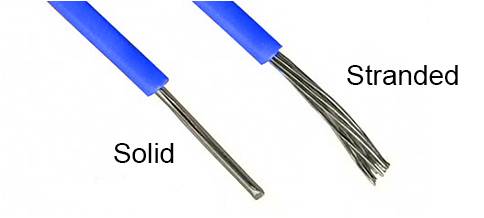

Solid vs Stranded Wire – Wire harnesses and cable assemblies, among other electrical devices, frequently utilize solid and stranded wires. While the stranded wire is made up of multiple thinner wires twisted together to form a bundle, solid wires have a solid core. Each has unique advantages, and the best option for a given application depends on the particulars of the project.

On the Linquip website, among the many options available to you, you will find all the information you need to know about Wires, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Wires for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is Stranded Wire?

Stranded wires are more flexible, complex, and delicate because they are bundled. They work well inside when bending and twisting are required to connect electrical components, such as on circuit boards, speaker cables, electronic gadgets, etc. For instance, stranded wire is best used in a car door because of the constant bending that will take place there.

What is a Solid Wire?

Solid wire is more durable, heavier, resistant to corrosion, robust, and able to sustain a frequent but slight movement. As electricity transmission via a building structure necessitates a high current, little movement, and long-lasting durability, this is a perfect use for solid wire.

Solid vs. Stranded Wires: The Major Distinctions

Examining the benefits and drawbacks of the two distinctly different types of wire is necessary when comparing stranded and solid wire. The options are reduced via comparison based on how the unique qualities of the wires relate to their anticipated use and the project requirements. You must first decide whether weather resistance, elasticity, and resistance to splitting or severing standards apply to your application. Then determine what wire best satisfies those requirements.

Among the main distinctions between solid and stranded copper wire are the following:

- The current capacity of stranded vs. solid wire: The greater thickness of solid wire results in less surface area for dissipation. In stranded wire, the thinner wires have air gaps and larger surface area due to the individual strands, which results in increased dissipation. The solid wire gives a larger current capacity when deciding between solid and stranded wire for residential wiring.

- Routing: Stranded wires are more flexible and bendable than solid wires, making it simpler to route them around obstructions.

- Flexibility: Wires with strands are more flexible and can withstand greater flexing and vibration without breaking. In situations where there is a lot of movement or vibration, solid wires might need to be replaced more frequently than stranded wires.

- Cost: Solid wire is more cost-effective than stranded wire since its production costs are so much lower.

- Ease of Production: Solid wire is significantly easier to create because it is single-core in nature. More difficult production procedures are needed to twist the thinner wires together to form stranded wires.

- Distance: Solid wires are preferable for longer distances since they have less current dissipation. Shorter lengths will see a good performance with stranded wire.

- Superiority: There is no obvious winner when deciding between the stranded and solid wire. Every choice has unique benefits under special circumstances.

Solid And Stranded Wire’s Capacity For Carrying Current

The solid wire will carry more current than the stranded wire if the diameter of both wires is the same. This is due to the air gap that exists between the conductor strands of stranded wire, which causes its cross-sectional area to be larger than that of solid wire. Because of this, an electrician must choose the right wire size depending on the wire gauge and ampacity needed for the intended application.

Another occurrence in AC current with frequency is the skin effect when the current flows on the conductor’s outer surface rather than the entire conductor. For high-power transmission, they do it using stranded wires. However, in the case of copper wire (up to 6mm) used for household wiring with a frequency of 50/60 Hz, skin depth may be disregarded.

Download Solid vs Stranded Wire PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip