Screw Pumps

Screw pumps are a well-known form of positive displacement pumps in which a series of screws move in a 360° rotational motion within a casing. They are also known as “water screw pumps”. They are also recognized as the most reliable pump for a variety of operations due to their superior suction capabilities and inexpensive maintenance for the same speed range. In the latest article at Linquip we re going to provide different types of screw pumps. So, follow the article.

⇒ View a List of Screw Pump for Sale and Their Suppliers ⇐

What are the different types of screw pumps?

Screw pumps come in a variety of types and are available on the market. Below are brief explanations of the most types of screw pumps:

- One Screw Pumps

- Two Screw Pumps

- Three Screw Pumps

- Four Screw Pumps

- Five Screw Pumps

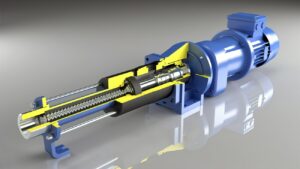

One Screw Pumps

PC pumps, worm pumps, single, and progressive cavity pumps are all names for one screw pumps. In general, these pumps are not regarded to be part of the screw-pump family since the rotor is not shaped like a screw but rather like a crumpled round shaft.

These types of screw pumps are reversible. They operate on the positive displacement principle. They are made up of two spiral elastomer stators and a single spiral metal rotor. These pumps are appropriate for liquids that require a constant, non-pulsating flow.

One screw pumps are well-known for their high suction capacity. They are used in a variety of applications such as transportation, oil and gas, paint, sewage, papers, ceramics, chemicals, and so on. These pumps may operate abrasive and non-abrasive fluids with or without solid components (bilge water, sludge, sewage, and so on) as well as food (ketchup, yeast, gelatin, etc.). These types of screw pumps are quite inexpensive. Also, they do not clog.

Two Screw Pump

Also known as a twin-screw pump (double screw pump), these types of pumps are commonly used for high-power applications such as heavy oil tube transfer. The screws in the pumps are powered by the motor, and timing gears are commonly used to turn the next screw.

These types of screw pumps are self-priming as well as rotating. Because of their excellent performance, these pumps are used in the food, energy, marine, and petrochemical sectors. The following are the characteristics of the two screw pumps:

- They can function at varying speeds

- They can run dry

- They have a low NPSH need

- They can handle a high volume of fluids and viscosities

- They tolerate pollution

- They have a low liquid sheer

- They are extremely reliable

Three Screw Pump

These types of screw pumps are also referred to as “triple-screw pumps”. Without the use of timing gears, the screws in the pump are decided by the motor to rotate the remaining two screws that surround it. They are made up of three screws and an electric motor that powers the screws. It has one driver and two screws that are driven. The electric motor powers the driver screw, which in turn powers the driven screws. These screws are intertwined. Three screw pumps are used in minor applications like lubricating systems.

Four Screw Pump

In general, these types of screw pumps are a two-screw pump with two screws on each rotor, however, each pump rotor contains two screws that revolve in opposing directions.

The four screw pump suctions fluid into the suction port, which is then divided evenly and sent to both ends of the pump. The two-fluid streams run through the pump to the center and then rejoin before entering the discharge outlet. The four-screw pump, like the twin-screw pump, uses timing gears to drive the second rotor. Four screw pumps are commonly utilized in multi-phase applications and oil transfer pipes. Four screw pumps are commonly used in multi-phase and oil pipeline applications.

Five Screw Pump

All four screws are driven by a single driving rotor.

The operation of these types of screw pumps is quite similar to that of a three-screw pump. However, instead of three screws, it employs five. These pumps, like three-screw pumps, have a single diving rotor that drives all of the remaining screws. These pumps are widely utilized in a variety of applications, including hydraulic and pipe oil.

Summary

A screw pump is a rotary pump that is a type of positive displacement pump that delivers a known amount of fluid with each rotation. There are many types of screw pumps based on the number of screws, such as one screw up to five screws.

One screw pumps or progressive cavity pumps are a type of screw pump. Because the rotor of these pumps is not fashioned like a standard screw, but rather a twisted round shaft, they are not classified as Screw Pumps. Two screw pumps are also known as double screw pumps, and they are the most common type utilized in high-power applications. Three-screw pumps, sometimes known as triple screw pumps, are commonly employed in tiny applications such as lubrication systems. Four Screw Pumps have a double suction configuration, with the suction stream divided at both ends and traveling to a discharge in the center.

Thus, this is all about the types of screw pumps. Occasionally, these pumps are chosen based on single suction, while others are chosen based on double suction. We attempted to provide a simple but clear explanation of types of screw pumps. However, if you have any questions about these pump types, why not speak directly to one of our specialist teams? Feel free to register at Linquip and then leave your questions.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- A Cheat Sheet For The Types of Pump Couplings

- Different Types of Pumps: Ultimate Guide

- Types of Water Pumps and Their Principles

- 3 Types of Well Pumps + Applications

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- 3 Types of Oil Pumps + Working Principle & PDF

- Types of Dynamic Pumps

- Types of Fuel Pump

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Top Dosing Pump Manufacturers and Suppliers

- Top Water Pump Manufacturers and Suppliers

- The 7 Best RV Water Pump (Clear Guide + Review)

- The 10 Best Electric Air Pump (Clear Guide)

- The Best HVAC Vacuum Pump (Clear Guide)

- 9 Different Types of Rotary Pumps + PDF

- Types of Centrifugal Pumps: All Classification & Working Principles

- 12 Types of Water Pressure Pumps with Applications & Characteristics

Thank You for sharing the information

Thanks for visiting our website and leaving your comment, Elgi! You are encouraged to visit Linquip Tech News, where you can find similar posts.

Thank you for sharing the information

Thanks for visiting our website and leaving your comment! You are encouraged to visit Linquip Tech News, where you can find similar posts.