Types of Well Pumps – Well pumps are most typically used to bring drinkable water up to the surface from wells and springs. Well pumps encompass a variety of pump types, including mud pumps, submersible pumps, jet pumps, and bladder pumps.

Other applications for the different types of well pumps include unloading tankers or storage tanks, as well as pumping other commodities than water, such as oil or natural gas; or, less typically, hazardous materials, chemicals and petrochemicals, slurries (particularly ash slurries), and wastewater. While they are most commonly used in household wells, municipal and agricultural water distribution, and mining or other fuel production applications, they are also utilized in the construction and commercial service industries.

Linquip is the right place for you if you are looking for information regarding well pumps. The Linquip experts can always provide you with expert advice when you are looking for your well pump, so you can be sure that you will get the right pump every time. Check out Linquip’s article titled “What is Deep Well Pump & How Does it Work?” if you want to get a basic understanding of these industrial devices.

Do you have any previous experience with well pumps? Find the right well pumps for your needs with Linquip’s selection of Well Pump Products. Have trouble finding a well pump that fits your needs? Look no further than Linquip right now! Linquip offers free access to a wide range of Well Pumps For Sale that is currently available on the market to all users. Furthermore, if you are interested in finding out the price of Well Pumps that are available in the market, Linquip allows you to send an inquiry/request for quotes to all the Well Pump Suppliers and Companies for free.

⇒ View a Comprehensive List of Deep well Pumps for Sale and Their Suppliers ⇐

What Is a Well Pump?

The majority of individuals in urban and suburban regions have nearly continual access to drinkable, clean water. However, millions of houses in more rural regions rely on wells for their water supply. A well pump is an electromechanical device that is placed after a well has been drilled or dug and its job is to transport water from your well to your home. An impeller of centrifugal pump, driven by an electric motor, propels water from your well through a jet or pipe. They come in a variety of sizes, and the optimum one for your home is determined by three factors:

- The size of your home

- How much water does your family consume?

- What is the total number of plumbing fittings in your home?

Later in the post, we’ll go through how to choose the proper pump size in further depth based on the different types of well pumps.

Basic Information about Types of Well Pumps

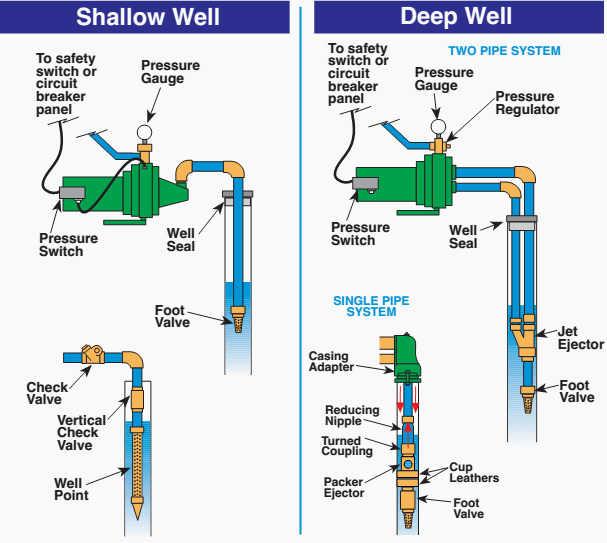

There are two types of water well pumps: shallow well pumps and deep well pumps. Shallow well pumps are usually positioned above ground and use a suction pipe to extract water from the earth. A suction pump’s usual lift limit is 33.9 feet at sea level, or one atmosphere of air pressure (760 Torr). Some shallow well jet pumps may have the ability to lift more water. However, at sea level, a shallow well suction pump’s usual maximum is 25 feet. With increasing altitude, this limit decreases.

When the water is near the surface or in an artesian well, shallow well pumps are employed. Jet pumps are commonly used in shallow wells. Deep well pumps are either submersible or surface pumps that push water uphill from an input that is below the water level, along with the remainder of the pump. Alternatively, they might be two pipe jet pumps. This arrangement is not constrained by suction lift limits and has a depth limit four times that of a water well. Impeller pumps are the most common type of submersible pump.

Well stimulation is a type of non-water well pump that is used to revive aged or underperforming hydrocarbon wells. Mud pumps aid in the drilling of the new well bore holes. They are commonly utilized in the oil and gas business and have characteristics that are comparable to deep well water pumps. However, they are industry-specific specialty pumps manufactured by oil and gas extraction industry supplier firms and are described in other areas of this website.

The most common sort of well water pump is one that is used to provide well water to a home. These water systems are widespread in rural locations when a personal well is used instead of a central water supply. These are usually submersible, enclosed electric pumps that work on regular home AC power. They’re designed to fit within a 6″ well pipe, normally made of cast iron, and have a die-cast top that permits it to be served by in-ground electric lines. The electric power connections are tied to a rope that lowers submersible well pumps into the well pipe.

Pumps with impellers are the most common. The jet type pump is another popular choice for deep well operations. The Venturi concept is used in jet pumps. Jet pumps can be employed in deep well capacity if properly piped. Jet pumps can also be utilized as a shallow well suction pump. Deep water well pumps have lower limitations of 80′ to 100′, but shallow well pumps have lower limits of 25′. At sea level, these limitations are enough. At higher elevations, they start to deteriorate. Visit here to know the function of well pumps properly.

Above-ground electric motors with diesel-electric generator backup are commonly utilized in water well pumps for municipal or bigger freshwater systems. In these situations, two pipe deep well design jet pumps are typically employed. The well water is then pumped uphill into a massive above-ground water tank, which provides storage and maintains a consistent pressure for the system.

Specifications of Different Types of Well Pumps

Well pumps can be powered by a variety of different sources. AC or DC power sources, gasoline or diesel engines, pneumatic or hydraulic power, manual power (hand well pumps), and solar well pumps are all examples. Aside from the tiny enclosed electric pumps used in household water wells, the power sources are above ground, such as a diesel engine or a typical farm windmill, and the power is conveyed to the below-ground pump through a mechanical drive shaft. A huge electric motor or a gas engine would simply not be practical or prudent to install underground in the well. Even if the engineering difficulties are rectified, pollution may result.

What Are the Main Types of Well Pumps?

- Centrifugal Well Pump

- Submersible Well Pump

- Jet Well Pump

The water table lies just a few feet below the ground’s surface in many parts of the United States, making reaching it simple — or at least simpler than in locations with a lower water table.

In locations with lower water tables or regions where there isn’t a regular supply of drinkable water near the surface, you’ll have to dig deeper to get the same effect. Deeper wells necessitate a different method since they must transport water over a longer distance.

How does a well pump appear? They are available in a variety of forms and sizes. We’ll go over the most prevalent types of well pumps in this part, as well as the scenarios in which each pump is best suited.

Centrifugal Well Pump

To produce suction, a centrifugal pump turns an internal fan. Centrifugal pumps, unlike other well pumps, are housed in a mechanical housing adjacent to the well rather than inside it, making maintenance easier.

One disadvantage of centrifugal pumps is that their suction is insufficient for deep well applications. Centrifugal pumps are only practical if your well is less than 25 feet deep. The centrifugal well pump is the most cost-effective option.

Submersible Well Pump

The most common form is the submersible pump, which is popular due to its versatility. These pumps may be used in almost any well, no matter how deep or shallow it is.

Submersible pumps are located underwater, deep into the well, as their name implies. These pumps are waterproof, long-lasting, and require little maintenance. Repairs, on the other hand, entail removing the pump from the well and bringing it to the surface. This job can be completed by a professional well pump repair specialist, but the effort needed will almost always raise repair expenses.

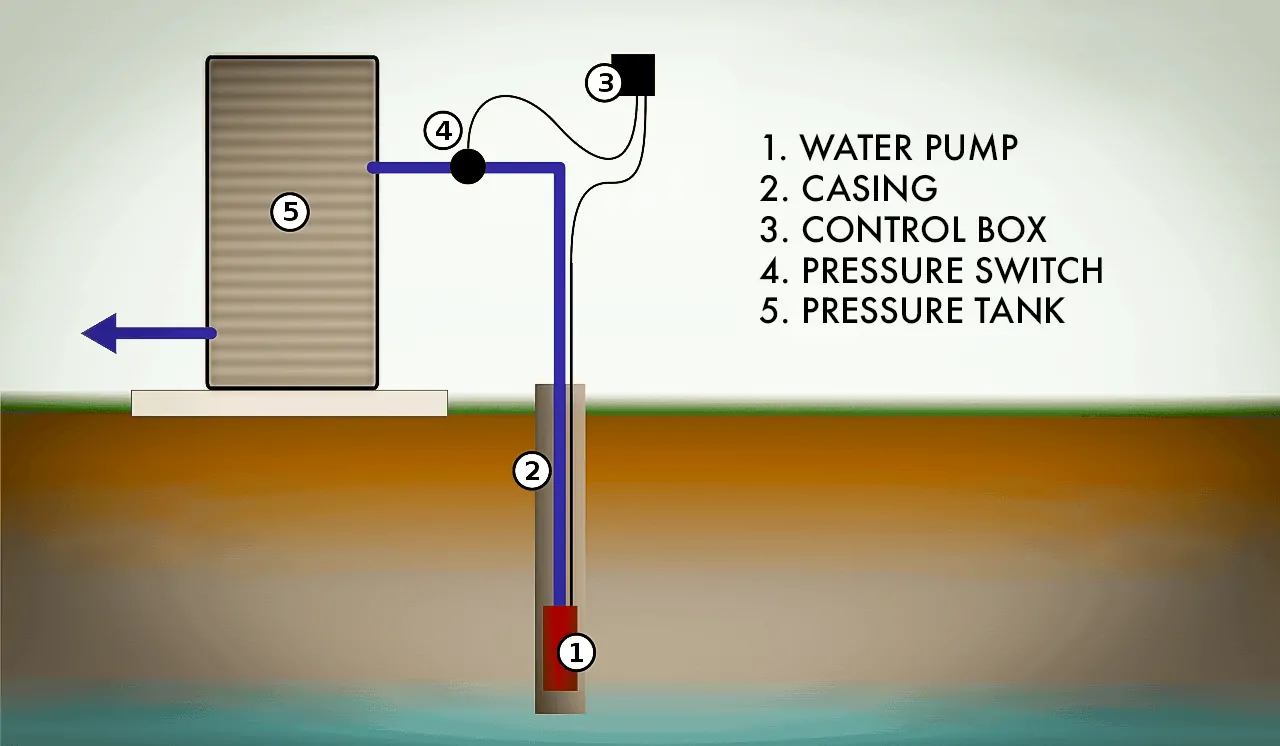

Submersible pumps have the following characteristics:

- They won’t work unless they’re completely submerged.

- The impellers that force water up the pipe are driven by the motor.

- When the pressure switch is turned on, the impellers spin, pushing water up into a tank on the surface.

Jet Well Pump

These high-tech pumps have the highest power and can transport more water more quickly than ordinary pumps. Jet pumps, like their submersible cousins, may be used in wells of any depth.

The installation of the jet pump will be determined by whether it is “single-drop” or “double-drop.” Single-drop variants are located indoors, either in your home or in an outbuilding, and are best for shallow wells. A split installation is required for double-drop variants, which are best suited for deep wells. The motor must remain above the earth, even when the jet assembly is in the well.

While submersible pumps have greater upfront expenses, their lower maintenance costs make them a more cost-effective long-term investment.

The following are some of the properties of jet pumps:

- Water is required for the jet pump technique to work.

- Impellers are used to produce pressure.

The impellers push water through a tiny opening in the housing in front of the impeller, which is also known as drive water. The water’s speed will rise as a result. A vacuum will be sucking more water from the well as the water leaves the jet. This water will mix with the driving water and will be released at high pressures into your home.

How to Choose a Well Pump

The depth of your well, or how far the water must go to reach the ground’s surface, is the single most important aspect to consider when choosing the correct pump for your well.

- A shallow well jet pump should be used if your well is less than 25 feet deep.

- A deep well jet pump should be used if the depth of your well is between 25 and 110 feet.

- Use a four-inch submersible pump if your well is between 110 and 400 feet deep. Remember that a submersible pump may be used in wells as shallow as 25 feet.

Examine the data supplied by your well driller to establish the depth of your well. You can also determine it yourself if no such report exists. Attach a fishing bobber to one end of a long piece of line, then lower the bobber until you feel it float. Remove the slack from the string and mark it.

Applications of Different Types of Well Pumps

In this part, we’ll go through the most common uses for well pumps and how they may help you with your specific needs.

The Best Types of Well Pumps for Shallow Wells

Linquip recommends the single-drop jet pump for shallow wells. One-way check valves are included with these pumps to keep them primed. The aboveground single-drop jet pump pumps water up through a single intake line. They don’t require as much maintenance as other sorts due to the relative simplicity of their mechanisms.

The most common solution for a shallow well is a jet pump, which stands on top of the well and suctions water up. The air pressure determines how far it can suck up water. While air pressure varies with altitude, jet pumps are not recommended for wells deeper than 25 feet.

The impeller of a jet pump creates pressure by pushing the driving water through a tiny hole or a jet within the housing in front of the impeller. The narrowing of the jet increases the speed of the flowing water.

A vacuum will then suck additional water out of your well when the water leaves the jet. When this excess water combines with the driving water, it will discharge at high pressure into your home. Keep in mind that the process of pulling water with a shallow well jet pump also relies on water.

The Best Pump for Deep Wells up to 110 Feet

Linquip proposes the double-drop jet-pump system if you have a deep well. Deep-well jet pumps are also above ground; however, they use two pipelines to pull water. One of these lines pulls water from the well while the other pushes it upward. A deep well jet pump suctions water from depths of up to 110 feet, and priming the pipe necessitates the use of a foot valve. Some types have a tailpipe to prevent users from completely draining the well.

If the jet is independent of the impeller’s housing and also in the water, a deep well jet pump may extract water from depths more than 25 feet. The impeller is in charge of pumping water into the jet’s body, while the jet is in charge of returning the water to your pump. To deliver water into the system, a deep well jet pump employs suction at the jet. Pressure is also used to pull water from the well and transport it to the home.

To prevent over-pumping, a jet pump in a deep well will come with a 25-foot-long tailpipe linked to the jet’s housing on the intake side. When the water level falls below the housing of the jet, the tailpipe ensures that no one can pump the well dry. The higher the jet is above the water’s surface, the more effectively it pumps. A deep-well system, like a shallow-well system, has to be primed with water. A foot valve is located at the bottom of the well, which prevents water from draining from the pipes.

The Best Pump for Deep Wells up to 400 Feet

Linquip recommends utilizing a submersible pump if your well is deeper than 110 feet but not more than 400 feet. Pressure tanks are used by deep-well submersible pumps to suck water through a single conduit that links the interior well to your home. Although these pumps can draw water from depths as low as 400 feet below the earth, one disadvantage is that they must be removed from the well casing for maintenance.

While a jet pump may function in wells hundreds of feet deep, they are not as effective as submersible pumps in deeper wells. The pump will no longer raise the water as you move it deeper down the well; instead, it will push it upward. Keep in mind, though, that submersible pumps won’t operate until they’re completely submerged in liquid.

A submersible pump has a cylindrical form with a sealed pump motor that connects to an aboveground power supply on the bottom half. The motor drives the impellers, which propel the water upward. When the pressure switch is turned on, impellers spin, pulling water into the pump. The water is pumped through the pump’s body and then into a ground-level storage tank.

Submersible pumps have fewer issues than aboveground well pumps, which are prone to mechanical failure. Because submersible pumps are submerged, they do not lose prime, which is a problem with aboveground pumps.

Cavitation, which occurs when gas or air enters the mechanical elements of a pump, is seldom an issue with a submersible pump since it rests well below the water’s surface and has constant access to water.

Despite the fact that a submersible pump may transport water more effectively than a jet pump with a similar-sized motor, any motor problems may necessitate the removal of the complete unit from the well casing. Fortunately, submersible pumps are extremely dependable and can function at optimum capacity for up to 25 years before requiring maintenance.

How to Size a Well Pump

You must establish the size of the pump you require in addition to selecting the best pump for your well. Pumps are rated in gallons per minute, and an ordinary three- or four-bedroom home requires 8 to 12 GPM. Add one gallon per minute for each of your house’s water facilities, such as dishwashers, laundry washers, refrigerators, faucets, and showers, when calculating how much water your home requires.

While your pump must be large enough to satisfy your home’s requirements, a larger one will result in decreased performance and energy inefficiency. If you need to replace your pump, be sure it has the same horsepower rating. However, if you intend to add new family members or appliances, you may want additional horsepower. Pumps that must move water over long distances will need a higher horsepower rating.

If you’re intending to replace your pump, look at the identifying plate to see how much horsepower it has. Remember that a submersible pump may require two or three cables, so you’ll need to figure out how many wires the new pump will need.

Download Types of Well Pumps PDF

You are now able to access this document in PDF format by downloading it. Simply click on the link below.

Contact Us About Repair the Types of Well Pumps

Linquip platform can help you with well pump repairs that are quick and dependable. We’re accessible 24 hours a day, 7 days a week to make emergency repairs and answer any concerns you may have. Fill out our contact form or visit Linquip Well Pump Experts page to get in touch with us.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 6 Main Types of Dynamic Pumps: Examples + PDF

- 3 Types of Oil Pumps + Working Principle & PDF

- 5 Main Types of Fuel Pump & How They Works?

- What is Deep Well Pump & How Does it Works?

- 3 Types of Vane Pumps: Working Principles & Application

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- 5 Types of Vacuum Pump and Applications + PDF

- 3 Types of Positive Displacement Pump + Name & PDF

- Types of Piston Pumps

- 6 Parts of Pool Pump + Diagram & PDF

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Types of Screw Pumps: How Each Type Gives Benefits?

- What is Head of a Pump? A Complete Guide

- The 5 Best Air Source Heat pump in 2022 (Clear Guide)

- 7 Best RV Water Pump In 2022 (Clear Guide & Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- The Best HVAC Vacuum Pump in 2022 (Clear Guide)

- The 5 Best Well Pump in 2022 (Clear Guide)

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Types of Centrifugal Pumps: All Classification & Working Principles

- Delving Deep into Submersible Well Pumps: How Do They Work?