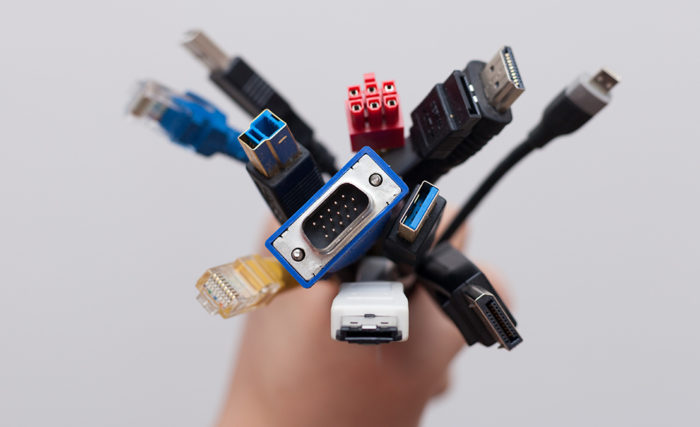

Common Types of Electrical Connectors – Electrical connectors are important components in a wide range of electronic devices because they allow and protect the transfer of an electrical signal. The tasks they perform are numerous, and the applications they support are varied, ranging from linking wires in our cars to connecting crucial computer components. Despite having a straightforward appearance, connections frequently function in intricate electrical networks. Connectors must be strong and trustworthy while also being simple to put together and use. Although not all electrical connectors are made to resist operation in extreme conditions, the wide variety of connector requirements makes it possible to find the right variation for a given equipment.

Linquip is a source of information regarding electrical connectors. Regardless of the situation you are in, we can help you identify the appropriate electrical connectors. Linquip provides a diverse range of Electrical Connectors Products to ensure that you can find one that meets your requirements.

On Linquip’s website, a comprehensive list of electrical connectors is available to all OEM fleets. Linquip vendors can help you with this. Please contact Electrical Connectors Experts to learn more about how to find a diverse choice of Service Providers who consistently supply high-quality products. If you want to find out how much an electrical connector will cost, the Linquip platform offers a free quotation request service from accessible Electrical Connectors Suppliers and Companies.

Electrical Connector Basics

An electronic system is a hierarchical network of connections that allows various electronic devices to communicate with one another. For the signal transmission and power distribution necessary to guarantee the proper operation of electronic equipment, numerous interconnects are needed. Electrical connectors are grouped into three types based on their termination ends:

- Board-to-board connectors,

- Cable/wire-to-cable/wire connectors, and

- Cable/wire-to-board connectors.

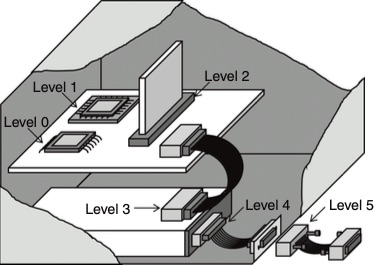

Electrical connectors typically have six levels of interconnection. The connection between a fundamental circuit component and its lead, such as the connection between a semiconductor chip and the lead frame, is referred to as level 0. Chip carrier sockets, dual inline package (DIP) sockets, and switches are examples of Level 1, which is the connection between a component lead and a printed circuit board (PCB). The connection between two or more PCBs is at level two. It is typical to have a motherboard-daughterboard link. A power supply and its related subassembly are an example of two subassemblies connected at level 3. Level 4 refers to the connection between a significant subassembly and the system’s input/output (I/O) port. The connection between physically distinct systems is known as level 5, and is typically represented by the connection between a computer and a printer or other piece of peripheral equipment, or by the elements of a local network.

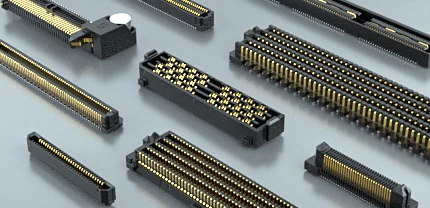

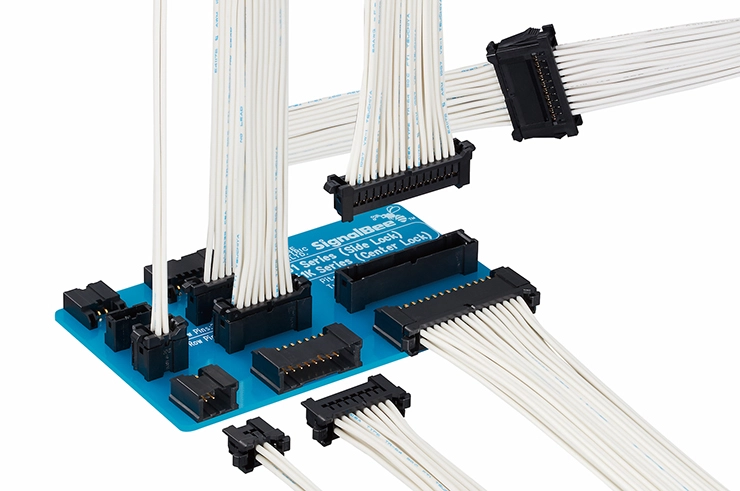

Board-to-Board Connectors

Board-to-board connectors are used to connect PCBs without the usage of a wire. The board-to-board connectors are appropriate for systems with limited space because they can reduce wire clutter. Connectors in either a parallel or perpendicular layout can be used to connect the PCBs. A mezzanine connector is a connector that joins two PCBs in a stacking configuration. However, the phrase is occasionally used to refer to PCB configurations that are perpendicular to one another. These configurations are typically used for motherboard-daughterboard configurations, where the parallel arrangement is highlighted.

When selecting a mezzanine connector, parameters such as separability, mechanical requirements such as stack height and tolerances, constraints such as standoffs, brackets, or chassis slots and frames, and mounting types must all be considered. Separability depends on a variety of variables, including the connector’s ability to be separated or not, the number of mating cycles needed throughout its lifetime, and the lowest and maximum insertion force needed. Both the operational temperature and humidity need to be taken into account. Mezzanine connectors must adhere to the EIA 700AAAB standard.

A backplane is a collection of electrical connectors arranged in parallel with one another, each one of which is connected to its corresponding pin on all the other connectors to form a connector bus. Due to its adaptability and dependability, backplane systems are frequently employed in computer and telecommunication systems. A comprehensive backplane system is created by connecting numerous plug-in cards along a single backbone using the backplane method. The signal produced by the transmitter travels via several connectors before arriving at the receiver. The backplane system of devices used in high-speed applications must have good signal integrity. The backplane and the related pin field are crucial parameters in a gigabit backplane channel design.

The backplane channels may weaken the sent signal as the data rate rises. Inter-symbol interference (ISI), reflection, and crosstalk are all effects of the channels. Crosstalk and reflection worsen channel jitter performance because they increase noise, reduce signal amplitude, and slow down signal edge rate. The signal integrity deteriorates at high data rates and wide channel spacing.

Backplane system connectors need to have adequate impedance matching and shielding. Additionally, the connectors must resist numerous circuit board insertion and removal cycles.

Specifications

The type, contacts, and characteristics of the product can all be specified by purchasers when choosing board to board connectors. Many of these characteristics are dictated by the PCB that the connector is designed to work with.

Header Type

The type of board to board connector is specified by its header, which is the plastic base or mounting plate to which the contacts are mounted. A box header connection has a header that entirely surrounds its contacts, whereas a pin header’s contacts are exposed.

Board-to-board connectors are available in two gender variations. Male connections, also known as plugs, are made up of a protrusion that fits into a female connector, also known as a receptacle. Furthermore, the connector’s geometry may differ. Straight connectors have pins or contacts aligned at the top or bottom, whereas right angle connectors have contacts located on the sides.

Contact

Contacts on board-to-board connectors include rows, pitch, and plating. A connection may have one or two rows of pins, depending on the PCB layout. The pitch of a connection is the distance between its pins. A greater contact pitch indicates a lesser connection density (less pins or connections per area). Pitch influences arcing, which occurs when two conductors are in close proximity (low pitch), generating interference. Common connector pitches range from less than 0.5 mm to more than 5 mm.

Connector contacts may be metal plated to improve their connecting capability because they are conductive parts that convey electrical energy. Copper, gold, nickel, and silver are examples of common metals. While gold-plated contacts are more expensive, they give a better electrical connection. Silver and copper have lower contact resistance as well.

Features

Board-to-board connectors may have a number of specific features:

- Connecting features are associated with the product’s connection mechanism. To prevent unauthorized disconnection, locking connections can be secured. Quick connect goods can be easily attached and disengaged, often by the use of a twist and seat contact method. The pins or leads of press-fit connections are pressed into the PCB rather than soldered.

- Environmental aspects described how well the gadget is protected from chemicals, liquids, and other external elements. Manufacturers may offer hermetically sealed connectors or connectors that are resistant to chemicals, oil, or water. Some connectors are designed specifically for cryogenic (subfreezing) use.

- To prevent electromagnetic and radio frequency interference, filters are inserted in connectors.

- Medical connectors meet stringent safety criteria, including the prevention of accidental plug disengagement and a higher shock rating.

Cable/Wire-to-Cable/Wire Connectors

Wire-to-wire connections are used to link two wire-terminated connectors. As electrical, electronic, and computer connectors, they are employed. The number of circuits or places, wire size, and mating combination or gender are some general requirements for a wire-to-wire connector. The purpose of male wire-to-wire connections is to fit inside of female wire-to-wire connectors. A wire to wire connector typically has 1 to 50 circuits or locations. American wire gauge (AWG), a standard for non-ferrous wire conductor sizes, is typically used to measure wire size. The diameter of the wire is referred to as “gauge.” The diameter, temperature range, and gauge number all decrease as the gauge number rises. Because there is less electrical resistance for a given length, thicker wire typically conducts more current. When choosing wire-to-wire connectors, you should also take durability, pitch or center spacing, plating material, orientation, and temperature range into account.

When choosing wire-to-wire connectors, the termination method is an essential factor to take into account. There are several options, including screw, quick disconnect to quick disconnect, crimp to crimp, IDC to IDC, FFC/FPC to crimp, crimp to FC/FPC, and FFC/FPC to IDC. A wire-to-wire connector’s connection method known as crimp termination involves mechanically crimping a metal sleeve to a conductor. With the aid of insulation displacement connection (IDC) technology, an insulated wire is compelled into a slot that is smaller than the conductor’s diameter. Flat flex cables (FFCs) feature two flat surfaces and can be smooth or corrugated. There is also frequently available flat printed circuitry (FPC) for wire-to-wire connectors. Screw terminals, frequently in conjunction with a pressure plate, tighten the wire against the current bar. Quick connect and quick detach devices can be readily assembled without the use of tools.

Specifications

Electrical and mechanical criteria apply to wire-to-wire connectors. Maximum current, maximum voltage, withstanding voltage, contact resistance, insulation resistance, and the number of rows or contact points are among the electrical parameters. Amps (A) are units of maximum current or current-carrying capability and vary from 1.0 A to 50 A. There are several options for maximum and withstanding voltage, including 25, 30, 100, 125, 250, 300, 500, 600, and 1000 volts. An electrical measurement across or between contact surfaces is called contact resistance. Insulation resistance is defined as the relationship between the total current flowing between two electrodes in contact with an insulator and the applied voltage. The number of rows commonly ranges from 1 to 4. Wire pull-out force, maximum mating force, minimum un-mating force, minimum normal force, and maximum contact insertion force, and minimum contact retention force, mating force, minimum un-mating force, minimum normal force, and maximum contact insertion force, and minimum contact retention force are among the mechanical requirements for wire-to-wire connectors.

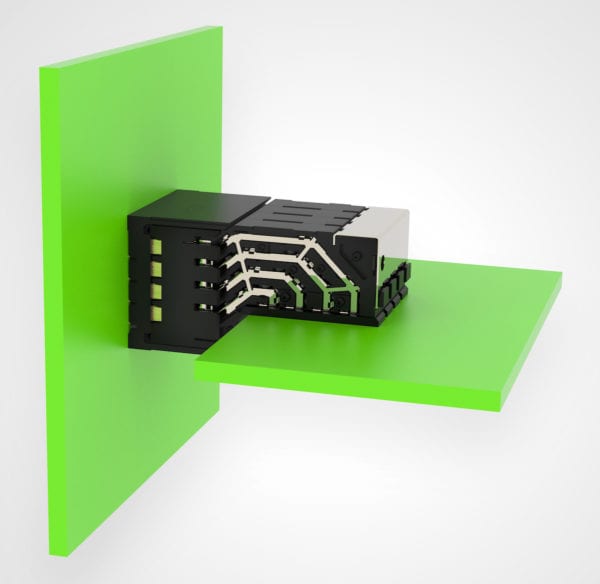

Wire/Cable-to-Board Connectors

Wire-to-board connectors commonly use crimp technology to connect a wire to a printed circuit board (PCB). The contacts or terminals can then be put into the corresponding housing to complete the interconnect once the connector has been crimped to the wire. IDC and SMT are additional wire-to-board connectors. Due to their flexibility and dependability, wire-to-board connectors are frequently utilized. The connectors from Greenconn can be utilized in low-profile designs that provide connectivity for systems that are submerged in water or have limited space and call for a more compact solution. Greenconn will always offer you a secure termination, so you can rely on them.

Wire-to-board connectors are used to route electricity between PCBs in an affordable manner. These connectors can be used in the telecommunications, automotive, commercial, and industrial fields. Due to their large nature, wire-to-board connectors once presented technical challenges during design. However, new and better wire-to-board connectors have been created to offer small alternatives that can now fit in any compact application. Wire-to-board connectors have improved in suitability for automated surface mount assembly along with this new breakthrough, enabling a speedier assembly procedure. Furthermore, these connections offer their applications reliable, long-term service. Overall, wire-to-board connectors provide straightforward, reliable solutions that are yet affordable.

Specifications

There are no “standard” wire-to-board connector designs, hence the type of connector selected will depend on the requirements of the application. Depending on the manufacturer, some products provide quick disconnect, friction lock, full lock, and low-profile mating for confined locations. Others have a locking bar or a snap-fit connection style to guarantee that the wire stays firmly in its socket. Some connectors contain pins that go through the board and are soldered to the other side, while others are surface mounted to the board.

Specifications for wire-to-board connections include their housing size, material, number of contacts, stacking height (the distance between the connector and the circuit board), length of contacts, and the number of contact rows. Pin pitch, which is the measurement of the separation between the centers of two conductors, is another way they are described. The size of the wire and the number of contacts have an impact on wire termination as well. For instance, connections that carry a lot of power frequently feature contacts that are crimped on and fixed with a tool. Other designs, including bulk termination connectors that can accommodate at least 20 wires, can be made to work with automated soldering equipment.

Common Electrical Connectors

- 8P8C Connector: The phrase “eight positions, eight conductors” inspired the naming of an 8P8C connector. This little connection, as the name suggests, has eight possible positions, each with its own conductor. It is a type of modular connection that was initially used in telephone cable applications but can now be utilized for a variety of other purposes, such as Ethernet jacks. Modular connectors are classified into four sizes based on the number of positions and conductors they have, which are 4, 6, 8, and 10. For example, a 10P8C would have ten positions and eight conductors. The 8P8C connector is made up of a plug and socket connection, having a male plug and a female socket. To transport electricity through the connector, the plug has eight contacts that correspond with the socket’s eight conductors. 8P8C connections are often encountered in computer applications and communication cables, in addition to Ethernet jacks.

- D-Subminiature Connectors: D-subminiature connectors, like the 8P8C connector, are widely used in computer applications, but in a different capacity: they serve as a critical port (RS232) on modems. D-subminiature connectors are currently very large in comparison to other, more recent computer connectors, despite the designation “subminiature.” A D-subminiature connector is made up of two or more rows of various pin counts, as well as a D-shaped metal component that protects and defines the connector’s shape (or sockets, depending on the gender of the connector). If pins are present, the connector is male and is known as a plug; the equivalent receiving device is known as a socket, and it houses the contacts that the pins must connect to in order to transport electricity. This variant’s capabilities include the capacity to protect against electromagnetic interference.

- DC Connectors: Direct Current (DC) connectors supply direct current to a specified application, hence they must be used with caution to avoid damaging equipment. DC plugs and coaxial DC power connectors are two common types of DC connectors that are used to connect a device to a power source.

- USB Connectors: Universal Serial Bus connections are compact interface devices that can connect to over 127 devices. Normal laptop computers typically include at least two USB ports for external connectivity through USB connections, whereas standard desktop computers have four USB ports. Because a USB connector may be plugged in and disconnected while the attached device is powered on, it is widely used in computer systems that require constant attachment and separation from external devices, as is required while conveying data.

There are numerous USB versions, as there are with various connectors. USB connectors 1.0, 2.0, and 3.0 are available for both low-speed and high-speed connections, with USB 1.0 models enabling connections for keyboards and mice and USB 2.0 models providing faster connections to the same devices.

FAQs about Common Types of Electrical Connectors

Which type of electrical connector is the most common?

The most popular kind of connections are wired connectors. They are the most basic but also the most constrained. By using wired connections, the signal is immediately sent through the wire between the two devices. As a result, both the connections and the cable itself are potential failure locations.

Why do we need electrical connectors?

In theory, electrical connections are made to temporarily link conductive paths so that electricity can flow from one device to another to power it or send signals.

Why do we have different types of connectors?

There are several types of connections available on the market. While some connections serve the same functions as others, some perform better. Yet, in general, connectors serve the same purpose, which is to join and detach the circular course of electric current.

What are the characteristics of electrical connectors?

In addition to the above categories, a connector can be distinguished by its pinout, mode of connection, materials, size, contact resistance, insulation, mechanical durability, ingress protection, lifespan (number of cycles), and how easy it is to use.

How are connectors classified?

Board-to-board connections, cable/wire-to-cable/wire connectors, and cable/wire-to-board connectors are the three categories into which electrical connectors fall. Electrical connections typically have six layers of connectivity.

Download Common Types of Electrical Connectors PDF

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by clicking on the following link.

linquip.com-3 Common Types of Electrical Connectors Clear Guide

Watch Videos about Common Types of Electrical Connectors

For more information about Common Types of Electrical Connectors, watch the following video.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Types of Circuit Breaker: A Basic Guide to Know Different Classifications

- 15 Types of Electrical Power Connectors (Clear Guide) + PDF

- Types of Thermometers: All You Need to Know

- Types of Electric Circuits: All Classification with Application

- 5 Types of Proximity Sensors (Application and Advantages)

- 3 Main Types of Pneumatic Cylinders With Application

- Types of Resistor: Classification, Application, and Finally Clarification

- 7 Types of Capacitors and Their Uses

- 3 Different Types of Hygrometers and Their Applications

- All Types of Pneumatic Fittings: Specifications and Applications

- 4 Types of Thermowell: Application and Duty

- 10 Types of CNC Machine + Applications & PDF

- Temperature Sensors: Types, working principle & Practical Applications

- Types of Sensors Detectors/Transducers: An Entire Guide

- What is Vacuum Circuit Breakers?

- Difference Between Isolator and Circuit Breaker: Ultimate Guide

- Difference Between Relay and Circuit Breaker: Everything You Need to Know

- How does a Circuit Breaker Work?

- What is Parallel Circuit? Definition & Example

- Difference Between Linear and Nonlinear Circuits

- The 10 Best Mini/Benchtop Milling Machine

- The 8 Best Rust Converter (Review Guide)

- The 10 Best Reciprocating Saw + Review

- What is the Equivalent Circuit of Transformer?

- The Only Guide You’ll Ever Need For Different Type of Industrial Measuring Tools

- Types of Resistor: Classification, Application, and Finally Clarification

- What is Thermowell? Types & Working Principle

- What is Electrical Identification? (Ultimate Guide)

- What Is the Advantage of AC Power Transmission