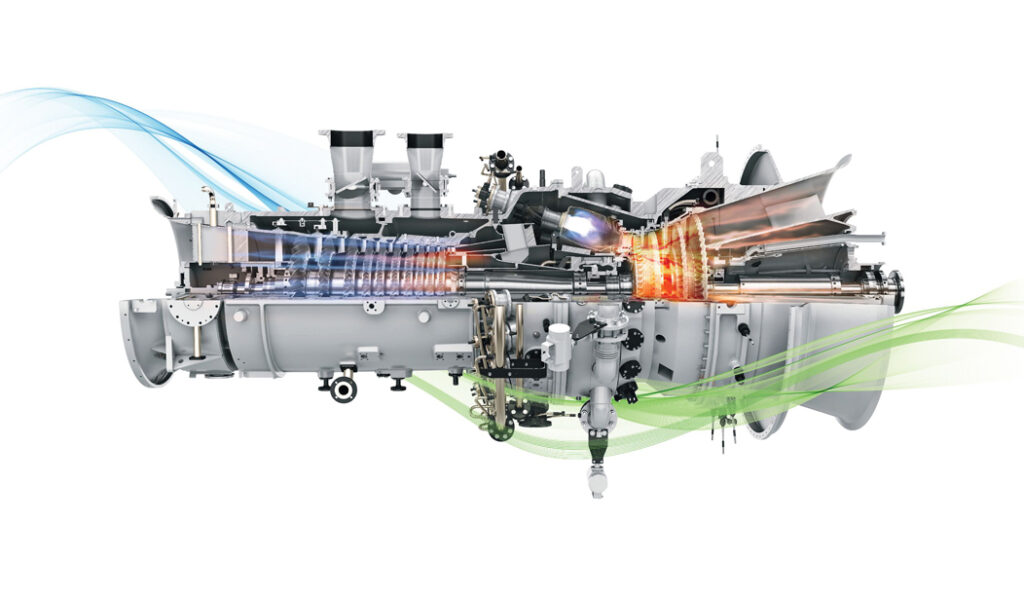

Hydrogen gas turbine – Hydrogen can be employed as a power generation fuel once it has been produced. Gas turbines can run on hydrogen, making them suitable for a range of industrial applications such as steel mills, refineries and petrochemical plants.

The Story of Hydrogen

Commercial use of hydrogen as a gas turbine fuel has been shown, but there are variations between hydrogen and natural gas that must be considered in order to use hydrogen in a gas turbine correctly and safely. Aside from variations in combustion properties, the effect on all gas turbine systems as well as the total balance of the plant must be regarded. Fuel accessories, bottoming cycle parts, and plant safety systems need to be changed in a power plant with one or more hydrogen-fueled turbines.

Since gas turbines are inherently fuel-flexible, they can be designed to run on green hydrogen or similar fuels as a new unit, or they can be modified after years of operation on conventional fuels like natural gas. The extent of the modifications needed to convert a gas turbine to run on hydrogen is determined by the gas turbine’s initial configuration and overall balance of the plant, as well as the required hydrogen concentration in the fuel.

Hydrogen Production

As shown in the following figure, hydrogen can be generated from a variety of feedstocks and chemical processes. Photosynthesis with algae, natural gas steam methane reforming (SMR), partial oxidation of crude oil, coal gasification, and water electrolysis are only a few examples. The following sections will go over steam methane reforming and electrolysis as possible hydrogen-generation pathways for energy production.

Steam Methane Reforming

The majority of hydrogen generated today originates from steam methane reforming. A large portion of this hydrogen is utilized in the manufacture of ammonia for fertilizers or petrochemicals. Natural gas (methane) is reacted with water and heat in this process to produce H2 and CO2 through two reactions:

CH_4+H_2O\rightarrow CO+3H_2

CO+H_2O\rightarrow CO_2+H_2

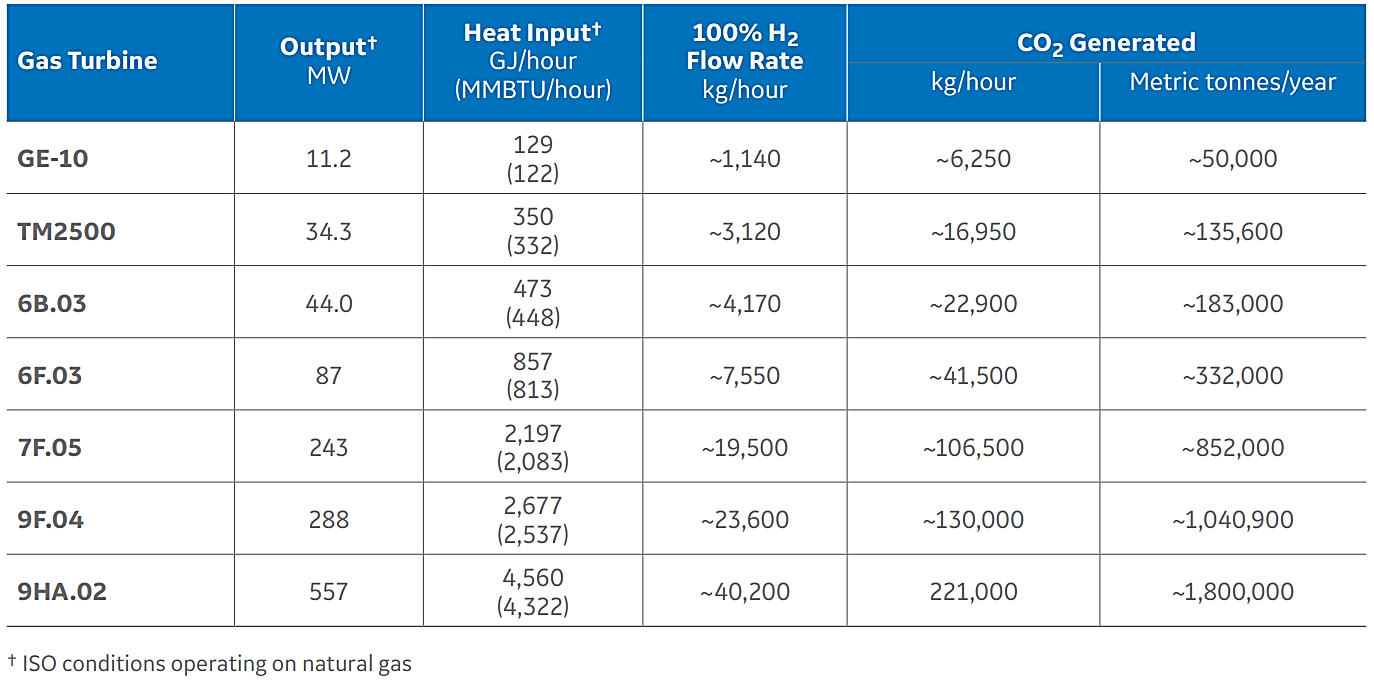

According to these equations, one mole of CO2 and four moles of H2 are formed for every mole of methane used. Using the molecular weights of each part, 0.5 kilograms of H2 and 2.75 kilograms of CO2 are produced for every kilogram of methane consumed. (Every kilogram of H2 produced creates 5.5 kilograms of CO2.) According to the GE report, in terms of the volumes needed for power generation, a single 6B.03 gas turbine operating for 8,000 hours per year will consume about 33 million kg of H2 (per year). SMR would produce 178,000 metric tons of CO2 per year if hydrogen was produced this way. For certain gas turbine platforms, the following table presents the rate of CO2 output when scaled to hydrogen production.

Despite the fact that generating hydrogen through SMR produces carbon dioxide, a number of projects are looking into combining it with carbon capture and sequestration (CCS) to generate hydrogen. The H21 Leeds City Gate and the Magnum Vattenfall projects are two examples of projects that are considering using SMR to generate hydrogen. The City of Leeds project is expected to generate 2.4 billion m3 of hydrogen each year, enough to provide heat and electricity to approximately 660,000 people. A 90 percent carbon capture device is being considered as part of this system, which would capture approximately 1.5 million tons of CO2 annually. In the Netherlands, the Magnum Vattenfall project proposes to convert an existing gas turbine to run entirely on hydrogen. The proposed plan is to produce hydrogen from natural gas, with the CO2 collected and deposited in underground bunkers as a byproduct. Transmitting hydrogen and storing it at the power plant are also open issues.

The challenge of these projects is to generate carbon-free electricity using a technology that necessitates large-scale CO2 sequestration. There are, however, technologies that can produce H2 without releasing CO2.

Water Electrolysis

The electrolysis of water is a well-known process for producing hydrogen. The chemical reaction that splits water is as follows:

H_2O\rightarrow H_2 + 1/2~O_2

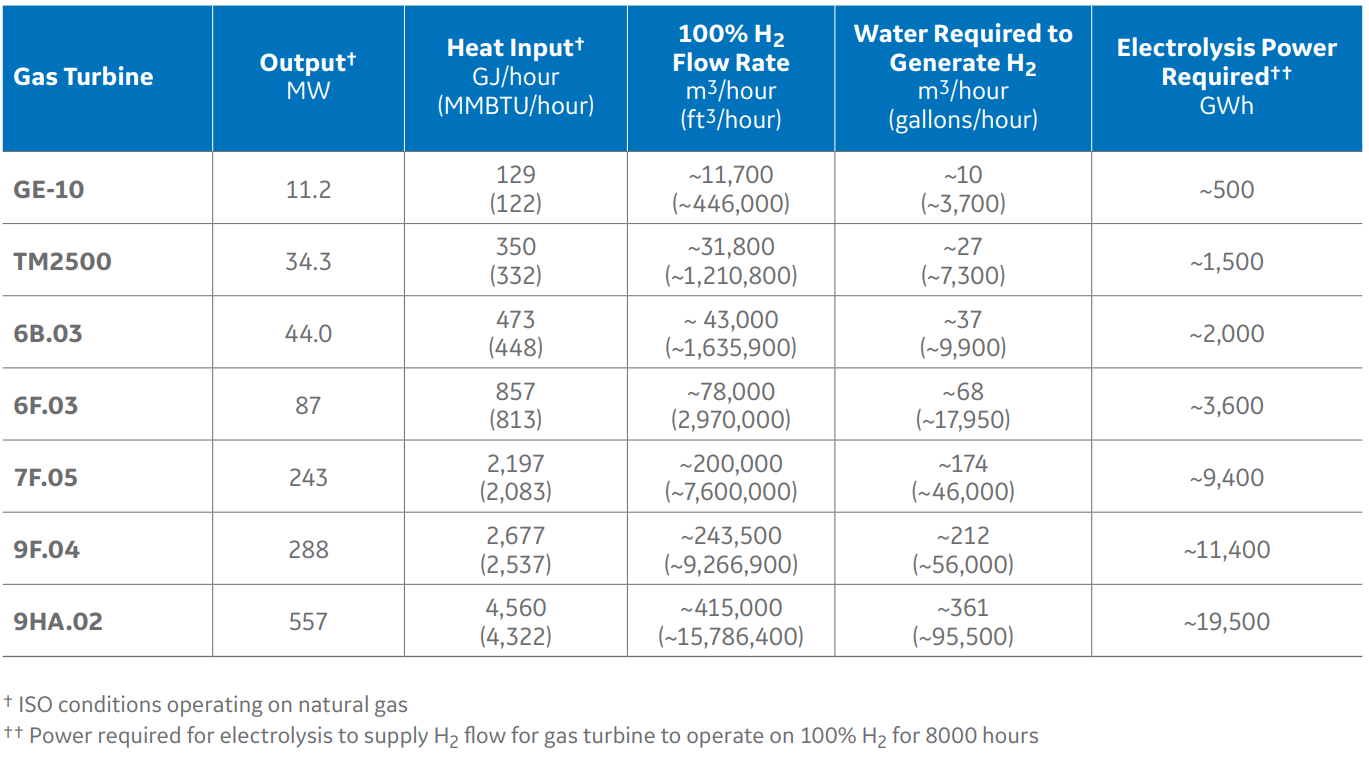

One mole of hydrogen and one-half mole of oxygen are produced for every mole of water used in this reaction. Using the molecular weights of each component, each gram of water would produce 0.11 grams of hydrogen and 0.89 grams of oxygen. (Note how the total mass remains constant.) In other words, considering no losses in the electrolysis process, producing 1 gram (1 kg) of hydrogen requires 9 grams (9 kg) of water. It is possible to determine the amount of water needed to support the power to hydrogen principle using this knowledge.

The table below shows how much water is required to produce enough hydrogen to run various GE gas turbines (according to their reports) on 100 percent hydrogen. For comparison, an Olympic-sized swimming pool requires 2500 m3 of water; an electrolyzer producing hydrogen for a typical gas turbine will use the same amount of water in around 250 hours (just over 10 days).

Not only running a gas turbine on a hydrogen/natural gas blend instead of 100 percent hydrogen minimize hydrogen flows, but it also decreases the amount of water needed to produce the hydrogen.

Electrolysis often necessitates the use of electricity to break the water molecules apart. The higher heating value (HHV) of hydrogen divided by the electrolyzer system efficiency determines the amount of power required:

“Electrolyzer Power” = HHV/\eta

Hydrogen has an HHV of 12,756.2 kJ/Nm3 (141,829.6 kJ/kg), which translates to 3.54 kWh/Nm3 (39.39 kWh/kg). Water to hydrogen conversion requires 5.45 kWh/m3 (60.61 kWh/kg), assuming a 65 percent efficiency electrolyzer system, which is commercially available technology. Increasing the electrolyzer’s performance, as well as running the gas turbine on a mixture of hydrogen and natural gas, would reduce some of the power requirements.

Renewable Power for Hydrogen Generation

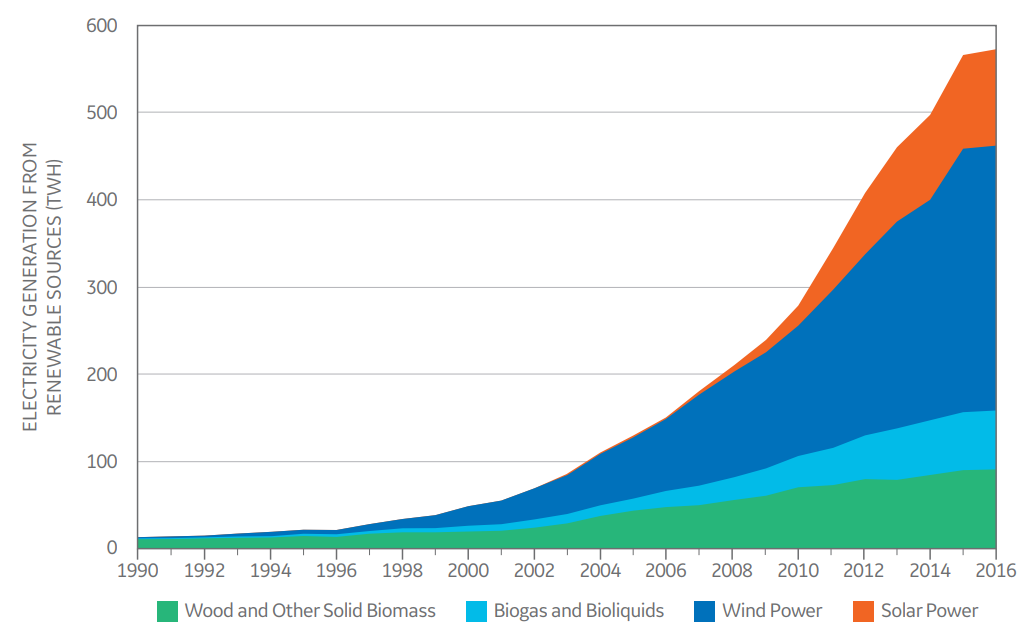

A significant amount of carbon-free electricity would be needed to support the idea of producing hydrogen with electrolysis using renewable power (also known as the power to hydrogen). The great news is that the global push for carbon-free energy has resulted in an unparalleled increase in renewable energy output, as shown by statistics on renewable energy generation. The amount of electricity produced in Europe from renewables, such as wind and solar, has risen from 12.6 terawatt hours (TWh) in 1990 to over 570 TWh in 2016.

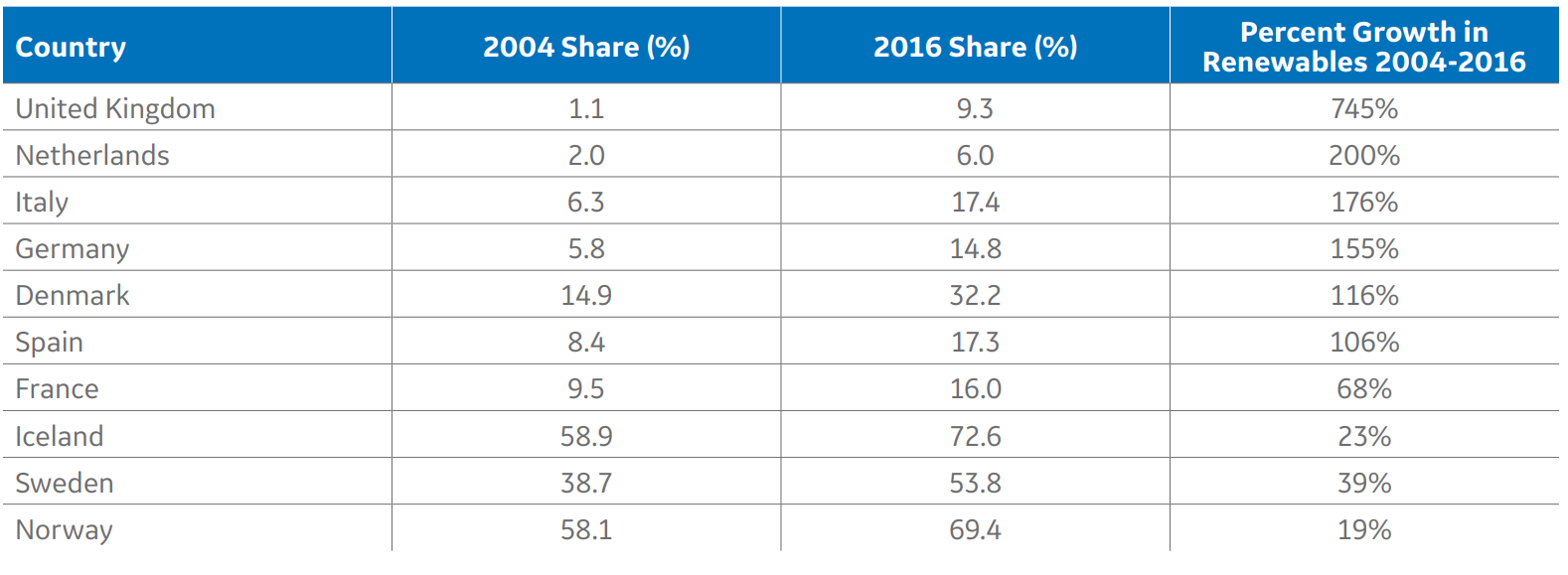

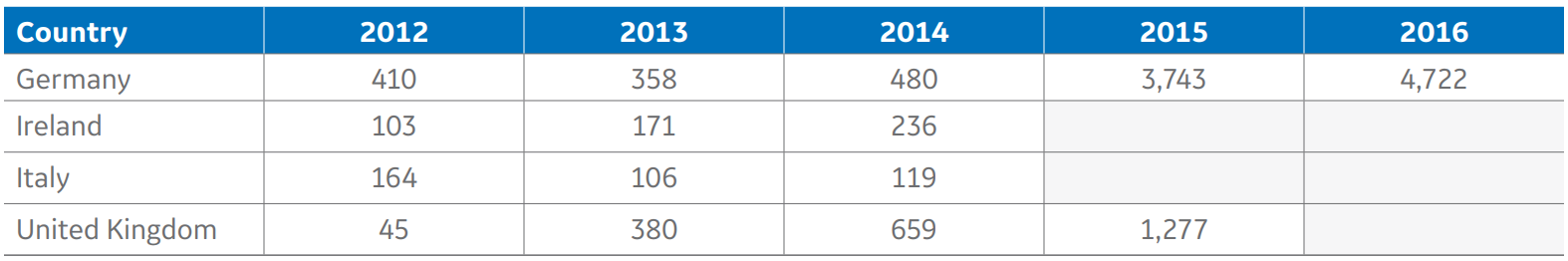

Not only was the overall (or absolute) amount of power generated by renewable sources growing, but the percentage of renewable power generated was the same compared to total grid power. The following table shows the development of renewable energy in a number of European countries between 2004 and 2016. It’s worth noting that numerous countries with the smallest increases in renewable penetration (such as Iceland, Norway, and Sweden) already had high rates of renewable electricity generation in 2004. In 2017, the increase in installed renewable capacity continued. According to Wind Europe, 6 GW of solar capacity was added in 2017, along with 15.6 GW of wind power capacity. In Europe, the established wind power capacity is now projected to be 169 GW.

A key to utilizing renewable sources to produce hydrogen is having excess power, above and beyond that which is required for electrical demand. One way to gauge this capability is with the curtailment of renewable sources. The following table shows wind curtailment for Germany, Ireland, Italy, and the UK between 2012 and 2016; data were not available for all countries in all years.

There is potential to use excess renewable energy to help power hydrogen systems, given the rapid increase in the use of renewable power sources. The power needed for electrolysis of water to provide hydrogen for energy production in an F or H class gas turbine, on the other hand, is greater than the renewable power curtailed. As a result, developing an energy environment that produces vast quantities of hydrogen used in power generation would necessitate even more renewable energy.

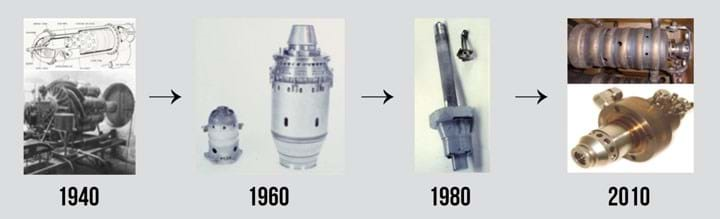

Hydrogen Combustion Evolution

For several years, the heat from coal-burning was used to boil water, superheat the steam, and then extend it via a turbine/alternator to generate electricity. The Rankine Cycle is a form of traditional power generation.

Another method for generating electricity was to burn natural gas in compressed air, extend the hot combustion products through a power turbine, and use the shaft power to drive both the compressor and the generator, a process known as the Gas Turbine arrangement (Brayton Cycle).

Additional energy can be generated by raising steam and producing additional electricity in a turbine/alternator utilizing hot exhaust gases. A Combined Cycle Gas Turbine is the name given to this combination (CCGT).

Two technical routes were created after environmental damage to trees and land was related to sulfur dioxide (SO2) emissions from power plants’ coal flue gas. One choice was to scrub SO2 from the flue gas, while the other was to gasify the coal to create a synthetic gas (Syngas, a mixture of carbon monoxide and hydrogen). Syngas is pumped into a Gas Turbine, which burns in the same way as natural gas. The sulfur species will be removed from the syngas using chemical processes designed for the petrochemical industry. Integrated Gasification Combined Cycle was the name of this operation (IGCC). Since the characteristics of the fuel gas differed, different combustion arrangements for the Gas Turbines were required.

Meanwhile, NOx development has sparked health and environmental concerns. Low-NOx burners and selective catalytic reduction were used in coal-fired power plants. Gas turbine manufacturers designed low-NOx burners for older models (in diffusion-type burners) that used water or steam injection (so-called “wet” systems), and then “dry” versions for modern machines that used staged or lean premix combustion techniques (so-called “Dry Low Emission”, or DLE burners).

The DLE path is appealing because it prevents the use of water or steam:

- To prevent impurities from depositing on the expansion turbine blades and reducing cooling, resulting in hot spots, water purity standards are extremely stringent.

- Water is released as steam along with the exhaust gases, costing the plant money.

- Water is recognized as a limited resource, and commercial freshwater use must be reduced in order to protect it.

- A conspicuous plume may occur under certain climatic conditions which should be avoided if at all possible.

- The lifespan of turbine blades is shortened by water injection and also by steam injection.

- The amount of water needed is significant, and it is often impossible to achieve the same rate of pollution reduction as “dry” techniques.

On the bright side, enhanced mass flow through the expansion turbine and as the water blinked off resulted in some power enhancement. Wet combustors are presently the only option for some fuels, particularly if very low NOx emissions are needed.

When global warming was related to increasing CO2 levels in the atmosphere, one of the key causes was described as pollution from power plant coal flue gas. Two technical paths were established once more. One was CO2 capture after combustion, which involved scrubbing CO2 from flue gas emitted by traditional power plants.

The other is pre-combustion capture, which entails separating hydrogen from syngas from IGCC plants and feeding it into a gas turbine to be burned like natural gas. The CO2 and SO2 could be washed out together. Due to the very different features of hydrogen as a fuel gas compared to natural gas, even further modifications to the combustion system, as well as modifications to the auxiliary systems, will be needed.

For the Gas Turbines, two paths were taken once again. The first was to improve water- or steam-injected diffusion burners for hydrogen use, while the second was to redesign DLE burners to burn hydrogen. Manufacturers are working on both approaches, with DLE being the ultimate target because it avoids all of the drawbacks listed above.

Even as enhanced designs continue to become popular, examples of each stage of improvement in the combustion process are still in use today.

Large Gas Turbines

The larger devices have different capabilities for natural gas/hydrogen mixtures depending on the type of combustor installed. Siemens has tested its F-class machines with hydrogen levels in the fuel gas varying from 30% to 73%. The results of the tests revealed that the pollution and activity goals could be met.

Light Industrial Gas Turbines

Siemens has put a lot of work into designing some of its smaller industrial Gas Turbines to run on natural gas/hydrogen mixtures, both for diffusion and DLE combustors. Work in this area is still going on, specifically with the DLE burners, and increased hydrogen capabilities are being looked into.

Introducing up to 30 vol percent hydrogen into the Natural Gas system would seem not to be a technical issue for most of these smaller Gas Turbines fitted with DLE combustors, but above that, some changes from the arrangement designed for Natural Gas would be needed. However, it has been demonstrated that the DLE combustor design used on turbines in the 25 MW–57 MW range (Simple Cycle, Natural Gas fuel) can burn up to 60% hydrogen (40 percent Natural Gas). Low NOx output at 100 percent hydrogen is currently being developed, with completion expected in the mid-2020s.

Aeroderivative Gas Turbines

With water injection and diffusion combustors for NOx control, the SGT-A35 (27.2–32.1MWe) aero-derivative with a DLE combustor can handle 15 vol percent hydrogen in the Natural Gas fuel, but with diffusion combustors and water injection for NOx control, the SGT-A35 and SGT-A65 (53.1–66MW) can handle up to 100 vol percent hydrogen. (With Natural Gas fuel at ISO conditions, all Gas Turbine performance figures are in Simple Cycle and based on configuration and model.)

High-Volume Hydrogen Gas Turbines

In preparing a large-scale power sector shift toward decarbonization, many major power equipment manufacturers are designing gas turbines running on a high-hydrogen-volume fuel.

Efforts by companies such as Mitsubishi Hitachi Power Systems (MHPS), GE Power, Siemens Energy, and Ansaldo Energia to build 100 percent hydrogen-fueled gas turbines have recently shifted into high gear, according to several experts, owing in part to new carbon reduction policies around the world that have accelerated renewables capability. The firms, which all make large gas turbines but are fighting for a share of a shrinking market, are also vying for a foothold in potential markets, including those that could prosper in a hydrogen economy.

Experts point out that hydrogen is odorless and nontoxic, and it has the highest energy content of common fuels by weight, allowing it to be used as an energy carrier in a wide variety of applications, from transportation and industry to power generation. The hydrogen industry is well-established in sectors using it as a feedstock, despite the fact that it is not discovered freely in nature and must be extracted (created, or “reformed”) through a separate energy source (such as light, electricity, or heat). However, as main technologies for producing hydrogen using renewable electricity, such as proton exchange membrane electrolyzer and fuel cells, achieve technological maturity and economies of scale, hydrogen is increasingly being seen as the missing link in the energy transition.

Gearing Up for a Hydrogen Society

MHPS, a joint venture among Mitsubishi Heavy Industries and Hitachi, has been particularly outspoken about its attempts to comply with Japan’s plans to become a “hydrogen society,” which were declared in the outcome of the Fukushima Daiichi nuclear plant meltdown in 2011. The government-industry partnership will be divided into three phases: first, it will expand its existing fuel cell initiative to help lower hydrogen and fuel cell prices; second, it plans to introduce large-scale hydrogen electricity production and hydrogen supply infrastructure; and eventually, it will provide a zero-carbon supply system in the production process.

MHPS presented a business case for increased hydrogen usage in the power sector at IHS Markit’s CERAWeek in Houston in March 2019, stating that it wants to make hydrogen-fired gas turbines a key component of a “world CO2-free hydrogen society using renewable energy by 2050.” Although natural gas will continue to play a significant role in addressing variability from renewables, the next step of growth “will include energy storage using hydrogen,” according to MHPS President and CEO Paul Browning. He clarified that hydrogen production from renewables through electrolysis—which uses excess renewable energy to break a water molecule—allows the “renewable hydrogen” to be deposited and used later in a combined cycle gas turbine (CCGT).

Since 1970, MHPS has tested 29 gas turbine units with hydrogen content ranging from 30 percent to 90 percent, totaling over 3.5 million operating hours. One of the company’s biggest problems was lowering the high NOx emissions associated with hydrogen combustion without sacrificing performance. Since hydrogen has a faster flame than natural gas, MHPS wanted to lower the risk of combustion oscillation and “flashback” (backfire) in higher hydrogen mixtures.

One approach was to create a “diffusion combustor” that injects fuel into the air using the company’s dry low-NOx (DLN) technology. The combustor decreases NOx emissions by injecting steam or water, but it maintains a reasonably broad range of stable combustion, even though fuel properties vary by up to 90%. According to the company, it can manage an output equivalent of 700 MW (in combined cycle form with a turbine inlet temperature of 1,600C) and minimize carbon emissions by about 10% compared to a traditional CCGT when fired with 30% hydrogen.

By 2023, MHPS plans to convert one of three units at Vattenfall’s 1.3-GW Magnum combined cycle plant in the Netherlands to renewable hydrogen. The Groningen project, which involves changing a 440-MW M701F gas turbine, would optimize combustion technology “to remain inside the same NOx envelope as a natural gas power plant but do it burning 100 percent hydrogen,” Browning said. He predicted that 100 percent would be achieved “within the next decade.”

Nonetheless, the project is critical to MHPS’s goal of providing customers with gas turbines that can be modified to run entirely on hydrogen, he said. He admitted that a hydrogen-fired gas turbine would likely require on-site electrolysis and storage for renewable hydrogen supply, which would necessitate a “very low cost of electricity.” “What we’re looking for is enough renewables penetration on electrical grids to make [on-site electrolysis] economically viable,” he said. “California is on its way there right now, but other states have a long to go.”

“We think lithium-ion batteries will plausibly be the best option if you want to store electricity for shorter periods of time,” Browning said when asked how the technology will survive against advances in battery storage. He acknowledged that the economics of hydrogen “will function no matter how long you store it.”

The Future of Hydrogen Gas Turbine

The difficulty with hydrogen gas turbines is that they must operate without sacrificing performance, startup times, or NOx emissions. This is accomplished by creating combustor designs that use a higher proportion of hydrogen in natural gas.

As the hydrogen economy develops over the next decade, Gas Turbines will be able to meet the market’s needs without compromising today’s high-performance standards in terms of emissions, response, and productivity.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Raed More on Linquip

-

- What is Tesla Turbine and How Does it Works

- The 8 Best Home Wind Turbines in 2021

- Axial Flow Turbines and Working Principles

- Power Solutions for the Crypto Mining Industry

- Radial Flow Turbine

- Low Head Turbines

- Mixed Flow Turbine

- Types of Turbines: Classifications and Types

- Combined Cycle Gas Turbine

- Open Cycle Gas Turbine

- Closed Cycle Gas Turbine

- More Information about GE Frame 7 Gas Turbine

- See List of Gas Turbine Products

- See List of Siemens Gas Turbine Products

- See List of General Electric (GE Power) Gas Turbine Products

I have read this article with great interest and would like to contribute to the design processes. I have one question at this point.

How in the hell are we talking about NOx production within a 100% Hydrogen fuelling system unless this is of course derived from the air intake to the turbine, air being 77% nitrogen in composition?.

I should like to actively participate in this quest. It’s the only forward in my opinion and we need to do it now, not waffle about it forever ( waffle being the domain of the politicians ).

Yours faithfully.

Richard Allen.