Flow control of liquid or gaseous solutions has long been carried out not only mechanically. Modern industrial enterprises are constantly upgrading the main devices to meet all requirements and standards. So, in recent years, so-called solenoid valves are increasingly used for industrial purposes. A solenoid valve is an electrically operated valve that is mainly used to regulate the flow of air or a liquid in pneumatic and hydraulic power systems. Different types of solenoid valves are available in the market based on application. To pick your type, Linquip provides a comprehensive guide for you. Read on to find out more about these different types.

Different Types Of Solenoid Valves

Based on the number of pipe connections:

- Two-way Solenoid Valve

- Normally open construction

- Normally closed construction

- Three-way Solenoid Valve

- Normally open construction

- Normally closed construction

- Universal construction

- Four-way Solenoid Valve

Based on working principles:

- Direct-acting Solenoid Valve

- Pilot-operated Solenoid Valve

- Internally piloted solenoid valve

- Externally piloted solenoid valve

- Semi-direct Solenoid Valve

- Pressure-operated Solenoid Valve

- Air-operated Solenoid Valve

Based on function:

- General-purpose Solenoid Valve

- Safety Shut-off Solenoid Valve

- Process-control Solenoid Valve

The common types of solenoid valves are explained below.

Read More on Linquip

- Types of shut off valve: Your ultimate guide

- Types of plumbing valves: A complete guide

- Types of isolation valve: All you need to know!

- A Comprehensive Guide To Different Types Of Air Valves

- Types of Water Valves: The Ultimate Guide

- A Complete Tutorial To Learn About Different Types Of Check Valves

- Types of pressure relief Valve: All you need to know about PRVs

- Types of non return valve: Introducing 6 types and more!

Based on the number of pipe connections

-

Two-way Solenoid Valve

As the name suggests, a two-way solenoid valve has one inlet and one outlet piping connection. Each of these two ports is alternately used to permit flow as well as close it off. The inlet pipe should have greater pressure compared to the outlet in order to force the fluid through the two-way valve. The equal pressure of the two pipes will not facilitate the flow of fluid.

Two-way valves can be categorized into the following two types.

- Normally open construction

In a normally open valve, the valve remains open until some type of current is applied to close the valve. Suspension of the electrical power causes the valve to automatically reopen to its normal state.

-

Normally closed construction

A normally closed solenoid valve is the most common type, working in the opposite fashion, remaining closed until a power source causes it to open.

-

Three-way Solenoid Valve

Three-way or three-port solenoid valves have three input/output ports and two valve seals, one of which will always be open and one of which will always be closed in normal (inactive) mode.

In response to an electrical input signal, the open/closed state of these two ports is reversed, allowing for various valve operations to be controlled. Flow can thus be diverted between channels as required, in accordance with the way the port connections have been set up and connected within the larger pipeline system.

Three-way valves operate in the following three modes:

-

Normally open construction

The pressure port is connected to the cylinder port when the valve is de-energized. But when the valve is energized the pressure port is closed and the cylinder port is connected to the exhaust port.

-

Normally closed construction

When the valve is de-energized, the pressure port is closed and the exhaust port is connected to the cylinder port. With the valve energized, the pressure port is connected to the cylinder port and the exhaust port is closed.

-

Universal construction

This type allows the valve to be connected in either the normally closed or normally open position. In addition, the valve may be connected to select one or two ports or to divert flow from one port to another.

-

Four-way Solenoid Valve

These valves can have four or more port connections. Four-way valves are commonly used with a dual-acting cylinder or actuator. In this version, half of the port connections supply pressure, and the remaining connections provide exhaust pressure.

Based on working principles

-

Direct-acting Solenoid Valve

These types of solenoid valves have a coil that magnetically opens the valve in direct action, causing the shaft and the seat of the valve to shift. Direct-acting solenoid Valves use the energy produced by the magnetic field of the solenoid to operate the valve. When the electrical current is removed, a mechanical spring returns the valve to its original position.

Direct-acting valves are utilized to prevent the development of too much pressure in a device.

-

Pilot-operated Solenoid Valve

In pilot-operated valves (sometimes referred to as an indirect-acting solenoid), the plunger opens up the pilot opening while the pressure causes the valve to open and close. In spite of the fact that pilot-operated valves require less electrical energy to work, they need to keep up full power with a specific end goal to stay in an open state, and they perform at a slower rate than direct-acting solenoids. Direct-acting valves just need full power when opening the valve, as they can hold their vacant position notwithstanding when working on low power.

There are two types of pilot-operated solenoid valves.

-

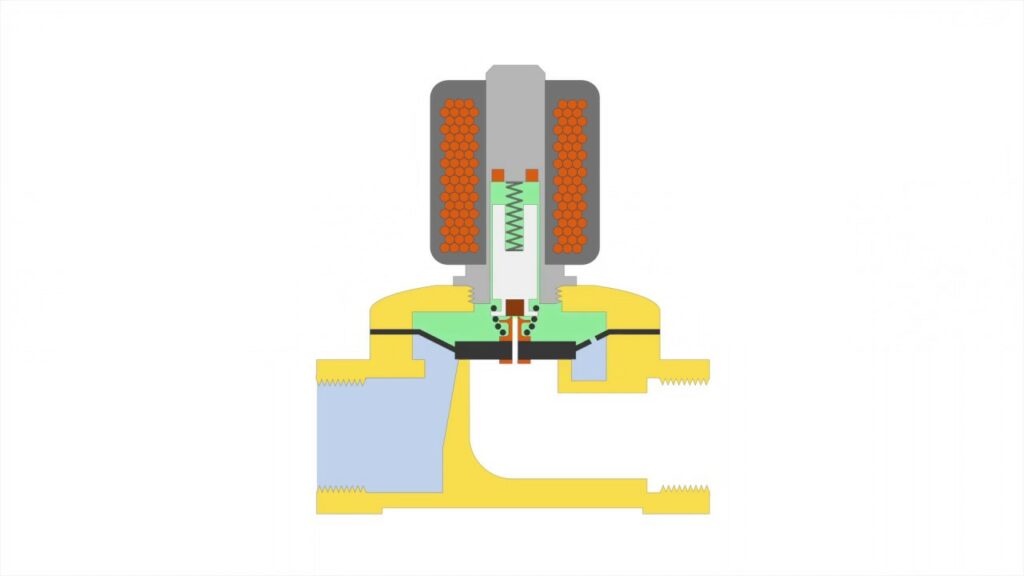

Internally piloted solenoid valve

For high flow rate and high-pressure applications, internally piloted solenoid valves are used. In this type of valve, pressure across the valve opens or closes the valve. To achieve this, an orifice or an equalizing hole is installed. The usual design involves the core blocking flow on the orifice. When the valve is closed, the fluid passes through the orifice and pressure builds up on both sides of the diaphragm. As long as the fluid flow is blocked, a shut-off force is created due to the larger effective area on top of the diaphragm. When the valve is opened, the core opens the orifice, and pressure is relieved from the top of the diaphragm. The line pressure then opens the valve.

-

Externally piloted solenoid valve

This type of valve applies the same concept from internally piloted valves, but the pressure used to actuate the valve comes from fluid from an external source. A separate fluid circuit is integrated into the valve through an extra port.

-

Semi-direct Solenoid Valve

Semi-direct acting combines the principles of direct and indirect-acting valves. Aside from the magnetic force from the solenoid, the pressure differential across the valve assists in opening or closing the valve. When the plunger is actuated, the diaphragm is lifted to open the valve. At the same time, an orifice is opened causing pressure to be relieved on top of the diaphragm. Closing this orifice by the plunger creates a larger pressure on top of the diaphragm closing the valve.

-

Pressure-operated Solenoid Valve

These types of solenoid valves are usually diaphragm or piston-operated valves. They are normally equipped with a 3-way or 4-way solenoid pilot that controls the opening or closing of the main valve using operating pressure.

-

Air operated Solenoid Valve

This solenoid valve type has two basic functional units.

- an operator with a piston or diaphragm assembly that develops a force upon pressurization.

- a valve with an orifice in which a plug or disc is positioned to allow or stop the flow.

A piston is normally used for pneumatic operation whereas low and instrument air-pressure range operators typically use a diaphragm.

Based on function

-

General-purpose Solenoid Valve

These types of solenoid valves are either normally open or normally closed valves used for controlling the flow of a fluid. However, these valves do not act as safety valves.

-

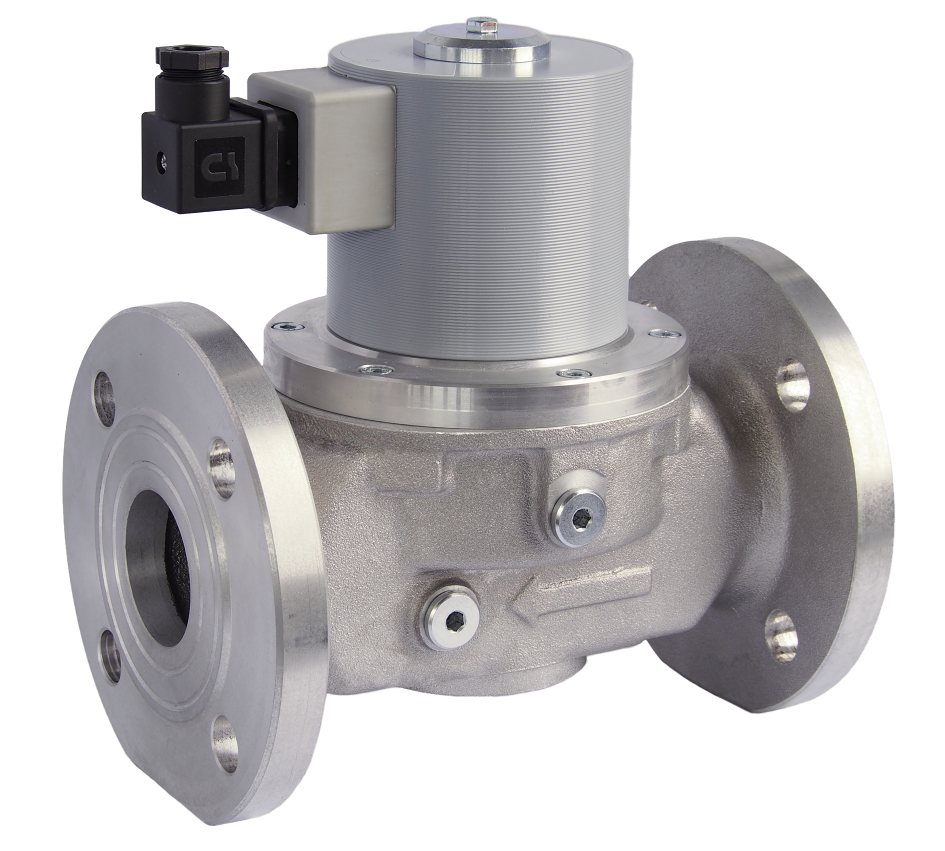

Safety shut-off Solenoid valve

This is normally a closed valve of the “on” or “off” type that actuates using a safety control device for preventing unsafe fluid delivery. A multiple port valve can work as a safety shut-off valve with respect to its normally closed port.

-

Process-control Solenoid Valve

These type of solenoid valves are approved to control flammable gases but does not reliably work as a safety shut-off valve.

So, this was everything you needed to know about different types of solenoid valves. If you enjoy this article, let us know what you think by leaving a reply in the comment section. We will be more than glad to have your viewpoint on the article. Is there any question we can help you through? Feel free to sign up on Linquip where our experts are prepared to provide you with the most professional advice.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

I was captured by the safety shut-off solenoid valve since you mentioned that it avoids unsafe fluid delivery. My brother should know this since he is looking for a solenoid valve to use in his project. I think he should look for a manufacturer that provides high-quality items.

I have a vacuum generator and an air pump. I need a solenoid valve that allows me to alternate between routing the section and positive pressure to a single tube. When one is not routed, it will need to exhaust to the atmosphere (as both the vacuum and pump will run continuously. Any help appreciated!

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various pumps based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.