Disc Insulator_ We see many electrical overhead systems outside. All of them have different electrical components, same as an insulator, conductor, and electrical pole or tower. This overhead system is employed for transmission as well as the distribution of electricity. To provide the insulation between the line conductor and earth to prevent the leakage current, there is an electrical device called an insulator. So, the insulating element plays a vital role in building different circuits and power systems. It offers high resistance so that the electrical current can not supply from one region to another. Different types of insulators are employed in transmission and distribution systems, namely pin, strain, post, stay, shackle, and disc insulator.

What is a Disc Insulator?

As the name suggests, the type of insulator with a disk-shaped geometry is called disk insulators. These insulators are utilized in the transmission of electric power and distribution systems. There are many designs for these insulators, mainly based on customer requirements. Every electrical insulator covers the following features:

- Mechanical properties should be sufficient to bear the conductor load.

- High resistivity.

- Dielectric strength must be high.

- Insulation materials are relatively high permittivity substances.

- They usually use non-porous or waterproof materials.

The design of a certain insulator can be provided using diverse materials depending on the application, such as wood, mica, rubber, plastic, glass, etc. The primary insulating materials in electrical systems are glass, polymer, porcelain, steatite, ceramic, PVC, etc. The porcelain insulators are the best in power systems and are widely used in transmission and distribution systems. Glass-type materials are used in strain/ suspension type insulators.

Types of Disc Insulators

Disc insulators can be classified into two types of suspension disk insulators and strain disk insulators.

Suspension Disk Insulator

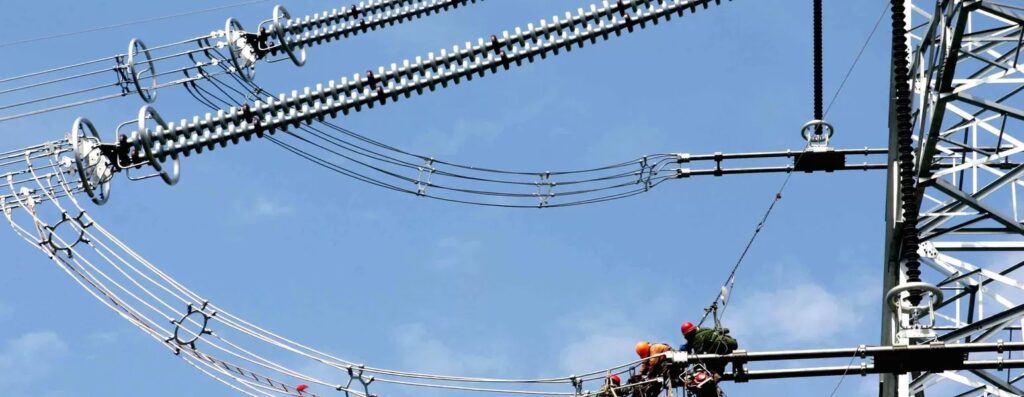

A suspension Disk insulator is usually made of insulating parts (e.g. porcelain and glass parts) with metal accessories (e.g. steel feet, flanges, iron caps, etc.) mechanically clamped or glued. We can find suspension Disc Insulator in power systems widely. They commonly refer to work under atmospheric conditions and external insulations.

As one of the vital equipment in transmission lines, the disc suspension insulator has the critical task of fixing wires and insulating the towers. Suspension disc Insulators can be used in high voltage and ultra-high voltage transmission lines worldwide to guarantee the reliable operation of transmission lines.

The disk-shaped suspension insulators are the most common and well-known type of line insulators. This insulator is made of porcelain insulators, an iron cap, and fittings assembled by cement. The iron cap, the spindle, and the cement connection are coated with a thin buffer film (frequently asphalt). There is a flexible liner between the porcelain body and spindle top. We have two types of suspension disc insulator: slot type connection and ball-and-socket connection.

The Slot Type Connection Structure

They are frequently used in low voltage lines. For ensuring that the insulators do not fall off from the string, each insulator is connected with a locking device, a cylinder pin is applied in the slot connection, and a humpback pin or a split pin is used for locking.

The Ball-and-Socket Connection

This type is non-directional and has the benefits of easy fitting and disassembly of the groove housing, incredibly convenient for replacing insulators on line. Consequently, the ball-and-socket connection assembly is usually used on the high voltage and ultra-high voltage lines.

Strain Disk Insulator

A strain disk insulator is also identified as a tension insulator. These insulators are employed in overhead electrical line for supporting radio antennas and overhead power lines. The discs are combined in a horizontal position. In some cases, many strain insulators are used by combining them in parallel. So two strings are attached through two yokes.

Fog Type Disc insulator

The disk insulators have a long underside of the umbrella, making it achieve a large creepage distance. The inner cavity below the umbrella is not responsive to moisture. It has a high pollution tolerance voltage; therefore, it is more proper to be used on AC and DC power transmission lines in humid areas, coastal areas, and saline-alkali areas.

Anti-Pollution Disc Insulator (Double Sheds)

Disc insulator with umbrella shape is smooth without edges beneath the umbrella and makes an open shape. As a result, they have excellent self-cleaning performance against wind and rain with a large creepage distance and a low natural pollution accumulation rate. The umbrella shape has a significant pollution and pressure resistance level, making them adopted in a dusty environment. The other geometry for disk insulator is the umbrellalike shape which is identified as “aerodynamics”. They are used in diverse operating conditions, particularly for AC and DC transmission lines in high altitude heavy pollution and desert areas.

Advantages and Disadvantages of Disc Insulator

We can name the following advantages for disc insulators:

- This insulator works at normal voltage rats similar to 11KV. A suspension long string can be designed with an assemblage of discs.

- If any of the discs are damaged in suspension disk insulators, it can be replaced much simply.

- Mechanical pressures on them are less because of the hanging line on a flexible suspension string.

- This kind of insulators can be used at higher voltages by combining discs separately.

- Repair is much easier as we can change just the damaged unit.

- It is a good shield for electricity and heat.

- It provides good support to the overhead conductors.

- We can use it in a substation to protect the switchgear, transformer, etc.

We can name the following disadvantages for disc insulators:

- The string of insulator is costly compared to the post and pin type insulators.

- They need more height for the supporting tower and also to keep similar ground permission of the conductor.

- They need cross arms with a high length.

- The tower must be much stronger to withstand the insulator’s weight.

Applications for Disc Insulators

We can use disk insulators in:

- Industrial applications

- Transmission systems

- Distribution lines

Commercial and domestic applications

Frequently Asked Questions

1) What is an Insulator?

The materials with the properties of blocking current flow are known as an insulator.

2) Why do We Use an Insulator?

It protects the devices by opposing the flow of current.

3) How are Disc Insulators Made?

Based on the material, they can be produced in many different ways. Porcelain is the most common material for their production

4) What are the Kinds of Disc Insulators?

They can be categorized into suspension and strain disk insulators.

5) What is the Best Insulator in the World?

Aerogel is the best insulator known because of the less thermal conductivities.

For 3 megawatt load how many Kn disc insulator required

Thanks for visiting our website. You can ask your question from hundreds of professionals available in our expert page.