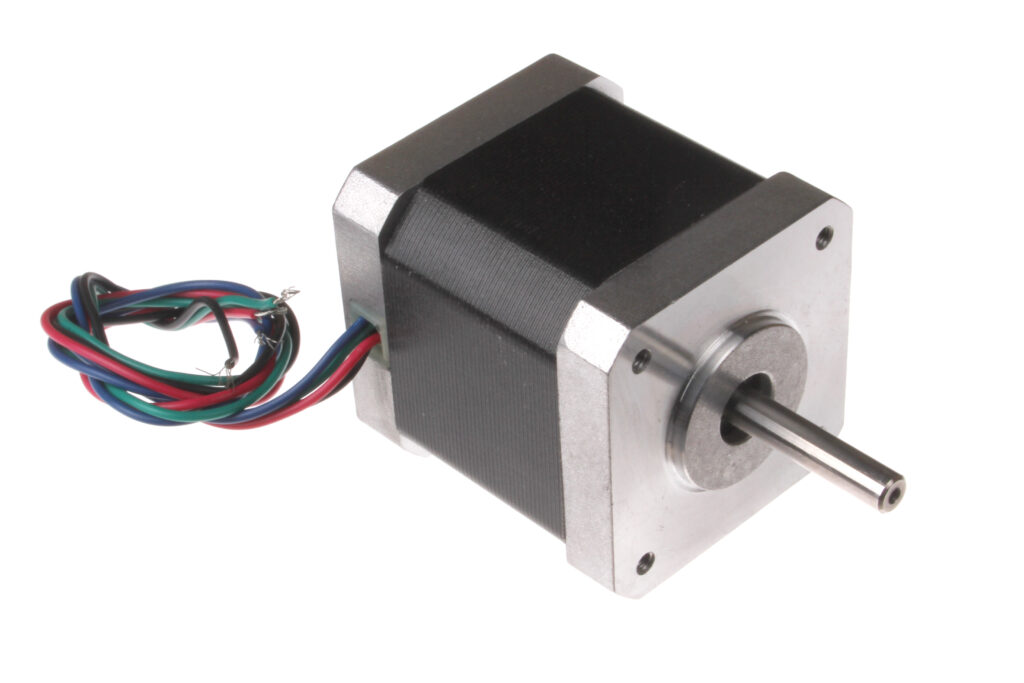

Stepper motors are a particular type of DC motor that is used every day in both industrial and commercial applications because of their low cost, high reliability, high torque at low speeds, and simple, rugged construction that operates in almost any environment. In this article, we will cover the working principle of stepper motor. Follow this new blog in Linquip to find out more about these motors.

What Is Stepper Motor?

A stepper motor is a type of brushless synchronous DC motor that, unlike many other standard types of electric motors, doesn’t just rotate continuously for an arbitrary number of spins until the DC voltage passing to it is shuts off.

Instead, stepper motors are a type of digital input-output device for precision starting and stopping. They’re constructed so that the current passing through it hits a series of coils arranged in phases, which can be powered on and off in a quick sequence. This allows the motor to turn through a fraction of a rotation at a time and these individual predetermined phases as what we refer to as ‘steps’.

A stepper motor is designed to break up a single full rotation into several much smaller and essentially equal part-rotations. For practical purposes, these can be used to instruct the stepper motor to move through set degrees or angles of rotation. The result is that a stepper motor can be used to transfer minutely accurate movements to mechanical parts that require a high degree of precision.

Stepper motors are typically digitally controlled, and function as key components in an open-loop motion-control positioning system. They’re most commonly used in holding or positioning applications where their ability to assert much more clearly defined rotational positions, speeds, and torques make them ideally suited to tasks demanding and extremely rigorous movement control.

Some industrial and scientific applications of stepper motors include robotics, machine tools, pick and place machines, automated wire cutting and wire bonding machines, and even precise fluid control devices.

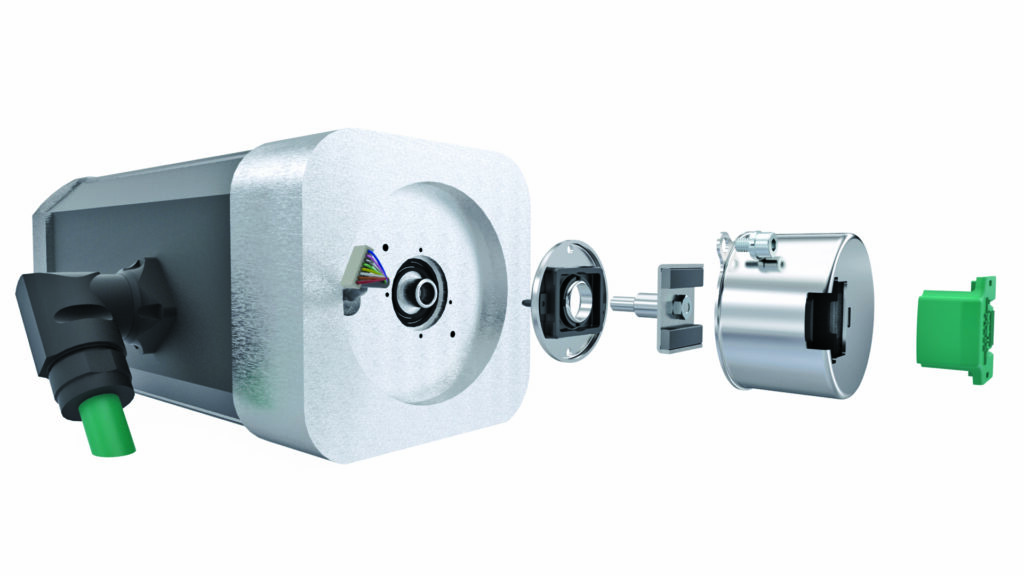

Stepper Motor Construction

The Stepper motor is made up of the stator and rotor. The rotor is the movable part that has no winding, brushes, and commutator. The stator is made up of multipole and multiphase winding, usually of three or four phases winding wound for a required number of poles decided by desired angular displacement per input pulses.

Read More on Linquip

- The Only Guide You’ll Ever Need For The Working Principle of Induction Motor

- Everything You Need to Know About Working Principle of AC Motor

- Your Guide To The Working Principle Of DC Motor

- A complete Guide to The Difference Between Stepper Motor and DC Motor

Working Principle of Stepper Motor

- In a normal brushed DC motor, voltage is applied to terminals which in turn causes a wire coil to rotate at speed inside a fixed magnet housing (the stator).

- In this setup, the spinning wire coil (the rotor) effectively becomes an electromagnet and turns rapidly at the center of the motor based on the familiar principle of magnetic attraction and repulsion. A combination of brushes (electrical contacts) and a rotary electrical switch is known as a commutator allows the direction of the current running to the wire coil to be alternated quickly. This creates continuous unidirectional spinning of the rotor coil for as long as the assembly is being fed with sufficient voltage.

- A potential downside of this type of motor is that it spins continuously and for an arbitrary number of rotations until power is cut off. This makes it very hard to control the exact stopping point of the motor, rendering it unsuitable for applications requiring greater precision control. Manually controlling the on/off the flow of power to the motor can’t give you the required start-stop precision for performing minutely accurate movements.

- In a stepper motor, the setup is quite different. Instead of a wire coil rotor spinning inside a fixed housing of magnets, stepper motors are built with a fixed wire housing (the stator in this case) arranged around a series of ‘toothed’ electromagnets spinning at the center. The stepper motor converts a pulsing electrical current, controlled by a stepper motor driver, into precise one-step movements of this gear-like toothed component around a central shaft.

- Each of these stepper motor pulses moves the rotor through one precise and fixed increment of a full turn. As the current switches between the wire coils arranged in sequence around the outside of the motor, the rotary part can complete full or partial turns as required, or it can be made to stop very abruptly at any of the steps around its rotation.

- Ultimately, the real strength of a stepper motor versus normal DC brushed motors is that they can quickly locate themselves to a known and repeatable position or interval, and then hold that position for as long as required. This makes them extremely useful in high-accuracy applications such as robotics and printing.

So, this was everything you needed to know about the working principle of stepper motor. If you enjoy this article, let us know what you think by leaving a reply in the comment section. We will be more than glad to have your viewpoint on the article. Is there any question we can help you with? Feel free to sign up on Linquip where our experts are prepared to provide you with the most professional advice.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Thank you for providing complete information about stepper motors. It is really useful and shareable.

Thanks for visiting our website and leaving your comment! You are encouraged to visit Linquip Tech News, where you can find similar posts.