Types of Fuel Pump – Your car may be fitted with one of three different types of gasoline pumps. Each has its own set of features, therefore, it’s crucial to know how they work together. When buying a gasoline pump, for example, you’ll need to know whether it feeds gas into a carburetor or into a fuel injection system. More information on the various kinds and what they signify for you may be found here.

⇒ View a Comprehensive List of Fuel Pumps for Sale and Their Suppliers ⇐

What is a Fuel Pump?

Mechanical, electric, and high-pressure fuel pumps are the three types of fuel pumps. A fuel pump is a fluid handling device that moves gasoline from the fuel tank to the engine. It’s often found in internal combustion engines. The fuel pump in spark-ignition engines transports gasoline from the tank to the fuel bowl, where the carburetor mixes the fuel with air and transports it to the engine’s combustion chamber.

In combustion ignition engines, the fuel pump delivers high-pressure fuel straight to the combustion chamber. In combustion ignition engines, the combustion enclosure is already filled with highly compressed air at the moment of combustion. As a result, the fuel pump must deliver fuel to the combustion chamber at a pressure greater than that of the combustion chamber, and ignition occurs.

Construction and Working of a Fuel Pump

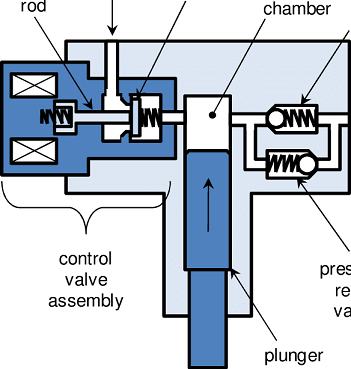

The plunger is driven by a bottom-mounted cam and tappet mechanism. The plunger reciprocates in the barrel. The number of cylinders in the engine equals the number of plungers in the engine. The plunger has a rectangular vertical groove that spans the length of it.

The delivery valve is lifted off its seat by the pressure of the gasoline on the spring. The fuel is supplied to the injector through the delivery valve. When the plunger hits the bottom of its stroke, the supply port and spill are exposed, and fuel from a low-pressure pump is pushed into the barrel after filtering.

The cam action has now driven the plunger up, and both parts have been closed. As the plunger advances farther, the fuel above it is compressed, raising the delivery valve and delivering the gasoline to the injector.

The plunger continues to rise, and the helical groove connects the spill port to the fuel in the upper portion of the plunger via the rectangular groove at a given point. The delivery valve is driven back into its seat by the spring force as a result of the rapid pressure drop. Furthermore, the pressure in the supply pipe falls. The injector’s nozzle discharge is abruptly turned off as a result. The cycle continues to repeat itself.

Whether the spill port is constructed to convey the high-pressure gasoline in the top portion of the barrel earlier or later affects the timing of each plunger stroke. The placement of the helical groove, which may be modified by rotating the plunger with the rack, determines this.

The rack is connected to the accelerator. It relates to a geared quadrant, in which the rack rotates, causing the gear quadrant to turn and the plunger to rotate as well. By pushing the accelerator pedal, the driver may control the fuel supply to the engine cylinder.

Difference Between Centrifugal Pump and Axial Flow Pump

Axial flow pump, which incorporates an alternating configuration of spinning and static aerodynamic blades to raise the pressure of the propellant, and centrifugal pump, which increases pressure by propelling fluid outward via its blades at high speed.

The centrifugal turbopump is far more potent and can easily hold high-density fuels, but it takes a big amount of room, whereas the axial turbo pump requires a small amount of space but can handle low-density fluids for modest pressure rise.

Types of Fuel Pumps

There are three primary types of gasoline pumps on the market, each of which is described below:

- Mechanical Fuel Pump

- Electrical Fuel Pump

- Fuel Pump with Diaphragm

- Diaphragm Fuel Pump

- Fuel Pump with a Plunger

1. Mechanical Fuel Pump

These are mostly low-pressure fuel pumps, however they are occasionally employed for high-pressure applications whose primary function is to move gasoline from the tank to the spark-ignition engine’s fuel bowl. There are two types of mechanical fuel pumps: diaphragm-type fuel pumps and plunger-type fuel pumps.

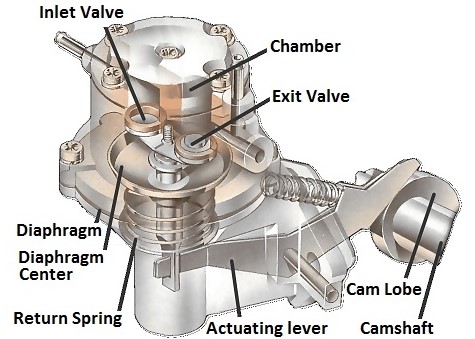

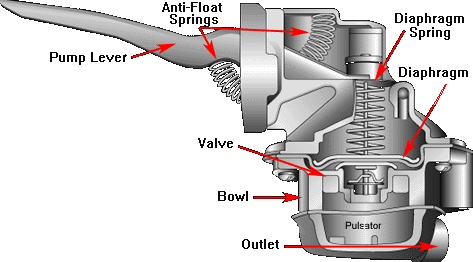

2. Fuel Pump with Diaphragm

The diaphragm type fuel pump is essentially a positive displacement pump that suctions fuel by the diaphragm expanding and compressing. The intake and exit check valves, which are one-way valves, make up the pump body. The pressure within the pump falls below atmospheric pressure as the diaphragm compresses, and the gasoline is sucked through the inlet valve. The fuel within the pump was forced out through the output valve when the diaphragm expanded. A lever activated by an eccentric cam motion controls the diaphragm’s expansion and contraction motion. Through a suitable gearing arrangement, this eccentric cam is coupled to the engine’s crankshaft.

3. Fuel Pump with a Plunger

The plunger type fuel pump is likewise a positive displacement pump that uses the reciprocating action of the plunger to suck and distribute fuel. The plunger is contained within a cylinder, and one side of the plunger is linked to the camshaft via a push rod. The valves are attached to the cylinder’s end. Fuel is pulled into the cylinder as the plunger goes backward, and fuel is delivered out of the cylinder as the plunger moves forward.

Although the pressure of the gasoline provided by the mechanical pumps is constant, the large number of moving components necessitates adequate maintenance. These pumps are no longer in use because automobiles have switched from carburetors to fuel injection systems.

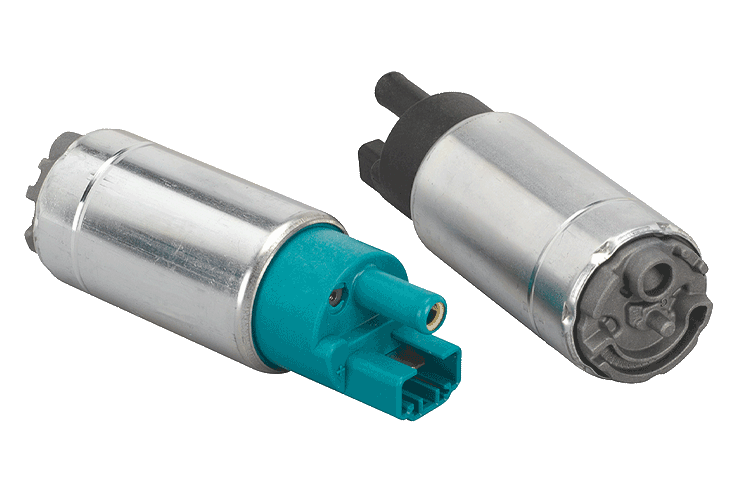

4. Fuel Pump (Electric)

These pumps are commonly found in fuel injection systems, which are an integral feature of contemporary automobiles. It generates high pressure in order to distribute gasoline from the pump. This tremendous pressure might cause the gasoline within the pump to ignite, resulting in an explosion. As a result, the electric fuel pump should be maintained away from the engine and, more particularly, within the gasoline tank, for safety reasons.

The vehicle’s battery provides the current required to run the fuel pump. There is also an electronic control unit (ECU) that regulates the output pressure and volume of the gasoline, as well as meters the incoming fuel from the tank. The ECU assists the car in conserving fuel, resulting in improved economy and power. The diagram depicts the setup of an electric fuel pump.

5. Fuel Pump with High Pressure

These pumps are often employed in combustion ignition engines for the direct injection of fuel into the combustion chamber. Pumps of this sort operate at pressures of more than 200 Pascals. These pump systems are particularly complicated and durable to manage such high pressure. The basic high-pressure pump system, which includes flow rails, metering units, and distribution units, aids the pump in delivering fuel to the combustion chamber without wasting or over fueling it.

What are The Symptoms of a Bad Fuel Pump?

A bad fuel pump will exhibit the following symptoms:

- Difficult Start

- Engine Stalling

- Fuel Tank Noise

- lower gas mileage

- Actual Stall

- Pressure Gauge Problems

- Lower Fuel Efficiency

A Difficult Beginning

The car will not start if the fuel pump cannot deliver gasoline from the fuel tank to the engine. In such situations, the pump does not supply enough fuel, making it difficult to start and operate the vehicle. This is a very typical and identical situation.

The worn pump fails to build pressure under such circumstances, and the engine runs out of gasoline. Your automobile may not start owing to issues with the fuel filter, starter, alternator, or battery.

Stalling of the Engine

Stalling can be pushed by a variety of faults inside the vehicle, but be cautious if stalling frequently occurs while the vehicle thermometer indicates a high temperature. Fuel pump motor failure frequently results in rising temperatures and stalling.

If the stalling frequently occurs while the temperature is high, it is possible that the pump has been damaged and has to be replaced.

Noise from the Fuel Tank

If you hear a loud shout coming from the gasoline tank, it means your fuel pump is broken. The failure of the pump bearings may be the source of this noise.

The pump can also make a lot of noise if the fuel is polluted or if there isn’t enough gasoline in the tank. There will be no or very little noise if your pump is working properly. Excessive loudness is a sign of a problem.

Reduced Gas Mileage

There might be a problem with the fuel pump if your car requires more fuel than usual to fill up the tank. This indicates that your pump valve is not correctly opening, resulting in an excessive amount of gasoline being fed into the engine. The engine does not store or consume additional gasoline.

Stall Location

Even though it isn’t essential, if the engine is getting gasoline from the pump, it is less likely to stall. A genuine stall may occur if your vehicle’s pump overheats the motor. Pump motors that are too old or worn might overheat the entire engine.

Fuel Efficiency Is Lower

The fuel pump injects a large amount of fuel into the engine, which results in the engine burning more gasoline than intended. This means you’ll have to go to the petrol station more often to fill up your bus, van, truck, or vehicle.

You can avoid your pump from failing or being damaged if you keep an eye on the miles between fills and detect a decline.

Problems with Pressure Gauges

The fuel pressure indicator indicates how much fuel has been supplied to the vehicle’s engine. Every car has a specific amount of gasoline that is delivered to the engine via the pump. If you want the engine to run smoothly, you’ll need a continual flow of gasoline from the pump.

Your car’s engine will be damaged or fail if the fuel pump does not supply enough fuel, and your vehicle will not start.

Tips for Fuel Pump Removal

You’ll want to do it perfectly the first time since accessing and replacing a fuel pump may be time-consuming. Follow these suggestions to get a decent job.

- Make sure there is no pressure in the gasoline line.

- Also, make sure there’s no active electrical near the gas tank.

- Take a photo of the fuel pump or use a marker to record its location in the tank. This will assist you in properly lining the tank when you return the pump.

- It’s conceivable that the pump’s top is covered with dirt and grime. Ensure that this area is very clean and devoid of anything that might fall into your tank and cause difficulties later. Compressed air is a great way to get rid of debris.

- Many pumps include a locking ring that might be difficult to remove. It may contain numerous locking mechanisms that can be snapped off if you’re not careful, so read how to remove it.

- Check your gasoline sending unit and float while you’re down there. You can learn more about gasoline sending units in our lesson “Do I Need To Replace My Gasoline Gauge If It Isn’t Working?”

How to Keep Your Fuel Pump Healthy

You don’t want to accidentally harm the device because you need to keep pumping, pumping, pushing it up like Joe Budden. These modest actions should assist in keeping it in good condition.

Gasoline doubles as a coolant when used with in-tank pumps. If you leave a tank low on a frequent basis, you’re accidentally causing your pump to overheat. Fill your tank entirely every time you fill it.

Replace the gasoline filter according to the manufacturer’s instructions. Unwanted pressure in the fuel system might result from a blocked filter.

Conclusion

The various types of fuel pumps have been briefly described here but a more detailed discussion of each is needed to fully understand the advantages and limitations of each technology. You are encouraged to visit the Fuel Pump for Sale on the Linquip Website to find various types and models based on your demand and application.

FAQs about Fuel Pumps

1. When a car’s fuel pump malfunctions, what happens to it?

You may most likely notice one or more of the symptoms listed above if your fuel pump is dysfunctional or has failed. A few examples are starting issues, sputtering, poor performance, low fuel efficiency, poor acceleration, and overheating.

2. Does a malfunctioning fuel pump have a code?

Although a broken pump will not generate a code, the wrong quantity of gasoline pushed through a car’s fuel system may cause sensors to expect particular amounts and ratios of air and fuel combinations. So, theoretically, a faulty fuel pump can cause a code to appear.

3. Is driving with a damaged fuel pump possible?

We don’t recommend driving with a defective fuel pump since it might cause an unexpected loss of power or even cause the car to completely shut down.

4. What is the best way to clean a fuel pump without removing it?

Fuel system cleaners do exist, but even if they do work (don’t depend on it), they will simply postpone the job until a later date. Get it out of the way now and do the work before something awful happens when you least anticipate it later.

5. What is the cost of replacing a fuel pump?

Depending on the car and how old it is, gas rates can range from $50 to hundreds of dollars at the pump.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Fuel Pump: Working Principles, Function & Diagram

- A Cheat Sheet For The Types of Pump Couplings

- Different Types of Pumps: Ultimate Guide

- Types of Centrifugal Pumps: All Classification & Working Principles

- Different Types of Hydraulic Pumps: a Complete Guide

- Types of vane pumps: review the types, select the best

- Types of Piston Pumps

- Types of Dynamic Pumps

- Types of Water Pumps and Their Principles

- 3 Types of Well Pumps + Applications

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- 3 Types of Oil Pumps + Working Principle & PDF

- The 5 Best Air Source Heat pump (Clear Guide)

- 7 Best RV Water Pump (Clear Guide & Review)

- The 10 Best Electric Air Pump (Clear Guide)

- The Best HVAC Vacuum Pump (Clear Guide)

- 9 Different Types of Rotary Pumps + PDF

- The 5 Best Well Pump (Clear Guide)

- The 10 Best Condensate Pumps: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- Keeping Fuel Injectors Clean: How to Clean Fuel Injectors Without Removing Them?