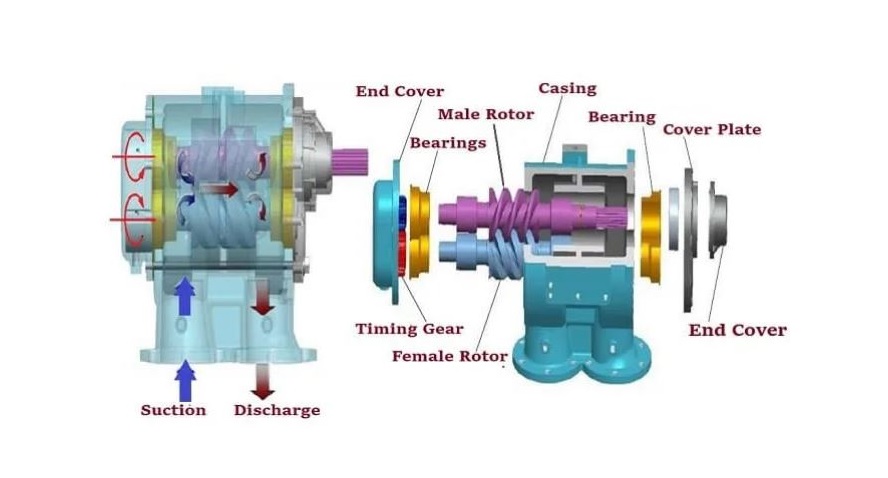

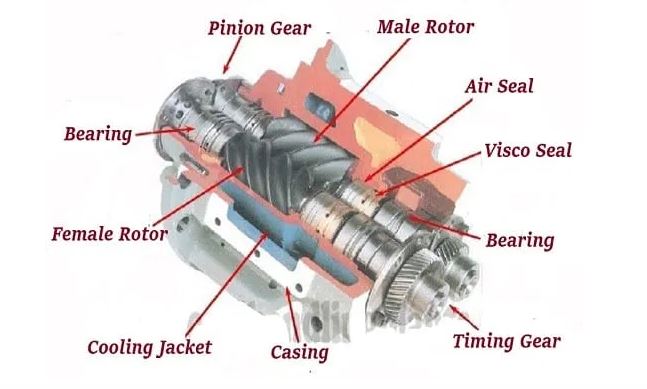

Parts of Screw Pump – A screw pump is a well-known positive displacement pump type. A water screw pump is another name for it. A screw pump is a device that employs one or more screws to transfer fluids or water along the screw’s axis. To pressurize the fluid and transport it inside the system, these screws interlock. These screws are intertwined and reciprocate within the cylinder’s hollow. A screw pump is made up of many components, including a casing, a screw (which may range from one to five screws depending on the kind of screw pump), bearings, a seal, a motor adaptor, and a driving shaft. Screw pumps have a straightforward design.

There are a number of reasons that will convince you that Linquip is the best place you can visit if you would like to know more about screw pumps. If you have any questions regarding screw pumps, our experts would be happy to assist you. To better understand screw pumps and their associated components, you might like to read Linquip’s article “What is Screw Pump & How Does it Work?“.

Do you have any experience with screw pumps? With Linquip, you will discover a comprehensive range of Screw Pumps Products that will make it easy for you to find exactly what you need and to reach the purchase decision. Need help finding a specific screw pump? Linquip is pleased to provide you with free access to all of the Screw Pumps for Sale that are currently available on this website. The Linquip free quote/inquiry service offers you an opportunity to ask for a free quote or inquiry to receive screw pump prices from all Screw Pumps Suppliers and Companies.

⇒ View a Comprehensive List of Screw Pumps for Sale and Their Suppliers ⇐

What is a Screw Pump?

As the name suggests, the screw pump’s shape is similar to a screw thread, and the fluid passes down the screw thread from the suction side to the discharge side of the pump by turning it. The volumetric efficiency of the pump is great, especially with viscous fluids, due to relatively close clearances inside the pump, which lowers the amount of fluid slippage from the high pressure to the low-pressure side. The pump, like any positive displacement pump, does not create pressure; it merely transfers fluid; yet, owing to friction loss, the real system produces backpressure.

Water or other fluids enter the pump through the intake valve and flow linearly along with the interlocking screws toward the outlet side of the pump. When fluid runs through the pump, the tiny space between the screw and the chamber raises the fluid pressure.

Rotary screw pumps are used in a wide range of industries, including power generation, chemical processing, shipping, refineries, terminals, pipelines, and oil and gas extraction. These pumps are used for jacking oil, high-pressure fuel injection, fuel delivery, gear and bearing lubrication, and water power for applications in the management of hydroelectric facilities in the power-producing zone.

The water screw, also known as a screw pump, is a machine with few spinning components that requires extremely little maintenance. You can efficiently pump fixed volume items in a variety of viscosity, pressure, and volume ranges with the aid of these pumps.

The construction of a screw pump is simple and dependable. It is really simple to create. There are three screw spindles in all, two of which are driven screws and one of which is a driver. There is sufficient room between these screws, which are in charge of pumping water or other fluid. The fluid is supplied to the screws by an electric motor.

A housing having suction and discharge sides is used in this type of pump. The suction valve is found at the bottom of the pump, while the discharge valve is found at the top. It also contains a check valve on the discharge side that stops the fluid from flowing backward. The pump design reflects all of this.

7 Main Parts of Screw Pump

7 parts of screw pump are:

- Inlet & Outlet Ports

- Driver Screw

- Timing Gear

- Bearings

- Driven Screw

- Pressure Relief Valve

- Driving Shaft

Driver Screw

It’s a screw pump’s spinning component. The driver screw connects to the motor’s driving shaft. It aids in the consistent volumetric flow rate of fluid pumping. The timing gear is connected to one end, while the drive shaft is connected to the other.

The driven screw is rotated by the driver screw, which is powered by the motor’s driving shaft. It has a good fit with the driven screw. High-tensile steel is used to make this screw. The driver screw’s main job is to rotate the driven screw through a timing gear, which is an intermediary component.

Driven Screw

High-tensile steel metal is also used for the driven screw. Because of the movement conveyed by the timing gear, it rotates around its axis. It spins in the opposite direction as the driver’s gear. The clearance area of this screw is constant. This aids in catching water inside the restricted space.

The water volume decreases and travels toward the outlet port as the driver and driven screws move together. The fluid’s pressure rises as a result of this movement. It then discharges through the discharge/outlet port.

Timing Gear

The timing gear drives the driven screws in such a way that the female and male rotor assemblies do not make metal-to-metal contact. It establishes a link between the driver and driven screws. The driver screw rotates the timing gear, which then transmits that rotation to the driven screws. It drives screws in this manner. Even if the pump is turned off for a short time, it guarantees that no such connections are made.

Inlet & Outlet Ports

The intake and exit ports of a screw pump are distinct. The water is sucked into the pump through the intake port, and it is discharged through the output port. When the pump ultimately stops, the inlet and output are designed to ensure that there is enough liquid medium. This aids in the delivery of the pump’s initial liquid medium. As a result, the suction tube should not dry out quickly, even if it is empty or dry.

Pressure Relief Valve

Screw pumps are a type of positive displacement pump that builds pressure even while the outlet is closed. This builds up pressure, which can lead to major problems including pump internal part damage and harm to the pump operator. As a result, every positive displacement pump has a relief valve to safeguard the pump, the operator, and any associated gear. Extra pressure is returned to the intake using this valve. Recirculating the exit fluid is another well-known method of reducing extra pressure.

Bearings

During pump operation, the top bearings of a vertically mounted screw pump sustain heavy loads as well as axial and radial stresses. As a result, the load on the lower bearings is minimal.

The bottom bearing’s primary function is to keep the pump’s components aligned. Water screw pumps, roller bearings and slide bearings mounted in parallel, on the other hand, they have relatively low loads. This is due to the fact that the generated radial and axial forces are opposed and cancel one another out.

Driving Shaft

The driving shaft links the pump assembly to the drive motor. This connection is made possible by the use of the proper set of flexible couplings.

This driving shaft is a critical component of many types of pumps, and it goes from side to side to ensure the driver screw’s operation. The driving shaft is secured by a set of bearings that fit in the axial direction in such structures. As a result, accurate driving shaft alignment is critical to preserve the pump’s service life and bearings.

What are the uses of screw pumps?

When compared to other pump types, such as centrifugal pumps, screw pumps are usually utilized on fluids with a greater viscosity. Moving these fluids using screw pumps results in energy-efficient and relatively small equipment. Because the screws are not geared together and rely on the fluid to lubricate the screws, screw pumps with more than two screws are often utilized for lubricating fluids.

The screws of a twin-screw pump are geared to keep them from touching each other, thus they may be used on non-lubricating fluids, chemicals, and foodstuffs, among other things. Twin-screw pumps have a higher flow rate than multi-screw pumps, which have more than two screws.

Oil-based fluids, tar bituminous, chemicals, industrial adhesives, and dairy products are some of the most common applications for a screw pump.

Advantages and Disadvantages of Screw Pumps

The following are the benefits and drawbacks of a screw pump:

Advantages of Screw Pump

Compared to centrifugal pumps, screw pumps have some benefits. First, there is no turbulence as the pumped liquid flows axially. This prevents bubbles from forming in thick liquids.

- Screw Pumps can be used for all fluids

- These pumps have easy maintenance.

- It has a compact construction

- It can run dry

- These have a quiet operation

- These pumps provide a steady, non-pulsing flow of fluid.

- This pump has higher volumetric efficiency.

- High reliability

- It needs very low maintenance

- High robustness

- Self-priming ability

- It is very resistant to dust particles and water vapors.

- The contamination of the fluid is not pumped by a screw pump.

- You can also pump a high viscous liquid with screw pumps without losing the flow.

- It has a frictionless rotation

- It pumps the fluid at a very high speed

- It has very high efficiency

- Low pulsations

Disadvantages of Screw Pump

- Installation costs a lot of money for small businesses.

- To transmit light gas, this pump requires a gas ballast.

- Without a gas ballast, it has a relatively slow pumping speed and a lower final pressure for light gasses.

Applications of Screw Pumps

- There are several lubricating and hydraulic machines on the premises. To provide oil to huge equipment, utilize screw pumps.

- Screw pumps are better for pumping heavier oils. They can even pump liquids with higher viscosity and higher flow rates.

- These pumps are capable of pumping both liquid and gas at the same time. As a result, these pumps are used in a variety of pumping businesses.

- The oil and gas, mining, and industrial industries all employ this pump.

- Ceramics, paint, food, chemicals, and paper industries all employ these pumps.

Is Priming Necessary for Screw Pumps?

Screw pumps require no priming since they are self-priming. The vacuum created within the pump allows the pump to self-prime. It will damage a screw pump if it becomes dry and continued to be used.

What Is the Timing Gear In a Screw Pump?

Timing gears are made to drive driven gears in a manner that avoids metal-to-metal contact between male and female rotor assemblies. Also, it ensures that such contact does not occur, even if the pump runs dry temporarily.

FAQ Section about Different Parts of Screw Pump

Which principle governs the operation of a screw pump?

The positive displacement principle governs the operation of the parts of the screw pump.

Is it possible for a screw pump to run dry?

Yes, a screw pump is built in such a manner that it may run dry without causing any damage or priming problems.

What is the distinction between a screw and a gear pump?

The fundamental distinction between gear and screw pumps is that a screw pump produces less vibration, noise, and pulsing flow than a gear pump. Screw pumps also outlast gear pumps in terms of service life. For more information about different parts of screw pumps, visit here.

Download Parts of Screw Pump PDF

In order to provide you with access to this content, we have included a PDF version of this article as one option. Click on the link below to begin.

Contact Us

Linquip is the most popular marketplace for buying and selling Screw Pumps in the United States. For both the chemical and process industries, we provide a comprehensive selection of Screw Pumps, including twin screw pumps and multi screw pumps. To meet your demands, we offer specialized technical support and on-site service engineers. We also have a large stockpile on hand to relieve stress in the case of an unforeseen emergency. If you have any queries about the parts of screw pump, contact one of our Pump Experts. Now is the time to contact our Screw Pump Specialists.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Top Dosing Pump Manufacturers and Suppliers in 2022

- Top Water Pump Manufacturers and Suppliers in 2022

- The 7 Best RV Water Pump In 2022 (Clear Guide + Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- The Best HVAC Vacuum Pump in 2022 (Clear Guide)

- 9 Different Types of Rotary Pumps + PDF

- The 5 Best Well Pump in 2022 (Clear Guide)

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Parts of Pool Pump + Diagram & PDF

- 20 Parts of Submersible Pump + PDF

- 12 Parts of Sump Pump + Diagram

- 8 main Parts of Piston Pump and Function + Work & PDF

- 7 Parts of Screw Pump: Advantages and Disadvantages

- 10 Parts of Hydraulic Pump + PDF & Function

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 10 Parts of Reciprocating Pumps + Function, Application and Working

- Parts of Oil Pump

- Parts of Water Pump

- Parts of Centrifugal Pumps

- Types of Centrifugal Pumps: All Classification & Working Principles