Welcome to Linquip Blog. Today and in this article, we are going to talk about the difference between thermistors and RTD. The information in this article gives a significant collection of data you need to know about the core difference between thermistors and RTD.

To understand the difference between thermistors and RTD, first, we should learn what a thermistor is.

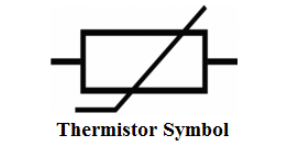

What is a thermistor?

Thermistors are thermally sensitive resistors whose prime function is to exhibit a large, predictable, and precise change in electrical resistance when subjected to a corresponding change in body temperature. Negative Temperature Coefficient (NTC) thermistors exhibit a decrease in electrical resistance when subjected to an increase in body temperature and Positive Temperature Coefficient (PTC) thermistors exhibit an increase in electrical resistance when subjected to an increase in body temperature. U.S. Sensor Corp.®, acquired by Littelfuse in 2017, produces thermistors capable of operating over the temperature range of -100° to over +600° Fahrenheit. Because of their very predictable characteristics and their excellent long-term stability, thermistors are generally accepted to be the most advantageous sensor for many applications including temperature measurement and control.

How Does a Thermistor Work

The working principle of a thermistor is that its resistance is dependent on its temperature. We can measure the resistance of a thermistor using an ohmmeter.

If we know the exact relationship between how changes in the temperature will affect the resistance of the thermistor – then by measuring the thermistor’s resistance we can derive its temperature.

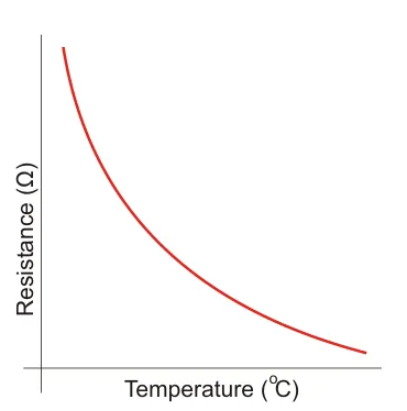

How much the resistance changes depends on the type of material used in the thermistor. The relationship between a thermistor’s temperature and resistance is non-linear.

If we had a thermistor with the above temperature graph, we could simply line up the resistance measured by the ohmmeter with the temperature indicated on the graph.

By drawing a horizontal line across from the resistance on the y-axis, and drawing a vertical line down from where this horizontal line intersects with the graph, we can hence derive the temperature of the thermistor.

Typically, thermistors are made from ceramic or polymer, and they come shaped into beads, rods, and disks. They can be extremely small, ranging from a restive sensing element just over a millimeter in diameter, up to much larger sizes that can handle a significant amount of current.

Types of Thermistors: PTC & NTC

- NTC Thermistors: Negative temperature coefficient devices, where the resistance decreases as temperature rises.

- PTC Thermistors: Positive temperature coefficient devices, where the resistance rises with increasing temperatures.

- Thermistors are inexpensive, easily obtainable temperature sensors constructed using semiconductor metal oxides. They are available with either a negative temperature coefficient, (NTC) of resistance or a positive temperature coefficient (PTC) of resistance. The difference is that NTC thermistors reduce their resistance as the temperature increases, while PTC thermistors increase their resistance as the temperature increases.

- NTC thermistors are the most commonly used (especially the 10KΩ NTC thermistor) and along with an additional series resistor, RS can be used as part of a simple potential divider circuit. Thus changes to its resistance due to temperature changes produce a temperature-related output voltage. However, the operating current of the thermistor must be kept as low as possible to reduce any self-heating effects. If their operating current is too high, they can heat up quicker than they can dissipate it, creating false results.

- Thermistors are characterized by their base resistance as well as their “B” value. The base resistance, for example, 10kΩ, is the resistance of the thermistor at a given temperature, usually 25oC so is defined as R25. The B value is a fixed material constant that describes the shape of the slope of the resistive curve over temperature (R/T).

Now, to understand the Difference Between Thermistor and RTD, we are going to explain what an RTD is and then compare it to a Thermistor.

What is an RTD?

RTD stands for Resistance Temperature Detector. RTDs are sometimes referred to generally as resistance thermometers. The American Society for Testing and Materials (ASTM) has defined the term resistance thermometer as follows:

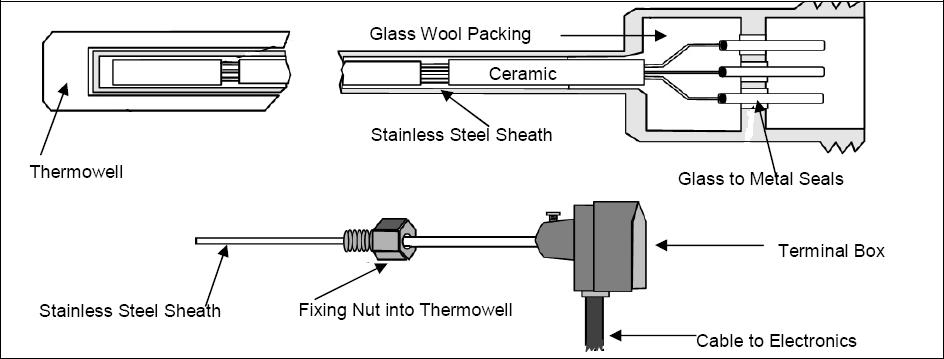

Resistance thermometer, n. – a temperature-measuring device composed of a resistance thermometer element, internal connecting wires, a protective shell with or without means for mounting a connection head, or connecting wire or other fittings, or both.

How do RTDs Work?

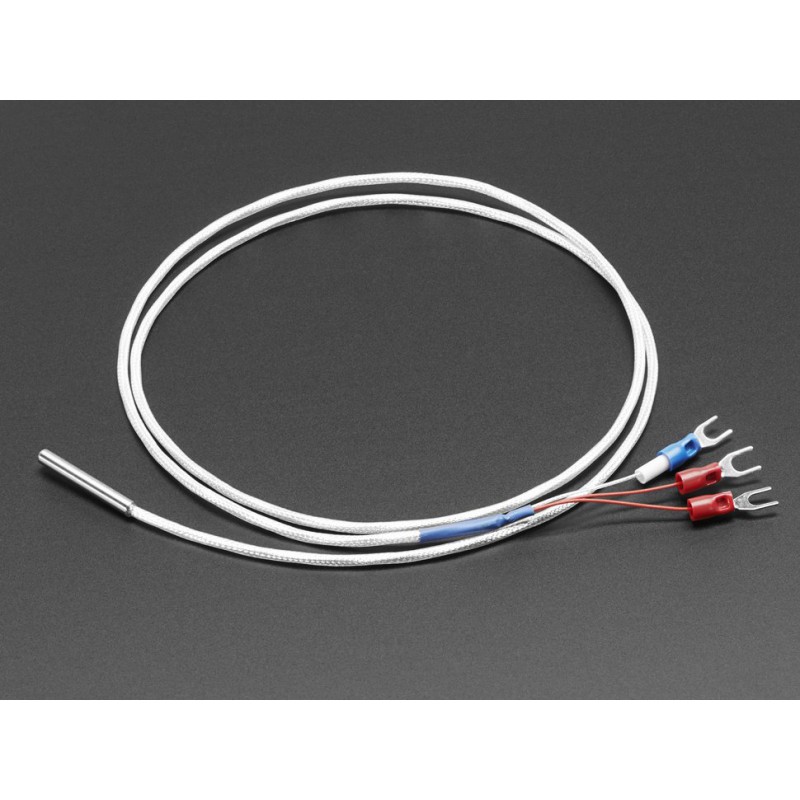

An RTD consists of a resistance element and insulated copper wires. The most common number of wires is 2; however, some RTDs have 3 or 4 wires. The resistive element is the temperature-sensing element of the RTD. It is usually platinum because as a material it is highly stable over time, it has a wide temperature range, it offers an almost linear relationship between temperature and resistance and it has a chemical inertness. Nickle or copper are also other popular choices of material for the resistive element.

An RTD works by using a basic principle; as the temperature of a metal increases, so does the resistance to the flow of electricity. An electrical current is passed through the sensor, the resistance element is used to measure the resistance of the current being passed through it. As the temperature of the resistance element increases the electrical resistance also increases. The electrical resistance is measured in Ohms. The resistance value can then be converted into temperature based on the characteristics of the element. The typical response time for an RTD is between 0.5 and 5 seconds making them suitable for applications where an immediate response is not required.

What is the difference between Thermistor and RTD?

Thermistors and RTDs or Resistance Temperature Detectors are two electrical devices that are used to measure electricity. They are usually used to monitor the temperature of certain devices for purposes of regulation. The main difference between the two is the type of material that they are made of. Thermistors are commonly made with ceramic or polymer materials while RTDs are made of pure metals.

In terms of performance, thermistors win in almost all aspects. The best RTDs only have comparable accuracies to common thermistors while lower classes of RTDs are more inaccurate. This even extends to the cabling of these devices. As cables add resistance to the circuit, using very long wires can alter the reading. While keeping the error levels within acceptable values, thermistors can be wired with thousands of feet of cabling while RTDs can only be used slightly over a hundred feet. This means that when long distances are a must, one must employ transmitters when using RTDs. Response time is also another aspect where thermistors are superior. Thermistors can detect sudden temperature changes much quicker, allowing the connected devices to execute important decisions more promptly.

Difference Between Thermistor and RTD:

| RTD (Resistance Temperature Detector) | Thermistor |

| RTD is a type of wire whose resistance changes with a change in its temperature. | A thermistor is a temperature-sensitive resistor whose resistance varies with temperature variation. |

| RTD is made of pure metals like platinum, nickel, or copper. | Thermistors are made up of ceramic or polymer materials. |

|

|

| It has a positive temperature coefficient. | It has a negative temperature coefficient. |

| RTD has low accuracy. | Thermistors have good accuracy. |

| Used for greater temperature range up to 600°C. | Used for lower temperatures ranging from -55°C to +130°C. |

| RTD allows smaller cable lengths. | It allows larger cable lengths. |

| Slow output response. | Fast output response. |

| Used in industrial installation applications. | Used in home appliances. |

| Good stability. | Less stable than RTD. |

| These are expensive. | These are inexpensive. |

| Low amount of self-heating. | A high amount of self-heating. |

| The size of the resistance thermometer is quite large. | Thermistors are built in a smaller sizes with different shapes. |

| It possesses good linear characteristics. | It possesses non-linear characteristics. |

Now let’s summarize the main difference between thermistor and RTD that we have learned:

- Thermistors are made out of ceramic or polymer while RTDs are made out of pure metals.

- Thermistors have equal or better accuracy than RTDs.

- Thermistors allow for greater cable lengths compared to RTDs.

- Thermistors have a much faster response time compared to RTDs.

- RTDs have a greater temperature range compared to thermistors.

- RTDs are generally used in industrial installation while thermistors are used in common home appliances.

Now you know the core Difference Between thermistors and RTD.

Hope you enjoyed the article! You can find similar content on Linquip, a professional network for equipment manufacturers, industrial customers, and service providers.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- Your Convenient Preventive Maintenance Checklist

- How to Use and Read a Hydrometer: Your Concise But Complete Guide

- Difference Between Actuator and Sensor: The Ultimate Guide

- Difference Between Thermistor and Thermostat: Which One Outperforms the Other?

- Thermistor vs Thermocouple: Complete Comparison & Practical Selection Guide

- Types of Thermistors; A Fundamental Comparison Between Them

- What is PTC Thermistor? (Applications & Advantages)

- What is NTC Thermistor? (Types, Applications & Advantages)