Welcome to Linquip Blog. Today and in this article, we are going to talk about Heat Exchanger Efficiency. The information in this article gives a significant collection of data you need to know about the meaning of efficiency in a heat exchanger system. The concept of heat exchanger efficiency is not very well defined in technical literature. The efficiency of any system has to be calculated based on the performance of some ideal system. In the case of heat exchangers, we don’t have very well-defined ‘ideal’ heat exchangers.

The ratio of heat transferred in the Practical Heat Exchanger to the heat transferred in the theoretical heat exchanger is known as heat exchanger efficiency. The notion of heat exchanger efficiency introduces a novel approach to heat exchanger and heat exchanger network design and analysis. The efficiency of the heat exchanger is critical when utilizing this product. Heat Exchangers are available from a variety of Suppliers And Companies, as well as manufacturers and distributors, and there are many Heat Exchangers For Sale on Linquip.

Linquip’s website has a complete selection of heat exchanger services that will meet all of your needs. Linquip vendors can assist you with this. Please contact Heat Exchanger Experts on Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver top-notch products.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic.

What Is the Heat Exchanger Efficiency?

Efficiency is a comparison between real-world performance and ideal performance; the ratio of the heat transferred in the actual heat exchanger to the heat that would be transferred in the ideal heat exchanger. Ideal performance is established with modeling and includes the limitations imposed by factors such as the second law of thermodynamics, which says that increasing amounts of energy are wasted every time it is transferred or transformed.

By establishing the levels involved in perfect or ideal heat exchanger efficiency, which transfers the maximum amount of heat and generates the minimum amount of entropy, a benchmark is set against which existing plate heat exchangers can be measured.

Ideal Heat Exchanger System

In most cases, the mean temperature difference is given. The heat transfer rate is mostly governed by the product UA, which is the product of surface area and heat transfer coefficient. UA can always be improved by changing the heat exchanger design or just increasing the surface area by getting a bigger heat exchanger. For that reason, we don’t have a practical definition of an ideal heat exchanger.

Calculating Heat Exchanger Efficiency

For any system, efficiency is normally calculated by comparing the actual performance with the ideal performance.

Efficiency = Actual output / Output of the ideal system

Since we don’t have an ideal heat exchanger to compare with, we cannot use the traditional concept of efficiency for heat exchangers. Instead, we can use the value of ‘UA’ (product of surface area and heat transfer coefficient) to represent the best heat transfer rate that can be achieved for given process conditions (ΔT). When you are comparing different heat exchanger designs, it is a good idea to compare their UA values. That should give you a good idea of how much heat transfer would be possible with each of them.

Moreover, two main models exist to help you calculate the performance efficiency of a plate heat exchanger. The log-mean temperature difference method (LMTD) provides a rate of heat transfer through the following calculation:

Q = UA(FΔTlm)

In this equation, U is the overall heat transfer coefficient, A is the total area of heat transfer, ΔTlm is the log-mean temperature difference, and F is the log-mean temperature difference correction factor. The LMTD approach is most commonly adopted when the inlet and exit temperatures are established, but the size of the heat exchanger is still to be decided. As an alternative to the LMTD approach, the thermal effectiveness method determines the real-world heat transfer occurring inside the heat exchanger against the maximum possible heat transfer. It is expressed as a ratio.

E = Q / Qmax

This approach is most common when building managers or engineers are attempting to determine the heat transfer rate and the fluid exit temperatures, and already know the size of the heat exchanger and the inlet temperatures.

Which Type of Heat Exchangers is the Most efficient Generally?

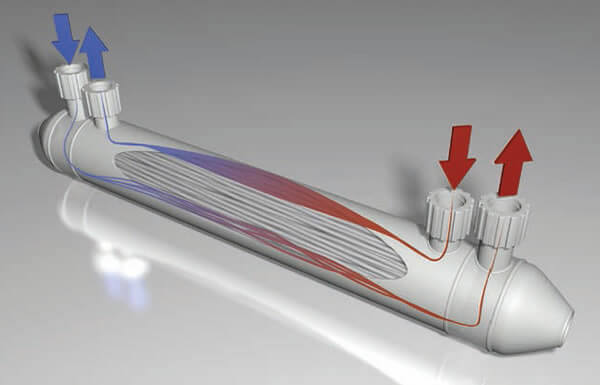

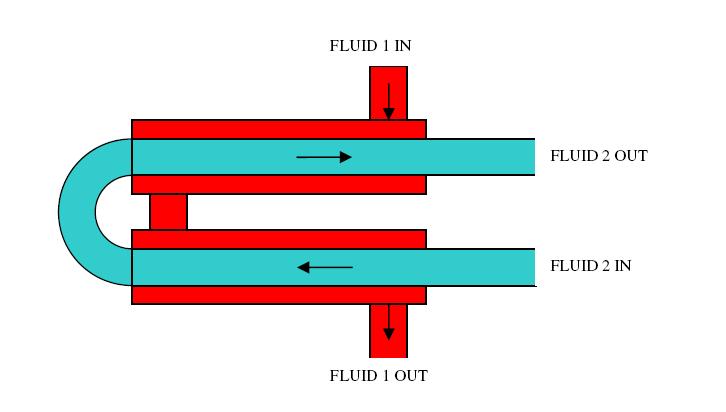

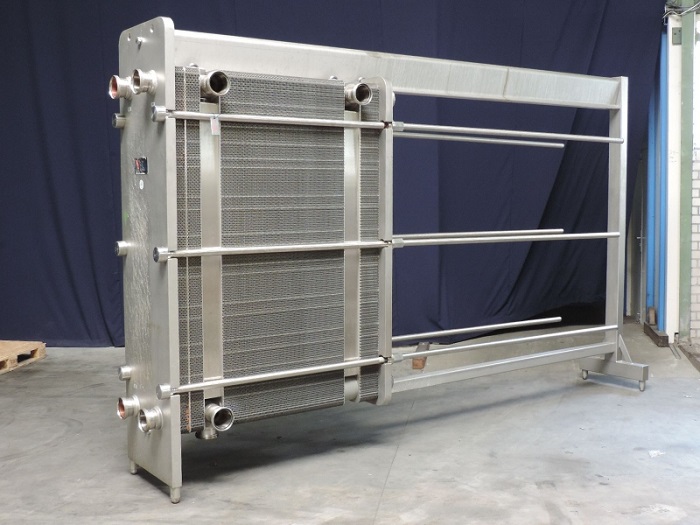

Plate heat exchangers are efficient heat recovery units used in a range of commercial, industrial, and residential settings. By extracting sensible energy from exhaust air, and using it to cool or heat incoming air, a plate heat exchanger can make a dramatic difference to a building’s energy costs and environmental impact. They are built using a simple engineering principle.

Layers of aluminum or polymer plates are positioned in the heat exchange core with gaps between them, enabling air to flow freely. Exhaust air is carefully funneled between some of the layers. At the same time, incoming air is funneled in the other direction between the other layers. Depending on the climate, the exhaust air heats or cools the plates. This sensible energy is then transferred to the incoming air. Modern plate heat exchangers can recover the vast majority of sensible energy, so their impact is significant.

Plate heat exchangers also offer other considerable benefits. Because a plate heat exchanger keeps incoming and exhaust air supplies separate, there is no risk of cross-contamination.

Plate heat exchangers are also capable of reversible energy recovery, making them well-suited to warmer climates where the focus is on cooling – rather than heating – incoming air. They are popular in hot regions such as the Middle East, where demand for HVAC solutions is permanently high. Finally, plate heat exchangers are available in a range of different sizes. This means they are appropriate for different buildings, different situations, and different industries.

With those factors embedded into industry calculations, plate heat exchangers are still consistently found to be the most efficient of all heat exchangers. Typically, they can achieve efficiency rates of approximately 90%. This is higher than the efficiency offered by the kettle, tubular, spiral, or shell, and tube heat exchangers. And it is that efficiency that makes plate heat exchangers so attractive for building managers looking to reduce their energy costs and lower their environmental impact. However, there is still a range of performances available within the plate heat exchanger family.

Are Heat Exchangers 100% Efficient?

Heat exchanger thermal efficiency is 100 percent for all practical purposes, except for a very little amount of heat loss (possibly less than 1%). As a result, very little improvement is conceivable, and we are unconcerned about it.

Because of the turbulent flow on both sides, the plate exchanger is the most efficient. It’s crucial to have a high heat-transfer coefficient and a lot of turbulence owing to an even flow distribution. A huge temperature difference, high fluid velocity, high turbulence, and a big surface area all contribute to more effective heat transfer.

FAQs about Heat Exchanger Efficiency

- What factors affect the efficiency of heat exchangers?

A heat exchanger’s ability to exchange heat is determined by several variables, including the inlet temperature of the hot and cold fluids, the rate at which the fluids enter, the physical characteristics of the fluids, the type of the heat exchanger, the configuration of heat exchanger elements, and the geometrical properties of the heat exchanger.

- Which heat exchanger has the highest efficiency?

Plate heat exchangers continue to stand out as the most efficient of all heat exchangers even when every specification is factored into calculations by the industry. It is not uncommon for them to reach 90% efficiency levels.

- Is it possible to prevent heat exchanger failures?

Exchanger failures can be prevented by guarding against mechanical failures and corrosion caused by chemicals.

- What is the importance of heat exchanger efficiency?

A high-efficiency heat exchanger can improve the energy efficiency of plant systems by recovering energy. Due to energy recovery, fuel usage, GHG emissions, and emissions are reduced.

- How can heat exchanger efficiency be improved?

Heat exchanger performance and process efficiency can be enhanced by following these 5 proven industry practices:

- Heat exchanger maintenance.

- Cleaning periodically.

- Using a manual cleaning method to clean PHE.

- Keeping the fouling factor to a minimum.

- Identifying and addressing efficiency issues in heat exchangers.

Conclusion

The present article was an attempt to deal with Heat Exchanger’s Efficiency and deliver all the essential information about what Heat Exchanger Efficiency is, how it is calculated, and which type of Heat exchanger is the most efficient. Efficiency is a comparison between real-world performance and ideal performance; the ratio of the heat transferred in the actual heat exchanger to the heat that would be transferred in the ideal heat exchanger.

The concept of heat exchanger efficiency is not very well defined in technical literature. The efficiency of any system has to be calculated based on the performance of some ideal system. In the case of heat exchangers, we don’t have very well-defined ‘ideal’ heat exchangers.

If you have any experience using Tubular Heat Exchangers, we will be very glad to have your opinions about their performance in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

A video for Heat Exchanger Efficiency

In this video, you will see how to determine the maximum effectiveness of a heat exchanger. Take advantage of this video to complete your knowledge.

Download PDF for Heat Exchanger Efficiency

You can download the PDF version of this article if you wish to read it later. You can access it by clicking the link below.

linquip.com-Heat Exchanger Efficiency Calculation amp Equation

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- Power System Services

- Power System Maintenance Services

- Power System Installation Services

- Power Systems Services in Texas

- Power System Maintenance Services in Texas

- Power System Installation Services in Texas

- Types of Heat Exchangers: An Introduction to All Essential about Specifications

- Heat Exchanger Design: How Is a Heat Exchanger Designed?

- Heat Exchanger vs. Chiller: Which one is the best?

- Difference Between Heat Exchanger and Condenser: A thorough guide 2021

- Coil Heat Exchanger: All Essentials You Need to Know

- Tubular Heat Exchangers: All Essentials You Need to Know

- Demystifying Heat Exchanger Sizing: A Comprehensive Guide

- What is Coil Heat Exchanger? Design Example

- Quick Guide On What Is Floating Head Exchanger

- Advanced Guide: What Is Tube In Tube Heat Exchangers

- What is Plate Heat Exchanger?

- What is Scraped Surface Heat Exchanger? Find it Where it is used

- Types of Plate Heat Exchanger: Different Types with Wide Use

- What is u-tube heat exchanger? An undeniable advantageous system

- Working Principle of Plate Heat Exchanger

- Types of Shell and Tube Heat Exchanger

- What are Counter Flow Heat Exchangers and its Working Principles?

- What are Double Pipe Heat Exchangers and Their Working Principles?

- Heat Exchanger Parts: Description of Configuration

- What is Cross Flow Heat Exchangers and its Working Principles

- How to Calculate the Efficiency of Heat Exchangers?

- Heat Exchanger Design: How Is a Heat Exchanger Designed?

- Types of Heat Exchangers: An Introduction to All Essential about Specifications