In this article from Linquip, we will explain alternator function and describe all you need to know about how it works. And even if you want to know the alternator components, this article would be your go-to guide! Are you ready to expand your knowledge? Then continue reading…

What is an alternator?

The charging system inside a vehicle contains three major components that are the voltage regulator, the battery, and an alternator! Alternators are called so because they provide AC which is alternating current! There are different things that alternators do such as recharging the battery, converting mechanical energy into electrical energy, powering accessories inside the vehicles, and so on.

Alternator definition is simple. Alternators are systems used to turn mechanical energy into electrical energy for different uses such as in modern automobiles for powering their electrical system while the engine is running or for charging their battery. An example of the electrical components of a vehicle that powers via the alternators is its exterior or interior lights.

Different alternator parts and function

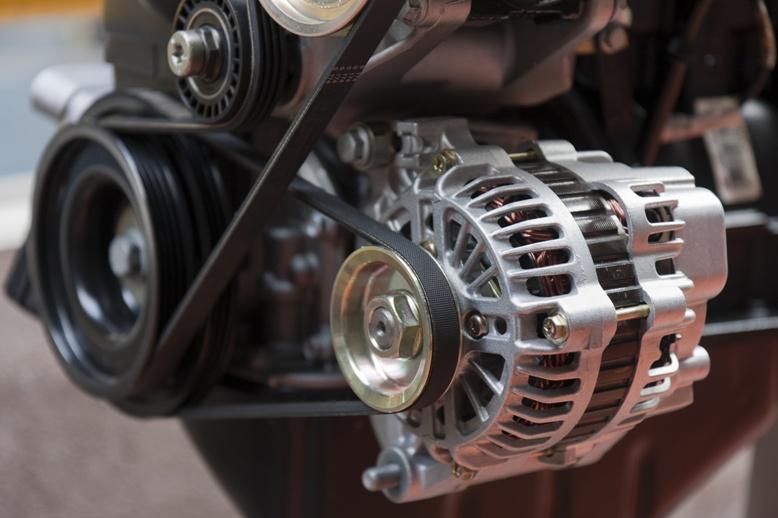

No system works without its parts and alternators are no exception. Different parts make the alternator function possible. These parts are regulator, rectifier, rotor, slip rings, slip ring end bearing, stator, drive end bearing, etc. But how they work together to create a seamless alternator function?

Alternator function

Alternators are considered to be one of the major components of different vehicles in their charging system. They mostly provide electric power for cars that have an internal combustion engine. Alternators charge the vehicle’s battery when the engine is running to supply the additional electric power for its systems. Almost all alternators are mounted with the use of brackets. These brackets are bolt to a specific point of the vehicle’s engine. These two brackets are used differently.

One of them is fixed in the place. The other has been designed in a way that it can be adjusted for tightening the drive belt. The drive belt or serpentine belt drives the alternator which is bolted to the vehicle’s engine. The way that an alternator is put together is quite simple. Alternators are small and they are usually near the engine’s upper part. Alternators are typically made of three major parts: Body or outer housing, a rotor, and a stator. A few vents have been designed in an alternator as well for ventilation purposes.

The body or the part that contains the inner units is made of aluminum since it’s capable of dissipating heat and cannot be magnetized.

Each rotor contains up to 20 magnetic poles connected to a center prime mover which alternate South and North. As you already know by this point, a belt turns the crankshaft of a running engine to power the rotor. This belt in modern vehicles is a serpentine belt. The belt is connected to the prime mover for turning the whole rotor, resulting in the generation of the magnetic flux. Different brushes near the poles produce a magnetic field in each and every one of them and with the help of slip rings that are located around the prime mover, send direct current to these poles. The power that they use is supplied from generators that are attached to the alternators or from an external source of power.

Alternator’s stator contains a system of copper coils that enables the stator to function properly within the whole system. This assembly is usually a three-phase type for many vehicles’ alternator function. It means that three sets of copper coils are evenly spaced and they are at 120 degrees intervals and are also located around the iron shaft. Using a three-phase assembly enables the alternator to provide three times more electricity than one set of copper coils.

With the rotation of the alternator pulley (the unit that’s connected to the drive belt system and the rotor shaft) via the engine, the rotor spins past three copper coils or stationary stator windings, surrounding an iron core that’s fixed in place. This makes up the alternator’s stator. It shows a three-phase current that provides three times more electricity. They are more efficient than single-phase ones which only produce a single-phase AC compared to the three-phase type.

The alternating current in the copper wire is created with the generation of the magnetic flux. The magnetic flux as we mentioned above, is the result of the movement of the rotor.

Since vehicles need DC power, and the alternator provides AC power, a unit is needed for converting this power into the desired one. This brings a diode in the process which is called a Rectifier. This rectifier is responsible for converting AC into DC so that it can be stored and used in the battery of the vehicle. This rectifier sits at the end of the alternator. Two diodes connect to each stator lead for regulating the current that’s fed through these stator leads into the diodes. They are capable of directing or blocking the current. In order to produce DC current that’s the desired product for the vehicle’s battery, diodes only allow current to move in the same direction and work as a one-way valve for the alternator.

The alternator function happens for the final goal of providing electricity for the vehicles. So the produced DC will flow into the vehicle’s battery via several terminals that are located at the back of the alternator. These terminals connect the alternator to the electrical system of the vehicle and that’s how it can be turned on or off and also send the related data to the ECU from its sensors.

New vehicles use ECU for voltage regulation, but with old vehicles, a voltage regulator is needed for regulating the voltage and ensuring that the amount of electricity that flows into the battery stays at the desired level since too much or too little electricity can harm the battery and related electrical components of the vehicle. Regulators have two types that are the Grounded Field type, and the Grounded Regulator. The first one works by controlling the amount of battery positive while the second one controls the battery negative or the battery ground that flows into the rotor’s winding.

So, what about the vents? What do they do in the alternator function process? They are used for ventilation. No need to mention that cooling and ventilation is among one of the critical elements when it comes to alternators. And if you want yours to function properly, it definitely needs vents! Both ends of the alternator contain vents for driving the excess heat away. There are also cooling fans designed to cool down the alternator.

These fans are powered by the drive belt. The airflow in a compact alternator which is used in modern cars is semi-radial. The air enters axially and leaves radially outwards. With better cooling, a smaller machine can receive more power from the alternator. This is usually the case with modern vehicles that use compact alternator layout that has improved cooling system compared to older alternators.

The output current for the older vehicles that have less lighting is somewhere around 30 Amps, while for a typical private car, it’s between 50 to 70 Amps. As the technology grows in the automobile design, its electrical system grows more complex, resulting in a higher demand for higher ratings in the produced output current.

Final Words

As you already guessed, alternators are among the vital components of our vehicles, so you should make sure that they receive the right care. Although they don’t need much maintenance, you still should check the unit once in a while. They have moving units, so they are subject to stress from cold and heat and also get dirty because of their moving parts. That’s how an alternator’s internal components wear out gradually. With the right care, they can last up to 15 years without any problems. What happens if an alternator fails? Well, as soon as the charge of the vehicle’s battery is depleted, the engine will stall.

That’s all there’s to know about alternator function and how it works. Now you can easily understand the inner process of an alternator and how it converts mechanical energy into electricity. If you have anything to share with us and our readers about alternators, write down below and tell us what you think. And if you need any help with your alternator, feel free to sign up on Linquip and our experts will help you right away.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Alternator Function: The Complete and Easy to Understand Guide to How Alternators Work

- What Does an Alternator Do?

- Alternator Construction and Design

- Types of Alternator : Features, Advantages, and Vast Usage

- Alternator vs Generator: Your go-to guide to learn their difference

- Alternator Slip Rings : discover the basic purpose and other detailed forms