Alternator construction enabled us to use our fancy cars without having to worry about running out on electricity quickly.

What is Alternator?

Alternators are types of electrical Generator (AC generator) and are considered as electrical machines for converting mechanical energy into electrical energy. This energy would be in the form of alternating current (AC). They are also called Synchronous Generators.

Different Types of Alternator Based on Design

Alternator construction enables two types of alternator to be designed:

-

Salient Pole Type

This design contains more poles and as a result its rotor diameter is large. Plus, the axial length is smaller in Salient Pole type. This type of alternator has low-speed prime movers such as hydraulic turbines. You can use this design when you need low and medium speed applications like that of hydropower stations or diesel power stations. It is worth mentioning that the Salient Pole rotor can cause excessive windage loss when driven at high speed and its construction is not suitable for high mechanical stress.

-

Cylindrical Pole Type

Unlike Salient Pole type alternator, the alternator construction of Cylindrical Pole type includes either 2 or 4 poles. Due to the number of poles, the rotor diameter is small and yet again unlike the previous one, its axial length is larger. You can use the Cylindrical Pole type alternator when you need high speed. The prime movers of this alternator are of high speed and can be used in steam power stations or gas power stations. The construction of a Cylindrical rotor has mechanical robustness which makes it noiseless when operating at a very high speed.

Alternator Construction

Inside each alternator, you’ll see Pole Core, Rotor, Stator, Air Gap, bearings, fan, slip rings, armature, and Yoke. But they have two major parts: Rotor and Stator. Different parts of the alternator are responsible for a specific purpose toward the end goal of the alternator.

The Yoke is the outer part of the alternator that works like a protector to protect the machine. Plus, it provides mechanical support to the machine as well. The environmental conditions might affect the way internal parts work, therefore, the machine needs a Yoke to protect these inner parts from any damage.

Pole Core includes pole shoe and winding. Pole shoe provides support for windings to rest on the pole shoe.

Alternator Stator, as the name suggests, is stable and never rotates. In the alternator construction of the stator, the armature winding is wound in this stationary part. It is made from an iron ring laminated by silicon steel with slots. The special magnetic material used in stator allows high magnetic permeability as well as low magnetic hysteresis. The core of the stator is laminated which minimizes the effect of eddy current losses. A thin coating of an oxide enables the passing of cool airflow.

The slots change their status depending on the speed of the machine. They can be open, semi-closed, or closed. They rarely change their status to “closed” and are normally open because of the coil’s function.

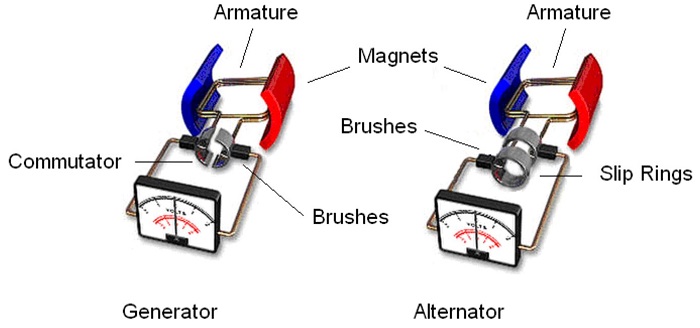

The armature core includes brushes, armature windings, and slip rings. When the coil cuts the magnetic flux, the armature then develops armature current. Brushes collect the current from slip rings. Slip rings in the armature core smooth the operation happening between the brushes, that’s to avoid twisting of the winding.

Bearings can also help to perform a smoother operation. And finally, the fan helps the exhaustion of the heat generated during the running conditions.

Alternator rotor rotates within the stator (armature conductor). This rotor in a synchronous generator carries a field winding supplied by the DC source (also known as exciter).

How does an alternator work?

Alternators work similarly to AC generators. The alternator construction has been designed in a way that it works based on Faraday’s law of electromagnetic induction since it rotates in the magnetic flux. The working principle of the AC generators and alternators are as follows:

A series of coils that are placed in the magnetic field is called armature winding. The coil rotates in the magnetic field with the help of a prime mover. This movement results in cutting the magnetic lines of forces. The process then generates an induced emf which works based on the principle of faradays law of electromagnetic induction. The developed current from the induced emf then flows in the armature winding. For finding the direction of the armature current, you should use the Flemings right-hand rule.

The induced emf maximizes when the coil is perpendicular and will be zero when it is in alignment with the magnets. With the rotation of the coil, the current constantly changes. Then the current passes through the slip rings and enters the brushes. The slip rings are used to smooth the process and the brushes collect the produced current from the slip rings. These brushes are responsible to deliver the current to the load.

What is the difference between an Alternator and a Generator?

Now some of you might wonder about the difference between an alternator construction and a generator. Both of them are considered as a machine for converting mechanical energy into electrical energy. The generator has 2 types known as AC and DC generators. DC generators have been designed to convert the ME to unidirectional EE. But the AC generator is used to convert the ME to an alternating EE. The AC generator converts the input mechanical energy into alternating electrical energy. The AC generators are used in the automotive industry. What you need to consider here is that the generator, in general, cannot be considered as an alternator, but an AC generator is considered similar to the alternator. The alternator construction includes a rotating magnetic field but a generator has a stationary magnetic field. Another difference is that alternators energy supply is received from the stator while the generators receive that energy from the rotor.

Where do we use an Alternator?

Alternators are generally used in automobiles. What they do is that when the engine is on, they charge the battery to provide electricity for electrical purposes such as supplying the need for lights, and so on.

Now that you know the alternator construction and how it works, how about sharing your comments with us and talk about your experience as a user of such machines? Need to talk to an expert regarding your alternator? Sign up on Linquip and we’ll get in touch with you in the blink of an eye to help you solve all your problems.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Alternator Function: The Complete and Easy to Understand Guide to How Alternators Work

- What Does an Alternator Do?

- Alternator Construction and Design

- Types of Alternator : Features, Advantages, and Vast Usage

- Alternator vs Generator: Your go-to guide to learn their difference

- Alternator Slip Rings : discover the basic purpose and other detailed forms