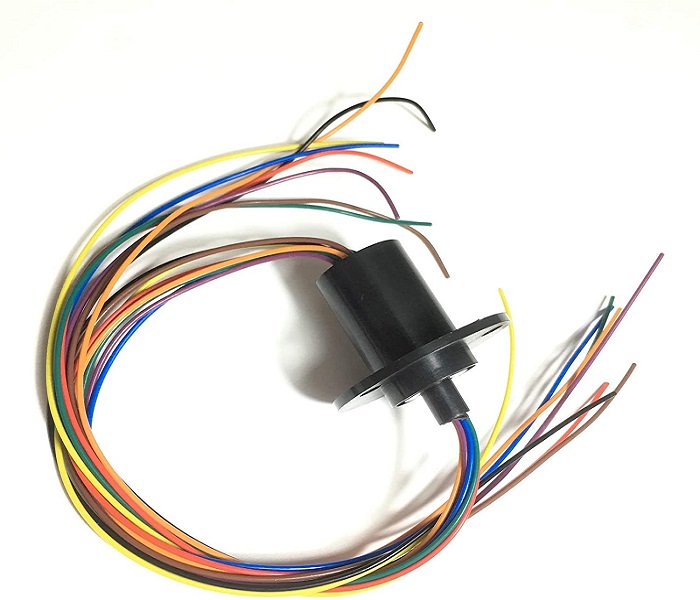

Alternator slip rings have a very important role or let’s say a mission. But what are slip rings? In general, slip rings are a part of an AC motor that transmits the energy between the machine’s stationary and rotating parts. Slip rings have various names such as the collector ring, rotary electrical ring, etc. Now let’s find more about alternator slip rings by reading this article at Linquip.

Linquip makes every effort to provide as much information as possible about slip ring alternators. For any questions regarding alternators and the equipment they are usually associated with, Linquip is the best source from which the answers can be obtained. The Linquip experts are always available to answer any questions or concerns that you may have about any of these industrial devices. Our recommendation for you would be to check out Linquip’s article titled, “What Are Slip Ring Alternators?“. You can gain a better understanding of this concept through this article.

For you to fully utilize the Linquip platform to the fullest extent possible, you will first need to register as a Linquip Expert. It is a very simple process to perform in this regard. You are able to create a Linquip account that will allow you to display your skills related to industrial equipment in a way that is tailored to the needs of the industry. Can you contribute a guest post to the Linquip website? By using the Guest Posting option, you can publish your content directly on Linquip’s platform.

What is the Purpose of Using Slip Rings in An Alternator?

The first question might be: what is the purpose of slip rings in an alternator? Slip rings are designed in different sizes, based on the function and purpose of their applications with different technologies. Alternator slip rings help in several ways. Below are the role of slip rings in alternators.

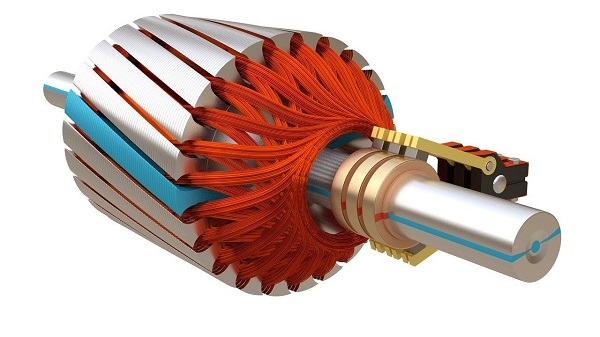

Alternator slip rings act as a band consisting of a conductive material provided by the shaft. The windings are connected to the electrical connections and the slip ring connects to the spinning assembly. A coil is used to help supply the magnetic field with the current that helps to rotate the rotor in the stator. A copper (alloy) is used in the rings. It is then mounted on a plastic material that insulates it from the rotor shaft.

There are a number of brushes used to establish contact between the slip rings. Alternator brushes consist of carbon that gives conductivity without being harsh to the rings. They are held securely onto the rings with the help of springs. During sliding with carbon brushes and other conductors in the alternator, the outside of the slip ring is kept in constant contact.

After the correction of the alternator output, the supply of the DC produced is kept firm and the other section of the DC rotates. The brush is used to supply the DC current to the rotating engine, by continuous connection to the slip ring rotor. The arrangement of the slip rings and brushes is thus considered to be the correct order of the DC current with that of the rotor.

Alternator slip rings, then what are alternator brushes?

Beside slip rings, we have alternator brushes. In fact, brushes supply power in a rotating shaft with the field coil that is mounted physically. This direct current is given by two slip rings. The power output of the alternator can be controlled by controlling the current flow to the field.

The function of slip rings in electric generator

A slip ring is a way to make an electrical connection through rotating assemblies. The slip rings are common to be found in the electrical generators for electrical systems and alternators as well as packaging machinery, cable reels, and wind turbines. The function of slip rings in an electric generator is that one of the two rings is linked with one end of the winding of the armature and the other to the other end of the winding of the armature. Electricity or signal is continuously transmitted by a slip ring connector from a stationary source to a rotating destination or vice versa.

Moreover, the function of slip rings in an electric generator is that the hollow rings are linked to the ends of the armature coil and it helps to rotate the coil. They also provide electrical contact via the brushes.

How many slip rings does a 3-phase alternator have?

A three-phase alternator has three slip rings and a two-phase machine that are very necessary. However, in the case of the rotating field, only two slip rings are necessary.

Slip ring motor

A slip ring motor is used when a high starting torque or low starting current is needed. It is particularly suited for applications with high load inertia, whereas slip ring motor comes at a higher price and its robust and cheap starters make it whole much more affordable. A slip ring motor is also highly resistant to dust, dirt, and moisture. It also has a great advantage when working on mill drives as it can provide a maximum boot torque out of a locked rotor point.

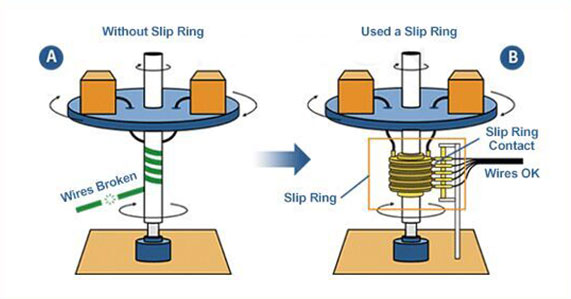

Slip Ring Commutator

Alternator slip rings are not the only elements. There are other parts. One of them is called a slip ring commutator which is an electromechanical device enabling power transmission and electrical signals from immobility to rotation. Slip ring commutator can recover mechanical action, facilitate system function and eliminate damage-prone wires that are attached to variable joints.

The slip ring commutator consists of an immobile brush, which washes the exterior diameter of a revolving metal ring, and it is known as a metal contact. While the metal ring is twisting, the signal is flowing by the immobile brush to the metal ring to connect the electric current. An additional ring or brush set along with the rotating axis is stacked if more than one electric circuit is needed.

What is Alternator Stator?

In addition to alternator slip rings and commutators, there is an alternator stator that is attached to the outside of the crankcase so that inside the rotor there is an assembly of the iron shaft, each with a wire wrapped coil. As the crankshaft spins, in each pole, the magnetism is continuously reversed. The reversals generate currents in the wire windings, which sends out a connector with three-phase power. The stator pushes out some power when the rotor is at 10000 rpm. An alternator stator is used to hold the armature windings. The recent trends in the construction of such a stator are more favorable to the use of mild steel sheets that are welded together rather than to casters.

Slip ring application

Up to now, you read about alternator slip rings plus other elements like brushes and commutators. Regarding the slip ring application, it is used in all electromechanical devices, where power and signals are performed unregulated, discontinuous, or continuous spinning. Slip rings are industrially applicable in: Wind power generators, Cranes, Rotating production machines, Precision instruments, for instance, those used for data transmission, Medical equipment, Radar equipment, Stage equipment, and Robotics.

How do you remove a slip ring from an alternator?

If the brushes have worn quite far into the material, it’s time to remove the alternator slip rings. It’s not hard to do it so don’t worry. For this job, you will only need a small bearing puller, a good soldering iron, and an ohm meter with a bit of skill.

First, the alternator must be removed and also the rear bearing in removing the slip rings. Test the reading through the two slip rings with the Ohm meter. Then, unsolder the wires from the tabs at the base of the slip ring assembly. If the slip rings are not fitted with a suitable puller, they can be broken and hacked, and so they come off. Note that the new slip ring has to be fitted so that the small knob on the slip ring enters the notch you can see on the fan which is stitched to the rotor. To press the alternator slip ring, you also need a tool. Cut a plastic pipe piece with a size of 40.75 mm. Then use a cap and cement it all the way inside. Now, use a strong solder to solder the wires. Be careful that the slip ring assembly has small holes so that the wires can be threaded and then soldered for an outstanding job. Finally, press on the new rear bearing and reassemble the alternator.

What Is the Proper Method for Cleaning the Slip Rings on My Alternator?

A 400 grain or finer polishing cloth can be used for cleaning and finishing dirty slip rings. Spin the rotor while holding a polishing cloth against the slip rings to clean them. It is crucial to rotate the rotor to ensure that the slip rings are cleaned evenly.

Download Alternator Slip Rings PDF

You can download all the contents of this article as a PDF file by clicking on the following link.

Final words

We covered the functions of alternator slip rings as well as other parts of alternators such as stators and commutators. We can now understand if slip rings are applicable in alternative tools. Now, what do you think of alternator slip rings? Is there something we missed? If you still have questions about alternator slip rings, sign up at Linquip and let us know in the comments what is missed.

Read More In Linquip

- Thermocouple Types: A Complete Comparison Between Them

- Types of Heat Exchangers: An Introduction to All Essential about Specifications

- What Does an Alternator Do?

- Signs of a Bad Alternator

- Alternator Function: The Complete and Easy to Understand Guide to How Alternators Work

- Alternator vs Generator: Your go-to guide to learn their difference

- Alternator Construction and Design

- Types of Alternator: Features, Advantages, and Vast Usage