If you are eager to find the answer to “what is a radial compressor?”, you are in the right place! In this article from Linquip, we want to explain all about radial compressors. By the end of this article, you know what a radial compressor is, its different parts, and also how it works. So, let’s begin.

What is Radial Compressor?

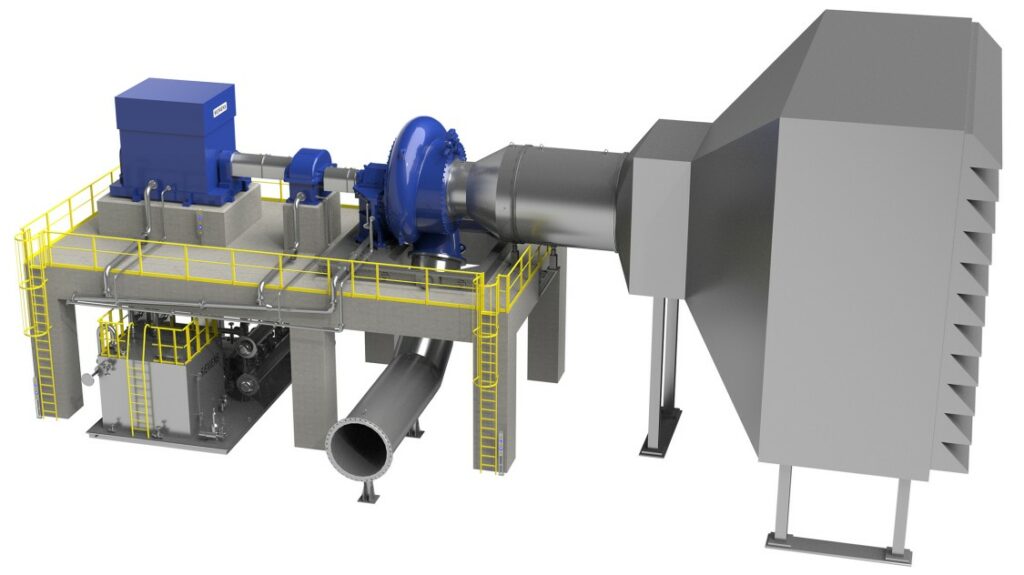

The radial compressor is also called a centrifugal compressor. This kind of dynamic compressor has a radial design. They operate at constant pressure and any changes in the external conditions will affect the performance of these compressors.

How does Radial Compressor Work?

In order to know “what is a radial compressor”, you should know how they work to be able to talk about these compressors and their working process.

A radial compressor contains radial blades on its rotating impeller and the air is drawn into the center of this unit. The centrifugal force pushed the air into the center. The air’s radial movement inside these compressors will raise the pressure, resulting in the generation of kinetic energy. The radial compressor transforms kinetic energy along with the velocity in its diffuser to form the desired pressure energy.

After the movement of the air into the impeller’s center, kinetic energy, and the velocity will be converted into pressure when the air or the chosen gas passes through the volute and the diffuser. The impeller’s rotation converts the kinetic energy to the chosen pressure when the velocity of the air increases. When the air or the used gas enters the diffuser, the velocity will decrease. This stage (reduction of the velocity) causes the pressure to increase.

Another thing you should know while learning “what is a radial compressor?” is that multiple stage radial compressors contain a series of different stages in their design, enabling the compression as well as the reduction of temperature of the air while flowing through these stages. Radial compressors usually have two to four stages for pressure generation of up to 150 PSIG. This process happens with the help of converting energy.

It can be used for compressing particular gas or vapor by using radial acceleration and the impeller as well as the unit’s case that has been designed to keep all the parts together. After each stage, the excess moisture is removed and the gas will be cooled down by using an inter-cooler, resulting in the increase of the air quality as well as efficiency. By increasing the number of stages, the device can achieve higher pressure for specific industrial plants.

Other uses and applications of radial compressors

It’s interesting to know that other types of this everyday system that we might use for small applications are also used in aero-engines of small and medium power. So, depending on the person who asks “what is a radial compressor?” you need to adjust your answer to fit either the small applications such as its application for compressing the gas in several household appliances, or other applications in the industry. They can also be found in airplanes, ships, and also trucks and tanks as their turbo-chargers in their reciprocating engines.

Different parts of a radial compressor

Radial compressors have different parts but a simple radial compressor usually contains 4 main parts including diffuser, inlet, collector, rotor/impeller. For completing our knowledge regarding the question of “What is a radial compressor?”, we will briefly explain each of these four parts:

- Diffuser

The diffuser is one of the key components of a radial compressor. As we mentioned above, the diffuser converts the gas’ kinetic energy into pressure when diffusing the gas velocity. The design of the diffuser can be adjusted according to the desired outcome and it can be vaned, vaneless or alternating combination.

- Inlet

The inlet is one of the simple but important parts of a radial compressor helping in the overall control of the unit and usually contains a valve, pressure and temperature instrumentation as well as stationary vanes/airfoils for swirling the flow.

- Collector

Another important part of a radial compressor that you need to know about when searching for the answer to “what is a radial compressor?” is the collector. The collector does different jobs and its name and shape differ based on these roles. It’s sometimes called a volute (aka scroll) when it collects the discharges of the diffuser from a device that looks like a shell. It also goes by the name Plenum when the diffuser discharges into a chamber. The collector collects the flow from the diffuser and guides it toward a downstream pipe for the desired outcome.

- Impeller

The impeller of a radial compressor is considered to be the heart of the compressor because it has a vital role. The impeller’s increasing radius enables the gases to reach higher energy levels along with higher velocity, making the application of the radial compressor easier for a wide variety of different industries.

All these components together (and sometimes some additional units and parts) create what we now know as the radial compressor.

Now you know the answer to “What is a radial compressor?”. What do you think about these compressors? And which compressor type do you think is the most efficient one? Comment below and share your thoughts with us. And if you have any questions, feel free to sign up on Linquip and our experts will solve all your problems and questions in a flash.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip