If you want to know how springs are made, this article is an invaluable resource for you. A spring changes shape when it is subjected to an external force and returns to its original shape when the force is removed. Upon returning to its original shape, it is able to recover the energy it expends in deforming it. The amount of shape change is generally directly proportional to the force applied to it.

In addition, our team of experts is always available to help you select the right spring for your specific needs. You will find all the relevant information you need about springs on Linquip’s website. Linquip’s article, “Springs and Shock Absorbers,” may be very helpful to you if you are interested in getting a basic understanding of what Linquip can offer you with respect to these devices.

You can find the right spring for you with Linquip’s selection of Springs Products. The Linquip platform is a great resource for finding spring prices if you are interested in doing so. You can submit your request/inquiry for free to all Spring Suppliers and Companies on the platform.

From mattresses to consumer goods to industrial machinery, springs are practically everywhere. Various applications use them for storing mechanical energy and providing tension and compression. Spring is generally understood by everyone, but most people don’t know what springs are made of or how they are made. The purpose of this article is to describe how springs are manufactured, what differences exist, and what materials springs are made from.

A Brief Introduction

In history, springs have been used in all kinds of things, such as bows and arrows, Egyptian chariots with primitive shock absorbers, and Leonardo da Vinci’s spring-loaded pistol. Springs have made our lives more convenient over the years.

The spring-driven clock was invented in the 15th century. The leaf springs were used to smooth out horse-drawn carriage rides in the 18th century. Without springs, there could not have been an industrial revolution. In the present day, their thickness can range from a hair to an arm.

There is no doubt that spring components play a crucial role in the durability of many products, so it is essential to choose springs that won’t fail prematurely. A spring malfunction can be caused by a variety of factors, including poor design, inferior materials, or an inferior manufacturing process.

Springs: How Are They Made?

It is relatively straightforward to manufacture springs, although there are some variations depending on the type of spring. At their most basic level, springs are manufactured with winding, heat treatment, grinding, coating, and finishing.

Following is a detailed explanation of each step:

1. Spring

The first thing that needs to be done is to feed the spring wire into the spring machinery. Using this semi-automatic machine, the wire is first straightened from its coil, resetting it into a straight line. The spring wire is then coiled, formed, or bent by the machine.

Below are more details about these processes:

Coiling

Spring coiling is done with a spring coiler or a machine controlled by computer numerical control (CNC). In order to make a specific coil, the technician sets up the machine for it and feeds the wire into rollers that pull the wire toward a set of guides. These guides eventually lead the wire to a coiling point or a set of coiling points, which coil the wire backward and create a spring. Such mechanisms are used to create compression springs, extension springs, and torsion springs.

Forming

In this process, a spring former or CNC spring former machine is used. It has six to eight tooling slides on the face, enabling it to perform several types of bending, hoops, and radii along with the spring coil. By using spring formers, a variety of spring shapes can be created. In addition to extension springs and torsion springs, they can also manufacture compression springs and wire forms.

Bending

CNC wire benders, which are mechanical machines controlled by computers, are used for bending wire. It functions by feeding wire into a set of rollers, which pull the wire into wire guides and push it to a computer-controlled movable tooling head. Various bends and shapes are performed by the tooling head. Creating wire forms is the main function of the wire bender.

For a wide range of industries and products, these processes are used individually or together.

2. Heat Treating

As soon as a spring is formed, it should be subjected to a stress-relieving process in order to retain its memory. As a result of this memory, springs can bounce back when stressed. It is necessary for manufacturers to heat treat springs after they have been formed in order to achieve this.

Spring manufacturers must heat-treat springs at a specific temperature for a certain amount of time during the heat-treating process. The temperature and time setting depend on the type and quantity of wire involved in the process. It may then undergo additional heat treatment steps, such as quenching or cooling down, before going through another round of heat treatment. Materials and manufacturing processes determine what type of material is used.

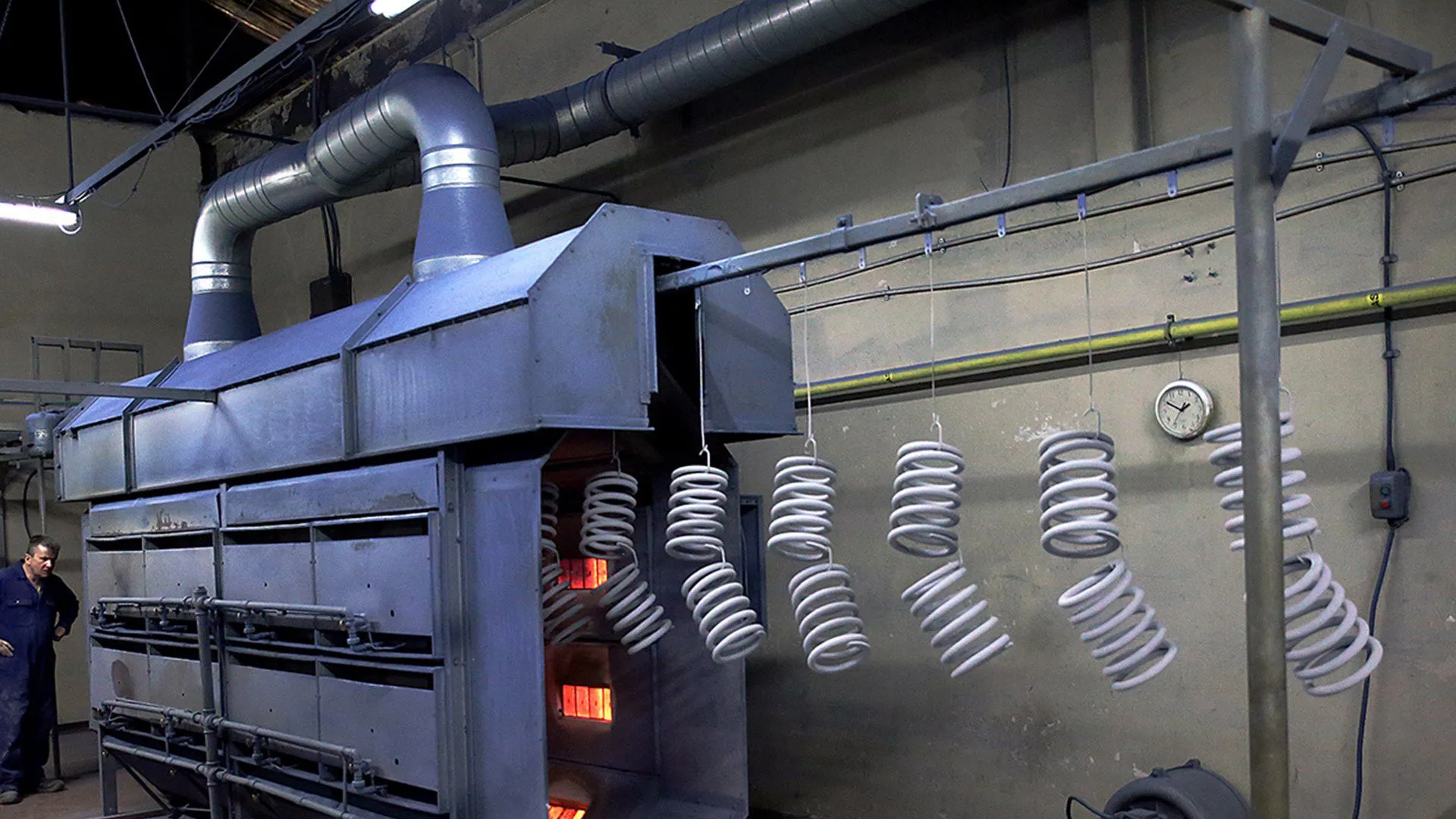

Usually, heat treating springs is done using conveyor belt ovens. As springs leave a spring machine, they fall down a slide and onto the conveyor belt, which takes them to the oven’s mouth.

In the oven, the spring moves along a conveyor belt, moving at a speed that allows it to remain in the oven for a suitable length of time. Once it is removed from the oven, it is conveyed to a cooling box.

3. Grinding

The ends of compression springs and coil springs can be ground flat during a grinding process if the design calls for it. This allows them to stand straight when oriented vertically without wobbling.

With the spring grinder, the length of the spring can enter between the two horizontal grinding wheels spaced apart in such a way that the spring can pass between them. In a separate part known as a spring dish, the spring is held and moved between the grinding wheels at a slow pace.

When the plate moves, the spring ends are ground down by the grinding wheels so that the end surfaces are perpendicular to the side surfaces. Once this has been accomplished, the spring dish discharges it into a receiving box.

4. Coating and Finishing

In addition, springs are often coated, plated, or finished for a final touch. During the finishing process, the spring’s surface is subjected to additional steps that can help combat erosion, improve the spring’s overall appearance, or lend new properties to the spring. Among the common finishing processes are:

Shot Peening

A cold-worked spring is finished with shot peening by shooting spherical shots at the wire, causing compression stress and creating layers of compression dimples. By hardening the surface, the material becomes more resistant to fatigue, corrosion, and cracking.

Plating

As a result of plating, a thin layer of metal is applied to the surface of a spring or wire form. Electroplating is a method of doing this which uses chemicals and electrical currents to bond the metal to the spring wire surface. As a result, the plating can enhance the spring’s corrosion resistance and strength. It can also improve its aesthetics or physical properties.

For example, an elevated electrical conductivity is provided by copper and gold platings, while a chrome finish is provided by nickel and cadmium platings.

Powder Coating

The powder coating option is another way to finish wire springs. Powder coating is usually added to hot-drawn springs and helps prevent rust from forming. They can also be dyed for aesthetic purposes.

Spring finishes enhance the performance of springs, giving them new properties or simply extending their lifespan.

5. Packaging

Bulk packaging of springs in boxes or plastic bags is an easy way to package desired quantities. To minimize spring damage or tangling, different packaging types have been developed. It is possible to bag them individually, string them on wires or rods, enclose them in tubes, or adhere them to sticky paper.

Quality Control

In order to ensure that springs meet specifications, a variety of testing devices are used. Testers measure properties such as the hardness of metal and the deformation of springs when subjected to a known force. Spring failures are discarded. Manufacturing companies can use statistical analysis of test results to improve processes and reduce defective spring production by identifying production problems.

Production problems account for approximately one-third of defective springs, while wire deficiencies account for the other two-thirds.

A computer-operated coiling machine improves quality in two ways. First, it can accurately adjust the spring diameter and pitch. Second, CNC coiling heads can precisely adjust to spring characteristics in real-time through the use of piezoelectric materials with varying sizes with electrical input. Consequently, these intelligent machines produce fewer springs that are rejected due to not meeting specifications.

Spring Types

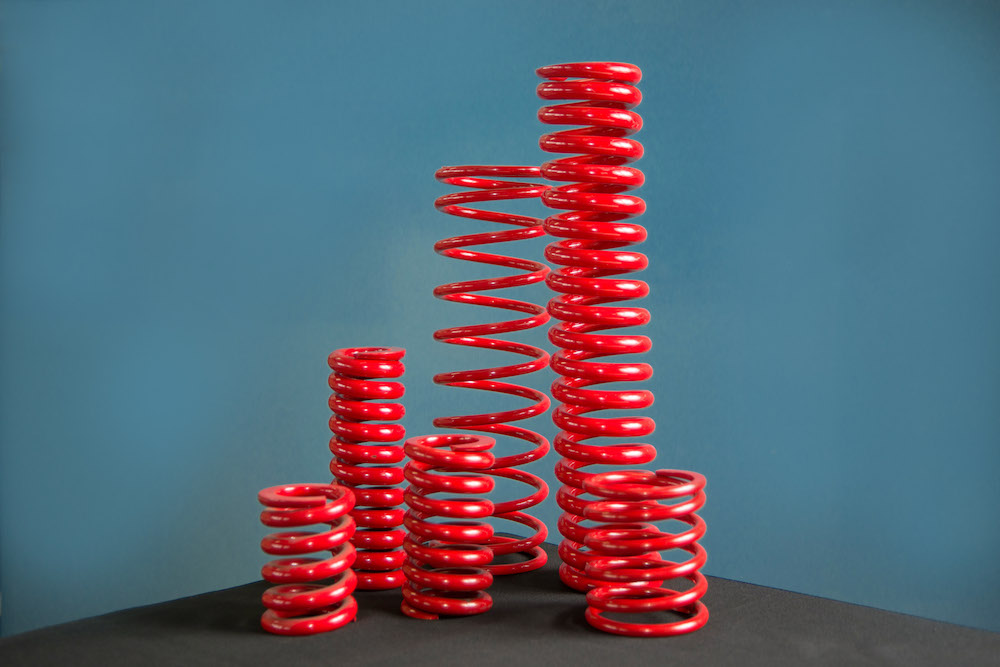

Springs are manufactured in a variety of ways, depending on their particular design and use. Springs may have coils or not, and coils, along with the type of spring used, all determine how springs are manufactured.

Most people think of springs as springs with coils, also called coil springs or helical springs. A coil spring is wound with wire coiling or wire-forming machines, resulting in a helical shape. There are several subtypes of coil springs, and each has its own variations in the manufacturing of helical springs.

Extension Springs

The extension spring consists of coils that touch each other when stretched. As the spring is stretched, the coils separate, but the spring exerts a force to return to its original position. In general, extension springs are made by coiling wire, but they may also be made by wire-forming machines, especially if they feature loops at their ends. Alternatively, extension springs can be ground down at their ends.

Compression Springs

A compression spring has coils that are separated at rest but squeeze together when force is applied, unlike an extension spring with coils touching at rest. Compression springs push back against an applied force. Manufacturing compression springs primarily involves coiling machines, but in some cases, spring formers may be used as well.

Tapered Springs

A tapered spring has a smaller diameter at one end than at the other, which creates a tapered appearance. Although it works like other compression springs, this spring has greater stability on the lateral plane than a standard cylindrical compression spring due to its shape.

Conical Springs

Another type of compression spring is the conical spring. The conical shape makes it possible for the spring to have a reduced height.

Hourglass Springs

The hourglass compression spring has a unique shape compared to the other compression springs. An hourglass spring has a narrower diameter in the center than at the ends. As with a conical spring, the concave shape allows for easier centering and lower solid heights.

Torsion Springs

A torsion spring is shaped differently from a conventional spring, extending from the coil at both ends. When force is applied to its ends, it twists into a tight spiral, pushing against it. Examples include springs used in utility trailers or truck doors. Similarly to extension springs, torsion springs are usually manufactured by coiling or forming machines.

Belleville Springs

With a compact volume and a large load, this spring is easy to combine and use and has the advantage of centralized load transmission. In the mechanical industry, it is often used in place of cylindrical springs. As compared to other types of springs, it has greater deformation energy and better shock absorption capacity. Due to the friction-damping effect of the surface, it is more effective at absorbing impact and dissipating energy. In recent years, it has been widely used in industries such as the military, metallurgy, engineering, power, machine tools, construction, and others.

Flat Springs

The springs are flat or plate-shaped and are sometimes known as plate springs or leaf springs.

Single-piece springs: These springs are formed from metal sheets, and the spring will be elastic if the direction of curling is opposite to the direction of the force application.

- Disc springs: this is a spring with a similar shape to a washer, which is used in small spaces.

- Power springs: long and thin metal sheets are wound into spiral shapes and placed in a box.

- Cantilever plate springs: one end of the spring is fixed, and the other is suspended in the air.

The energy efficiency of a leaf spring is slightly lower than that of a spiral spring, but it can carry a heavier load, so it is commonly employed in automobiles, trains, and other motorized vehicles.

Friction Springs

There are several inner and outer rings in the spring that have conical surfaces, and these rings are made of friction-resistant alloy steel or high-quality carbon steel. In order to improve bearing capacity, each ring is rolled and heat-treated according to its required shape. As a kind of powerful spring with great shock absorption capacity, friction springs are used when space is limited, and buffers are strong.

Air springs

By incorporating pressure air into a flexible closed container, this spring is able to achieve elastic properties by utilizing its compressibility. As a result of its excellent elastic characteristics, it significantly improves the ride comfort of high-grade vehicles when used in suspension devices. In automobiles and railway applications, air springs have been widely used for many years.

Customized Spring Manufacturing

As well as varying based on the type of spring involved, spring manufacturing processes may also change in cases of custom springs. Often, custom springs are needed for unique manufacturing applications where a unique spring shape, material, or finish is required that does not fall within normal specifications. As a result, clients collaborate with coil spring manufacturers to design and manufacture the springs they require.

A client will provide designs to their custom spring manufacturer as part of the custom spring manufacturing process. The manufacturer then produces prototypes for testing that the client can use to tweak the design to meet the application’s requirements. A spring manufacturer can produce a production run of the spring once the design is finalized.

What Are the Materials that Springs Are Made of?

After examining how springs are made, let’s take a look at what a spring is made out of.

Metals that make up springs are categorized into three categories: high carbon, steel alloys, and stainless steel.

High Carbon

A high-carbon spring is one of the most common spring materials because it is relatively inexpensive and versatile. A high carbon wire can be either a music wire or a hard-drawn wire. Music wires are often used in tools, while hard-drawn wires are commonly used in commercial products. In general, however, high-carbon wires aren’t suited to high temperatures or corrosive environments.

Steel Alloys

Among the materials used in large springs are steel alloys such as chrome silicon, which can withstand high temperatures but still corrode at high temperatures.

Stainless Steel

In metal springs, stainless steel wires are the third most popular, primarily because of their corrosion resistance. There are many types of stainless steel springs, each with its own level of elasticity and hardness. Medical devices and outdoor applications often use stainless steel springs.

So, what is the best material for spring production? That depends entirely on the application. Physical properties and cost will play a big role in selecting the best material.

The most common material for springs is metal; however, certain applications may require non-metallic materials. Rubber or urethane can be used for cylindrical non-coil springs, whereas ceramic has been developed for high-temperature coiled springs. Although each of these uses is highly specialized, most springs used in machines are still made of metal today.

History

For thousands of years, humans have used springs to store energy. From bows and arrows made of non-coil tree branches to catapults, humans have developed spring-loaded devices for storing energy. Tutankhamun’s carriages featured layered leaf springs developed by Egyptians.

As mechanical clocks spread throughout the fifteenth century, coiled springs were introduced. Mechanical clocks store energy by tightening their springs, which, as the springs loosened, pushed the hands around the face of the clock.

The idea of Hooke’s law was developed by Robert Hooke in 1676. He proposed that the force exerted by a spring is proportional to the length of its extension. By the 19th century, springs were mass-produced, and that principle would, in many ways, drive the Industrial Revolution. With the development and improvement of steel production, spring usage rapidly increased, allowing for rapid and innovative advances in spring technology.

There have been a number of new discoveries in metallurgy that have greatly expanded the uses of springs over the years. Some iron alloys and metals have been heat-treated to improve their strength after being coiled.

It is important to use a proper mixture of alloys to increase spring ductility and resistance to environmental damage. The wire used in spring production is made from a variety of materials, depending on the application. High-carbon spring wire, alloy steel wire, and stainless steel wire are the most common types. Whenever electrical properties and corrosion resistance are required, nonferrous or copper-based alloys such as phosphor bronze or beryllium copper are also used.

There is a wide range of applications for springs today, just as they have throughout history. They are essential components of industry and manufacturing throughout the world. It is not necessary to look any further than a pen or a car, but if you do, you will likely find a spring in the device.

Download PDF for How Springs Are Made

You can download a PDF version of this article for future reference and reading by clicking the link below.

linquip.com-How Springs Are Made

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Is 3D Printing and How Does It Work? + Applications

- What Are Solid Rivets And How Do They Work? (Clear Guide)

- What Are Blind Rivets and How Does It Work? (Comprehensive Guide)

- What is Pop Rivets and How Does It Work? (A Comprehensive Guide)

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 17 Types of Hinges and Hinge Materials: A Complete Guide

- How to Use a Laser Level? (Clear Guide)

- 13 Types of Syringes With Purpose and Features

- 12 Types of Pipe Benders and Their Characteristics

- 12 Types of Tweezers + Their Advantages & Usage

- 12 Types of Gas Springs with Their Mechanisms & Characteristics