In this article from Linquip, we want to talk about different types of isolation valves. Isolation valves are crucial parts of a fluid handling system. They have been designed specifically to stop the process media flow to a given location. This can be either for safety or simply for maintenance purposes.

Different Types of Isolation Valves

Isolation valves can be categorized based on their movement or based on their internal structure design. These types of isolation valve are as follows:

- Rotary Movement Valves

- Linear Movement Valves

- Rocker Style Isolation Valves

- Diaphragm Isolation Valves

- Pinch Valves

First, let’s see what isolation valves are and then dive into the world of different types of isolation valves and see how they differ from each other.

What are Isolation Valves?

Isolation valves are used to control the flow of different fluids. They are usually installed in a series of pipes. Isolation valves have different modes. When they are opened, the fluid can flow freely. By closing the isolation valve, the fluid stops flowing.

Isolation valves can also be categorized based on movement as well. They can be categorized into two different categories: Rotary movement valves and linear movement valves.

-

Rotary Movement Valves

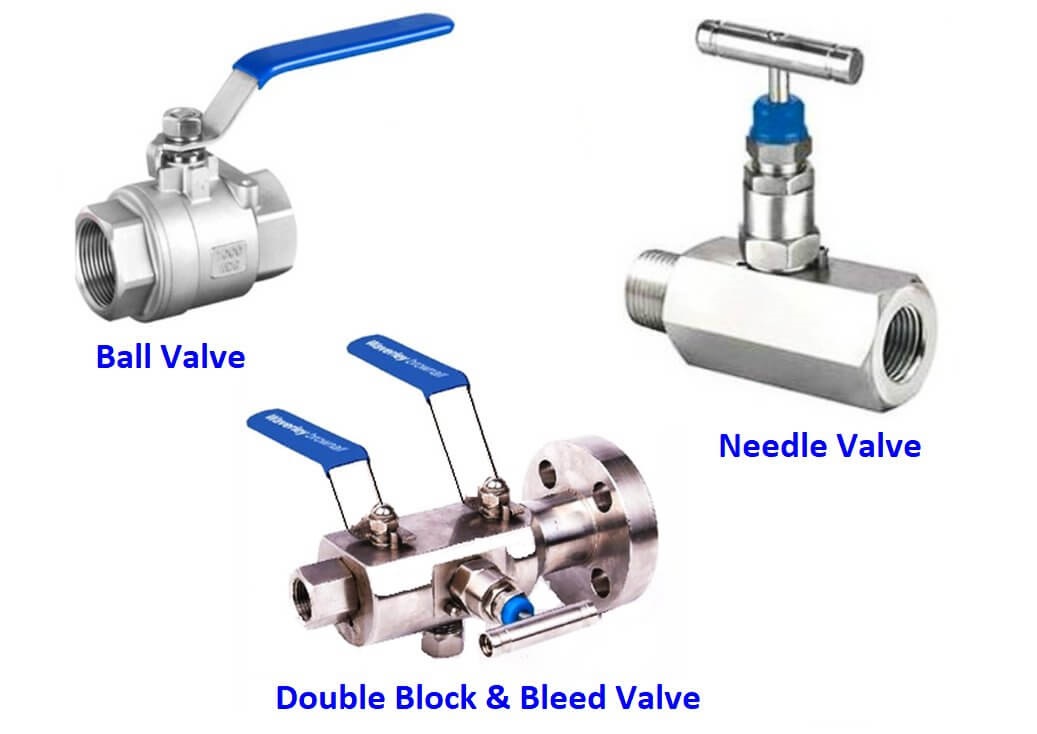

One of the popular types of isolation valves is the rotary movement valve. Rotary movement valves have a rotational movement. They have two main designs: Ball valves and butterfly valves.

Ball valves contain a handle that shows its status. By checking the status you can ensure whether the valve is closed or open. These valves are great for a tight shutoff. One of the great advantages of ball valves is that they can be easily cleaned and their maintenance is not difficult as well. Since they can be easily cleaned, they have less potential for choke up. Because the sudden movement of the valve can damage the gauge or diaphragm of the transmitter, they should have a slow operation.

Needle valves, just like ball valves, are perfect for instrument isolation. Ball valves contain a hollow sphere with holes on each side. When the flow path aligns with the holes, there won’t be any obstruction and the valve is in the open state. With the rotation of the ball, the valve will be closed and blocks the flow path of the fluid.

Butterfly valves contain a disc that rotates around a shaft. The disc’s plane is parallel to the flow of the fluid when it’s in the open state. This position is perpendicular when closed. These types of isolation valves are great for low-pressure situations. Butterfly valves are compact as well. That is why they are great for places with limited space.

-

Linear Movement Valves

One of the different types of isolation valves is the linear movement valve. These valves move in a straight line and that’s why they are called linear movement valves. These valves have different designs such as gate valve, globe valve, diaphragm valve, and pinch valve.

-

Diaphragm Isolation Valves

Membrane valves are also known as diaphragm isolation valves. These solenoid-operated devices utilize a diaphragm for sealing the valve seat. This enables the valve to isolate the flow path of the fluid. They can also work as a two-way or 3-way on and off system to work just for opening and closing the flow of the fluid.

-

Rocker Style Isolation Valves

Rocker style isolation valves are just like diaphragm isolation valves and are solenoid-operated tools. These valves use a rocker system for rotation in order to seal the seat of the valve and stop the flow route of the fluid. These valves can be configured to work as a two-way system or as a multi-port diverter/selector.

-

Pinch Isolation Valves

A pinch isolation valve is also used for opening and closing the fluid’s flow route. They have a disposable, removable tube that by pinching can open/close the route.

Read More on Linquip

- Types of shut off valve: Your ultimate guide

- Types of plumbing valves: A complete guide

- Types of Water Valves: The Ultimate Guide

- A Comprehensive Guide To Different Types Of Air Valves

- Types Of Solenoid Valves: Everything You Need To Know

- A Complete Tutorial To Learn About Different Types Of Check Valves

- Types of pressure relief Valve: All you need to know about PRVs

- Types of non return valve: Introducing 6 types and more!

Why do we use different types of isolation valves?

Different isolation valves have been designed to stop the flow of different fluids. They can facilitate instrument removal for maintenance purposes. Using isolation valves can facilitate the stopping and diverting process media for different purposes such as changing the flow into another location. They are also capable of helping to shut down the process plants in the case of drain lines or vent lines. For maintenance or repair purposes, they are closed, but under normal circumstances, they remain open.

Advantages and Disadvantages of Different Types of Isolation Valve

Now let’s see the advantages and disadvantages of different isolation valve types.

Gate valve and piston valve contains advantages such as flow control, being able to work at high temperature, and well metal-to-metal sealing. Their disadvantages include only one-way flow (except for the gate valve), fluid accumulation may occur on the damper based on the type of the fluid resulting in the shortening of the stroke length.

Other types such as ball valves, butterfly valves, and monoblock valves have advantages such as minimum pressure drop, easy to use, perfect sealing, and remote position detection. They have a few disadvantages including heavy weight, and ruptures that may occur from the sealing element during the process. Another disadvantage is that opening and closing torque values after a certain nominal diameter are high because of their design.

But keep in mind that while different types of isolation valves have their own disadvantages, they have great advantages as well. Using them can ease up the flow control and help in maintenance purposes. So, you should decide which one offers more advantages and is suitable for your application.

That was all there is to know about different types of isolation valves. What do you think about these isolation valves? Which one do you think is the best? Comment below and share your thoughts with us! And if you have any questions about these types of valves and any related parts, signup on Linquip and our experts help you find your answers right away!

Read More on Linquip

- Pinch Valve Manufacturers

- Air release valve Manufacturers

- Diaphragm Valve Manufacturers

- Needle Valve Manufacturers

- Ball Valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers