Types of Solid Rivets – Being one of the oldest and most dependable forms of fasteners, solid rivets may be traced back to Bronze Age artifacts. Simple shaft and head that are bent using a hammer or rivet gun make up solid rivets. This type of rivet can also be deformed by using a rivet compression or crimping tool, albeit this method is more commonly utilized on rivets that are near to the edge of the attached material because the tool’s depth is constrained. Installing solid rivets using a rivet compression tool is typically the most reliable method because it doesn’t require two persons.

On the Linquip website, among the many options available to you, you will find all the information you need to know about Rivets, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Rivets for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is a Solid Rivet?

Simple shaft and head that are bent using a hammer or rivet gun make up solid rivets. This sort of rivet can also be deformed using a compression or crimping tool. Since the depth of the tool’s frame restricts its use, it is often employed on rivets that are near the edge of the material being secured.

Working Principle of a Solid Rivet

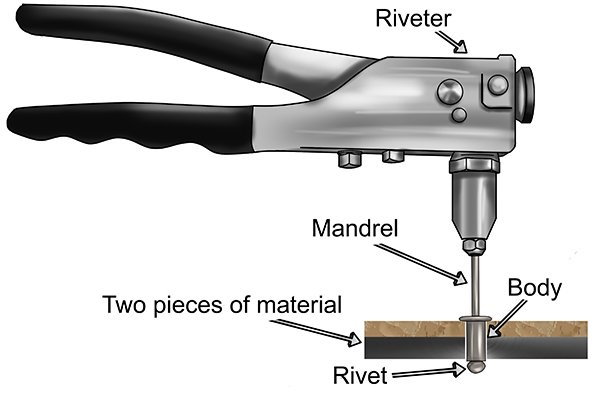

The snap is clamped into the jaws of a vise before a rivet is placed into it. The lined-up holes in the material being joined then cover the rivet.

A rivet snap is a required tool to create the head on the tail (formerly the non-headed end) of a rivet. The snap features a hole and an internal dome (concave) shape at one end and a flat surface to be struck with a hammer at the other.

The rivet’s tail, which is now the headless end, may be bent with a hammer so that both the old head and the new head can now grab the material on either side. The tail’s deformation, which tightens it against the materials, also somewhat compresses the rivet. A second rivet snap gives the new rivet head a dome-shaped form. When a hydraulic or electric riveter forcefully presses the rivet’s head on the snap, the pin end will immediately deform.

Various Types of Solid Rivets

4 Types of Solid Rivets include:

- Flat Head Solid Rivet

- Round Head Solid Rivet

- Pan Head Solid Rivet

- Countersunk Head Solid Rivet

Solid rivets have a cylindrical body and a head.

They come in a number of metals and come with a range of head forms, including round, flat, countersunk, and pan.

The sorts of heads can be chosen based on either aesthetic preference or practical needs. Functional specifications may consist of:

- A flushed face (whether the head is level or flush [in line] with the surface of the material)

- Shear strength and fatigue strength

- Substantial bearing surface (underside of the head)

The fatigue strength of a rivet measures how weak it becomes under repeated applied stresses.

When the two components a rivet is holding together attempt to move in opposite directions, the strength of the rivet against shearing action is measured.

A variety of sectors, including the manufacture of locomotives, airplanes, ships, automobiles, and boilers, employ solid rivets.

Flat Head Solid Rivet

This style of the solid rivet has a flat head and a sizable bearing surface on the bottom, which makes it perfect for riveting thick or extremely hard materials. Flat head rivets are very fatigue resistant.

Round Head Solid Rivet

A wide range of materials may be fastened with the round head solid rivet because it has an ample bearing surface on the underside of the head.

Pan Head Solid Rivet

This particular head shape has a tapering head that creates a flat (pan) top. The fatigue resistance of the pan head rivet is quite good.

Countersunk Head Solid Rivet

Countersunk head solid rivets are the best choice for materials that require a smooth surface without any protrusions. As long as the countersunk hole is at the same depth as the rivet head, the top of the rivet will sit at the same level as the surface.

How To Install a Solid Rivet?

In what follows, various steps for installing a solid rivet are described.

Metal Sheet Identification Marks

Mark the region of the metal sheet where the riveting will take place first. By marking, the possibility of incorrect or erroneous riveting is eliminated. As a result, marking is crucial before riveting every substantial rivet.

Placing in Order Metal Plates

As you are probably aware, riveting is the method used to unite two metal sheets. Thus, in order to create the ideal riveting environment, both metal sheets must be put in the designated region prior to placing solid rivets.

Drilling

Making a space for a sturdy rivet to go into the drilled hole is done by drilling. For precise rivet placement, drilling is done to both metal sheets inside the indicated region.

Here, keep in mind that the hole cannot be larger than the radius of a rivet. This can make the rivet less tightly clamped and accelerate the failure of the rivet.

Inserting Rivet

A strong rivet is put into the drilled hole in the metal sheets after alignment and hole drilling. The positioning of the rivet in the hole has to be verified here.

Hammering

The solid rivet is next expanded by applying pressure to its tail, which aids in locking both metal sheets from one side, in the following step. Rivets are simple to hammer into aluminum.

Rearranging and Reformatting

The following process is formatting and adding shape to the tail end that is worn out from hammering, giving it shape to give metal sheets a better finish.

Repeat

Repeat the procedure with the following solid rivet at the designated region or location.

Download Types of Solid Rivets PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- What Are Solid Rivets And How Do They Work? (Clear Guide)

- The 10 Best Rivet Tool in 2023

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- What Is The Difference Between A Blind Rivet And A Pop Rivet?

- What Are Blind Rivets and How Does It Work? (Comprehensive Guide)

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- What is Pop Rivets and How Does It Work? (A Comprehensive Guide)

- 13 Types of Rivets + Applications & Working Principle

- What Is Flush Rivet And How Does It Work? (A Comprehensive Guide)

- 17 Types of Handles In Industry + Features & Applications