What is Block Valve? Working Principle & Types – Any valve that is used to stop the flow of something, such as water through a pipeline or out of a tank. Gate valves, ball valves, and plug valves are some of the valves that are employed in this type of service. To prevent tampering or vandalism, a block valve may usually be secured in either the open or closed position.

What is A Block Valve?

In technical terms, a block valve is any valve that may prevent movement in one or more directions. In practice, a block valve is defined as a valve that may either prohibit or enable motion to occur without limitation. This means that in the off position, the valve must have no influence on movement and must completely obstruct movement in the on position. This description distinguishes it from several common valve types and excludes one-way valves entirely. The basic gate valve is the most common sort of block valve, however, there are hundreds of distinct versions.

The gate valve features casings that are somewhat bigger than the pipe it is linked to, as well as a control stem that protrudes from the side. The valve has a built-in gate that may be raised and lowered using an external control source. This sort of valve may be found in a variety of machines and can be operated manually or by an automated system that is directly connected to the valve.

A block valve can be almost any valve type in the widest sense. All that is required of the valve is that it prevents motion in at least one direction part of the time. Because that word refers to any valve, there is a temptation to restrict it down to a more specific classification.

The valve must accomplish two things with a more restricted meaning. When the valve is open, it must not affect the flow of the substance. It must completely prohibit material from going through the valve when it is closed.

Certain typical valve types are eliminated from the group by allowing the material to flow uncontrolled through the open block valve. A globe valve, for example, usually contains two chambers through which the substance passes. The process of traveling from one chamber to another disrupts the flowing fluids even though they are open. Because the substance is only limited in one direction, the second limitation eliminates check valves and other one-way valves from the list.

This term is more of a guideline than a formal definition. Because the underlying definition of block valve is so broad, many businesses and processes use it to describe their equipment in their own unique way. As a result, it’s very uncommon for one industry to refer to a certain type of valve as a block valve while another does not.

Types of Block Valves

3 Types of Block Valves are:

- Ball Valves

- Gate Valves

- Pinch Valves

The word “block valve” is not an official categorization of a certain type of valve, which is a crucial distinction. Rather, it’s a catch-all term for a variety of flow-stopping valves.

Due to their design, certain valves instantly disqualify themselves as block valves. Globe valves are a type of control valve that, due to their design, limit flow no matter how wide they are open. Butterfly valves, which have discs in the center of the pipeline, are similar. A few types of valves with block valve characteristics are listed below.

Ball Valves

Ball valves are by far the most prevalent form of valve, particularly in the PVC applications we find.

These valves typically employ a spherical seating with a hole in it to completely switch on/off flow in a system. When the valve is in the “on” position, liquid can flow through this hole.

Some ball valves come in “full-bore” versions, meaning the hole in the ball is the same diameter as the pipeline. Full-bore ball valves are excellent examples of block valves since they aren’t designed for slowing or restricting flow but excel at entirely halting it and allowing it to pass through without interruption. Ball check valves aren’t block valves since they normally limit flow even when liquid pushes them open.

Gate Valves

Another wonderful illustration of the various block valve types is gate valves. They have a vertical gate with a flat surface that stops liquid in its path. The standard gate valve is designed to function as a shutdown valve rather than a control valve. In a full-bore design, when gate valves are open, the gate is fully out of the way. When the valve is open, this signifies that flow is unrestrained. A gate valve, like a ball valve, is a textbook example of a “block valve.”

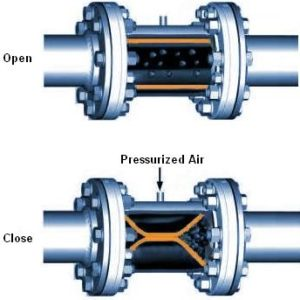

Pinch Valves

Pinch valves are not the same as the other two types of block valves we’ve spoken about. Because pinch valves may act as both a stop and a limiting valve, they are useful in a variety of situations. They feature an internal tube that may be pinched shut or left open (either fully or partially). Ball and gate valves do not operate well when just half-open, which is why this is different.

Pinch valves have a full-port design that allows fluid to pass through without slowing down as long as the valve is fully open. Depending on the pressure, they can also shut and entirely halt liquid. Pinch valves are unusual block valve examples because of all of these qualities.

Working Principle of A Block Valve

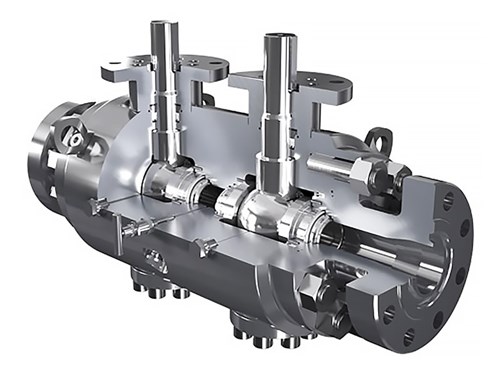

Double block and bleed Valves work on the premise that they can isolate themselves from both upstream and downstream process flow/pressures. Two balls, a gate, a globe, a needle, and so on are used to accomplish this. Back-to-back valves, with a third “isolatable” valve in the hollow in the middle. The cavity generated between the primary process isolation Valves can be emptied once isolation has been established in one or more of them. This is useful for flow diverting, sampling, or injection, as well as maintenance and or integrity checks where seat leakage can be monitored via the third “bleed” Valve. To understand more about the working principle of block valves, watch this video.

Applications of Block Valves

Double block and bleed valves are most typically seen in the oil and gas sector although they can be useful in a variety of other applications.

It’s often utilized when the valve chamber has to be bled, piping needs to be isolated for repair, or any of the following scenarios:

- Prevent contamination of the product.

- Remove the equipment from service so that it may be cleaned or repaired.

- Calibration of meters

- Liquid service near rivers or communities

- Transmission and storage

- Injection of chemicals and sampling

- Separate pressure indicators and lever gauges from the rest of the equipment.

- Primary process steam

What Should You Look For In a Twin Block and Bleed Valve?

When choosing a valve, consider the fluid characteristics, pressure, and temperature, just as you would with any other. However, the most critical consideration is how the valve is utilized. With a variety of variants accessible, decide which of these will match your process and needs best.

Consult an engineer if you’re uncertain about which double block and bleed valve are best for your application. They can assist you in determining which one will best achieve your goals.

Do you need assistance choosing a double block and bleed valve? Inquire about it at the Linquip platform! There you can find numerous Manufacturers and Distributors of valves along with various Service Providers.

FAQs about Block Valves

1. What is the purpose of a block valve?

When completely open, block valves allow fluids to pass through with minimal flow restriction and pressure loss, while fully closed, they offer a tight seal. Gate valves are the most typical way to turn things on and off.

2. What is another name for a block valve?

“Any valve that has the potential to impede movement in one or more directions,” according to the strictest definition of “block valve” (or shutdown valve). However, most people utilize the phrase to refer to a valve that may completely stop or enable motion.

3. What is the purpose of a block and bleed valve?

The function of the block and bleed valve system is to isolate or stop the flow of fluid in the system, so that fluid from upstream does not reach downstream components.

4. What is a manual block valve?

Manual valves, by definition, are valves that utilize a manual operator (such as a handwheel or handlever) to stop and start flow (block or on-off valves), however, certain designs may also be used for simple throttling.

5. What is block and bleed arrangement?

A block and bleed manifold is a hydraulic component that combines one or more block/isolate valves, often ball valves, and one or more bleed/vent valves, typically ball or needle valves, into one component for interaction with other components (pressure measurement transmitters, gauges, switches, etc.)

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Solenoid Valve and How Does It Work? 2022 Guideline

- What is Automatic Expansion Valve: A Basic Guide

- Types of Pressure Relief Valve: All you need to know about PRVs

- Types Of Solenoid Valves: Everything You Need To Know

- Types of Pneumatic Valves: Specifications and Working Principles

- How to Prevent Sewer Backflow Valve Problems?

- Backflow Preventer vs Check Valve: What’s the Difference?

- 5 Main Types of Isolation Valve

- 10 Types of Water Valves: The 2022 Ultimate Guide

- The 6 Best Tubeless Valve Stems in 2022

- What is Poppet Valve? Working Principle, Types & PDF

- What is Manifold Valve? With Function & Types

- What Is Linear Valve? With Example, Working Principles & Types

- What is Balancing Valve? Working Principles,Types & Function

- What Is Actuated Valve? Working Principle & Types

- What is Air Valve? Working Principles & Types (Clear Guide)

- What are Rotary Valves? Working Principles & Types

- 6 Types of Non Return Valve (Ultimate Guide)

- Best Pressure Reducing Valves of 2022