Thermistor vs Thermocouple is a controversial issue in the measuring equipment. The main difference between the thermistor and thermocouple is their sensing factor. This parameter is the resistance in thermistors, while in thermocouples it is the voltage that induces between different materials. It is necessary to consider the pros and cons of each type since they are both appropriate options for monitoring and sensing the temperature, but the final selection is based on the particular application requirements.

Difference Between Thermistor vs Thermocouple

Why should we focus on the Thermistor vs Thermocouple Concept? Temperature sensing is a crucial matter in most industrial measurements. Temperature sensors specify the temperature of the given system or target according to their format. This is considerable because most applications and procedures need maintaining a special temperature for their function. A signal or alarm is generated if the temperature ranges change the defined limitations. Considering this temperature limit on a special basis reduces the risk of system damage from any probable hazard.

There are several types of temperature transducers and probes based on the requirement such as thermocouples, thermistors, tubular probes, etc. This post provides a comparative discussion about thermistors and thermocouples as the main temperature sensors, and how to select the best one based on your application.

Electrical designers should manage temperature detection systems precisely. Therefore, selecting the best temperature measuring instrument can usually be confusing. It is vital to consider both the needs of the device’s diagram and the specified machinery.

The Concept of Temperature

Heat is a parameter of measuring energy produced in a body according to the irregular movement of its atoms or molecules. The internal heat of a body rises with increasing temperature. Temperature is a variable factor related to other parameters like specific heat or mass and explains the energy state of a body. At zero Kelvin, the molecules of each body are at rest state and it has no thermal energy.

It is practical to utilize the Celsius scale in everyday terms. Its zero is located at the solid-state of water since this point is very simple to obtain in practice. By sensing the Celsius scale to the lowest feasible temperature where the atom movements stop, we have a temperature of -273.15 degrees. We can measure temperatures through our senses within a restricted level although we have no precise reproduction of quantitative parameters. If you want to explore more about the concept of temperature in thermistor vs thermocouple, visit here.

Measuring Temperature Electrically

The measurement of temperature is vital in many applications including building monitoring, food procedures, and the manufacturing of steel and chemical materials. These various applications need temperature detectors of several physical productions and usually different technologies.

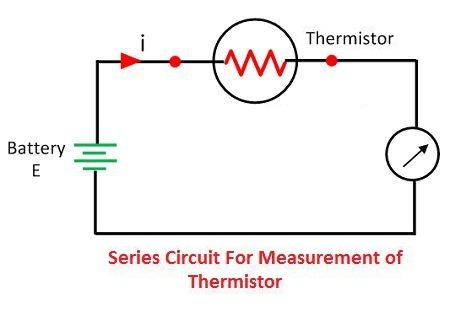

There is a necessary requirement for complex processing of the measurement in recorders, controllers, or monitors in commercial and industrial applications because the measured target is typically far away from the control section. We cannot use direct thermometers or sensors in these applications because they require modifying temperature into another type such as an electrical signal. It is practical to utilize RTDs, thermistors, and thermocouples to avoid using these remote electrical receivers.

The Variation of Resistance with Temperature

The electrical situation of a metal is based on the motion of the conduction electrons. When a voltage is operated on the metal wire, the electrons are transferred to the positive state pole. They consist of grain boundaries, foreign or missing molecules, and atoms on inter-lattice positions. They generate constant resistance because these fault places are fixed. The atoms of the material present increase in movement instead of their rest positions by raising the temperature and provide the motion of the conduction electrons. This effect increases directly by increasing the temperature with a linear diagram, so the resistance increase is directly depending upon the temperature.

For instance, the resistance of platinum has found common acceptance in industrial applications. Its main advantages contain easy production especially for wire construction, chemical reliability, the possibility of forming in a highly pure state, and electrical features that can be considered. These properties make the platinum resistance transducer the most usable type of interchangeable sensors regardless of comparison and working principle between thermistor vs thermocouple.

While the thermistor or thermocouple are both temperature detecting instruments, they have different working methods. In thermistors, the temperature modification varies the resistance of the basic material, while this change induces the output voltage between the wires within the metals in thermocouples. Before explaining more about the differences in thermistor vs thermocouple, let’s have a brief discussion about them in the next paragraphs.

Definition of Thermistor

The thermistor is an instrument with a thermal resistor whose resistance varies with the temperature. It is constructed from semiconductor substances. The thermistor has two forms of temperature coefficient, including commonly the negative and rarely the positive states. This constant describes the relation between the resistance and the temperature variations in their value. The resistance increases with the increase in temperature in the positive temperature coefficient whereas it decreases with the increase in temperature in the negative type.

This instrument is typically employed for measuring a few temperature variations. Thermistor has lead material whose resistance decreases their accuracy. They are basically too sensitive and can identify even small variations in temperature. Thermistors are commonly constructed from particular metal oxides whose resistance changes immediately with temperature variation.

The number of particular electrons rises exponentially with temperature variations according to the nature of the materials. This effect illustrates a disadvantage of NTC resistors due to their non-linearity and reduces their useful temperature ranges close to 100ºC. They can be determined by an automation diagram. Nevertheless, precision and linearity typically do not solve the requirements over larger measurement ranges.

It should be said that thermistors’ offset under temperature variation is also more than for RTD’s. Therefore, their application is restricted to detecting and identifying parameters where the temperatures are not more than 200ºC. Otherwise, in simple applications, the cost of thermistor vs thermocouples and RTD’s is more expensive because of their simple electronic circuit which is required. But they can also be constructed in very small shapes with a fast reaction and low thermal coefficient. If you want to explore more about thermistors and their working principle, visit the “What is a Thermistor” post in our blog.

Thermistors Features

Here are some considerable features of thermistors:

- They are generally utilized in industrial applications more than domestic ones to control the temperature measurement.

- Thermistors are constructed from materials, including manganese, cobalt, nickel, or other semiconductor substances, and are typically covered with Teflon, epoxies, or glass.

- They have a very fast reaction time fewer than a second in some particular types. Nevertheless, their range change from 0.2 to 10s in different models.

- They have a particular characteristic diagram which is typically linear.

- They can namely tolerate temperature levels from -200 to +1200 o

- They detect temperature variations according to the resistance because it is their basic parameter.

Thermistors Application

Thermistors application areas are presented here briefly:

- Incubator temperature systems for maintaining

- Gas, Oil & petroleum temperature systems

- Coolants in automatic devices

- 3D printers

- Particular digital devices like thermostats

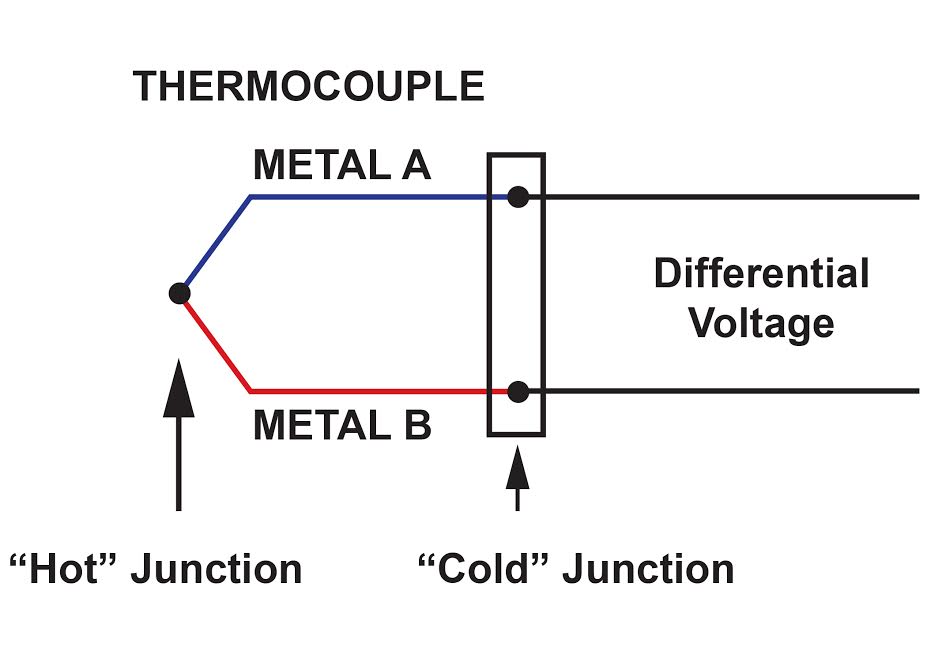

Definition of Thermocouple

The thermocouple is an instrument used for measuring and monitoring the temperature. The thermocouple is a temperature sensing system. Two wires of different types are combined at one section in the thermocouple. These two different materials generate a voltage by inducing due to the difference in temperatures. The thermocouples are employed for sensing the temperature in huge industries. They are more precise and less costly.

As discussed before, thermocouples are based on the influence of junctions between two dissimilar metals. For more information, visit the “What is a Thermocouple” post to explore more about their working principle.

The basic principle of thermistor vs thermocouple is that they generate a voltage that changes by the temperature. They provide clear benefits of a higher temperature level, up to several thousand values in comparison with resistance thermometers. They are typically utilized in furnaces, ovens, flue gas sensing, and other areas with temperatures more than 250 ºC.

Thermocouple Features

Some main features of thermocouple are explained here:

- They are usually made from copper, iron, or alloys made of chromium, nickel, iridium, tungsten, and more. Some of them have mineral structure and can be configured based on calibrating, bending, and other properties.

- These are utilized for thermal conductivity, temperature sensing, and control systems.

- They have a quick reaction between 0.1 to 10 seconds.

- They can tolerate temperatures from -50 to +500 o

- Their characteristic diagram is non-linear.

- They can sense the temperature variations according to the junction voltage.

Thermocouple Applications

Some of the thermocouple applications in industrial systems and domestic appliances are mentioned here:

- Fire alarm systems

- Temperature monitoring and control in boiling systems, kilns, and furnaces

- Gas-powered turbines

- Steel and iron industrial construction

- Ovens

- Refrigerators

Which is Right for You, Thermistor or Thermocouple?

Thermistor vs Thermocouple should be comprised of different aspects. For instance, thermistors are constructed in various sizes, shapes, and styles. The most usual forms are chip and disk style, and glass encapsulated. The advantages of thermistors make them be used widely in medical, green energy, and aerospace applications. Thermistors generally operate according to resistance versus temperature, but they also can be utilized in applications such as current-time circuits and voltage-current systems.

On the other hand, thermocouples are electrical instruments manufactured of two conducting metals that are combined at a particular point. They start to generate low temperature based on DC voltage when junctions are faced with temperature variation. However, thermocouples have little accuracy in low-temperature systems, but they operate appropriately in high temperatures.

Many electrical circuit-designers select instruments between thermistor vs thermocouple due to the six significant qualities. These contain:

- Accuracy

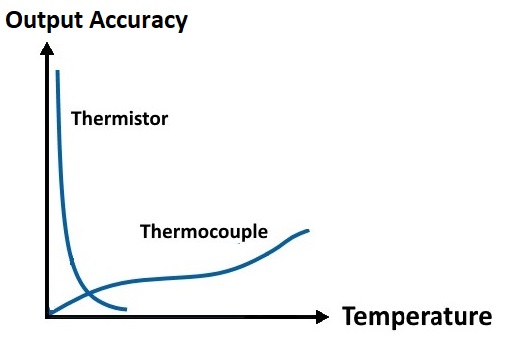

Accuracy is an important aspect of any process or instrument. You must determine the state of accuracy you want in the application. You should notice the temperature range, temperature toleration, and the smallest temperature range the instrument can determine during the checking process of the accuracy of a temperature sensor.

- Temperature Range

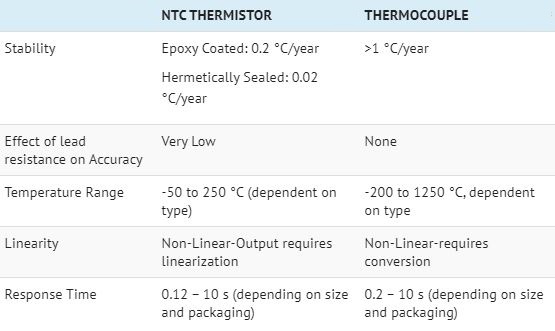

Thermistor vs thermocouple is a particular issue according to the temperature range. They both work within a wide level of temperatures, making them both appropriate for a broad range of applications. While NTC thermistors operate well in a temperature range from -50 to 250 °C, thermocouples perform within the widest operating range between -200 °C to 1750 °C.

- Stability

Stability is a feature that is mainly based on the quality of substances used in constructing the thermistor vs thermocouple. Covering or encapsulation the instrument with special materials can increase the stability of the transducer. Stability is required for applications with a long-term working procedure because temperature sensors including thermistor vs thermocouple can shift over time based on different factors.

For instance, coating epoxy on NTC thermistors can cause a shift close to 0.2 °C per year; while, hermetically sealing on them produce a much fewer shift of about 0.02 °C/year. Otherwise, thermocouples have a drift close to 1-2 °C per year, typically because of chemical variations in the sensor, such as chemical corrosion.

- Noise Immunity

You should consider the sensors’ resistance to electrical damages and noises when operating to select the best instrument between thermistor vs thermocouple. You must also check the lead resistance, particularly on thermistors.

- Packaging

The packaging is based on the environment in which the temperature sensor will be operated. For example, coatings and sealings are vital for thermocouple packaging in the harsh surrounding.

- Application

How to select the best one according to your application? Both thermistors and thermocouples can be employed in various applications. Nevertheless, NTC thermistors are usually found in safety applications of life such as thermometers and fire detectors because they are precise and durable. Thermocouples are typically utilized in industrial systems according to their stability and less-expensive installation costs.

The main differences between the thermistor vs thermocouple are briefly presented in the next comparison figure.

Key Differences between Thermocouples and Thermistors

If you are searching for a high-quality temperature transducer between thermistor vs thermocouple to give you precise outputs, you should explore more about the instruments’ constructor, designer, and supplier. Also, you must check the relation between the customized application and your device to meet your requirements.

Some key differences to comprise thermistor vs thermocouple precisely are mentioned below:

- The thermocouple is the temperature sensing instrument and the thermistor is a kind of thermal resistors.

- The thermocouples are produced of metal or alloys of materials. However, the thermistor is constructed by the semiconductor substances or mixed oxides of nickel, magnesium, or cobalt.

- The thermocouple has high precision in comparison with the thermistor in high temperatures. Because thermistors have lead sections whose resistance decreases their accuracy in high temperatures.

- The temperature sensing level of thermistors is between -50 to 250 °C while that is between -200 to 1250 °C for thermocouples.

- The thermistor has a quicker response in comparison with the thermocouple. However, the reaction time of both the transducers is based on their construction size.

- The main diagram of the thermocouple between features is linear. This curve illustrates that the voltage of the instrument increases by the temperature. On the other hand, the main diagram between the temperature and resistance is non-linear in the thermistors when the system has a negative temperature constant.

- The thermocouple is cheaper in comparison with the thermistor because the thermistor needs an external power source to operate properly.

- The thermistor and thermocouple both are utilized for monitoring and measuring temperature. But the thermocouples are employed in great industries, whereas the thermistors are applied in building applications.

Conclusion

The thermistor and the thermocouple are both common forms of temperature transducers. Nevertheless, the thermistor vs thermocouple subject is a hot topic because the thermistor is employed in small appliances for monitoring the temperature, and the thermocouple is applied for identifying the high temperatures.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is the core difference between Thermistor and RTD?

- Thermocouple vs Thermopile: A Complete Comparison & Advantages of Each Type

- What is a Thermocouple & How Does It Work?

- What is a Thermistor and How its Working?

- What is PTC Thermistor? (Applications & Advantages)

- What is NTC Thermistor? (Types, Applications & Advantages)