Warehouse Management In Manufacturing – Every firm that stores items in a warehouse know that warehouse management is the difference between completing client orders efficiently and accurately while keeping costs low and hearing complaints about delayed or erroneous shipments and greater operational expenses.

To find out more about Warehouse Equipment and Supplies, please visit our Warehouse Equipment and Supplies for Sale pages, where you can also request a quote. You can also find vast verities of big companies such as Prologis Essentials, which is the only integrated solutions provider with the expertise to optimize your warehouse today and the vision to futureproof it for tomorrow.

What Is Warehouse Management?

The ideas and practices involved in running a warehouse’s day-to-day operations are referred to as warehouse management. Receiving and organizing warehouse space, scheduling personnel, maintaining inventory, and fulfilling orders are all examples of this. Closer inspection indicates that good warehouse management entails optimizing and combining each of those processes to guarantee that all elements of a warehouse operation function together to boost productivity and save expenses.

Benefits of Warehouse Management

Customers are constantly unaware of warehouse operations, although they play a critical role in guaranteeing on-time delivery. Good warehouse management ensures that all warehouse operations function as effectively and precisely as possible to reach this aim. Warehouse management, for example, entails maximizing warehouse space for inventory storage, making inventory easy to find for employees, ensuring adequate staffing, efficiently fulfilling orders, and trying to coordinate communication between providers and transportation companies to ensure materials arrive on time and orders ship on time.

The advantages of efficient warehouse management, such as quick, high-quality service at a reasonable cost, may spread across the supply chain, building relationships with both suppliers and consumers.

However, optimizing warehouse management may be a difficult endeavor due to the numerous factors involved. As a result, many businesses are turning to warehouse management solutions for assistance.

What Is a Warehouse Management System?

A warehouse management system (WMS) is a software solution designed to make warehouse management easier. A warehouse management system, which is frequently included as part of an integrated enterprise resource planning (ERP) suite of business software, may assist and optimize every element of warehouse management. A WMS, for example, can:

- Leverage data and automation to undertake demand assessments, anticipate sales and establish effective daily operational plans.

- Provide real-time inventory location and amount information.

- To improve the effectiveness of corporate operations, share data with other ERP modules or independent software products, such as transportation management systems and accounting software.

- Monitor and report productivity to have a better picture of how effectively your warehouse is running and where improvements in warehouse geography and space optimization may be made.

- Using preset rules, provide step-by-step instructions to assist people through everyday tasks such as receiving, selecting, and packaging orders.

Inventory Management vs Warehouse Management

Before diving into the nuances of warehouse management, it’s a good idea to familiarize yourself with a few key words. The terms inventory management and warehouse management, for example, are frequently used interchangeably, but there are important distinctions:

Inventory Control Is Important.

Inventory management is concerned with efficiently ordering, storing, transferring, and choosing the supplies required to manufacture items or fulfill orders.

Management of The Warehouse

Other areas of warehouse operations, such as warehouse layout and design, labor, order fulfillment, warehouse monitoring, and reporting, are included in warehouse management.

Inventory Control

Stock management is frequently used interchangeably with inventory management, but it’s critical to understand the distinction between the two, especially for businesses that manufacture goods. Stock often refers to finished products ready for sale or distribution. Inventory, on the other hand, refers to everything in the warehouse, including raw materials, materials in the process of being turned into products, and finished goods (stock).

As a result, stock management is a subset of inventory management that focuses on storing as little stock as possible in order to save space and money while still meeting consumer demand.

Principles of Warehouse Management

Understanding the fundamentals of warehouse management can help you focus your efforts on improving the efficiency of your warehouse. These are some of the principles:

- Know what you want to achieve: First and foremost, a warehouse organization must understand its goals. Do your consumers, for example, have certain delivery requirements? Is there a requirement for specialist storage for your inventory? Furthermore, all warehouse operations strive to make the most effective use of warehouse space, manpower, and equipment.

- Control over the entire process: Warehouse management is coordinating complicated procedures with several moving elements, including people, equipment, orders, and inventory. Warehouse managers must be able to track each process in order to ensure that it runs well and to address any issues that arise. To guarantee that orders are completed correctly, quality control is essential.

- Flexibility and resiliency are important qualities: Warehouse managers must be prepared to adjust plans on the fly, whether it’s because materials came damaged or shipments are being delayed due to severe weather. It’s also critical to be able to change workflows to increase efficiency, whether that means reorganizing warehouse space or rethinking picking operations.

- Focus on the customer: When it comes to customer service and happiness, on-time delivery of the proper goods is one of the most critical criteria. You must be able to complete orders fast and precisely in order to deliver on time.

- Making decisions based on data: Even though everything looks to be moving smoothly in the warehouse, it doesn’t guarantee everything is running as efficiently as it might be. A WMS can assist you in identifying and analyzing areas that require development.

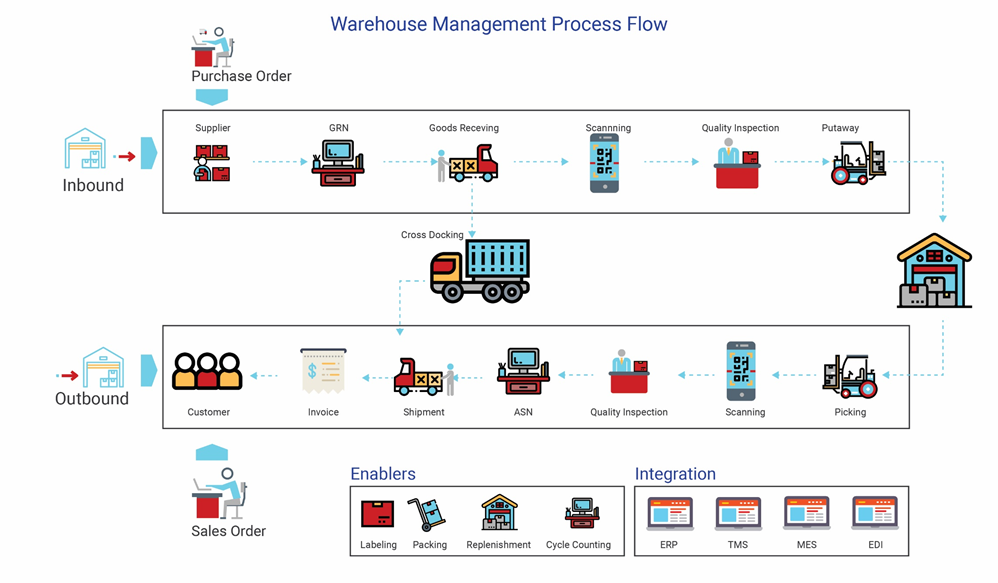

Warehouse Management Processes

Six main procedures make up warehouse management. Because each procedure has an impact on the efficiency of the next, each step must be improved for the warehouse operation to function smoothly:

- Receiving: Check in and keep track of the products that arrive. Make sure you’re getting the proper amount, in the right condition, and at the right time.

- Put-away: Transfer things from the receiving dock to their designated storage areas.

- Storage: Safely store and organize inventory so that it may be picked quickly and accurately.

- Picking: Gather the products required to complete sales orders.

- Packing: Prepare the things you’ve chosen for dispatch. They must be securely wrapped in the appropriate container and accompanied by an accurate packing slip.

- Shipping: Send out the finished sales orders, making sure they’re on the proper vehicle, at the right time, and with the necessary paperwork so that consumers can get their purchases on time.

Optimization of the Warehouse

Each of these warehouse management procedures must be fine-tuned in order to optimize your warehouse business. When receiving products, for example, an organization can use mobile barcodes or RFID tags to make them simpler to find when choosing. A well-managed warehouse operation puts products in the smallest amount of space possible during put-away to optimize the warehouse’s capacity. Other warehouse optimization best practices include putting popular commodities in conveniently accessible places and isolating things that are easily confused.

Warehouse Management Fulfillment Strategies

Choosing fulfillment tactics that are appropriate for the company’s size, as well as the amount and kind of orders it gets, may help it send items quicker, reduce waste, and enhance customer happiness. Picking tactics that are tailored to the types of orders you receive can help you maintain the most efficient workflow. Consider the following scenario:

- Batch picking is a strategy for swiftly filling many orders for the same product without having to return to the same inventory location several times.

- Pickers are assigned to distinct zones of SKUs in zone picking. Pickers are responsible for choosing all SKUs from their allotted zone for each order.

- Picking perishable products and things first expired, first out (FEFO) guarantees that they reach consumers before their expiration or sell-by dates. The items that are designated to expire first are supplied first using FEFO.

- First in, first out (FIFO) picking guarantees that the first products that arrive at the warehouse are distributed first, ensuring that older items are sent before they become outdated.

Any warehouse management fulfillment plan must incorporate technology. Picking speed and accuracy can be improved by using handheld mobile devices that display packing lists with item positions, serial numbers, and lot numbers. Based on product measurements, the software can propose safe and cost-effective packaging to guarantee that each item is sent safely and with as little waste—and wasted space—as feasible.

Warehouse Monitoring & Reporting

Measuring and analyzing key performance indicators (KPIs), which are operational statistics that reflect how effectively a warehouse is performing, may assist in identifying problems and highlight opportunities to increase efficiency and fulfill client orders more promptly and correctly. For example, you may set a goal to enhance picking and packing accuracy, then make adjustments to your picking procedures and see whether they help you reach your objective.

KPIs for the warehouse

The following KPIs, among others, are often monitored by warehouse managers:

- Receiving efficiency or productivity: The volume of items received per warehouse operator per hour is referred to as receiving efficiency or productivity. Higher ratings imply better reception efficiency, but lower scores suggest potential issues that should be examined.

- Picking accuracy: Picking accuracy is calculated by dividing the number of orders correctly chosen by the total number of orders picked (including incorrect or short orders). The closer to perfection you can get, the better.

- Order lead time: The average time it takes for a client to receive an order after it has been placed. The shorter the lead time, the better for maximum client satisfaction.

- Product return rate: The percentage of sold goods that are returned by customers, computed by dividing the number of returned things by the number of items sold. To gain a whole view of this KPI, evaluate why things are being returned—a customer buying the wrong product by accident may not indicate warehouse operating concerns, but if consumers frequently get inaccurate or damaged goods, there is space for improvement.

- Inventory turnover: Inventory turnover is the amount of inventory that is sold and replaced in a specific time period. It’s computed by multiplying the total cost of products sold for the period by the average inventory cost. This KPI measures how well a warehouse maintains inventory in order to satisfy demand. Higher inventory turnover is preferable in general. Inventory turnover may be poor if a warehouse overestimates demand. Having too much slow-moving inventory may be expensive, especially for organizations that deal with commodities having a set shelf life.

Warehouse Management Statistics

Global ecommerce has exploded in recent years and is predicted to reach $29 trillion by 2023, necessitating additional warehouse capacity to meet rising consumer demand. By 2025, ecommerce development is predicted to raise demand for warehouse space in the United States by 1 billion square feet. It’s hardly a surprise that 79 percent of warehouse operations expect to expand, according to a poll published in the trade monthly Logistics Management.

Given this expansion, warehouse operations confront a number of challenges, including the difficulties of attracting and keeping skilled hourly workers. Warehouse operations are progressively using technology to automate processes to improve productivity, reduce operating costs, and keep up with customer demand—all while battling tight space and a tight labor market. According to the Logistics Management survey, 85 percent of warehouse operations use WMS.

Choosing a Warehouse Management System (WMS)

The best WMS for your warehouse business will be determined by the characteristics of your operation and the goals you wish to achieve. Above all, the ideal WMS should assist your company increase efficiency and reliably complete orders, allowing you to accomplish more with less. Because the primary purpose is to save money, the return on investment (ROI) is crucial.

A WMS should also serve as a guide to help all warehouse employees become more productive in the workplace. To do so, the right WMS will deliver real-time actionable insights into every aspect of your warehousing operation, including receiving, inventory, shipping, order fulfillment, and labor—while also providing simple statistics and reports that managers and workers can understand and use to enhance daily and long-term processes. A WMS should also be scalable, allowing your company to expand and react to changing market conditions.

The correct warehouse management system can boost your warehouse’s efficiency, speed, and order accuracy, boosting your company’s competitiveness and increasing customer satisfaction while lowering operational expenses.

You are also encouraged to visit the Linquip website to find out more about warehousing management and also find a great deal of Warehousing Management Services.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Top Manufacturing Warehouses in 2022: A Clear Guide

- 11 Essential Warehousing Services Offered by Warehousing Companies

- Top Warehouse Suppliers in 2022: The Best All over the World

- Best Warehouse Pallet Shelving of 2022: A Clear Guide

- High Bay Lighting Buying Guide: An Ultimate Guide

- Best Pallet Jacks of 2022: A Clear Guid

- Prologis Essential Company Page on Linquip

- List of All Prologis Essential Service

- Prologis Essentials General Services

- Prologis Essentials Installation

- Prologis Essentials HVAC Maintenance

- Structural Pallet Racking for Sale by Prologis Essentials

- Warehouse Lighting Products by Prologis Essentials

- High bay LED lighting Products by Prologis Essentials

- Warehouse Solar Products by Prologis Essentials