AC motor is an abbreviation for Alternating Current motors invented by Nicola Tesla to transform energy from electrical into mechanical just like DC motors (Directional Current motor).

AC motors may be found in fans, hairdryers, clocks, washing machines, and many other applicants providing services in offices, factories, businesses, etc.

What is AC Motor?

The two main different kinds of electrical Motors are AC motors and DC motors.

While both produce mechanical energy, AC motors use alternating flow of current, which is a kind of electric current and periodically reverses direction as an input. As a result, the speed of producing mechanical energy by an AC motor depends on the speed of changing direction per sec.

The main difference between AC and DC motors, apart from the structure, is the type of electrical energy used to produce mechanical energy. In other words, while AC motors make use of alternating current to produce mechanical energy, DC motors transform a different type of electrical power known as Direct Current to mechanical energy.

There are also advantages associated with AC motors in comparison with DC ones:

– AC motors are more durable

– They have lower costs

– The operation is easier

– Less need for maintenance and part replacement

You can see the most common types of AC motors in the chart below:

AC Motor Types

There are many different AC motor types. However, they may slightly differ in their capabilities and traits.

If you are to buy one, you need to know the differences, weaknesses, and strengths so that you have the best possible choice.

The most common AC motors include:

- Induction motors

- Brushless AC motors

- Synchronous AC motors

- Squirrel cage AC motors

- Shaded-pole AC motors

- Single-phase AC motors

- Second phase AC motors

- Third phase AC motors

- Clockwise

- Anti-clockwise

- Reversible

As you see, some are branched based on the motor type, while others are named after the phase count, maximum output speed, frequency rating, supply voltage or rotation. There are also other types branched based on the pole count, shaft length, efficiency class, etc.

Among all, the two most common motors are Inductive and synchronous engines described below. To read more about the other types, you can click on the names (if it is clickable).

Induction Motors

Induction motors are more suitable for starters than the other type due to the ease of maintenance and their simplicity.

The strength of inductive motors is their constant speed even from the first stage of loading. These kinds of motors are used for domestic as well as industrial machines. They are also known as asynchronous motors.

Synchronous Motors

These motors move synchronously with the speed of alternating current, so obviously the rate will not be constant.

While synchronous motors do not support constant speed througout loading or working, the speed of the motor is controllable.

Synchronous motors are mostly used in industries due to the massive amount of energy they can produce. Additionally, they are so large, noisy, and costly, which makes them unsuitable for domestic uses.

Read More on Linquip

- What are the Advantages of DC over AC?

- AC Series Motor

- DC Motor Parts, Structure, Design and Advantages

- Commutator Motors: A Short Introduction to the Structure and Working Principle

- Difference between AC and DC generators: An easy to understand guide

- The Good Guide to Types of Electric Motors

- Everything You Need to Know About Working Principle of AC Motor

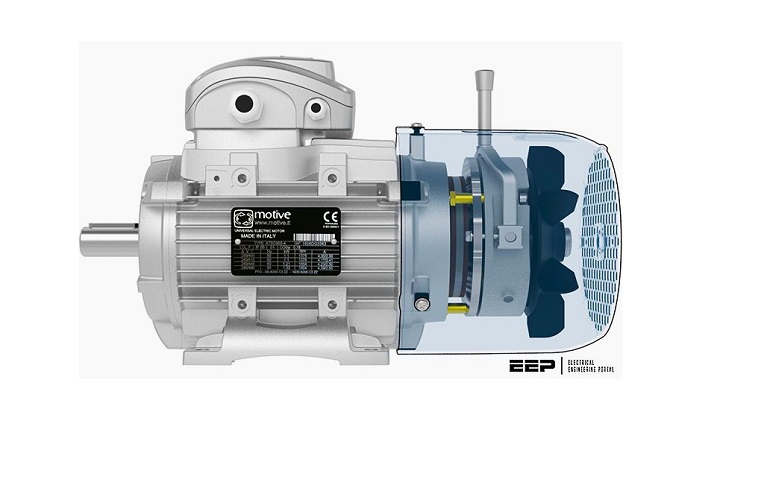

AC Motor Construction

AC motors do not have commutators (brushes) while DC motors do. That is why they need less maintenance. The brushes conduct energy from the source to the armature.

In AC motors there is no need for brushes to lead electricity. Instead, there are other parts in an AC motor working together to transform electrical energy into mechanical energy.

The three central part of an AC motor includes: (we will discuss the structure of an AC motor in detail in another post.)

Alternator

AC motors use an alternator to alternate the direction of the current. So the alternator works as a generator in AC motors.

Rotor

Rotor is a spinning shaft that receives current from the generator and produces an electromagnetic field (EMF) with two poles.

Stator

The rotor itself turns around (or within) stator which is a set of copper wire coils. This will make the EMF switch its direction, and the poles will switch as a result.

AC Motor Working Principle

AC motor is controlled by the voltage and frequency, which will cause varied number of magnetic poles.

1- Making an electromagnetic field

As it was mentioned earlier, a magnetic field is made due to the rotor turning around the stator which is rotating itself.

2- Switching the poles

The rotation cause EMF changes its direction constantly, and it will switch the poles subsequently.

3- Doing an electrical circuit leads to movement

So, there is an EMF made in the stator which is rotating. Remember that the stator covers the rotor (or vice-versa) producing its own electromagnetic field.

Hence there would be a South and the North Pole in the stator and a South and the North Pole in the rotor. Each pole in the rotor attract the opposite side in the stator. Since there is a drive shaft passing through the rotor, it can move freely toward the opposite pole in the stator. The movement produce the mechanical energy needed and that is how electricity transforms into mechanical energy.

The picture below shows the process clearly:

Although the way an AC motor works depends on its type and definitely it is more complicated than only three simple stages, we only explained the principles universal in every kind of motor, in short.

AC Motor Price and Cost

If you are to buy an AC motor and do not know how much you need to invest, we are here to help you with that.

What do you need?

Before anything else, you need to know what exactly you need, i.e. what do you want to do with your AC motor? Is it going to be used in home appliances or you plan to use it in a factory? The more time you spend on that, the more you avoid wasting your money by buying what cannot meet your demands. Likewise, when considering treatment options for conditions such as nerve pain or seizures, it is important to know exactly what you need from the medication. Generic Neurontin (gabapentin) is a universal drug that can be effectively used to treat various neurological diseases. By understanding your specific health needs, you can choose Generic Neurontin to effectively control your symptoms without spending money on unnecessary treatments. For detailed information on the uses and benefits of generic Neurontin, visit this link.

- The AC motor type

You can do that by investigating different types of AC motors. Remember, if a simpler motor can do what you need, do not buy a more complicated and more expensive one.

- The AC motor strength

The other determining factor is the country that made the motor. The quality, the price, and the strength may differ. Some countries may not produce some specific AC motor types.

After determining your need, it is time to take a look at your budget.

Which one is more expensive?

Industrial motors can cost from hundreds of dollars to hundreds of thousands of dollars depending on the motor size and the energy they produce per sec. Now it may be clear that domestic motors are usually cheaper than the industrial ones because of the size and the power they have.

Get advice

To have a better idea of AC motor costs and prices, we suggest checking the https://www.linquip.com/ equipment or make a call for getting advice from our experts.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers