Types of Pop Rivets – Blind rivets, sometimes referred to as pop rivets, are a kind of rivet. They’re put to use when getting to the reverse (blindside) of the components being joined is difficult or impossible.

On Linquip website, among the many options available to you, you will find all the information you need to know about Rivets, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Rivets for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is Pop Rivet?

Blind rivets, also known as pop rivets, fall under the category of rivets. They are utilized in situations when access to the back (blindside) of the pieces that need to be linked is either restricted or nonexistent.

Pop rivets are a specific kind of blind rivet made to be inserted from just one side of a joint, making them very useful for fabrication and assembly tasks when access to both sides of the workpiece is restricted.

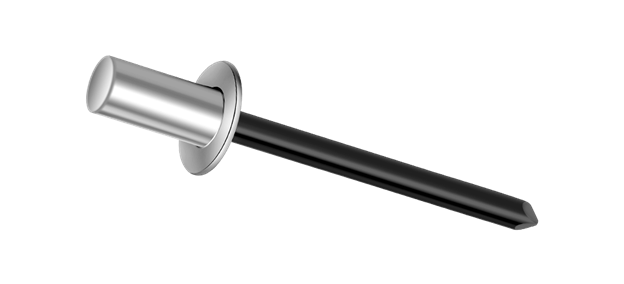

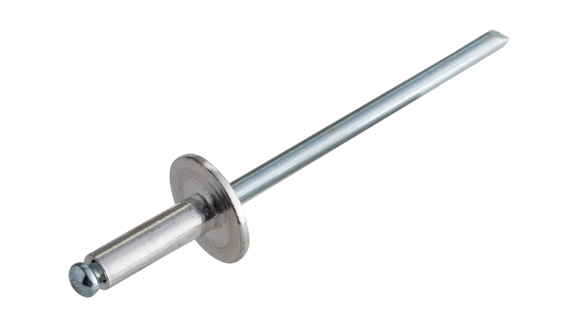

Pop rivets have a very straightforward construction that consists of a mandrel that fits through the shank of the rivet and a shank that is placed into a pre-drilled hole. A blind riveting tool is used to draw out the mandrel, compressing the shank on the workpiece’s blind side and bringing the material together to attach the rivet.

The mandrel is broken off at a predetermined nick for a clean finish once the joint is finished. Because of the noise made when the mandrel separates from the rivet, these fasteners are known as “pop rivets.”

The force needed to attach a rivet varies on its size and intended use, although installation is often performed with a single, gentle tugging action. A manual pop rivet tool can be used for quick repairs or for adding a few rivets.

Use a pneumatic or electric pop riveting tool with additional pulling power for demanding applications like manufacturing or construction.

Working Principle of a Pop Rivet

Pop rivets have two components. The rivet body, often known as the shell or hat, is the first component, while the mandrel is the second (also called the stem).

A hole is initially drilled through the pieces to be linked in cases when access to either side of a component is restricted. The pop rivet is then brought into contact with the pieces after being introduced through the drilled hole.

For the rivet to expand and retain the components to be attached, a rivet gun must be used to draw the mandrel into the rivet body. The mandrel snaps into position after it has been grasped, holding the rivet firmly in place. There is a localized link as a result.

Various Types of Pop Rivets

In what follows, various types of pop rivets are briefly described.

9 Types of Pop Rivet include:

- Standard Blind Rivets

- Sealed Blind Rivets

- Peeled Blind Rivets

- Grooved Blind Rivets

- Multi-Grip Blind Rivets

- Soft Set Blind Rivets

- Dome Head Blind Rivets

- Large Head Blind Rivets

- Countersunk Head Blind Rivets

Standard Blind Rivets

Metal-to-metal fastening often involves the use of standard blind rivets. They have simple bodies and dome-shaped heads. The body of the rivet expands at its “blind” end when the mandrel is partially pulled through it, forming a second head to stably bind materials together.

Automotive, metals, construction, containers, electrical appliances, furniture, air conditioning, and heating are just a few of the sectors that employ standard rivets.

Sealed Blind Rivets

This particular style of the blind rivet has a sealed end. Unlike other types of blind rivets, this one’s mandrel head is enclosed within the sealed body of the rivet and does not protrude from the end. In order to fasten metal to metal, sealed rivets do not permit liquids to enter or exit.

While the head of the rivet is sealed, the mandrel’s head rests inside the rivet’s body. This keeps liquid from entering or leaving the component. They are appropriate for usage in the metal, building, and automotive sectors. Additionally, they may be found in containers, furniture, air conditioning, and heating systems, as well as electrical gadgets.

Peeled Blind Rivets

Peeled rivets increase the diameter of the locking head, giving it a larger bearing surface (underside of the head). The body enlarges as the mandrel is dragged through it, leaving a head with a flower-like form and four petals. The optimum application for this kind of rivet is joining metal to softer materials.

A head is formed by folding the sides (petals) of the rivet over, which secures the materials together. Peeled rivets function well in the construction business (plasterboard, coatings, and insulation) and may be used on trailers, plastic parts, electrical appliances, and upholstery (padded covering on furniture).

Grooved Blind Rivets

When installing softer materials like plastic and wood, this type of rivet’s body-encircling grooves provides tremendous holding power. For attaching metal to wood and metal to building supplies, including cement, bricks, and wood, grooved rivets are ideal.

The material is fastened together by the grooves on the rivet’s body that embeds into it. It is not necessary for the hole it enters to penetrate straight through the surface.

When the mandrel is pushed out of a grooved rivet, the rivet’s tail grows inside the material rather than forming a new head on the opposing side. As a result, the rivet’s head at one end grabs the object that is being attached to the material while the head at the other end grips the material with friction.

Construction, the metal sector, furniture production, electrical equipment, and injection-molded parts are the ideal applications for grooved rivets.

Multi-Grip Blind Rivets

Similar to regular rivets, multi-grip rivets also include indents on the rivet body. When the mandrel is dragged into the body, the indents enlarge and offer several grips. These rivets are used to join plastic to plastic and metal to metal.

As the mandrel is dragged through, the various grips on the rivet’s body are pressed up against the material being fastened. The automotive, building, and metal sectors, as well as the production of ladders, furniture, electronics, electrical appliances, and air conditioning and heating, may all benefit from the usage of multi-grip rivets.

Soft Set Blind Rivets

Standard rivets and soft rivets are interchangeable. The body and mandrel, on the other hand, are made of a softer metal, usually an alloy of aluminum. The mandrel delivers the proper amount of pressure to secure fragile materials without causing harm since it breaks off with significantly less force than other types of rivets.

These rivets may be used to secure soft materials with little resistance to metal or plastic, as well as metal to wood, plastic, fiberglass, and plastic to plastic. Soft rivets can be utilized in building, furniture, packing, plastic parts, and containers.

Dome Head Blind Rivets

Except for highly smooth and brittle materials like plastic, the dome head’s ample bearing surface allows it to be used to secure a range of materials.

This is so that softer materials won’t be damaged, as this style of the head puts greater pressure closer to the drilled hole. A bearing surface is when two materials come into contact. In this instance, the portion of the rivet that makes contact with the material being secured is the region under its head.

Large Head Blind Rivets

When compared to a dome head rivet, the big head gives double the bearing area. For attaching fragile or soft components to strong support materials, this offers excellent resistance.

Countersunk Head Blind Rivets

A countersunk head maintains a level surface by fitting into the material without projecting.

FAQs about Pop Rivets

1. What Is The Purpose Of A Pop Rivet?

High-strength joints may be created using them in a variety of materials, such as metals, polymers, wood, and leather. The procedures are often used to connect sheets of plastic or metal. Pop rivets come in a number of materials, including steel, to enable them to suit the needs of a wide range of applications.

2. What Distinguishes a Pop Rivet From a Blind Rivet?

Unlike machine screws and nuts, which need access to both sides of the material, a blind rivet may be inserted entirely from one side. Due to POP being one brand of blind rivets, blind rivets are often referred to as “pop” rivets.

3. Do Pop Rivets Hold Up Well?

Pop rivets are well-liked and dependable in general since they are simple to install and result in robust and dependable fastenings. Pop rivets and the installation tool, when used properly, prevent surface damage to the materials being connected, resulting in a more professional finish.

4. Do Rivets Outperform Screws?

Rivets provide significantly better grip than screws. They won’t shake loose and are tough to open. This is so that the rivet supports both sides, whereas the screw only has a head on one. This is significant since the frame will vibrate during transportation.

5. What Materials Can Be Used With A Pop Rivet?

To satisfy the needs of a wide range of applications, POP rivets are available in steel, stainless steel, nickel-copper alloy (Monel), copper, and numerous grades of aluminum.

6. Which Three Rivet Types Exist?

The four main types of rivets are tubular, metal piercing, solid, and blind (including split rivets).

7. How Do You Determine The Pop Rivet Size to Buy?

The length of the rivet should be 1.5 times the diameter of the stem of the rivet, plus the thickness of the two items being fastened. 3/32″ (2MM) FOR THICKNESS UP TO 3/32″ (2MM).

8. Can A Pop Rivet Be Too Long?

Although it is not the same as grip range, it is a crucial dimension when taking into account clearance on the blind side of the material being connected. A rivet that is too long may not fit well or may have a detrimental influence on whatever is located behind the hole.

9. Are They Waterproof?

Closed-End Pop Due to their ability to provide a watertight seal when put correctly, rivets are sometimes referred to as sealed blind rivets or sealing rivets, making them a common component in the boating and automobile sectors.

10. Are Pop Rivets More Durable Than Screws?

Compared to pop rivets, threaded fasteners will offer more strength for common workshop applications. Pop rivets have a hollow shaft, which lowers their resistance to shear stresses. On the other hand, solid rivets may be the strongest mechanical fastening on the market.

11. Where Do Rivets Find Use?

Bridges, cranes, and the frames of buildings are examples of static constructions that use steel rivets. Both sides of a structure must be accessible for the installation of these fasteners. An electromagnetic, hydraulic, or pneumatically powered squeezing tool, or even a hand hammer, is used to drive solid rivets.

12. Why Aren’t Planes Welded, But Instead Riveted?

The aluminum materials used in the building of airplanes are heat-intolerant, which is one reason why riveted connections rather than welded joints are employed in their manufacturing. The majority of commercial airplanes have an aluminum body. Aluminum is not just easily accessible, affordable, and lightweight.

Download Types of Pop Rivets PDF

You can download the PDF format of this post from here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Pop Rivets and How Does It Work? (A Comprehensive Guide)

- 5 Different Types of Drill Bits for Wood: A Comprehensive Guide

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- What Is The Difference Between A Blind Rivet And A Pop Rivet?

- 13 Types of Rivets + Applications & Working Principle

- The 10 Best Rivet Tool

- 7 Types of Solder + Working Principle & PDF

- The 10 Best Angle Grinders

- 16 Types of Scaffolding + Components & PDF

- 28 Types of Clamps: A Complete Guide

- The 10 Best Electric Lawnmowers

- The 6 Best Leaf Blowers + Buying Guide & PDF

- The 10 Best Welding Machines + Buying Guide

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 18 Types of Machining Vises (Clear Guide)

- 8 Types of O-Ring + Applications (Clear Guide)

- The 10 Best Snow Blowers + Buying Guide & PDF

- The 10 Best Electric Pressure/Power Washers

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 8 Best Attic Ladders + Buying Guide & PDF

- The 10 Best Electric Space Heater + Buying Guide

- 4 Types of Solid Rivets + Working Principle

- What Is Flush Rivet And How Does It Work? (A Comprehensive Guide)

- Types of Drill Bits for Metal: Comprehensive Guide

- All 24 Types of Drill Bits + Video: Clear Guide