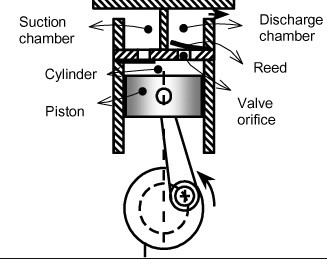

Reciprocating compressors also widely known as piston compressors are mainly used to move air/gas at high pressure to be stored and used for different purposes. The main elements of the compressor are one or more cylinders and pistons which move within them. Automobile engines work almost the same way as reciprocating compressors do by letting the air in from one chamber, mixing it with fuel, and letting the fume out from another chamber with pressure. The picture below is a schematic structure of a reciprocating compressor and its main components.

The Linquip team can provide you with any information you need regarding reciprocating compressors for any application or requirement. Please feel free to contact Linquip with any questions or concerns you may have. You can learn more about what Linquip offers you regarding reciprocating compressors by reading the article “What Is Reciprocating Compressor?“.

Are you in need of reciprocating compressor products and devices? Linquip offers a wide selection of Reciprocating Compressors Products for free. If you are searching for reciprocating compressor equipment and device prices, you can send inquiries to all Reciprocating Compressor Suppliers and Companies via Linquip and receive free quotes.

Introduction

A reciprocating compressor has a piston that moves downwards thus reducing pressure in its cylinder by creating a vacuum. This difference in pressure forces the suction chamber valves to open and bring gas or air in. When the cylinder goes up, it increases pressure thus forcing the gas or air out of the cylinder through a discharge chamber. Reciprocating compressors are used in a variety of industries and for different purposes. The following are the main applications of reciprocating compressors:

- Natural gas processing and delivery

- Chemical plants

- Oil refineries

- Refrigeration technology

As stated earlier, reciprocating compressors are found in almost every work setting including but not limited to diving, dental surgeries, automotive workshops, and agriculture. Pneumatic (air-powered) tools, such as drills and angle grinders, are important in industry because they are generally lighter and safer than those with an electric motor which further highlights the significance of reciprocating compressors.

Reciprocating Compressor Efficiency

Reciprocating compressors are considered the most energy-efficient type of all compressors for most applications. This is while they tend to have a higher maintenance requirement than compared to other compressor types.

The primary components of a typical reciprocating compressor system can be seen in Figure 1 and it includes a cylinder, two chambers for suction and discharge, a piston, an orifice, and a reed.

Simply put, a piston moves in a reciprocating manner to compress the gas. This may be of single-or dual-acting design.

Some dual-acting cylinders in high-pressure applications will have a piston rod on both sides of the piston to provide equal surface area and balance loads.

Gas pressure is sealed and wear of expensive components is minimized through the use of disposable piston rings.

Cylinders for larger industrial applications come with coolant passages or circulating liquid coolant-type systems, whereas some small-scale home and shop compressors are typically cooled by air. Large application cylinders are generally fitted with replaceable liners.

A detailed Mechanism of Action

Process gas is drawn into the cylinder, compressed, contained, and then released by mechanical valves that typically operate automatically by the difference in pressure. Depending on the system design, cylinders may have one or multiple suction and discharge valves.

The crankshaft is fitted with counterweights to balance dynamic forces created by the movement of the heavy pistons.

Suction gases are generally passed through suction strainers and separators to remove entrained particulates, moisture, and liquid phase process fluid that could cause severe damage to the compressor valves and other critical components, and even threaten cylinder integrity

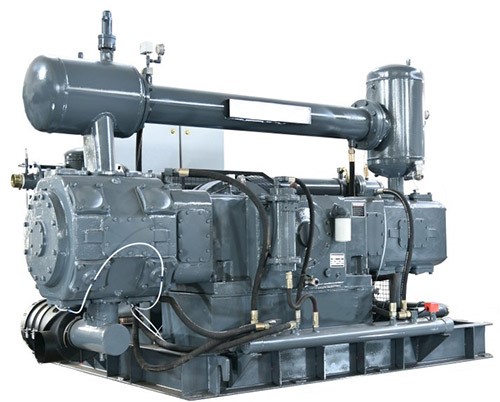

Typically, reciprocating compressors are relatively low-speed devices, and are direct- or belt-driven by an electric motor, either with or without a variable-speed drive controller.

Often the motor is manufactured to be integral to the compressor, and the motor shaft and compressor crankshaft are one-piece, eliminating the need for a coupling. Gearbox-type speed reducers are used in various installations.

Sometimes, though less commonly, they are driven by steam turbines or other sources of power such as natural gas or diesel engines. The overall design of the system and the type of driver selected will influence the lubrication of these peripheral systems.

Types of Reciprocating Compressors

Single-Acting

This is the most typical air compressor in the market. They tend to be quite loud but can be relatively powerful for their size and weight. Given their portability, they can be placed close to point of use so if your needs are limited you can avoid the installation of large amounts of piping and their simple design makes maintenance easier. As a rule, they have a higher cost of compression than their double-acting siblings so they work best in environments where constant compressor use is not required.

Double-Acting

A double-acting reciprocating air compressor uses both sides of the piston to compress air. The result is a more efficient compression than the single-acting counterpart. Such compressors are likely to be used in industrial settings. They also have a rather simple maintenance routine. Potential problems include high up-front costs, huge space requirements, and strong vibrations which means special mountings are necessary.

Conclusion

Reciprocating compressors are the most widely used compressors in almost all settings and regardless of the type, both versions of reciprocating compressors come with both single and multi-piston models, lubricated and non-lubricated, and can provide long-term and effective air compression depending on costumers’ demand. Please feel free to contact Linquip’s Reciprocating Compressor Experts with any questions you may have about reciprocating compressors or their related equipment. In case you need a special service, check out the Reciprocating Compressor Service Providers on Linquip to find a local service provider.

Download PDF for Reciprocating Compressor

Please find attached a PDF file for your use. You can download it and use it whenever convenient for you.

linquip.com-Reciprocating Compressor Introduction Efficiency amp Types

Watch Video About RECIPROCATING COMPRESSOR

Read More on Linquip

- Reciprocating Compressor Parts: A Simple, Yet Useful Guide

- How an Air Conditioners Compressor Work?

- What is Hydrovane Compressors ? (Ultimate Guideline)

- What Is the Difference Between a Single Stage and Two Stage Compressor?

- Everything You Need To Know About Different Types Of Compressor

- The Differences Between Rotary & Reciprocating Compressors

- The 5 Best Air Compressors for Nail Guns

- Top Air Compressor Suppliers & Manufacturers In The World

- The 8 Best Small Air Compressors

- The 10 Highest CFM Air Compressors

- The 10 Best Air Compressor for Home Garage

- The 10 Best 12v Air Compressors

- The 7 Best Air Compressors

I need more increase my knowledge

Thanks for visiting our website, Hafeez! We also encourage you to visit the Linquip website, where you can find numerous industrial equipment, along with companies and experts. We hope to hear from you again in our other posts.

I have a 4 stage Ingersoll Rand make Air Compressor in working condition which I would like to sell . Would you be interested to buy , if not , could you share the details of probable buyer’s for such an Compressor.

I’ll be referring individuals to this in the future. Great work.

Thanks for visiting our website, Claude! We also encourage you to visit the Linquip website, where you can find numerous industrial equipment, along with companies and experts.