Differences Between Worm and Helical Gear- Whether you are using servo gears, worm gears, or any other form of industrial gears, by improving torque output and regulating the direction of spinning, gears are an important part of many industrial motors and machinery. Worm gears and helical gears are two of the basic kinds of gears, but now, we want to explain the differences between worm and helical gears in this post.

What are the Main Differences Between Worm and Helical Gear?

It may be a typical idea that employing a helical gearbox model will lead to more system efficiency than using a worm gear type. However, improvements in worm gearbox type, as well as advances in lubrication, are closing the efficiency space to the condition where the efficiency of worm gears is more than competitive with helical models.

Right-angle worm gearboxes that formerly had efficiencies between 82% to 84% are now illustrating ratings in the upper 80% rate, whereas types that were in the upper 80% rate now are 93% to 95% efficient. Some constructors have created higher strides in these efficiency developments than others.

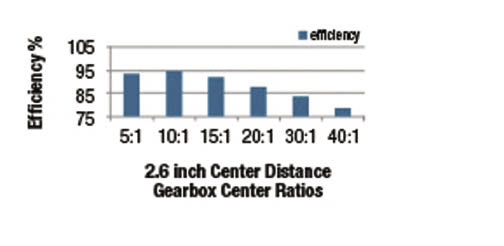

Generally speaking, the right-angle type of worm gear reducers starts to see a reduction in efficiency as they cross into greater ratios. Greater center distance worm gearboxes are usually more efficient than lower center distances. For instance, a normal unit with a 2.6-in. center gap sees efficiency reduce slowly as the ratio improves.

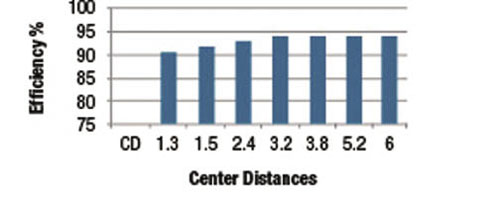

Likewise, as the center gap grows, efficiency increases, as seen here where the improvement in efficiency for seven center gaps is at a 10:1 ratio.

Right-angle worm gear reducers try to reduce efficiency as they cross into greater rates. Larger center gap worm gearboxes are typically more efficient than smaller types. For a normal unit with a 2.6-in. center gap, for instance, efficiency drops slowly as the ratio improves.

The problem is, what the trade-off between purchase cost and cost storing within efficiency is? Is it more cost-effective to pay additive for greater efficiency, or is the price of that efficiency too great to recover through smaller operating costs?

When comparing the power savings for a helical gearbox in comparison with a worm gearbox in the same case, there are several conditions where the dollars saved are minimal. As a general explanation, several stages needed within a helical gearbox add cost and complexity. Helical gearboxes are typically more expensive than worm types for the same gear ratios and HP. When the power dollars stored are compared to gearbox purchase prices, there are complete reasons to choose right-angle worm types in many lower HP usages.

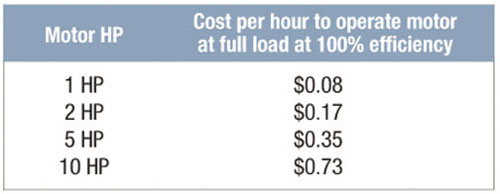

To compare the saving prices in some usual lower HP cases, we have evaluated the dollar cost to perform a system at the full-load current for an 8-hour shift employing a normal AC motor. Motor costs are estimated using a US Department of Power website, which determines a national average industrial energy ratio of 7.5 cents per kilowatt-hour as of March 2020.

As center distance rises, efficiency grows, as presented here where the improvement in efficiency for seven center distances is at a 10:1 ratio.

According to the market costs and catalog determining efficiencies, the payback time for a low HP case can be long. For instance, in an easy case for a 1 HP unit with a 10:1 ratio, the price of a worm gearbox is $840 less than the identical helical form. The efficiency of the worm type would be 92% in comparison with 97% for a helical form.

In the case of a 1 HP unit with a 10:1 ratio, you can carefully anticipate paying a $300 or more premium while employing a helical right angle type instead of a worm gearbox. Even the most effective helical form will not exceed 97% (more commonly, it is in the low to mid 90% range). As a result, you can utilize an efficiency of 97% as the most appropriate way for the helical right-angle reducer, in comparison with 92% for worm types that are constructed using current technology. That transforms to less than a penny per hour of performance. At that state, it would take more than 200,000 hours of function to revise the differences in costs between the two.

As discussed before, the greater the ratio, the lower the efficiency of the system. For the same 1 HP case, a 30:1 rate would see a worm-type efficiency reduction to 81%. Even in this application, the purchase cost differential between a worm and a helical gearbox is great enough that the time to make up the price difference would be 48,000 hours.

This chart presents the potential dollar price to perform a motor at the full-load situation for an 8-hour shift employing a standard AC motor. Motor prices are estimated using US Department of Power instructions which show a national average industrial energy ratio of 8 cents per kilowatt-hour as of March 2020.

The crossover section, where it becomes more effective to use helical types rather than worm gearboxes, is at the 10 HP level with rates above 20:1. With low rates, the worm type still has a lower purchase price in comparison with the helical form and still has an efficiency of about 94%. But, as ratios increase, the relative efficiency drops, and in greater ratios, the purchase price and efficiency state both demonstrate that the helical types may be a more cost-effective model at both costs of use and purchase.

The purpose of these instances is not to result that worm types are more appropriate than helical gearboxes in all cases. You will figure out that in applications needing greater torque (for example, 10 HP at a 30:1 rate), a helical reducer typically presents a better solution. In this case, the differences between worm and helical gear in efficiency play a major role in the calculations and permit the capability to downsize. The finalized result is that it is essential to measure published efficiency rates of both worm and helical gears for the suitable HP and ratio during the specification procedure.

Definition of the Worm Gears

A worm gear is a particular form of gear composition, whereby a worm – or screw – contacts a gear. The specific composition of this type of gear enables the consumer to control the velocity. Greater torque can also be obtained by the worm gears.

This model also means that the worm can rotate the gear, but the gear is unable to do this and turn the worm. Worm gears are commonly employed in large gear reductions. Worm gears are typically found in cases such as conveyor systems where the mechanism of locking performs as a brake. They are also generally used in tuning instruments, lifts, and gates.

There are three various forms of worm gears, including single-throated, double-throated, and non-throated.

Single-throated

The single-throated type of worm gears has incurvate helical teeth. These teeth are designed around the worm for a contact line, which results in higher powers being obtained without additional wear.

Double-throated

Double-throated type of worm gears has a concave form of teeth on the gear and the worm screw. Growing the contact surface enables increased touching loads with less additional wear.

Non-throated

The non-throated worm gear includes a straight worm that doesn’t contain a grooved circumference. Having a single rotating point means that the non-throated type has a high unit of tear and wear.

If you are employing worm gears and tend to improve the efficiency of the industrial systems, you should consider the differences between worm and helical gears to put less strain on systems with industrial gears. Visit here to know more about them.

What are the Advantages of Worm Gearboxes over Helical ones?

Worm gearboxes are compact instruments that, despite their commonly small size, have a high power capacity. Simply designed and manufactured, because they are constructed of few components, they present a precise linear movement that can be employed by a myriad of mechanisms. And this versatility is even greater since, unlike helical gearboxes, worm gearboxes produce no noise. They need minimal maintenance, which is cost-effective.

One of the main advantages of employing worm gearboxes is that they present a high-velocity reduction in minimal gap. Because their gear level is quite small, it allows for a great reduction in reduced gaps.

In addition, it can be employed to construct non-reversible drives – in other words, systems that can just be performed in one direction. Another interesting property of these gearboxes is the non-reversibility of the system when the angle of the worm screw is about 6 degrees.

Main Disadvantages of Worm Gearboxes?

The main disadvantage of a worm gearbox is the low performance presented by this gearbox stage, which can be close to 15% based on the associated axial stresses and high friction.

Besides, the greatest wear in these instruments takes place on surfaces that are faced with friction, which is why they should be greatly resistant and completely calibrated to provide a long service life. There are some wear problems in the fillets if there is additional friction in the area.

Definition of the Helical Gears

As Machine Design explains, according to the method their teeth interact, compared to many other forms of gears, especially worm gears and spur gears, helical gears perform more smoothly and quietly. The teeth on this form of gear are cut in a curved direction to the face of the gear. When the teeth start to interact, the touching is gradual and slow. The common range of a helical gear angle is approximately between 15 to 30 degrees.

The helical gear is the form of gear that is most commonly used in transmissions. Helical gears also create hefty volumes of thrust. Bearings are employed to tolerate this heavy thrust of power.

Advantages of Helical Gears over Worm Gears

- The angled teeth perform more slowly, allowing for more silent and smoother gear performance when compared to worm gears or toothed wheels.

- Helical gears last longer and are perfect for high-load cases because they have a greater amount of teeth in contact.

- Load is distributed at all times among several axes, which generates less wear.

- They can transmit power and motion both among straight-angle and parallel axes.

Disadvantages of Helical Gears

- One of the main disadvantages of these gears is the thrust which affects the gear axis and requires to be accommodated by employing adequate thrust bearings.

- The efficiency of the helical gear is lower based on the contact between its teeth, which creates axial thrust and produces heat. A greater waste of energy drops the efficiency.

- There is a larger degree of sliding friction between the teeth of the helical gears. This creates higher wear during their function and the requirement for lubrication systems.

- They have a higher production cost than worm gears.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip