Types of Rivets – The four main types of rivets are tubular, metal piercing, solid, and blind (including split rivets). The solid and blind rivets are the most significant rivets from the perspective of structural design.

On Linquip website, among the many options available to you, you will find all the information you need to know about Rivets, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Rivets for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is a Rivet?

To put it simply, a rivet is a mechanical fastener or connection with a head and tail on opposite sides. It features a head, a slender cylindrical body, and a tail that resembles a metallic pin more than anything else.

Although most rivets are made of steel or aluminum, some are also constructed of other materials. These fasteners are not tightened in the same way as standard bolts and nuts. Using unusual rivet installation techniques aids in ensuring long-lasting part assembly or connection.

Working Principle of a Rivet

In the building of machines and structures, rivets are a very important instrument. Drilling, punching, or inserting the rivets into a hole and deforming the tail are various methods of installing them. The most common riveting method involves drilling a hole in the component that will be fastened. This is due to how much easier and more widely available it is.

To properly attach the rivet, a hole that is 1.5 mm larger than the rivet’s diameter is bored into the material. The tail emerges at the other end with a distorted shape as soon as the rivet is inserted. The material is flattened when the rivet tail is pounded or smashed, which frequently causes the tail to unfurl or spread. It increased in size to nearly 1.5 times its initial size.

In other words, by hammering or tugging to break off the tail flatter on one end and produce a new head on the other head, you may construct a rivet the size of a dumbbell. The tail then assumes the form of a dumbbell. The joint has been riveted in this manner.

Various Materials Used for Rivets

Rivets may be made from a variety of metal sources. They consist of stainless steel, copper, brass, aluminum, and steel. To meet their demands, designers and producers pick these various materials.

Rivets now have a limitless range of uses because of these abundant materials. Therefore, it is wise to choose a rivet-making material that complements the characteristics of the components you intend to link.

Steel

Applications requiring rivets can benefit from steels with low carbon characteristics. This is because it can clinch or fit snugly in the application. In contrast to hard high-carbon steel rivets, it is also incredibly adaptable and flexible. High carbon steels have a worse moldability and require more material to produce rivets.

Stainless Steel

The stainless steel rivets are exceptionally tough, durable, and deterioration-resistant. These rivets are used in the aerospace, power generation, and locomotive sectors. Because they can withstand corrosion, these stainless rivets are used.

Aluminum

Another type of metal with a well-known use for rivets and fasteners is aluminum. It is renowned for both its gentleness and lightness. Aluminum is a versatile material that gives a high level of degradation resistance. Aluminum is also extremely malleable, making it possible to build intricate component arrangements readily.

Brass

Flexible, low-friction, and elastic describe brass as a material. It is incredibly strong and tarnish-resistant, which is pretty intriguing. Brass cannot produce sparks because of its characteristics. Brass rivets are the type that works well with gas appliances due to their characteristics.

Copper

In both look and use, copper is a flexible substance. It is remarkably good at transferring heat and electricity. Because copper is such a good conductor of electricity, copper rivets are frequently used in electrical and plumbing appliances.

Various Types of Rivets

There are so many rivets available, which in what follows, a brief description of each will be presented.

13 Types of Rivets include:

- Solid Rivet

- Split Rivet

- Blind Rivet

- Snap Head Rivet

- Tubular Rivet

- Pan Head Rivet

- Mushroom Head Rivets

- Flush Rivets

- Flat-Head

- Conical Head Rivet

- Self-Piercing Rivets

- Drive-Pin Rivet

- Friction-Lock Rivet

Solid Rivet

The shank of a solid rivet is solid and is employed generally. The strongest rivet of them is this one. It may be installed with a hammer or rivet gun and is the most straightforward and durable rivet discovered during the Bronze Age.

The materials used in production come in a variety of colors and sizes and include aluminum, brass, copper, stainless steel, etc.

Split Rivet

Split’s shank is made up of several pieces, each of which may be recognized by a pair of legs on its tail that are folded back on themselves after installation. It is utilized in tiny, lightweight items like bicycle seats, fabrics, leather, and tin plates.

As the name implies, it has a single head at the top and is divided into two pieces from the body side. A bifurcated rivet is another name for it.

Blind Rivet

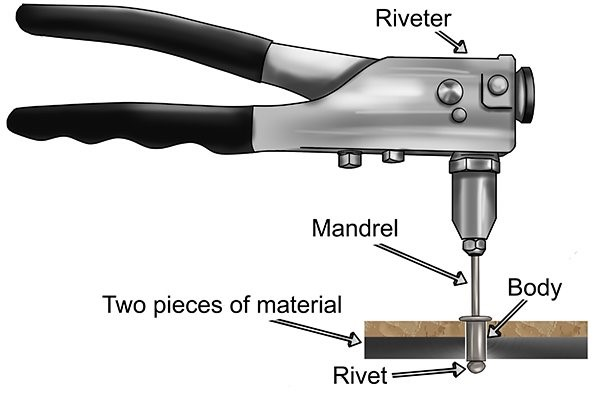

Blind rivets are employed in situations when it is impossible to access the opposite side of the surface, such as something hollow, as their name indicates. The rivet-gun is used to attach metal sheets and other hard materials using blind rivets.

These rivets are frequently used in fragile and soft materials, electrical components, cars, hand tools, locks, household appliances, etc. Common names for it include POP and Break stem rivet.

Snap Head Rivet

The most popular type of rivet, the cup or snap head rivet, provides a highly robust joint. The need for maximum strength in a variety of industries, including manufacturing and construction, is met by the widespread usage of these rivets. The head is 0.7 inches long, and the shank is approximately 1.6 inches in diameter.

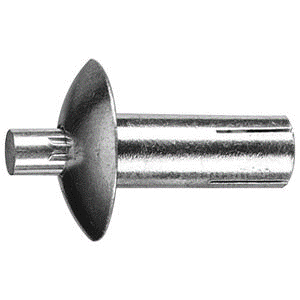

Tubular Rivet

The shank of a tubular is hollow, while the rest is just like a solid rivet. Shoes, file covers, and other items are drilled into it. Additionally, this may be used to fasten leather, plastic, thin metal sheets, aluminum, and pivot points where movement is necessary.

Because of the hollow form at the body end, this is also known as a hollow rivet. This is divided into two groups: Full tubular and semi-tubular.

Pan Head Rivet

Its distinctive shape, which includes a head that is somewhat rounded and slopes downward from the top of the head to offer a firmer grip during attaching, is seen in the diagram.

This may generally be manufactured of materials with a length range of 6mm to 100mm, including carbon steel, brass, copper, aluminum, and stainless steel.

In order to offer the most strength and grip, pan heads are employed in heavy structural construction.

Mushroom Head Rivets

A mushroom head provides the locking required for optimal strength and is used to determine the height of the rivet head on the metal surface.

These rivets have lower profiles than conventional rivets and feature mushroom-like heads, as their name indicates. These rivets are made of materials such as titanium, nickel alloys, and aluminum alloys.

Flush Rivets

For exterior surfaces, flush rivets—also known as countersunk rivets—are utilized to maintain the aesthetic appeal and reduce aerodynamic drag.

This is because it employs both heads and countersunk holes. On the outside of an airplane, flush rivets are useful for aerodynamic reasons that reduce drag and turbulence. To increase airflow, further post-installation procedures could be required.

Flat-Head

Fits ideally for attaching joints, spinning components, and other industrial requirements since it is round, flat, and solidly cylindrical in shape. Compared to solid rivets, this needs less force to penetrate. The slotted rivet is another name for this.

Conical Head Rivet

With a neck angle of 60°, 0.125d of length from neck to bottom (Shank), and a head height of 0.8d, this rivet has a somewhat complicated design.

Self-Piercing Rivets

Before using this type of fastener, no drilling or punching of holes is required. This is because the bevel drill or chamfered poke on the end of these rivets is designed to puncture the target components. Self-piercing rivets create a gas-tight or water-tight junction by piercing the top layer of the material while leaving the bottom layer only partially punctured. The rivet’s tail flares and interlocks with the bottom sheet as a result of an upsetting die, forming a low-profile button.

Drive-Pin Rivet

Drive-pin rivets feature a mandrel pinned in the middle that acts as a self-locking mechanism. Other names for this rivet are Drive rivet and hammer drive rivet.

Because it contains an internal locking mechanism, this type of rivet is frequently employed in situations where it is impossible to access the rear side of the metal sheet.

The rivet will automatically extend from the bottom and lock with the support of the mandrel after you merely hammer the mandrel.

Friction-Lock Rivet

If enough force is applied, friction-lock rivets, which are ones that can be snapped from the shaft end, will do so. This rivet, which is frequently used in maintaining light aircraft, is said to resemble an extended bolt. Self-plugging rivets are included in the category of friction lock rivets.

Applications of Rivets

The main function of a rivet is to provide a solid and trustworthy fastening of two or more metallic or wooden components. By doing this, you may create a joint that is more durable than a screw of the same diameter.

Here are a few applications for rivets:

Rivets in Aerospace

Initially, projects for aviation machining should be created of reliable, sturdy, and solid materials. Unfortunately, if workers don’t properly tighten these hefty and robust components together, everything might come apart. Therefore, just like brazing, welding, and bolting, riveting is crucial for the manufacturing of airplanes.

In order to achieve the fundamental goal of having excellent alignment and the strongest possible combination of elements linked together, riveting is crucial. Due to the difficulties of soldering aluminum alloys, rivets are used to secure them together. Additionally, riveting guarantees order and strength, allowing for lower weight in airplanes. Reaching the far end of a constricted structure may be challenging or practically impossible while working on an airplane. The only solution, in this case, is riveting.

Jewelry

Both expert and novice jewelry makers use riveting as a cold joining technique in their production processes. By employing some instructional videos, fundamental metal forming abilities, and certain common equipment, jewelry makers may quickly apply riveting to establish cold connections. Jewelry makers may now attach metallic components without necessary soldering by using riveting.

Joints

When it comes to building, Rivet is renowned for its effectiveness. It is a complex connector that makes it simple to join various components of a machine or construction. This fastener makes it easier to attach lockers, wooden shelves, and cupboards. Any wooden substance may be connected by using rivets as joints.

Rivets act as a junction that is far more dependable and long-lasting than screws and lines. For instance, furniture that has joints made of rivets is likely to survive longer. This is because, over time, the rivets held the furniture in place.

Building a Home

Perchance should carefully consider what you have inside and outside of your house. One or two rivets that you haven’t seen previously are probably waiting for you. The truth is that they probably exist in your immediate surroundings. The fiberglass roofing can use these rivets. Therefore, rivets assist in holding the glass together if your home has this style of roofing.

Additionally, rivets are a useful element while building gutters. They are a more reliable option than nails for joining metal sheets. More importantly, riveting is used to create structures such as hanging straps, wind barriers, doors, and window shades.

Download Types of Rivets PDF

You can download the PDF format of this post from here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Pop Rivets and How Does It Work? (A Comprehensive Guide)

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- What Is The Difference Between A Blind Rivet And A Pop Rivet?

- The 10 Best Rivet Tool in 2023

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 16 Types of Scaffolding + Components & PDF

- 28 Types of Clamps: A Complete Guide

- 18 Types of Machining Vises (Clear Guide)

- 8 Types of O-Ring + Applications (Clear Guide)

- The 10 Best Welding Machines + Buying Guide

- The 10 Best Electric Lawnmowers

- The 6 Best Leaf Blowers + Buying Guide & PDF

- The 10 Best Snow Blowers + Buying Guide & PDF

- The 10 Best Electric Pressure/Power Washers

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 8 Best Attic Ladders + Buying Guide & PDF

- The 10 Best Electric Space Heater + Buying Guide

- 4 Types of Solid Rivets + Working Principle

Tubular Rivet

Hi There,

Thanks for sharing information about the process and various types of industrial rivets. It seems to be very helpful and knowledgeable.

Keep Updating…

Thanks for visiting our website and leaving your comment! We hope to hear from you again in our other posts.

Based on their characteristics and geographic factors, rivers can be divided into several different categories. These include straight rivers that follow a linear course, braided rivers that have numerous interconnected channels, and meandering rivers that follow a twisting, sinuous path. There are also intermittent rivers that only contain water during specific seasons and perennial rivers that flow continuously. Every type of river contributes differently to the sculpting of landscapes and the support of ecosystems.

To fit diverse purposes, rivets are available in a variety of types. Blind rivets, also known as pop rivets, are practical in situations with limited access while solid rivets, also known as pop rivets, are fundamental and best for structural purposes.