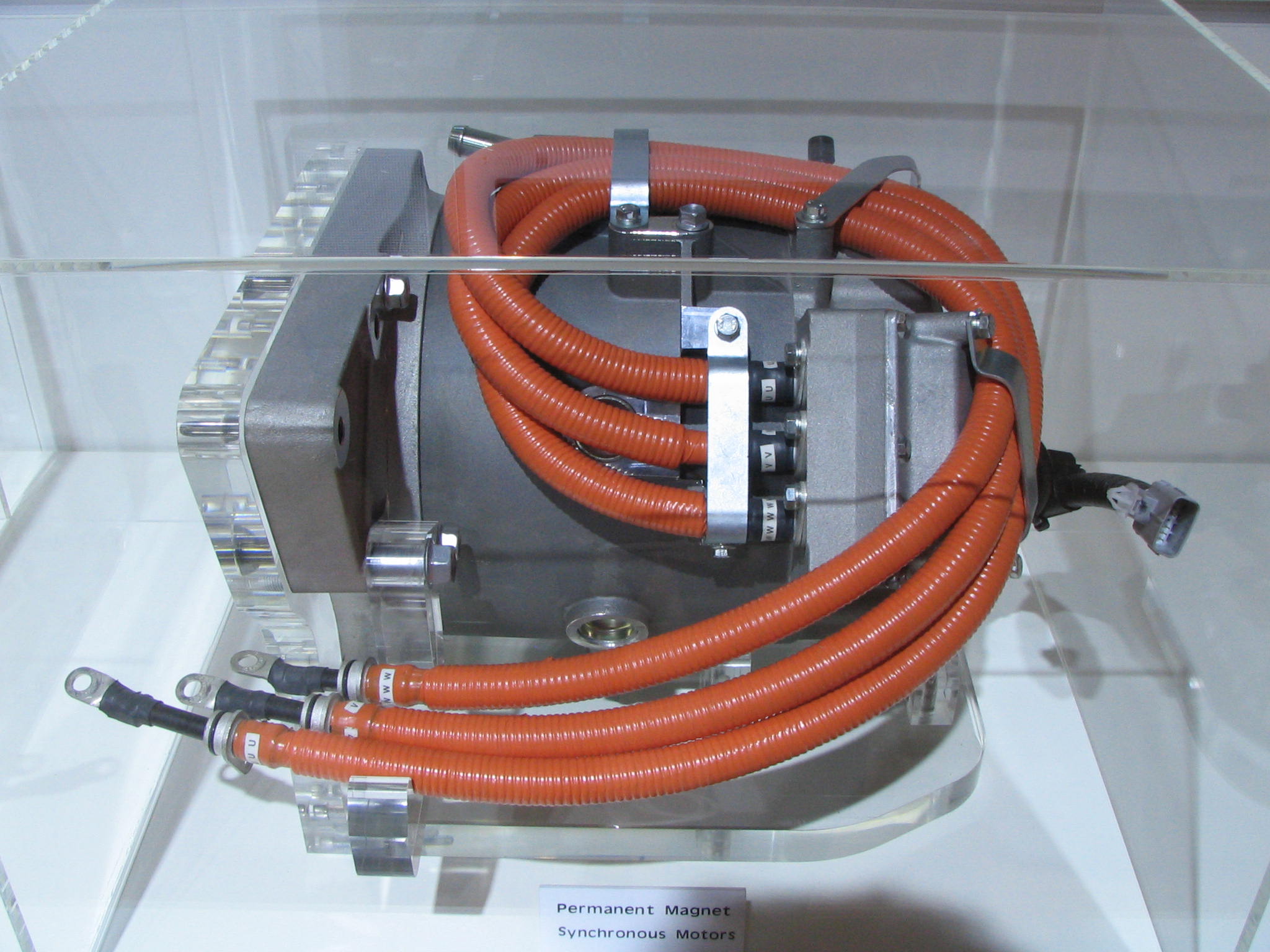

The Permanent Magnet Synchronous Motor (PMSM) is an AC synchronous motor whose field excitation is provided by permanent magnets. The permanent magnet synchronous motors are very efficient, brushless, very fast, safe, and give a high dynamic performance. Due to their advantages, permanent synchronous motors have many applications and find use in several fields.

A permanent magnet synchronous motor (PMSM) is a synchronous electric motor with permanent magnets as the inductor. In industrial applications, the Permanent Magnet Synchronous Motor is an Important Product. Permanent Magnet Synchronous Motors are available from a variety of suppliers and companies, as well as Manufacturers and Distributors, with several Synchronous Motors for Sale on Linquip.

There is a comprehensive list of Synchronous Motor services on the Linquip website that covers all of your needs. Linquip can connect you with a number of industrial Synchronous Motor professionals and service suppliers. Linquip offers a team of Synchronous Motor Experts available to help you test your equipment.

Follow this new blog in Linquip to find out more about permanent magnet synchronous motors.

What Is a Permanent Magnet Synchronous motor?

Permanent Magnet Synchronous Motor (PMSM) is brushless and has very high reliability and efficiency. Due to its permanent magnet rotor, it also has a high torque with a small frame size and no rotor current. Instead of using winding for the rotor, permanent magnets are mounted to create a rotating magnetic field. As there is no supply of DC source, these types of motors are very simple and less cost. The permanent magnet synchronous motors are AC synchronous motor whose field excitation is provided by permanent magnets and that has a sinusoidal back EMF waveform. The permanent magnets enable the PMSM to generate torque at zero speed. This motor delivers high-efficiency operations and requires a digitally controlled inverter.

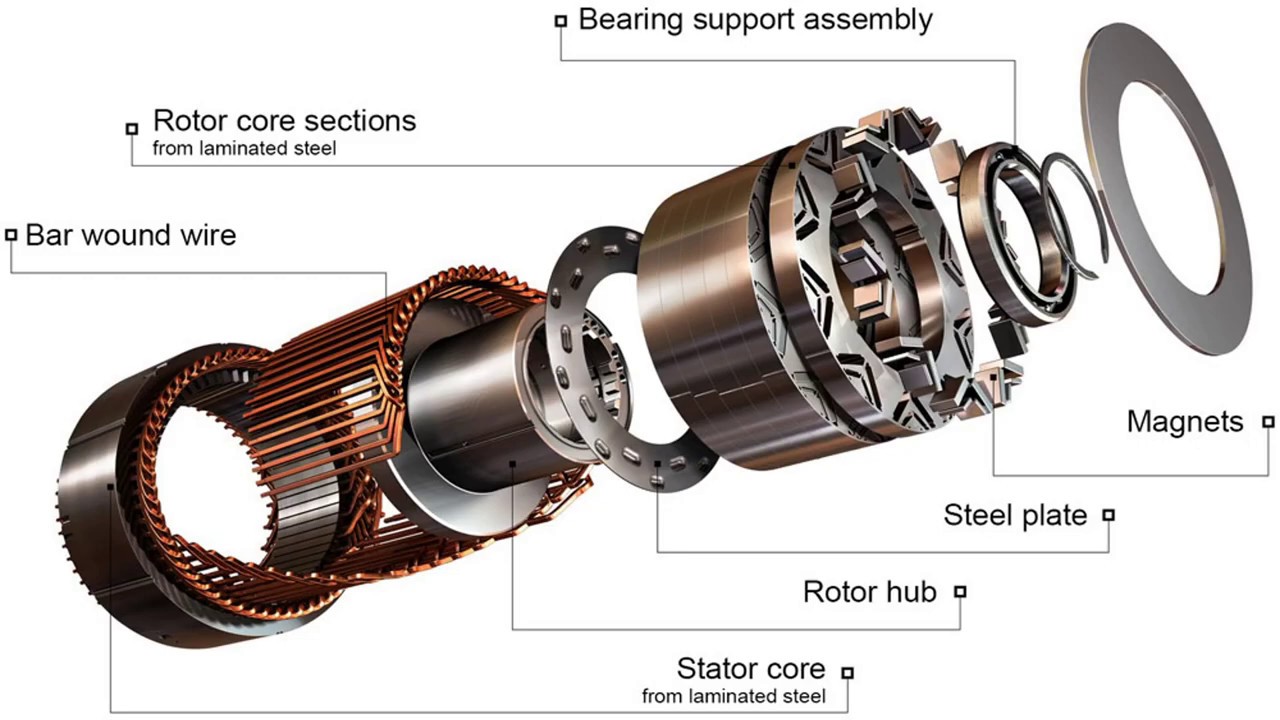

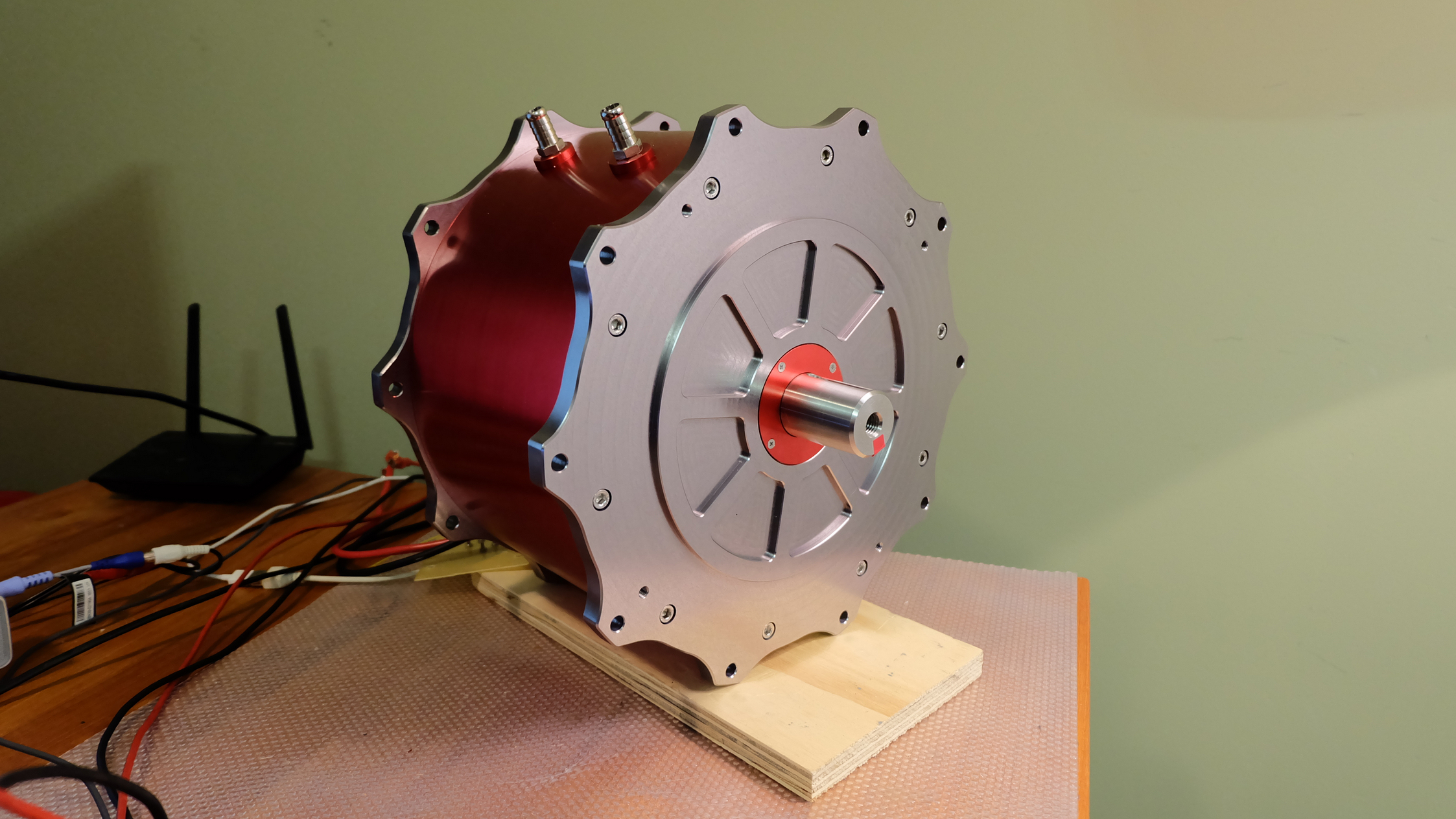

Construction

The permanent magnet synchronous motors, like any rotating electric motor, are consisted of a rotor and a stator. The permanent magnet synchronous motor construction is similar to the basic synchronous motor, but the only difference is with the rotor. In this type of motor, the permanent magnets are mounted on the rotor and the rotor doesn’t have any field winding.

The permanent magnets are used to create field poles. The permanent magnets used in the motor are made up of samarium-cobalt and medium, iron, and boron because of their higher permeability. The most widely used permanent magnet is neodymium-boron-iron because of its effective cost and ease of availability.

Working Principle

The permanent magnet synchronous motors working principle is similar to the synchronous motor. The principle of operation is based on the interaction of the rotating magnetic field of the stator and the constant magnetic field of the rotor. It depends on the rotating magnetic field that generates electromotive force at synchronous speed.

When the stator winding is energized by giving the 3-phase supply, a rotating magnetic field is created in between the air gaps. This produces the torque when the rotor field poles hold the rotating magnetic field at synchronous speed and the rotor rotates continuously. As these motors are not self-starting, it is necessary to provide a variable frequency power supply.

Characteristics

- No sparks, safer in explosive environments

- Clean, fast, and efficient

- More compact, efficient, and lighter than an ACIM

- Designed for high-performance servo applications

- Runs with/without position encoders

- Low audible noise and EMI

- Smooth low- and high-speed performance

- Produces optimal torque when coupled with Field-Oriented Control (FOC)

Types

Depending on how magnets are attached to the rotor and the design of the rotor, permanent magnet synchronous motor can be classified into two types:

- Surface permanent magnet synchronous motor (SPMSM)

- Interior permanent magnet synchronous motor (IPMSM).

SPMSM mounts all magnet pieces on the surface, and IPMSM places magnets inside the rotor.

Also, depending on the stator design, a permanent magnet synchronous motor can be:

- With distributed winding

- With concentrated winding

Permanent Magnet Synchronous Motor Control

Because permanent magnet synchronous motors must be driven with sinusoidal waveforms, the complexity of the control increases. A permanent magnet synchronous motor requires a control system, for example, a variable frequency drive or a servo drive.

There are a large number of control techniques implemented control systems. The choice of the optimal control method mainly depends on the task that is put in front of the electric drive. To solve simple tasks is usually used trapezoidal control with Hall sensors. To solve problems that require maximum performance from the electric drive, field-oriented control is usually selected.

Do Synchronous Motors Have Permanent Magnets?

Permanent magnets placed in the steel rotor provide a continuous magnetic field in a permanent-magnet synchronous motor (PMSM). A revolving magnetic field is created by windings coupled to an AC source in the stator (as in an asynchronous motor).

Advantages

The advantages of permanent magnet synchronous motor include,

- Dynamic performance in both high and low-speed operation

- High power density

- Low rotor inertia makes it easy to control

- No torque ripple when the motor is commutated

- High and smooth torque

- High efficiency at high speeds

- Resistant to wear and tear

- Available in small sizes at different packages

- Easy maintenance and installation

- Capable of maintaining full torque at low speeds

- High reliability

- Efficient dissipation of heat

- Less noisy

Disadvantages

The disadvantages of permanent magnet synchronous motors are

- High initial cost

- Very expensive

- Difficult to start up because it is not a self-starting motor

Applications

The permanent magnet synchronous motors applications are

- Air conditioners

- Refrigerators

- AC compressors

- Direct-drive washing machines

- Automotive electrical power steering

- Machine tools

- Control of traction

- Data storage units

- Servo drives

- Electric vehicle drivetrain

- Large power systems to improve leading, and lagging power factor

- Industrial applications like robotics, aerospace, and many more.

Thus, here is all about an overview of the permanent magnet synchronous motors. If you enjoyed this article in Linquip, let us know by leaving a reply in the comment section. Is there any question we can help you through? Feel free to sign up on our website to get the most professional advice from our experts.

Download Permanent Magnet Synchronous Motors PDF

Read More on Linquip

- Working Principle of Induction Motor: 2022 Full Guide

- The Construction of Synchronous Motor: All the Necessary Details You want to Read About

- Types of Synchronous Motors: A Full Description

- Why Synchronous Motor is Not Self Starting ?

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- 10 Types of CNC Machine + Applications & PDF

- 13 Parts of CNC Machine + Function & PDF: A Clear Guide

- What Is CNC Machining & How Does It Work? (A Comprehensive Guide)

- Working Principle Of DC Motor: 2022 Complete Guide

- Working Principle of Stepper Motor: 2022 Ultimate Guide

- Working Principle of AC Motor: 2022 Ultimate Guide

- Working Principle of Induction Motor: 2022 Full Guide

- DC Motor Efficiency: Calculation: Formula & Equation

Thank you for your useful information

Thanks for the article. Very informative.

Thanks for visiting our website and leaving your comment, Tek! You are encouraged to visit Linquip Tech News, where you can find similar posts.

Hello,I wonder why an ac motor needs a cooling fan,and a PMSM motor doesn’t have one.

Thanks for visiting our website, Abel! You can visit our expert page and take advice from hundreds of professionals on your issue.