The electronic expansion valve is a device that is used to control the refrigerant flow into the evaporator in precise amounts. Therefore, they can be found in air conditioners, heat pumps, and other equipment that follow the refrigeration cycle.

Refrigeration systems employ electronic expansion valves to accurately control the flow of refrigerant into the evaporator. In Industrial Applications, The Electronic Expansion Valve Is A Critical Component. Electronic Expansion Valves are available from a variety of suppliers and companies, as well as Manufacturers and Distributors, with several Electronic Expansion Valves for Sale on Linquip.

There is a comprehensive selection of Expansion Valves services on the Linquip website that covers all of your needs. Linquip can connect you with a number of Industrial Expansion Valve service providers and experts who can help you. Linquip offers a team of Electronic Expansion Valve experts available to help you test your equipment.

You can find what you are looking for regarding your HVAC requirements here at Linquip, and we encourage you to read along to get to know an important component of your cooling system.

⇒ View a Comprehensive List of Valves and Their Suppliers ⇐

The role of expansion valves

An expansion valve is a flow regulator that is intended to decrease the pressure of the fluid reaching to it by partially vaporizing it, which leads to lowering the temperature of the refrigerant in the case of cooling systems due to increase of heat transfer surface area. Not only does it regulate the fluid temperature, but also it regulates the flow rate to entering the evaporator.

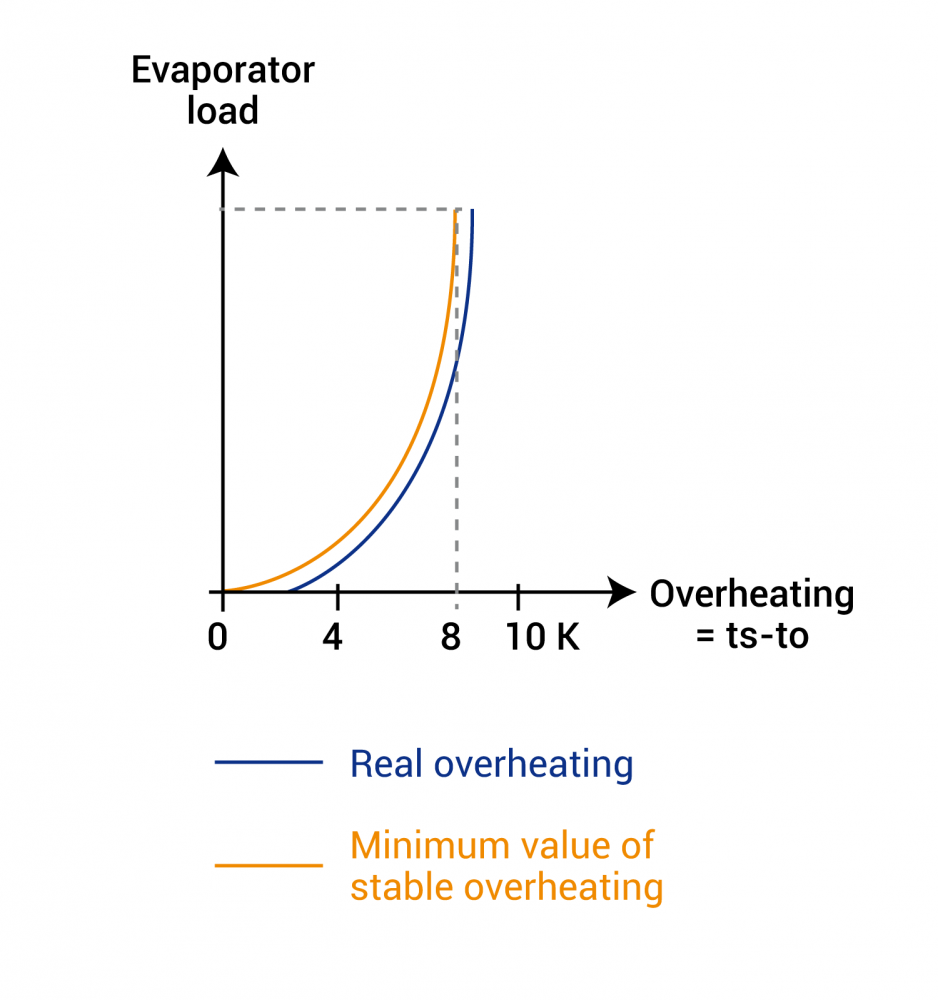

Refrigerant flow rate regulation is a sensitive task. If the refrigerant flow is too little, then evaporation would take place at a fast pace, leading to a consequent rise of temperature due to further heat transfer. This means that the evaporator efficiency would decrease as a result of refrigerant warm-up and overheating. Moreover, excessive refrigerant transmission leads to insufficient evaporation, which could damage the compressor.

It is, therefore, desired to avoid any excessive refrigerant flow passage and adjust the amount of the fluid transferred to the evaporator by monitoring the level of overheating.

The amount of overheating can be calculated by subtracting the compressor’s suction side temperature from the evaporation temperature. A temperature sensor is installed on the expansion valve, and another temperature sensor is placed at the exit of the evaporator (which is the suction temperature of the compressor) to provide the values for overheating calculation.

Now, expansion valves come in two different types. The first type is the thermostatic or thermal expansion valve, aka TXV, and the second one is the electronic expansion valve, or EEV.

Advantages of the electronic expansion valve

Despite the fact that an EEV costs more than a TXV, it has many benefits that could make it the better solution for your needs. To begin with, the electronic expansion valve is highly reliable, quickly installed, and can be integrated with a centralized controlling unit to automate and optimize the control of the refrigerant throughout the entire refrigeration circuit. Moreover, it is quite flexible in terms of the refrigerant type.

In addition to the aforementioned, it can deliver a good performance at low condensing pressures where the pressure difference across the evaporator is very low due to better overheating control. Now, the strength of the electronic expansion valve here is that it maintains the compressor’s performance at similar levels, no matter how much the evaporator load is. It would more precisely control the amount of evaporation and save energy consumption as much as 15%.

Main parts of an EEV

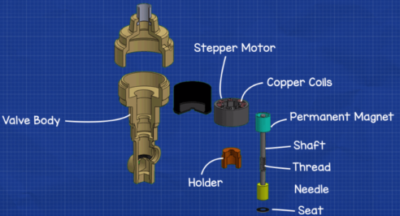

Although there are different designs for an electronic expansion valve, the general design would include a permanent magnet and a copper coil inside the stepper motor body, placed at the top, by which an electromagnetic field is generated. The stepper motor is coupled with a shaft that is connected to a thread. When energized, the shaft pushes the thread and then the needle onto the valve seat, and this is how an electronic expansion valve controls the refrigerant flow rate.

Principle of operation for an EEV

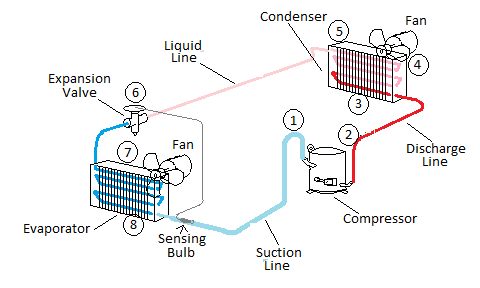

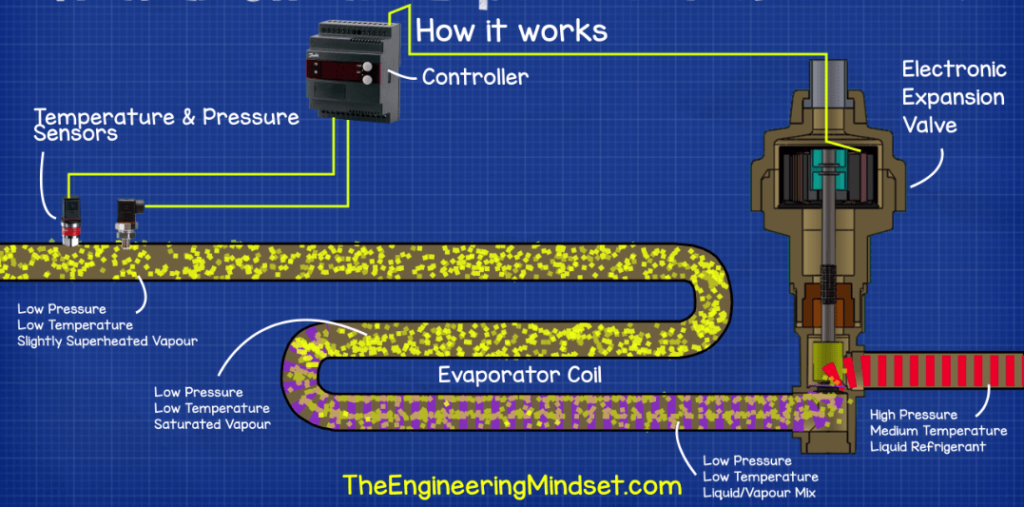

A refrigeration system comprises of different parts that make the cycle. These parts include the evaporator, compressor, condenser, and the expansion valve.

What happens in the evaporator is that it transfers the heat from the conditioned environment to the low temperature, gas-liquid-mix refrigerant, evaporating it in a process that lowers its pressure.

The low-pressure, low-temperature evaporated refrigerant is then taken to the compressor, in which the gas pressure and temperature rise to high levels, and it turns into a super-heated vapor.

The condenser receives this super-heated refrigerant and rejects its heat to the atmosphere during a condensation process. During this process, the pressure of the condensed refrigerant would remain high, but its temperature falls to medium levels.

The saturated refrigerant then reaches the EEV, which would partially be evaporated based on the evaporator demand in a process that lowers the pressure and temperature of the refrigerant to low levels.

In order to complete the cycle, the liquid-vapor mixture would be sprayed into the evaporator to absorb the heat from the environment during passing through the evaporator coils into which the environment air is blown by a fan. The rest of the liquid would evaporate during this phase in a quasi-isothermal process, leaving the evaporator as a superheated vapor.

As was mentioned earlier and also the figure above, a controlling unit would constantly measure the pressure and temperature of the superheated vapor as well as the temperature of the refrigerant at the expansion valve in order to produce the right amount of evaporator demand signal.

The way that the measured pressure will help with this demand signal sent to the electronic expansion valve is that its corresponding saturated temperature is calculated at the controller unit based on thermodynamic tables, which is then compared against the measured temperature. It enables the control to decide on how much refrigerant to pass the electronic expansion valve. The signal will then be transmitted to the stepper motor, energizing the coils accordingly, enabling flow control by pushing down or pulling up the needle on the valve seat.

The adjustment of downwards or upwards motion of the needle is handled by the rotation of the permanent magnet due to the polarity of the magnetic field in the coil. As the magnet is rotated by fractions of a revolution, the shaft would also rotate accordingly. Based on the direction of shaft rotation, the threaded assembly would pushe down or pulls up the needle.

See All High pressure valves for Sale

Points to consider

The electronic expansion valve is the proper solution when the performance of the cooling system is a priority, and you are looking for saving operational costs. However, you need to consider the fact that refrigerant bleeding from the electronic expansion valves to the condenser could be the case for some of EEVs. This means that excessive refrigerant would enter the condenser leading to some liquid remaining in the stream entering the compressor that could damage it. In such cases, you need to place a solenoid valve prior to the EEV.

How The Expansion Valve Is Controlled?

The thermostatic Expansion Valve controls the flow of liquid refrigerant into the evaporator coil by a valve mechanism. The pressure in the evaporator regulates the flow. This sort of metering device is appropriate for use in air conditioning systems since it can perform effectively when the load varies.

How Do You Test an Electronic Expansion Valve?

As directed by Service Facts, do a “Closed Valve Test.” 15 seconds after jumping the pins, remove the stepper motor from the EEV. The check valve is leaking if the valve is closed but the refrigerant continues to flow. Crimp the tubing between the check valve and the EEV with a pinch-off tool.

More on the electronic expansion valve

To learn more about how an EEV works, you can watch the video here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Download Electronic Expansion Valve PDF

Read More on Linquip

- Control Valve Types 101: Different Classifications, Advantage and Disadvantages

- Ball Valve Types and Their Uses

- Angle Valve: The Most Essential Tips of Features, Functions & Applications

- Types of Expansion Valves: an Easy to Understand Guide

- Industrial Valves A Comprehensive Review on Parts, Types and its Usability

- What is Automatic Expansion Valve: A Basic Guide

- Flow control valve types and functions

- Facts About The Flow Control Valve Function

- List of Valves Manufacturers

- Control Valve Manufacturers in United States

- Check Valve Manufacturers

- Hydraulic Valves Manufacturers

- Butterfly Valve Manufacturers

- Needle Valve Manufacturers

- Solenoid Valve Manufacturers

- What is Actuator Valve

- What is Air release valve

- What is Angle Valve

- What is Ball Valve

- What is Bleeder Valve

- Flanged Control Valve V150 for Sale

- Fisher EZ Control Valve EZ for Sale

- Control Valve ET for Sale

- Thermal Expansion Valves: Everything You Need To Know

in regard to refrigerant bleeding to the condenser or EVAPORATOR ?? How does the EEV react in a reverse cycle, does it shut down or fully open ??