How to Select the Right Pallet Rack Repair Kits – Thousands of tons of items are held high above your personnel on pallet rack systems. It is your responsibility to keep those tons of stuff moving securely and effectively. It’s literally lives and livelihoods on the line. It is your obligation to repair any damage. Repairing your pallet rack system may be your most important responsibility because it can truly save lives and jobs.

To find out more about Warehouse Racking, please visit our Warehouse Racking for Sale pages, where you can also request a quote.

What Is Pallet Rack?

Pallet rack is a material handling storage help system for materials stored on pallets (also known as “skids”). Pallet racking comes in a variety of shapes and sizes, but all allow for the storage of palletized products in horizontal rows with several levels. In most cases, forklift trucks are needed to load the pallets onto the storage racks. Pallet racks have become a common element in most modern warehouses, manufacturing plants, retail stores, and other storage and distribution facilities since WWII. Pallet racking of any kind increases the storage density of the goods being stored. With increased storage density, the cost of racking rises.

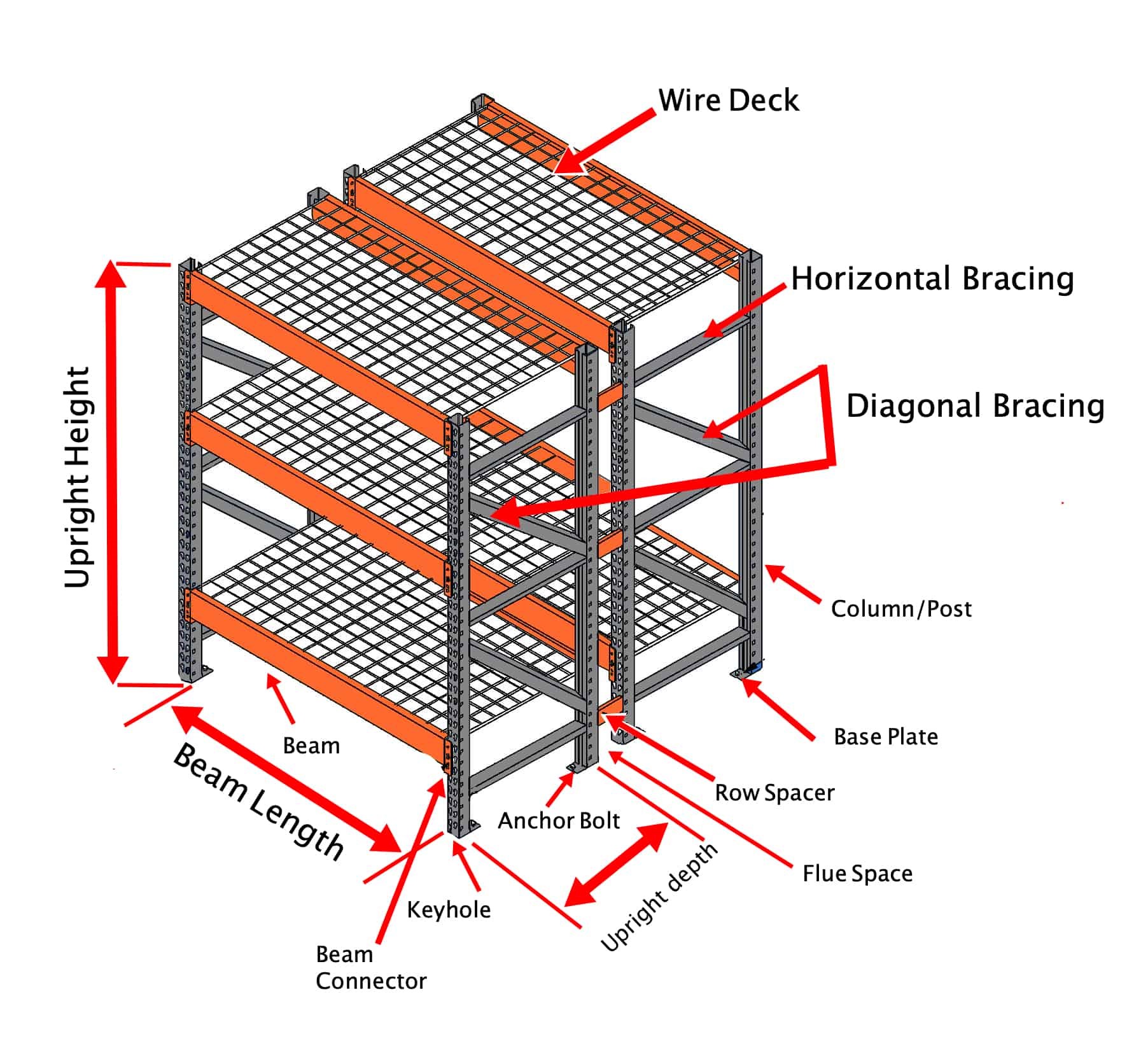

Pallet Rack System Structure

Pallet Rack systems are made up of four primary structural sections: upright frames, beams, struts, and anchor systems, which are all made up of 100 % OEM parts. There are other smaller sections, but the focus of this article will be on the main structural components that are damaged. Even then, we’ll be concentrating on the upright frames because they carry the majority of the weight and stress in the system overall. Furthermore, beams are easily changed with OEM parts, and they are frequently replaced rather than repaired. Let’s take a look at why the column is such an important part of a racking system and how foundation row columns are even more critical.

Foundational Row Section

The foundation row of the racking system is the lower 5′-0″ segment of the upright frame. Of all the components in your system, the foundation row segment carries the most pressure and stress. It’s also the one that’s most likely to sustain serious injury. Lift vehicles with a high mass that travel on the ground at the level of the fundamental row section cause the most harm. The foundation row is the most common location where the complete mass and velocity of a vehicle impact can occur; higher levels receive less mass and velocity damage. Steel deformation, steel and component fracture, anchor displacement of location, or all of the above can occur as a result of mass at velocity impacts on upright columns. Multiple column damage adds up to overall system stress until the system reaches a breaking point. The tipping point is when your racking system experiences one final impact or stress that causes it to collapse catastrophically. This form of failure results in the loss of lives, products, trust, money, and the disruption of the entire supply chain. One of the main goals of the repair is to preserve the foundation row segment free of damage by inspecting, maintaining, and repairing it on a regular schedule. While detecting and repairing damage in all parts is essential, paying particular attention to the foundation row for impact is critical, as this is where most of the damage occurs.

Pallet Rack Repair Kits

Due to forklift impact, the most typical warehouse rack damage is discovered on the front column of the pallet rack frame. When column damage is discovered, more damage to the reinforcing horizontal and diagonal struts is expected. Linquip introduces experienced suppliers who can provide damaged rack repair solutions for all forms of pallet rack damage, as well as nationwide rack repair and rack installation services for all of your products. With the correct pallet rack repair services and rack safety equipment, you can keep your warehouse secure. Pallet racking repairs can be risky, so be aware of so-called “rack repair companies” who lack the skills and experience necessary to deal with damaged pallet rack and other rack remediation projects. Allow the experts to handle it!

Many rack sellers will sell you potentially hazardous things. They may appear to be tough, but actually they are not. The steel may be weak, the engineering may be poor, and the inspection or installation may be inadequate. When it comes to choose a pallet rack repair kit and company, there are many hidden things to consider. This article will describe everything you may need to know about pallet rack repair kits in general.

Importance of Engineering in Pallet Rack Repair

The principal core of a pallet rack repair kit is engineering design. According to ANSI/RMI requirements, each part must have the same strength as the OEM part, but it should ideally be stronger. A part’s compliance with standards can only be ensured by good engineering. Furthermore, most pallet rack frames are not designed to withstand impact damage, which is common on the foundation row. The OEM upright frame elements used in the higher levels of the frame are frequently the same as those used at the bottom of the frame, where the majority of the impact occurs. Impact damage resistance is rarely given additional engineering consideration. A repair part has the potential to be more securely built to withstand impact. Built-in protection reinforcements or internal reinforcements, as well as more robust steel requirements, can be used to accomplish this. Consider that the original parts were mainly intended for vertical forces rather than impact forces.

Custom Engineering vs. Modular Designs

Pallet rack repair kits that are built and adapted to your exact racking standards are the best practice. Each rack system has its own set of stress vectors that must be considered. Furthermore, each racking system has its own set of design elements that must be replaced by an OEM part or a part that closely mimics the original designs, such as vertical, slant, or cantilever designs. Rather than solid welded frames created precisely to your needs, many companies provide modular solutions that are adaptable to your specifications with screws and expansion pieces. Engineers refer to open panels as portions of a modular design that lack a diagonal cross strut.

The modular strategy is not as effective and should be avoided. Look for a supplier that offers a wide range of engineered pallet rack parts so that they can meet your exact engineering requirements. Hence, they can supply you with custom design engineered solutions as well as the exact technical documents required to meet your local codes and criteria.

Risks of Non-Engineered Components

Products that lack the engineering to back them up may appear to be repairs, but they are often inferior in many ways: steel, coatings, anchoring, and structural design. Because so many of these characteristics are not apparent, you would never know you were getting a poor product. Non-engineered products can cause the repaired component to fail catastrophically. Consider the following details of good engineering of a pallet rack repair product.

Steel Quality

It’s all too easy for repair part manufacturers to skimp on steel. People are unaware that not all steel is created equal. You may have noticed this while purchasing low-cost tools and the steel just breaks, snaps, or bends. Have you ever wondered why certain automobiles endure so much longer than others? It’s usually due to the steel quality specified in the original parts. Consider what would happen if your racks were made of inferior steel. Steel that isn’t good enough can be brittle and break. It may be inconsistent, have impurities that weaken points, or possess other attributes that are insufficient to endure your system’s demands. Make certain you understand what you’re purchasing. The quality of the steel is a significant aspect of your decision in selecting a pallet rack repair kits. When purchasing your next pallet rack repair kit, keep the following in mind.

Foreign Steel

The first place that pallet rack manufacturers skimp is by purchasing foreign steel. Prior to sale, foreign steel, mainly from China, is not subjected to quality testing. Other elements, such as Boron, are frequently found in Chinese steel, as was discovered in 2015. This can render the steel brittle, susceptible to stress damage, and unable to withstand welding. Chemical composition and strength standards for steel grades are provided by organizations like the American Iron and Steel Institute (AISI) and ASTM. Purchasing a rack repair or protection product made of steel from an unknown supplier is dangerous. Any product that isn’t created in the United States should be avoided.

Steel Grade

Even in the United States, where steel is highly regulated, it is important to recognize that several grades of steel exist. Steel comes in many different of chemical compositions and characteristics. Even if you buy a part made of steel from a US steel plant that meets quality standards, it may not be the proper grade of steel. Look for AISI 1006 carbon steel with a tensile strength yield of at least 41,300 psi. Look for a new manufacturer with clear steel requirements if your vendor doesn’t know what grade of steel is used or where the steel was from.

Process of Steel Forming

Beyond the steel’s country of origin and grade, there are concerns about how it is made. To shape the steel used in pallet rack components, two types of forming methods are used. It’s crucial to know whether structural steel or roll form steel is better for your application. Let’s look at which steel type is best for your purpose.

Roll Form Steel Rack

In most systems, this is the most common type of steel rack. It’s less expensive, and it’s lighter and easier to deal with in general. It is made when the steel has cooled and is then extruded and shaped into its final form by rollers. The final form has a more exact shape thanks to the cold rolling. Roll form rack, on the other hand, has a lower impact tolerance and a lower total weight bearing capacity than structural steel rack. Because of its low cost and precise shape tolerances, roll form steel is commonly utilized in racking systems. Roll form may be the ideal option depending on the design and weight requirements of your racking system. If you need the same punching system flexibility as well as the ability to adjust the beam profile, roll form can be the best option. On the other hand, some impact damage resistance and overall weight bearing capacity would be sacrificed. It’s vital to consider all of your options before deciding on roll form steel for your repair kits.

Structural Steel Rack

The hot rolling process is used to create structural steel. This entails rolling the steel into its final shape at temperatures above 1700° F. The steel gains strength and resistance as a result of this process, at the cost of some shape perfection due to the cooling. Structural steel is an excellent choice for pallet rack uprights and replacement parts in difficult environments such as refrigerated warehouses, outdoor racks exposed to the elements, food storage, and areas prone to forklift impact on the foundation row. Although structural steel is used as the principal kind of upright in many rack systems, it is in the minority. Structural steel is frequently an upgrade because it provides better impact resistance and strength to sustain your product load. For the top of the racking system, most OEM racks employ the same rolled form part as for the foundation row section. When possible, we recommend upgrading to structural steel pallet rack repair kits over roll form, as structural steel repair kits offer numerous advantages.

The only disadvantage of structural steel is that the punch holes on the front of the repair portion are difficult to reach. However, in most cases, this isn’t a problem. Because the damage occurs below the first beam level, allowing the original punch holes to be accessed after the repair.

Reinforcements and Protectors

On most of the upright column repair kits, suppliers offer additional integrated pallet rack impact protectors in the lowest zones as an option. These protectors are also composed of structural steel, so you’ll have two layers of protection where you need it the most. These protectors are available in two styles: v-nose and non-protruding. To give you even more alternatives, these structural steel protectors can be attached to roll form or structural steel uprights.

Anchor Points

Pallet rack repair often overlooks anchor points as a minor element. They are, nevertheless, an essential component that prevents the entire racking tower from collapsing. Anchor points have two purposes. First, they retain all of the frame elements in their most stable positions. Second, they are responsible for transferring impact energy to the ground. Even though a weakly anchored upright has significant vertical strength, it is nevertheless subject to impacts that can cause it to move off of its ideal placement and vertical orientation. The issue is that increasing the upright’s strength necessitates increasing the anchoring’s strength. When the uprights are strengthened, greater force is transferred to the anchors, which could cause the anchors to break if they have not been improved. If there are too few or weak anchors, an impact will force the entire column to shift in harmful ways. When analyzing anchor points, there are various factors to consider: undamaged holes, anchor depth, anchor hardware quality, anchor plate strength, and the number of anchors.

Anchor Hole Damage

One of the major challenges in rack repair is existing anchor hole damage. When the original anchor points’ concrete holes have been destroyed, anchors cannot be reinstalled in those holes. Reinstalling the OEM part with the same anchor attachment points into the same anchor holes is either impossible or severely compromised due to the previous damage. Looking for a repair part where the foot plates adjust the anchors so that new holes may be drilled is critical. Damage to the concrete anchor holes can be a serious issue that necessitates the use of a special anchor foot plate.

It’s crucial to have multiple anchor points. Several extra anchor locations can be found on the foot plates. In order to improve your impact resistance, they should have more than are normal on OEM parts.

Thicker Steel Foot Plates

It’s also important to use thicker steel in the anchor plate. Anchors with thicker steel footplates have higher shear resistance rates. Kit impact resistance is directly proportional to anchor shear resistance rates. Also, make sure to obtain a footplate that meets any prospective seismic engineering requirements in your region, which usually necessitates a footplate that is much larger and more durable. Most generic components will not adequately fulfill all of the demands listed above.

Connection Points

The connection points between the designed repair kit and the undamaged rack part are a significant issue. To make the repair, OEM components have a lot more connection points, so you’ll have to unload and reassemble a lot of your racking system. This takes time and necessitates the use of important warehouse space.

The connection is made above the damage point with third-party pallet rack repair kits. The damaged rack can be jacked up, and the damaged portion of the rack may be removed and replaced. A qualified technician must perform this procedure, which requires a specifically designed rack lifting jack. It’s also important to look for bolted connection connections rather than welded ones, as this eliminates the necessity for a hot permit for welding. This enables a more secure and quick replacement. There will be limited unloading of the rack section, no disassembly of the rack section, and no pallets will be moved from their current places.

Beam Connection Points

Some major repair kit manufacturers prefer to cut the end plates off of beams and attach them to the repair kit with supplementary devices such as hooks or angles fastened or screwed to the repair kit’s side. This is an extremely risky technique that endangers the entire rack system’s structural integrity. Not all beam plates are made equal. For load and seismic compliance, numerous alternative weld patterns for the same end plate or bigger end plates are necessary. When the endplate is cut off, it negatively impacts all seismic engineering and compliance of the system.

Surface Finishes

Simple paint is a low-quality finish that is quickly scratched and susceptible to rust damage. Pallet rack repair kits with a powder coat or galvanized finish are ideal. These coatings offer the most long-term corrosion protection. Rust may destroy a steel element in just a few years, compromising structural integrity. In reality, the rust destruction rate in industrial applications is around 40-160 millimoles per year. Depending on the climatic circumstances, the strength might be compromised in a few years. The best finishes for protecting your parts are powder coating and galvanizing. A thick enamel shell is formed by powder coating attached to the steel. When galvanizing is applied at high temperatures, it makes a chemical connection with the steel, protecting it on a molecular level.

Adjustable Pallet Rack Repair Parts vs. Custom Factory Replacement Frames

Many vendors provide adjustable pallet rack repair parts to compensate for their lack of component inventory. Adjustable parts may not be as durable as factory-welded solid parts. Bolts on sliding joints keep adjustable kits together. The lateral sway strength of adjustable components is frequently weakened, which is a considerable disadvantage compared to custom-sized replacement parts. Adjustable kits can’t be set to a specific height. Adjustable components are frequently created and marketed by vendors in order to reduce the number of custom high-strength solutions they produce and sell. Some manufacturers import their products from China or other foreign countries because they lack the manufacturing capacity or competence to produce any different sort of product locally. Rack repair is not a one-size-fits-all solution. Look for companies who provide a wide range of customizable pallet rack repair kits since this means they don’t need to rely on adjustable components to fill in the gaps with a poor product.

Component customization to the precise designed part for your unique application is simple and may be achieved fast. Custom components may be created to fit the damage points and match the exact requirements for beam attachments and struts. Typically, these adjustments include alterations to the dimensions rather than the entire design. Engineering certification can also be tailored to meet your specific requirements depending on local building codes. The best parts are those that are specifically designed to handle each design goal and are not adaptable to be a jack of all trades and master of none.

Lifetime Impact Warranty

Make sure that the pallet rack repair kits are covered by a warranty, preferably a lifetime impact warranty. Check the warranty to ensure it is an impact warranty. Some companies only provide warranties for manufacturing defects; while, an impact warranty indicates that the item was designed to withstand impact and displacement as well as bearing the weight of your inventory.

Product Support Team

The people who create the product are just as important as the new part itself. The following are the seven essential characteristics to look for in a pallet rack repair company:

- Experience: The quality of your results is determined on your experience and knowledge of pallet rack repair. It is suggested that you conduct business with the industry’s leaders and innovators in designed rack repair and protective guarding.

- Availability: You might come across a company with a restricted product selection, but can or will they meet all of your requirements? Will they be too busy with other projects to complete your order? Do they have their own product line and production, or do they rely on items from other countries or outsourced vendors? It is advised that you find a supply chain partner who will be available to you 365 days a year. the partners that have their own production facilities and can satisfy your capacity needs when you need it.

- Honesty, Warranty, and Honor: Integrity decides if they will provide you with a warranty and stand by it, not because they have to, but because their honor requires it.

- Turnkey Service for Pallet Rack Repair: A warehouse manager requires a partner that can handle all aspects of pallet rack repair and protection. As a result, the manager will not have to deal with 3-5 suppliers and contractors to complete the project.

- Warehouse Damage/Repair Survey: The first and most important stage in a successful rack repair process is an inspection and survey of your current damage. You need an expert who can see all of the existing challenges as well as possible future issues.

- Pallet Rack Kit Manufacturing: Choose a supplier that controls the whole pallet rack repair part manufacturing process and isn’t reliant on others in the supply chain. Now, more than ever, “Made in America” means something. It can help you maintain your part availability wait time to a minimum. Especially if the parts must be tailored to your specific application.

- Installation of Pallet Rack Repairs: The installation process must be carried out by skilled and certified experts. While removing damage and installing the new pallet rack repair kit, they should be able to bear essential weights and stresses. They must ensure that everything is installed according to engineering specifications.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

- Prologis Essential Company Page on Linquip

- List of All Prologis Essential Service

- Prologis Essentials General Services

- Prologis Essentials Installation

- Prologis Essentials HVAC Maintenance

- Structural Pallet Racking for Sale by Prologis Essentials

- Warehouse Lighting Products by Prologis Essentials

- High bay LED lighting Products by Prologis Essentials

- Warehouse Solar Products by Prologis Essentials