You might be shocked to hear that different parts of our everyday life are connected to steam boilers! The food we eat, the clothes we wear, and even the water we use are all affected by steam boilers. Different industries depend on the existence of a boiler in their set up and they can even be helpful for residential uses as well! But what are steam boilers and how do they work? Linquip is here to answer all your questions in this article. Read on to learn more about steam boilers and their use in our daily lives.

What is a Steam Boiler?

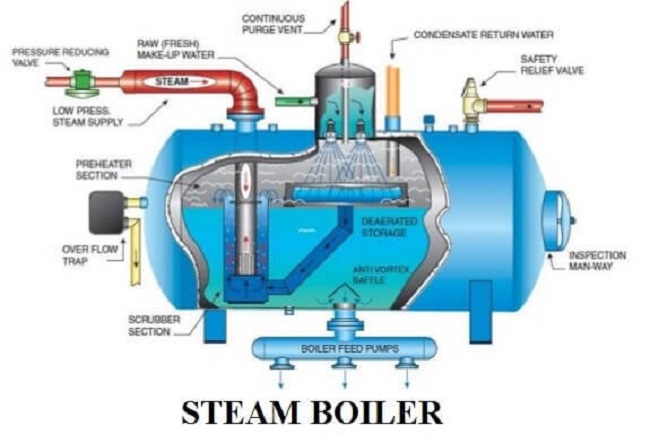

Steam Boiler (also known as Boiler) is a heat exchanging system that creates steam for outside use. This vessel contains a set of tubes and two other parts, one for combustion and another to contain water. These are the main component but the system is far more complicated than that and contains many other components that together help achieve the desired outcome.

What are steam boilers used for?

The main job of a steam boiler is to produce steam. Steam boilers are essentials whenever you want to create heat or steam. These boilers can be small or large depending on the task they are designed for. Whether it is for commercial use or industrial use, boilers are there as an important part of the process.

A steam boiler can be used to generate electricity, process foods, chemical manufacturing, create pulp and paper, and they are even an essential part of the fashion industry to help in dyeing process. These are just some of the great tasks of steam boilers not to mention that even making a small candy might need steam boilers! So, they play a huge role in our everyday life.

Types of steam boilers

Steam boilers have different types but there are two basic ones and others are somewhat an extension of these two: Firetube and Watertube.

Firetube boiler

In this steam boiler type, the combustion gases flow inside tubes and transfer heat to the water. They can be categorized into the number of passes, meaning the number of times that gas flows around the vessel to transfer heat to water. Two zones have been designed for turnaround: Dryback and Waterback. First one is refractory-lined and in the second design, the turnaround zone is water-cooled which eliminates the refractory lining.

Watertube boiler

In this type of steam boiler, the tubes contain flowing water and the exhaust gases are in the shell side passing around the tube surface to affect the temperature of the water inside the tubes. Watertube boilers are used in places that go through high steam pressures since they can withstand higher internal pressure than chamber shells in the firetube type. The steam pressure for these types can be as high as 3,000 psi or sometimes even higher.

Watertube boilers are also capable of generating saturated or superheated steam for different uses specially for processes that include dry, high energy, and high-pressure steam such as steam turbine power generation.

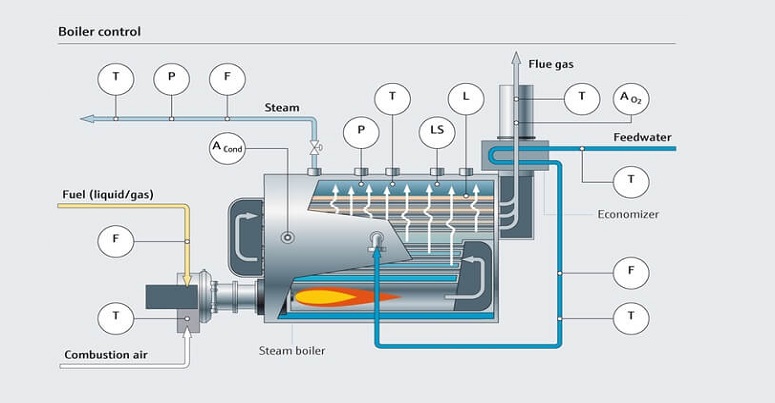

Steam boiler parts and components

Different boilers might have different designs, but three main parts remain the same throughout various designs: The combustion chamber, the heat exchanger, and the burner. Now, we will briefly explain each one.

1. The combustion chamber

This chamber, usually made from cast iron, is responsible for burning the fuel inside. The heat this chamber generates will be transferred to the heat exchanger part of the system. plus, the temperatures inside the combustion chamber can be increased up to several hundred degrees in a short period of time.

2. The heat exchanger

A series of flue passages filter the water around the combustion chamber in a hydronic boiler system. Next, the boiling water gone under pressure will be pumped through pipes into heaters or radiators and the heat energy produced in the boiler will be separated from the water.

3. The burner

When the system is required to produce heat, the thermostat will send electronic signals to the burner to activate the reaction. The burner is the part that initiates the combustion reaction inside the boiler. An outside source with the help of a filter mechanism pumps fuel to the boiler. The source is often an adjacent fuel tank. The fuel then turns into a fine spray with the help of burner’s nozzle and will be ignited which results in reaction in the combustion chamber.

How do steam boilers work?

Steam boilers mainly work the same way. They create a combustion reaction between fuel and air to ignite a flame into different tubes. The heat produced from this reaction will be transferred from the tubes into the water and the water evaporates into steam. The produced steam will then be used for a specific heating application. Next, the steam is condensed back into the water as condensate and can be collected and returned to the boiler.

Which steam boiler is better?

It is difficult to say which steam boiler is better. Although firetube boilers sell more in the market, watertube boilers are more capable for different uses. As it was mentioned earlier, tolerating high pressure is among the most important traits of watertube boilers. So, it depends on the customer use to pick the better choice.

Steam boilers maintenance

Steam boilers need low maintenance that includes cleaning the system to keep the efficiency of the set up as high as possible. Removing residue and debris from the chamber and replacing gaskets and different equipment, as well as efficiency check, are all on the list of steam boiler maintenance and it requires an expert to keep an eye on the system.

Is steam boiler the same as a steam generator?

Many people assume these two are the same, but it is a little tricky. Steam generators compared to steam boilers, contain less steel in their design and they use a single tube coil instead of boiler tubes and a feedwater pump continuously pumps feedwater through the coil. Steam generators convert water into steam but in a single pass through the water coil transferring the hot gas into the desired output.

Steam generators, on the other hand, are smaller than steam boilers since they don’t use any pressure vessel. But the main difference is that steam generators have low turn-down rates and are less capable of providing steam. with that being said, let’s review some of the advantages of steam boilers.

Advantages of a steam boiler

If you need to know what the perfect system that can fulfil each and every requested demand is, you should consider the output and the capabilities of the system. Even though steam generators are quick, their capacity is low. So, one of the advantages of a steam boiler can be the fact that they can live up to your expectations through various demands. They are durable and robust enough to get you through many years. All you need to do is to have an expert for its annual maintenance.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Steam Boiler Maintenance Ultimate Guide

- How Steam Boiler System Works?

- 5 Best Steam Boilers Worth Buying

- Top 22 Boilers Suppliers and Manufacturers in the World

- List of Top Suppliers of Boilers

- 5 Best Residential Boilers: A Practical Guide

- Boilers, Suppliers, Indirect Fired Water Heaters

- Boiler Efficiency: Definition, Formula Caculation

- How Much Does a New Combi Boiler Cost? A Clear Guide

Pingback: Discord

Very good

Thanks for visiting our website and leaving your comment, Mussa! We hope to hear from you again in our other posts.