Here is an article about different types of heat exchangers. In this article, we intend to introduce you to the main categories and subcategories of heat exchangers. To do this, it is better to know how a heat exchanger is and how it is constructed and how it works. So, to begin with, we generally answer the question of “what is a heat exchanger?”. In the following sections, we will see how a heat exchanger is constructed and how it performs. There are many articles on the internet with a lot of information. Some of them are comprehensive some others are not. Linquip tried to gather all the necessary and available pieces of information about this topic for you and retell it in simple language to eliminate the need for you to wander through the vast amount of confusing content. Stay with us until the end to get answers to all your questions about different types of heat exchangers.

What Is a Heat Exchanger?

To better understand the types of heat exchangers, it is better to first get acquainted with what they are.

Heat exchangers are machines produced to transfer heat between two or more fluids such as liquids, vapors, or gases with different temperatures. The heat transferring process based on the type of heat exchanger can be gas to gas, liquid to gas, or liquid to liquid. This exchanging is conducted through a solid separator preventing direct contact of these fluids.

The suitability and compatibility of a fluid with a heat exchanger relies on the type of heat exchanger being used and the materials used in the construction of the exchanger. Some standard heat exchangers are suitable for most fluids including oil, water, and even Sea Water. For some corrosive fluids such as chlorinated saltwater, refrigerants, and acids, there is a need for other materials such as Stainless Steel and Titanium.

Other characteristics, including construction materials, components, parts, a different mechanism for heat transfer, and so on will assist to categorize and classify different types of heat exchangers. These characteristics also help us find which one is more compatible with given applications across a wide range of industries, and general use.

In the following section, we will talk about how heat exchanger works. The working principle of almost all the heat exchangers is the same. However, the purpose of describing the overall performance of heat exchangers is to familiarize you better with the fact that despite their different designs, they all do the same thing.

How Does It Work?

As we mentioned before, there are many different types of heat exchangers and all they do is to transfer and move heat in different processes and situations including space heating, refrigeration and cooling, power stations, chemical plants, and other processes. But how do these machines work?

Heat exchangers work by transferring heat from one place to another. The combustion produced from the burning natural gas or propane fuel in the furnace enters and travels through the heat exchanger. As the gas makes its way to the exhaust outlet of the furnace, the hot flue gas heats the metal. The hot metal heats the air circulating over the exterior of the heat exchanger. Note that it is only one way of heat exchanging that happens in different types of heat exchangers but it is the whole point in almost all types of heat transfer machines.

Heat Exchanger Components and Materials

In the previous section, we elaborated on how generally a heat exchanger work. And also, we mentioned that different materials and components are used in making a heat exchanger. In this section, we want to make you more familiar with these materials and components.

There are several types of materials that can be used to construct heat exchangers. The components and materials used depend on what type of heat exchanger we require and for what purpose or goals we need a heat exchanger.

Shells, tubes, coils, plates, fins, and adiabatic wheels are some of the most common components used to construct heat exchangers.

While metals have a high resistance and are commonly used in constructing heat exchangers due to their high thermal conductivity, as in the case of copper, titanium, and stainless-steel heat exchangers, other materials, such as graphite, ceramics, composites, or plastics, may offer greater advantages depending on the requirements of the heat transfer application.

What Are the Types of Heat Exchangers?

Finally, after getting acquainted with the totality of heat exchangers and how they work and familiarity with the components and materials used in them, we come to the main topic of this article, which is familiarity with the types of heat exchangers.

These machines are usually classified according to their flow arrangement and type of construction. The simplest heat exchangers are those that the hot and cold fluids flow in the same, opposite, or Perpendicular directions. These kinds of heat exchangers consist of two concentric pipes of different diameters and are Parallel-flow, Counter-flow, and Cross-flow arrangement.

- Parallel-flow Arrangement: In the kind of parallel-flow heat exchangers, the hot and cold fluids enter at the same end, move in the same direction, and leave at the same end.

- Counter-flow Arrangement: In the kind of counter-flow heat exchangers, unlike the arrangement of parallel-flow, the fluids enter at the opposite ends, move in the opposite directions, and leave at the opposite ends.

- Cross-flow: The fluids can also flow in perpendicular directions which is known as cross flow arrangement. The two main types are finned and unfinned tubular. With a finned tubular heat exchanger, both fluids are unmixed, the one between the fins is guided in a direction transverse to the tube flow direction. In the unfinned exchanger heat can be exchanged in all directions, and the fluid can mix.

By comparing these two types of heat exchangers, we found that more heat is transferred in a counter-flow arrangement than in a parallel flow heat exchanger. In addition, the temperature profiles of the two heat exchangers indicate two major disadvantages in the parallel-flow design:

A huge temperature difference between the two ends causes large thermal stresses.

The temperature of the cold fluid exiting the heat exchanger never exceeds the lowest temperature of the hot fluid.

However, the design of a parallel-flow heat exchanger is advantageous if two fluids are required to be brought to nearly the same temperature.

The heat transfer surface in heat exchangers can be arranged in several forms. Based on the heat transfer surface in Heat exchangers, they are therefore also categorized as Double pipe heat exchangers, Shell and tube heat exchangers, and Plate heat exchangers.

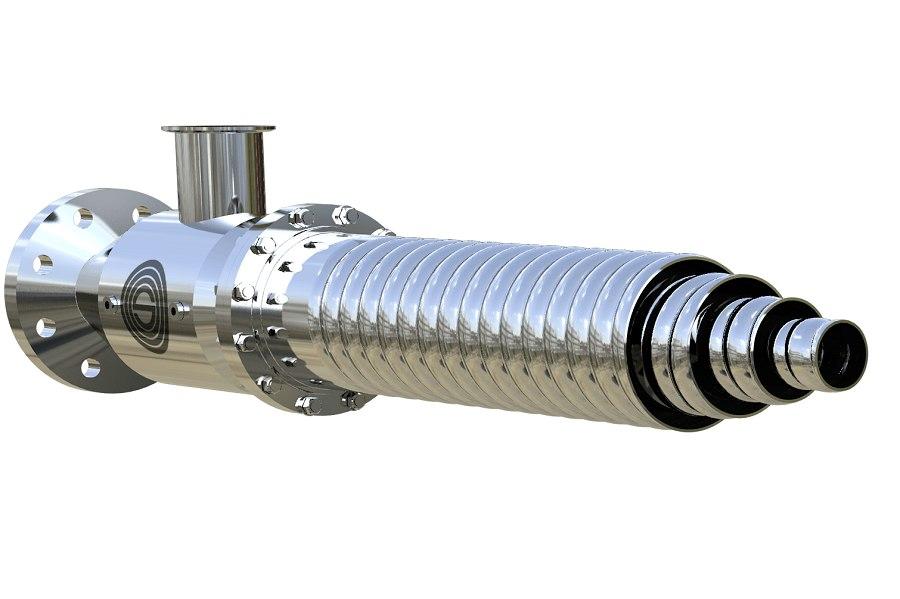

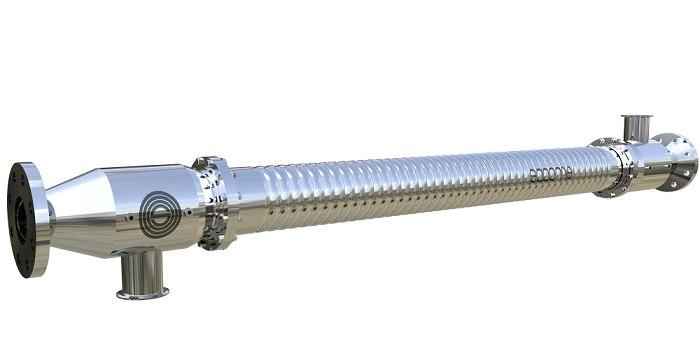

- Double pipe heat exchangers: one of the cheapest heat exchangers in terms of design and maintenance is Double pipe heat exchanger that makes them a good option for small industries. The process of heat exchanging in these exchangers performs by one fluid flowing inside the tube and the other fluid moving on the outside. Although this kind of heat exchanger is simple and cheap in design and maintenance, their low efficiency along with their high space occupied on large scales has caused modern industries to use more efficient heat exchangers like shell and tube.

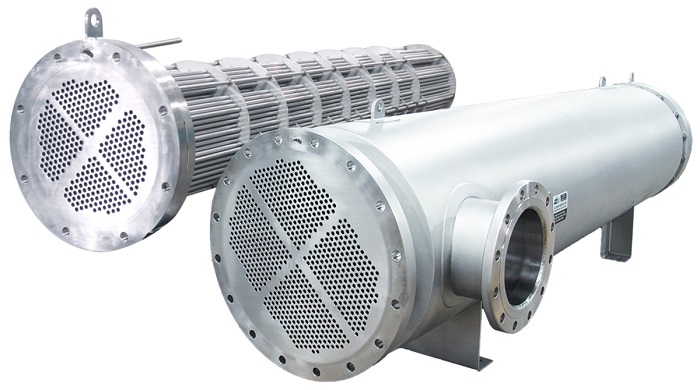

- Shell and tube heat exchangers: this type of exchanger family with their various construction modifications is probably the most widespread and commonly used heat exchanger in the industry. Shell-and-tube heat exchangers are further categorized according to the number of shell and tube passes involved. Shell and tube heat exchangers with pressures greater than 30 bar and temperatures greater than 260 °C are typically used for high-pressure applications. The shell and tube heat exchangers thanks to their shape can withstand high pressures. This type of exchanger possesses some small bore-pipes fitted between two tube plates that the primary fluid moves through these tubes. The tube bundle is set inside a shell and the secondary fluid moves through the shell and over the surface of the tubes. This design is widely used in nuclear engineering as the steam generator. The heat exchange surface is maximized to increase the amount of heat transferred and the power generated. To maximize the surface, this design is benefited from tubes.

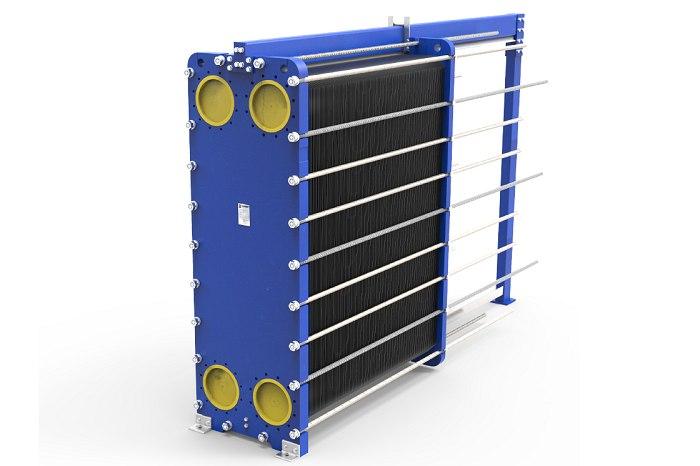

- Plate heat exchangers: in this type of exchanger, metal plates are used to transfer heat between two fluids. The heat exchangers using air or gas as well as lower velocity fluid flow use this kind of arrangement. The classic example of a heat exchanger of this kind is found in an internal combustion engine in which an engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. As we compared plate heat exchanger to shell and tube exchangers, the stacked-plate arrangement typically has lower volume and cost. Another difference between the two is that plate exchangers typically serve low to medium pressure fluids, compared to medium and high pressures of shell and tub

- Scraped Surface Heat Exchangers: Some applications require heat transfer to highly viscous or sticky products. In those applications, scraped surface heat exchangers are the best method to provide effective heat transfer due to the scraping blades that keep product from settling on the interior surfaces. Product enters a cylinder at the bottom of the scraped surface tube. Heating or cooling fluids travel in a counter-current flow in a cylinder surrounding the product channel. Blades inside the product channel remove product from the channel wall to ensure uniform heat transfer to the product. The scraping blades are made a variety of materials to meet different processing requirements, and are designed specifically for gentle product handling to avoid compromising product quality and consistency. Scraped surface exchangers can be mounted vertically or horizontally. Inside, an electric motor turns a rotor fitted with scraping blades. To prevent damage to product, rotors turn and product the move through the heat exchanger in the same direction, with product entering at the bottom and exiting at the top. The heating surface is polished to a high finish on the inner surface.

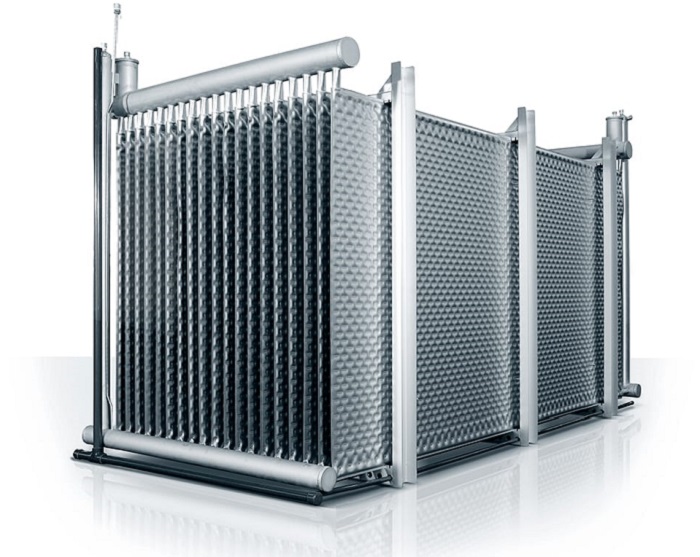

- Dimple Plate/Plate Coil Heat Exchanger: Although its market share is much less than that of the previous two categories, dimple plate/plate coil technology is the best solution for applications where one of the fluids isn’t moving. It’s also useful in retrofit applications, such as waste heat recovery that wasn’t accounted for in the initial blueprints. In general, this is a good option for passive heating or cooling a storage tank (such as a bright beer tank or dairy tank) where refrigeration or heating would otherwise be expensive. The premise is very simple – two steel sheets are spot-welded together, then inflated to make channels between the plates for fluid to flow. Due to its simplicity and low-cost materials, dimple plate/plate coil technology can generally be customized to any particular application. The most prevalent application is tank jackets for beer and dairy tanks, but sections of dimple plate can also be cut to fit inside a tank and submerged in the stored liquid for efficient heat transfer. Dimple plate/plate coil offers the best of both above kinds of heat exchangers – it’s cheap, customizable and compact, but can withstand incredibly high pressures and temperatures due to design and materials. It can also be added as an afterthought to many industrial processes, most notably to cut energy costs or comply with environmental regulations.

- Air Cooled: Air Cooled Heat Exchangers are commonly used in vehicles or other mobile applications where no permanent cool water source is available. Cool air is provided either by a fan or by air flow caused by the movement of the vehicle.

How to Make a Heat Exchanger More Efficient?

Heat exchanger efficiency can be defined in many ways, in terms of thermal performance there are several key factors to consider which are listed below:

- Temperature differential: the difference between the hot fluid and coolant is very important when designing a heat exchanger. The coolant always needs to be at a lower temperature than the hot fluid. Lower coolant temperatures will take more heat out of the hot fluid than warmer coolant temperatures. If you had a glass of drinking water at room temperature for example, it is much more effective to cool it down using ice rather than just cool water, the same principle applies to heat exchangers.

- Flow rate: Another important factor is the flows of the fluids in both the primary and the secondary side of the heat exchanger. A greater flow rate will increase the capability of the exchanger to transfer the heat, but a greater flow rate also means greater mass, which can make it more difficult for the energy to be removed as well as increasing velocity and pressure loss.

- Installation: The heat exchanger should always be installed based on a manufacturers’ guidelines. Generally speaking, the most efficient way to install a heat exchanger is with the fluids flowing in a counter-current arrangement (so if the coolant is travelling left to right, the hot fluid travels right to left) and for shell and tube heat exchangers the coolant should enter at the lowest inlet position (as shown in the diagrams above) to ensure that the heat exchanger is always full of water. For air-cooled heat exchangers, it is important to consider the air flow when installing a cooler, any part of the core which is blocked will compromise cooling capacity.

Applications

If we want to briefly describe the applications of each of these three types of heat exchangers, we must say that double pipe heat exchangers are suitable for industrial cooling processes and Small heat transfer area requirements while sell and tube heat exchangers are used in oil refining, preheating, oil cooling processes and as steam generator, boiler in heat recovery and vapor recovery systems. On the other hand, plate heat exchangers are commonly used in food and chemical processing, and furnaces.

Conclusion

In this article, we tried to give you essential and comprehensive information about the types of heat exchangers. we talked about the design and construction of different types of air heat exchangers, what they do, and for what purpose they were basically designed. Besides, for better understanding, we brought some basic pieces of information about what a heat exchanger is. For each type of heat exchanger, we brought some advantages and disadvantages to make it easier for you who are about to buy one. We compared them with each other to show you their strengths and weaknesses.

If you have any experience of using different types of heat exchangers, we will be very glad to have your opinion in the comments. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts in Linquip to answer your questions. Hope you enjoyed reading this article.

Read More on Linquip

- Heat Exchanger Parts: Description of Configuration

- Demystifying Heat Exchanger Sizing: A Comprehensive Guide

- Quick Guide On What Is Floating Head Exchanger

- Advanced Guide: What Is Tube In Tube Heat Exchangers

- Heat Exchanger Efficiency: Tips for Having an Efficient Heat Exchanging System

- What is Scraped Surface Heat Exchanger? Find it Where it is used

- Heat Exchanger Design: How Is a Heat Exchanger Designed?

- What are Double Pipe Heat Exchangers and Their Working Principles?

- Types of Plate Heat Exchanger: Different Types with Wide Use

- What is u-tube heat exchanger? An undeniable advantageous system

- What is Plate Heat Exchanger?

- Types of Shell and Tube Heat Exchanger

- Heat Exchanger vs. Chiller: Which one is the best?