two nonstop hours. During the two hours, the gadget should be utilized as follows:

- At 75% of the nameplate Kilowatt rating for 60 minutes.

- At 50% of the nameplate Kilowatt rating for 30 minutes.

- At 25% of the nameplate Kilowatt rating for 30 minutes.

The “training” offered by load bank testing can increase a generator’s operational capacity and make it more responsive during a real power outage.

Monthly and annual checkups are essential, but they shouldn’t be the only ones performed to ensure generators are prepared for power outages.

In addition to NFPA 110 emergency generator testing, building owners should make sure that their generators receive routine maintenance, yearly infrared scanning, modernization, and retrofitting, as needed. The efficiency of a generator can be assessed, but maintaining or increasing it necessitates a multidimensional approach that includes the aforementioned measures. For more information about DC generator repair, maintenance, and testing, visit this video.

Summary

Although it is recommended that you test your DC generator twice a year, you can do so whenever you need to. Conducting a test before hurricane season or a major storm can be useful. So that you have it, make a note of your test in a notebook. If you experience any problems, get in touch with a residential generator specialist for a more thorough test and inspection.

Our Team of Experts is now able to provide full-service commercial generator sales, servicing, and repair to go along with the HVAC and electrical services. It is a duty to provide backup power options in the event of an emergency power outage so that operations can continue and temperatures can be maintained. Since we offer turnkey service, you will work with a single team from sales to servicing. For more information, you can use the complete list of Linquip’s DC Generator Service Providers to meet all your requirements.

Download DC Generator Repair PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip