Expansion valves are devices used to control the refrigerant flow in a refrigeration system. They remove pressure from the liquid refrigerant to allow expansion or change of state from a liquid to a vapor in the evaporator. Expansion valves serve two purposes: controlling the amount of refrigerant entering the evaporator and maintaining the pressure difference between the condenser (high-pressure side) and the evaporator (low-pressure side). In this article, Linquip will investigate the different types of expansion valves. Read on and find out more about them.

At Linquip, we can provide you with all the information you require to make an appropriate choice regarding expansion valve equipment based on your application or requirements. We at Linquip are eager to answer any questions you have about expansion valves. Start by reading this Linquip article entitled “What is Expansion Valve?“.

Need an expansion valve device? A wide selection of Expansion Valve Products can be accessed for free from Linquip. What are your plans to purchase expansion valves? You can view all Expansion Valve Devices for Sale with Linquip for free. In addition, Linquip can offer you free quotations from Expansion Valve Suppliers and Companies if you would like to learn more about pricing and availability.

⇒ View a Comprehensive List of Valves and Their Suppliers ⇐

What are the Different Types of Expansion Valves?

The Main Types of Expansion Valves are as Follows.

- Thermal Expansion Valves (TEVs)

- Manual Valves

- Capillary Tubes

- Automatic Valves

- Electronic Expansion Valves

- Float Valves

1. Thermal Expansion Valves

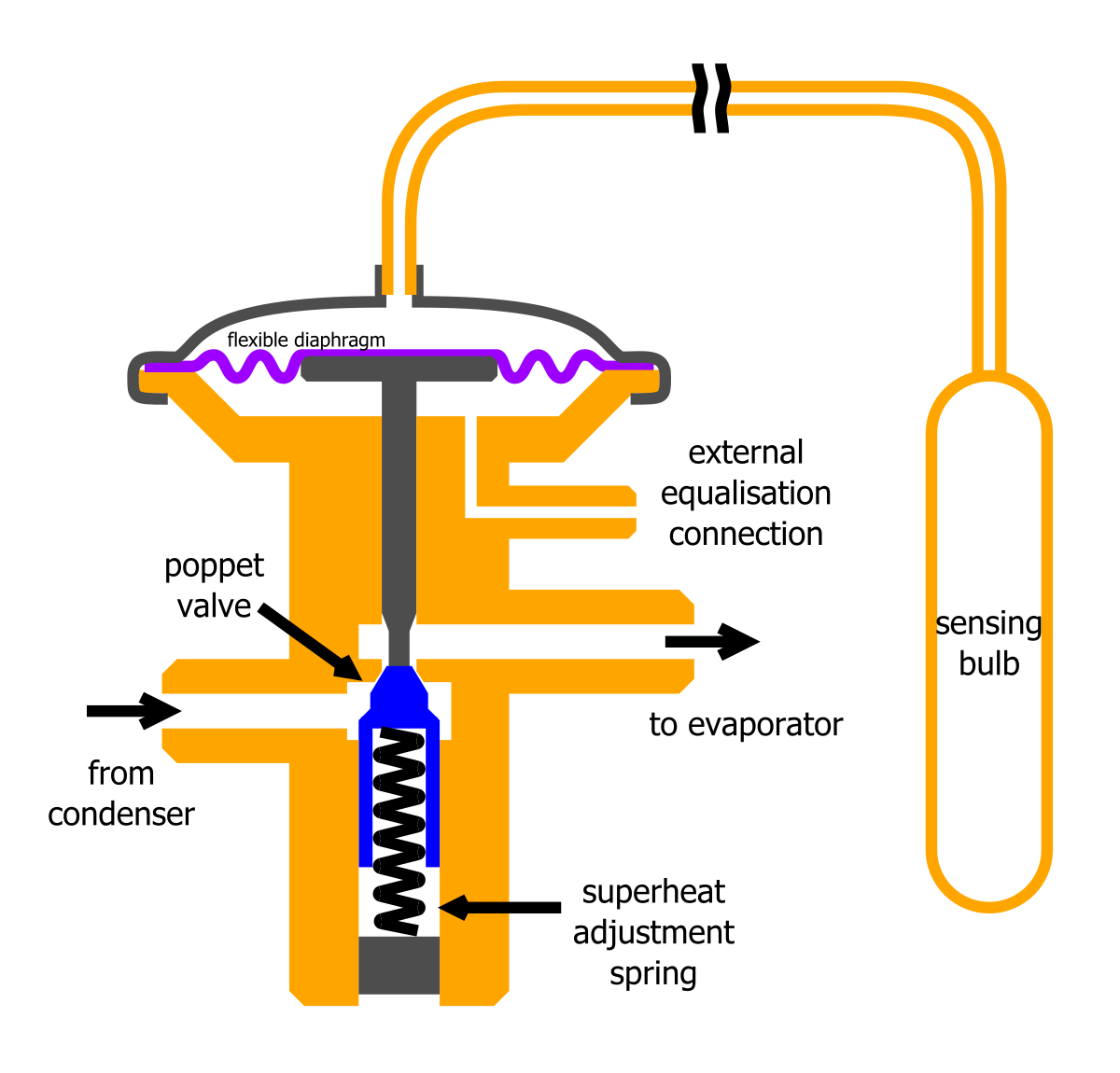

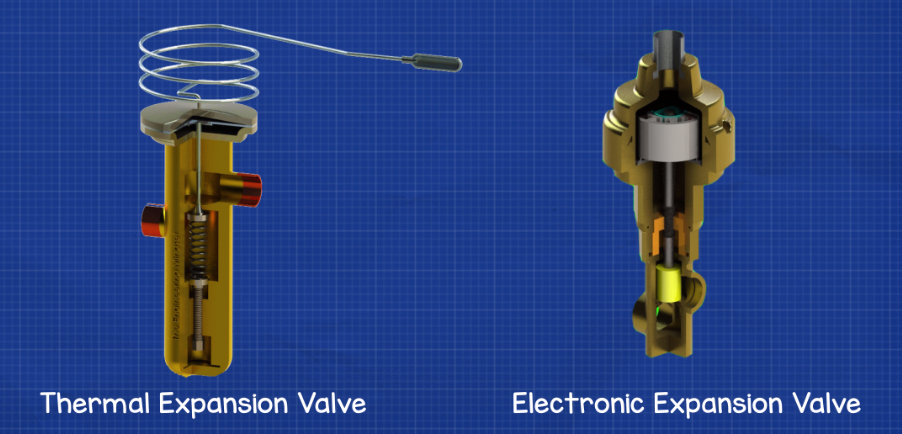

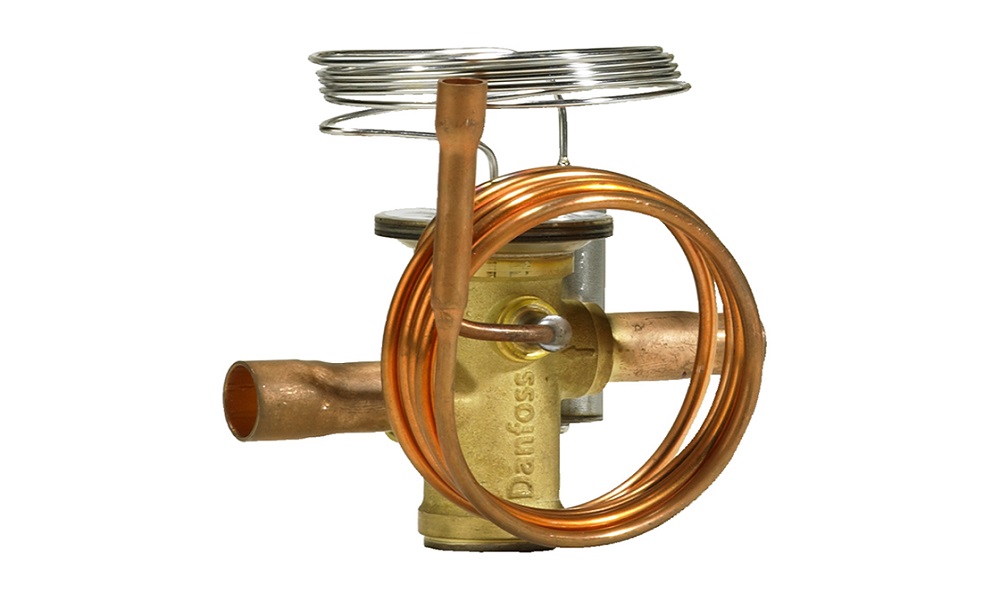

A thermal expansion valve or thermostatic expansion valve (often abbreviated as TEV, TXV, or TX valve) is a device that controls the amount of refrigerant released into the evaporator and is intended to regulate the superheat of the vapor leaving the evaporator. Although often described as a “thermostatic” valve, an expansion valve does not regulate temperature; the temperature of the evaporator will vary with the evaporation pressure.

These types of expansion valves are popular due to their simplicity and availability, and their relatively good sensitivity and accuracy in regulation. The large choice of expansion valve sizes and bulb charges means the capacity and temperature ranges are very good. The disadvantage of TEVs is the necessity for relatively high superheating, which steals the heat transfer area from the evaporation process.

The TEV strives to maintain a stable level of superheating inside the evaporator under all conditions by adjusting the mass flow of refrigerant in response to the evaporator load. This is achieved by a membrane inside the valve housing, which compares the temperature before and after the evaporator. To be able to compare the pressures before and after the evaporator, the TEV has to be combined with another device, a bulb. The difference in pressure between the saturation pressure of evaporation and the pressure of the bulb is balanced across a membrane inside the head of the valve. The movement of the membrane controls the position of a needle and hence the mass flow of refrigerant entering the evaporator.

See All Actuator Valve for Sale

2. Manual Valves

These types of expansion valves are manually operated needle valves. The needle position is fixed, and the mass flow through it depends on the pressure difference across the valve. The hand expansion valve is normally used as a supplementary safety valve installed in a bypass line. It is also commonly used to control the flow rate through oil bleeder lines. The manual expansion valve is non-regulating and should not be used as an expansion valve with a BPHE evaporator, because any changes in operating conditions would instantly change the evaporation process inside the rapidly responding plate heat exchanger. Regulating the flow manually would require immediate adjustment, which is not practically feasible.

These types of expansion valves have the disadvantage of being unresponsive to changes in load or seawater temperature and must be adjusted frequently. The valve itself is a screw-down needle valve dimensioned to give fine adjustment.

3. Capillary Tubes

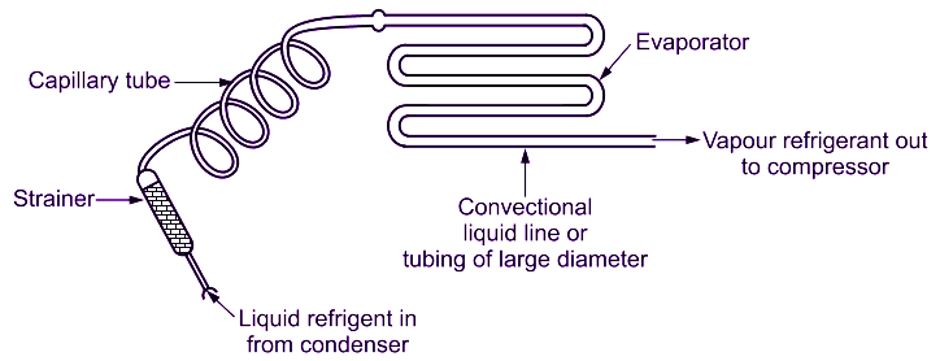

A capillary tube is a long, wound-up copper tube with a tiny opening that receives hot, high-pressure liquid refrigerant from the condenser. This small opening holds high pressure on one side of the tube and low pressure on the opposite side. The friction from the walls of the tube rapidly reduces the pressure of the refrigerant flowing through it.

It is installed on the suction line. A filter-drier is sometimes fitted before the tube to remove dirt or moisture from the refrigerant.

This device is simple, and does not have any moving parts and lasts longer. For using this device, the amount of refrigerant in the system must be properly calibrated at the factory level.

Due to its lower cost compared to TXV, this metering device is used in units that are produced in a large quantity such as a room or window air conditioners.

4. Automatic Valves

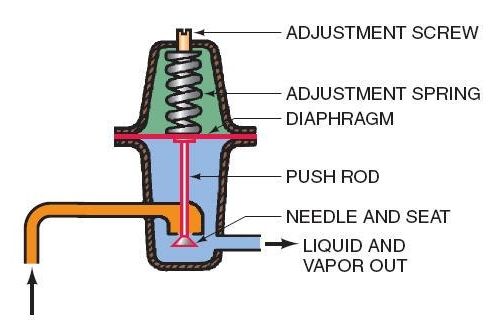

Automatic Expansion Valve regulates the flow of refrigerant from the liquid line to the evaporator by using a pressure-actuated diaphragm. It maintains a constant pressure in the evaporator.

These types of expansion valves consist of a needle with a seat and a pressure bellows or diaphragm with a torsion spring capable of adjustment. Operated by evaporator pressure their chief disadvantage is their relatively poor efficiency compared with other types.

Constant pressure in the evaporator also requires a constant rate of vaporization, which in turn calls for severe throttling of the liquid. There is also the danger of liquid being allowed to return to the compressor when the load falls below a certain level.

See All Air Release Valve for Sale

The setback is that it is not efficient if the load fluctuates, thus this type is not suitable in air conditioning as the load fluctuates a lot during its operation. It is used principally in small equipment with constant loads, such as domestic storage cabinets and freezers.

5. Electronic Expansion Valves

The electronic expansion valve (EEV) operates with a much more sophisticated design. These types of expansion valves control the flow of refrigerant entering a direct expansion evaporator. They do this in response to signals sent to them by an electronic controller. A small motor is used to open and close the valve port that is called a step or a stepper motor. Step motors do not rotate continuously; they are controlled by an electronic controller and rotate a fraction of a revolution for each signal sent to them by the electronic controller. The step motor is driven by a gear train, which positions a pin in a port in which refrigerant flows.

6. Float Valves

The Float Valve operates by a float immersed in the liquid refrigerant. Both low-side float and high side-float are devices used to control the flow of liquid refrigerant.

The low-side float valve helps maintain a constant level of liquid refrigerant in the evaporator. It opens when there is no liquid in the evaporator and closes when there is liquid in the evaporator.

The high-side float valve is located at the high-pressure side of the system that maintains a constant level of refrigerant in the condenser. When the compressor operates, the condensed refrigerant flows to the float chamber and opens the valve.

See All Bleeder Valve for Sale

This causes the refrigerant to flow into the evaporator where it is stored. As the liquid level falls in the float chamber, the valve opening will be closed, hence, preventing the liquid from flowing to the evaporator.

So this is all you need to know about the different types of expansion valves. If you enjoyed this article in Linquip and want to share your kind of experience with us, leave it in the comment section. Is there any question we can help you with? Sign up in Linquip, where our experts provide you with the most professional advice you need.

What Is the Function of an Expansion Valve?

Upstream the evaporator, the expansion valve is positioned to decrease the refrigerant fluid pressure. As a result of the pressure drop, the fluid is cooled and then sprayed into the evaporator. An expansion valve is always connected to an evaporator.

Download Types of Expansion Valves PDF

You can download this article as PDF if you would like to read it whenever you like.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Float Valve

- What is Foot Valve

- What is Gate Valve

- What is Globe Valve

- What are High-pressure valves

- All About DC Motor Types and Their Applications

- Easy Intro to Electronic Expansion Valve

- Ball Valve Types and Their Uses

- V150 Flanged Control Valve for Sale

- EZ Fisher EZ Control Valve for Sale

- ET Control Valve for Sale

- Flow control valve types and functions

- Globe valve types: basic types plus bold pros and cons

- Types of Pneumatic Valves: Specifications and Working Principles

- Valve Manufacturers

- Globe Valve Manufacturers

- Gate Valve Manufacturers

- Air release valve Manufacturers

- Control Valve Manufacturers

- Flow control valve types and functions

- What is Automatic Expansion Valve: A Basic Guide

- Types of Temperature Sensor and Their Application

- The Ultimate Guide to Knowing Everything About All Types of MCB

- Industrial Valves A Comprehensive Review on Parts, Types and its Usability

- Control Valve Types 101: Different Classifications, Advantage, and Disadvantages

- Thermal Expansion Valves: Everything You Need To Know

- Types of Hydraulic Valves and Their Working Principles

- A Comprehensive Guide To Different Types Of Air Valves

- Types Of Solenoid Valves: Everything You Need To Know

- A Complete Tutorial To Learn About Different Types Of Check Valves

- Types of pressure relief Valve: All you need to know about PRVs

- Types of non return valve: Introducing 6 types and more!

- Control Valve Types 101: Different Classifications, Advantage and Disadvantages

- What are Rotary Valves? Working Principles & Types

Need more information and to keep up with the new technology applications.

Thanks for visiting our website and leaving your comment, Martin! You are encouraged to visit Linquip Tech News, where you can find similar posts.

Nice

Thanks for visiting our website and leaving your comment. You are encouraged to visit Linquip Tech News, where you can find similar posts.

Was helpful in my research.

Thanks for visiting our website and leaving your comment, Peter! We hope to hear from you again in our other posts.