The compression of gases and vapors in the process industry is very important. Compressors find use in a variety of applications. There are three basic designs for compressors: dynamic, positive displacement, and thermal. Dynamic compressors include centrifugal and axial compressors. Both types operate by changing the velocity of gas and converting energy to pressure. Dynamic compressors accelerate airflow by drawing air in axially and spinning it outward (centrifugal compressors) or in a straight line (axial compressors). In this article, we review the differences between axial compressor & centrifugal compressor in all aspects. Follow this new blog in Linquip to find out more about the difference between these compressors.

Depending on your application, you can find all the information you need about compressor equipment and devices on Linquip’s website. Linquip’s team of experts is available to answer any questions you may have about various types of compressors. Start by checking out Linquip’s article, “What is Compressor?” to learn more about these turbomachines.

You can also register as a Linquip Expert to access all services Linquip offers. Are you interested in Guest Posting for Linquip? By using the Linquip platform, you can submit content as a guest.

⇒ View a List of Compressor for Sale and Their Suppliers ⇐

Axial Compressor

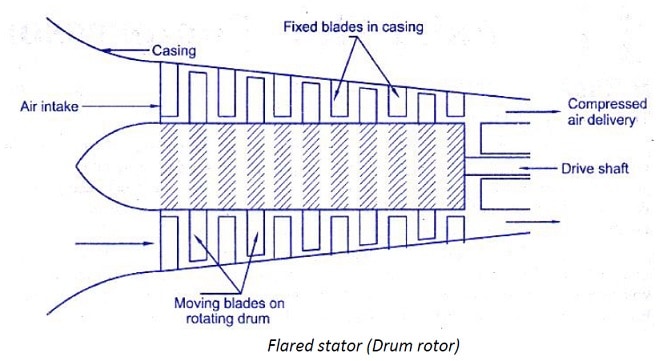

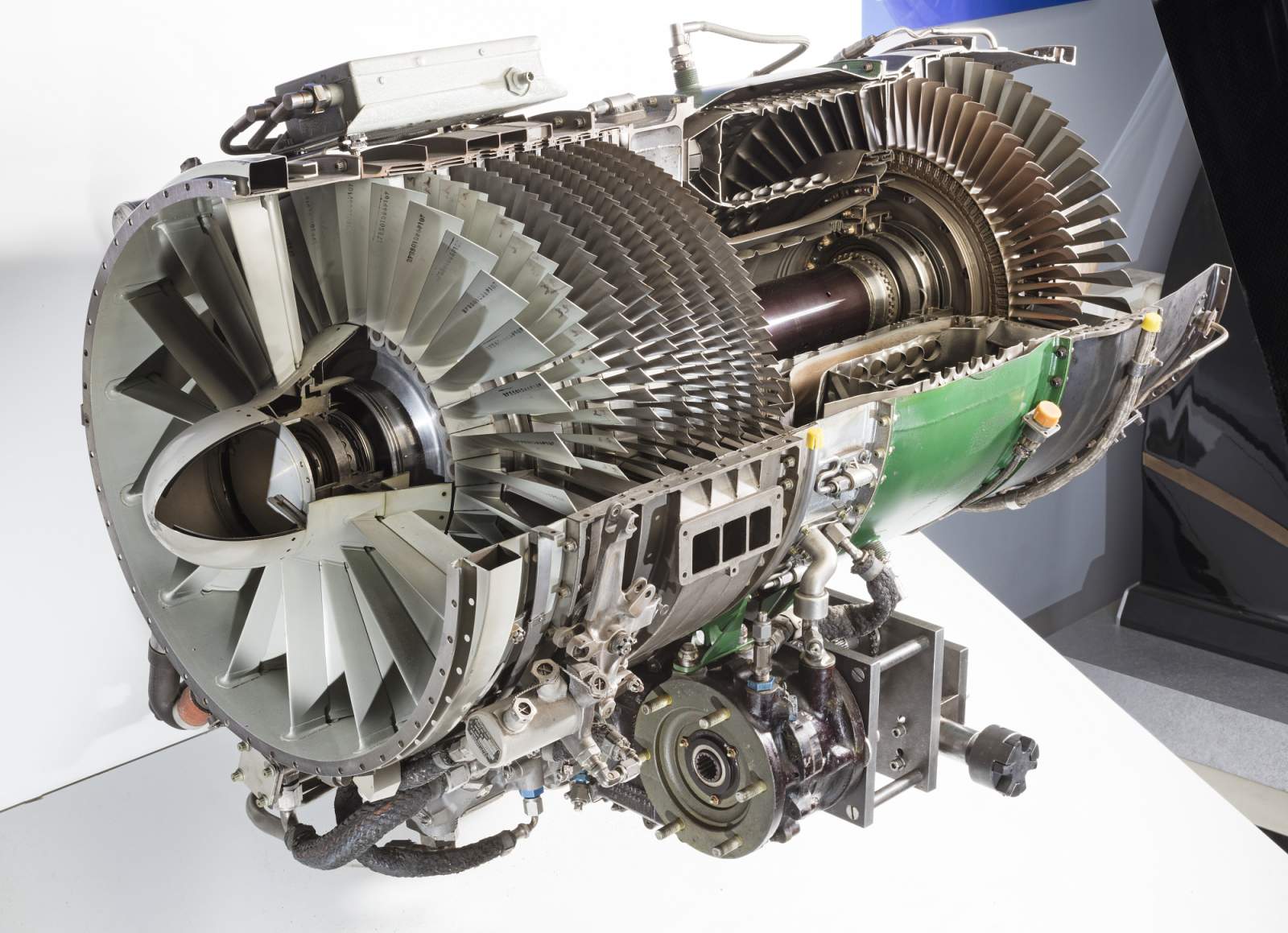

Axial compressors are one of the two main types of dynamic compressors that continuously compress air. Axial compressors in their very simple form are also known as axial flow fans. They are called axial compressors because the flow through the compressor travels parallel to the axis of rotation.

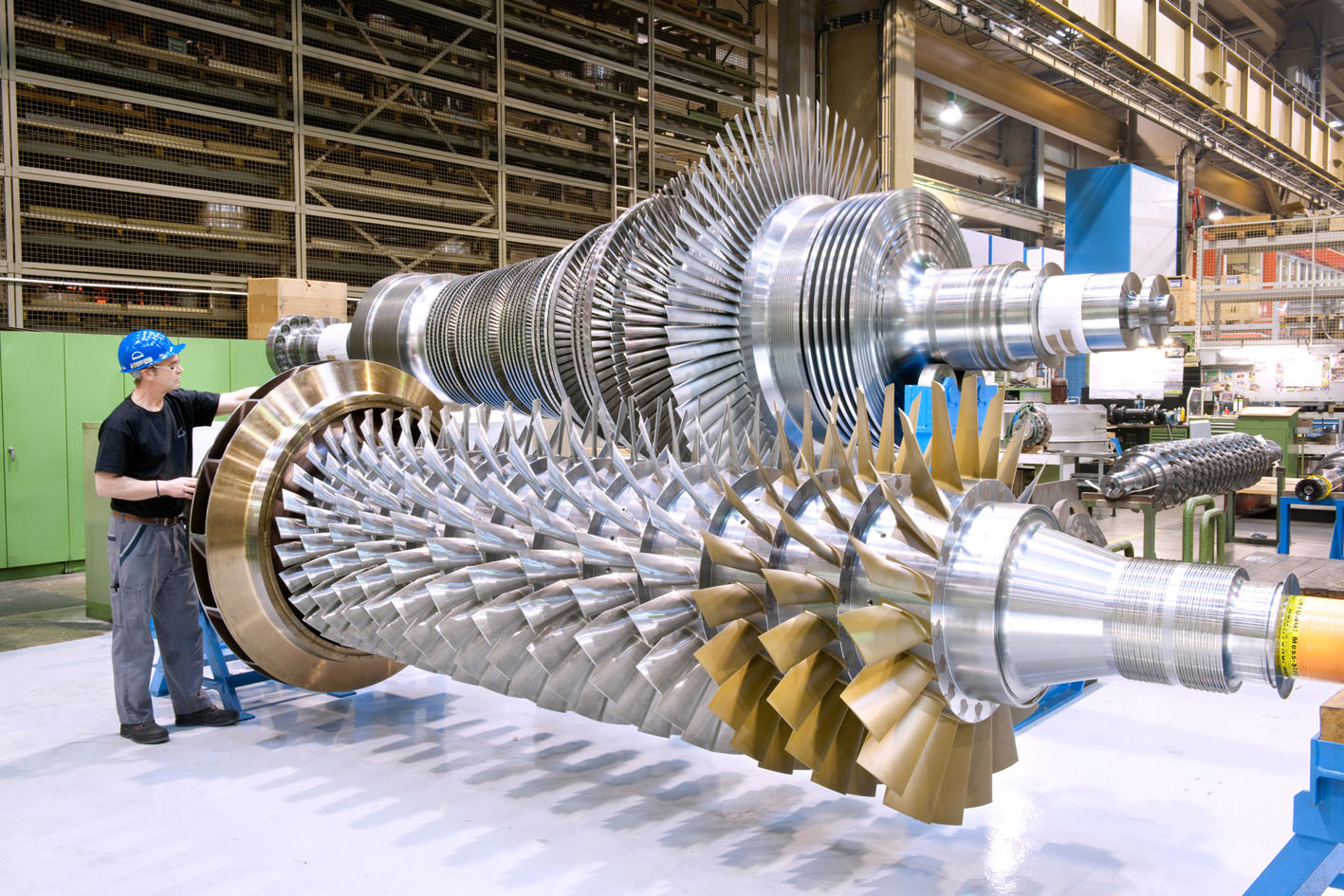

A typical axial compressor consists of a drum, to which blades of specific geometry are attached. As the compressor sucks the air axially and increases its energy level by flowing air through the rotor blades that rotate and exert a torque on the air. Now the stationary blades slow down the speed of the fluid and convert the circumferential component of air into pressure. So the air gets compressed in this way. A few facilities in the world have axial compressors to generate high match number flow for continuous wind tunnel testing.

They do require several axial stages to achieve large pressure rises, making them complex and fragile relative to other compressor designs such as centrifugal compressors. Modern engines can use 10-15 compressor stages.

Axial compressors have the benefits of high efficiency and large flow rates, particularly concerning their sizes and cross-sections. They offer the most compact and lightweight compressor design for large volumes and the lowest cost per-flow rate for large flow rate applications.

Advantage

- High peak efficiency

- Small frontal area for a given flow

- Straight through flow, allowing high ram efficiency

- Increased pressure rise due to an increased number of stages with negligible losses

- Good efficiency over the narrow rotational speed range

Disadvantages

- Difficult manufacturing

- Very expensive

- Heavyweight

- High starting power requirements

- Sensitive to the aerodynamic stall and angle of attack

- Sensitive to flow disruptions

- Not effective as a single-stage axial compressor in increasing the gas pressure

Applications

- High-speed ship engines

- In small scale power stations

- Blast furnace air

- Air separation plants

- Aircraft turbojet engines

- Land-based gas turbines

Centrifugal Compressors

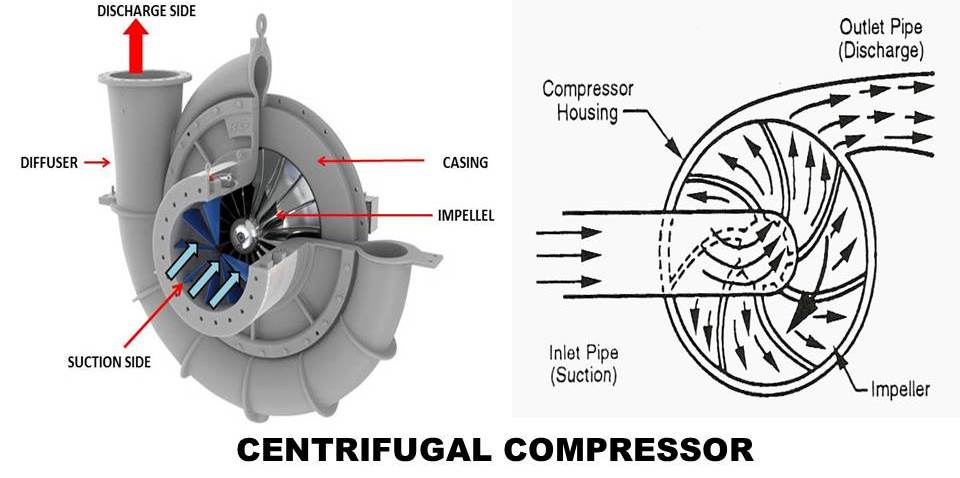

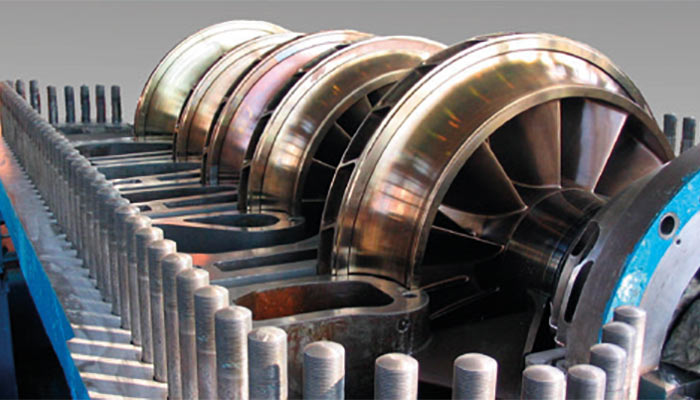

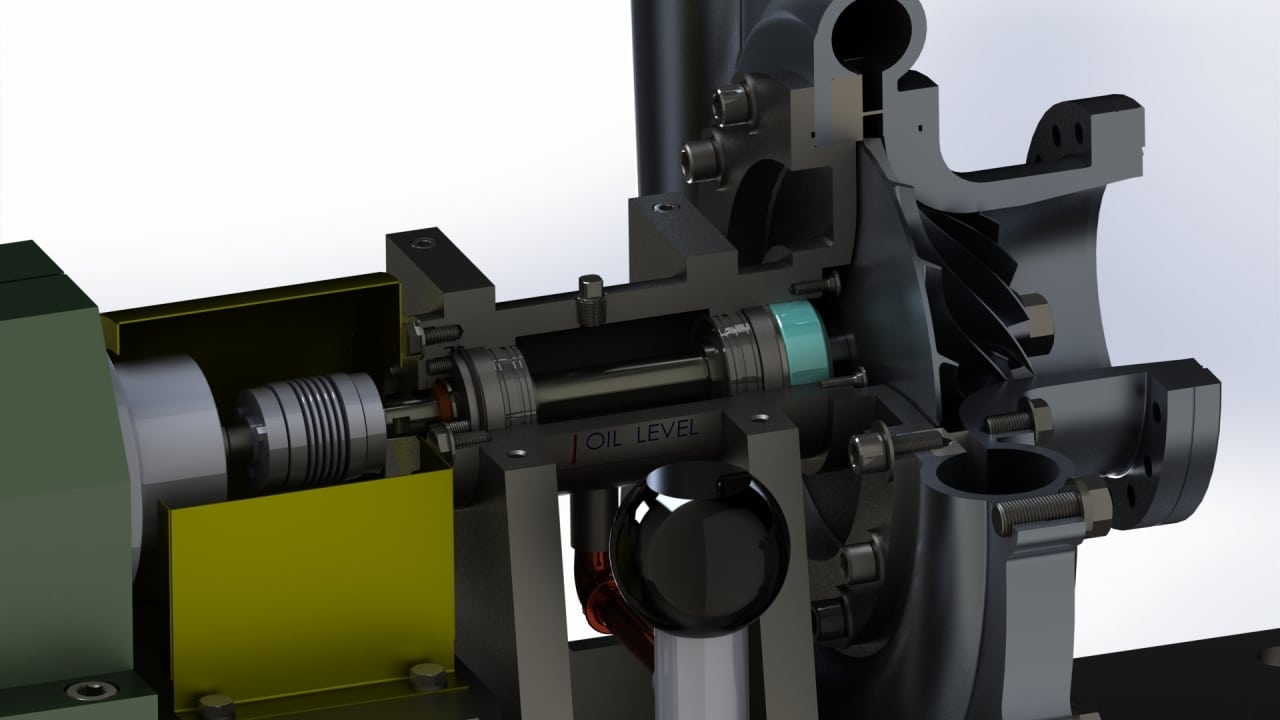

The other type of dynamic compressors is centrifugal compressors or annular compressors that depend on the transfer of energy from a rotating impeller to the air. A centrifugal compressor has a simple rotating element, mounted onto the shaft which is usually connected directly to the prime mover.

They are divided into four parts; Input, centrifugal impeller, diffuser, and collector. The compressor sucks the air or the air enter through the input and then the centrifugal compressor raises the energy of working gases/air by rotating a set of blades. From here the velocity of the air is increased before moving to the diffuser. Diffuser converts the kinetic energy of the air into the pressure energy by gradually decreasing the air velocity. And in this way air is compressed and collects from the collector.

One of the interesting characteristics of the centrifugal compressor is that as the speed of the impeller reduces, the capacity of the compressor increases. These compressors may have single or multiple stages (up to 5stages) and can operate at very high inlet pressures. With the development of aero engines, axial compressors have nearly replaced centrifugal compressors.

Advantages

- Reliable, low maintenance

- Low weight, easy to design and manufacture

- Suitable for continuous compressed air supply, such as the cooling unit

- High-flow rate than the positive displacement

- Oil-free in nature

- Fewer rubbing parts

- Relatively energy efficient

- Insensitive to flow disruptions

- Wide range of rotational speed

- No special foundation required

Disadvantages

- Large frontal area for a given airflow rate

- Unsuitable for very high compression, limited pressure

- Sensitive to changes in gas composition

- Sophisticated vibration mounting is needed

- The problem of surging, stalling, and choking

Applications

Centrifugal compressors are used in many industrial applications such as refineries, chemical, and petrochemical plants, natural gas processing and transmission plants, very large-scale refrigeration, and iron and steel mills.

- gas compression in oil platforms

- LPG storage and transport installations

- The turbocharger in many sports cars

- Turbochargers in diesel engines

- Small turbofan engines

- Small turbojets and turboshaft engines and as pumps on rocket engines

Axial Compressor VS. Centrifugal Compressor

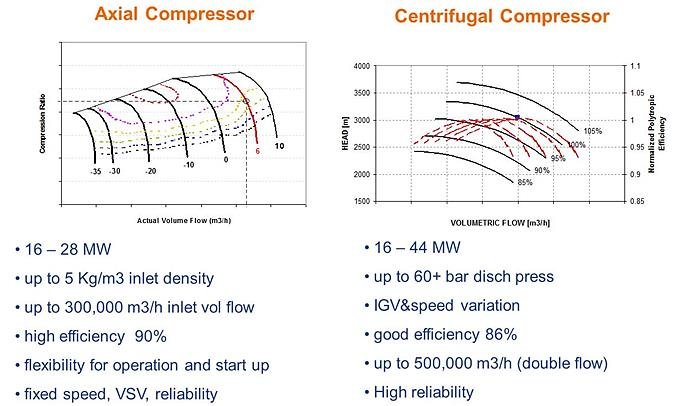

The main differences between axial compressor & centrifugal compressor are in how they operate, and how they are maintained. Several differences play an essential role in choosing the best compressor for your application and your need.

- Flow-through centrifugal compressors are turned perpendicular to the axis of rotation, while the air in axial compressors flows parallel to the axis of rotation.

- Typically centrifugal compressors are one solid piece that looks like a turbocharger and axial compressors are a flat disk that looks like a fan with individually manufactured blades inserted.

- Centrifugal compressors are easier to design and manufacture compared to axial compressors.

- Centrifugal compressors can handle much less gas flow compared to axial compressors.

- Centrifugal compressors can often create more differential pressure for efficient combustion with a single compression stage.

- Contrary to centrifugal compressors, axial flow compressors are not easy to fix and maintain.

- Axial compressors are very expensive while centrifugal compressors are cheaper and have a wider operating range.

- The mass flow rate in centrifugal compressors is less than 15 Kg/s and in the axial compressors is very large (more than 100 Kg/s).

- Axial compressors operate more efficiently (about 94%) than centrifugal compressors (about 87%).

- Centrifugal compressors can accommodate much lower airflow than axial compressors of the same size, and their pressure ratio is generally lower, meaning they are much less effective for creating thrust and less fuel-efficient.

- The pressure ratio per stage in centrifugal compressors is high about 5-7 and in axial compressors is low (less than 1.5).

- Contrary to centrifugal compressors, axial flow compressors do not change the direction of the gas.

So, this is all you need to know about the differences between axial compressor & centrifugal compressor. If you enjoyed this article in Linquip, let us know by leaving a reply in the comment section. Is there any question we can help you through? Feel free to sign up on our website to get the most professional advice from our experts.

Download Difference between Axial Compressor and Centrifugal Compressor PDF

Linquip has made this article accessible as a PDF file for easy viewing and printing. Have this file on your hard drive for quick access whenever you need a review of the differences between axial and centrifugal compressors.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The Differences Between Rotary & Reciprocating Compressors

- Types of Centrifugal Compressor: An Ultimate Guide

- Axial Flow Compressors 101: The Essential Overview

- How Does a Centrifugal Compressor Work?

- The 8 Best Small Air Compressors

- The 10 Best Air Compressor for Home Garage in 2022

- Everything You Need To Know About Different Types Of Compressor

- The Differences Between Rotary & Reciprocating Compressors

- What is Radial Compressor?

- Reciprocating Compressor Parts: A Simple, Yet Useful Guide

- Piston Compressors: The Most Comprehensive Guide to Know Piston Compressor

Very helpful!

Very helpful foe beginners like me!

Your kind words are much appreciated, Messi! It was a pleasure having you visit us.