Types of O-Ring – O-rings are a type of seal or gasket with a circular cross-section. They are often used in a range of sectors to stop fluid or gas leaks from happening in goods, systems, or machines. They have found employment in many popular items, including cars and engines, because of their inexpensive cost, straightforward manufacturing process, ease of installation, and resilience to pressure. O-rings are utilized by the aerospace industry in several rocket and aircraft applications.

On the Linquip website, among the many options available to you, you will find all the information you need to know about O-Rings, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all O-Ring for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

How Does an O-ring Work?

O-rings are round, donut-shaped mountings that are squeezed between two distinct components to create a better, tighter seal, as their name implies. O-rings are essentially quite similar to a common type of gasket, with the exception that they are made expressly for industrial usage in situations where they would be exposed to severe temperatures, pressures, or materials. O-rings are such a simple yet effective answer to an ancient problem across many industries because, in these situations, a normal gasket consisting of rubber, cork, or metal would not survive the force imposed upon it.

O-rings, on the other hand, are made of tougher elastomers that can endure the harsh circumstances to which they are exposed. They function by being inserted into the channel or groove, or “glands,” between two separate pieces of equipment, which may be static or dynamic. The O-ring is made to conform to the specific dimensions of the surfaces pressing against it when the two components are pushed together, forming an impermeable seal that won’t let air or water in. Up to a certain degree, the O-ring will generate a tighter seal the more pressure is applied to it. To prevent damage to the O-ring and compromise of the seal itself, it is crucial to avoid applying too much pressure to the O-ring.

O-rings also have the appealing feature of returning to their original donut shape when the two compressed components of the equipment have been removed and the pressure applied to them has been released. O-rings may be reused for a variety of reasons thanks to this, but it’s important to keep in mind that recycling cannot go on forever. The consistency and resilience of the O-ring will eventually be adversely affected by the stresses applied to it, necessitating its replacement with a new one in order to maintain a sufficient seal.

How to Use O-ring Seals

Pumps, cylinders, connections, and valves all frequently contain O-rings, which are used to seal gaps between different parts and stop the leakage of fluids and gases. They are a very adaptable solution to a very common engineering problem since they may be employed with static, dynamic, hydraulic, and pneumatic components.

As previously mentioned, using an o-ring is very similar to using any other kind of gasket: the circular cross-section made of elastomer is placed in a specially designed groove (whose geometry is fairly universal), where it is compressed between two or more parts once they are assembled and interlocked. The resultant o-ring seal is affordable, dependable, reasonably durable, and simple to maintain or replace as necessary.

An O-ring-type seal’s ability to revert to its former shape when the components it connects are detached and the compression forces acting on it are eliminated is one of its main advantages. The robustness and homogeneity of the materials and the torus shape of the seal will begin to deteriorate with repeated use over time, and eventually, a new o-ring will need to be installed if the seal is to stay tight.

When subjected to pressure, the o-ring will shift in its groove towards the side of the seal that is under lesser pressure, pressing harder and harder against the inner and outer walls of the gland that is formed between two components. Up to a point, this will result in a tighter and tighter seal, but it’s crucial to avoid placing an o-ring under more pressure than it was made to bear since excessive deformation can eventually result in the seal starting to leak again.

What Distinguishes Static O-Ring Seals From Dynamic O-Ring Seals?

Designing static and dynamic O-ring seals varies in several significant aspects. A dynamic O-ring aids in creating a seal between moving elements, whereas a static O-ring is any o-ring made to connect with two or more surfaces that do not move relative to one another.

In general, static o-rings are made of less durable materials than their dynamic counterparts. Additionally, it’s critical that the parts being linked together in a dynamic environment be precisely engineered and polished so that they won’t wear out or otherwise damage the O-ring that is positioned in between them. O-rings utilized in static applications provide less of a risk because compression is typically their primary source of stress (to which they tend to be fairly resilient).

All o-rings need to be lubricated to some extent for them to function at their best, however, dynamic o-rings need heavier and more frequent lubrication (as well as more frequent checking, maintenance, and replacement) than static equivalents. Different forms of dynamic motions, such as rotary, reciprocating, and oscillating, necessitate the fabrication of o-rings with various material characteristics in order to function at their best.

Different Types of O-rings

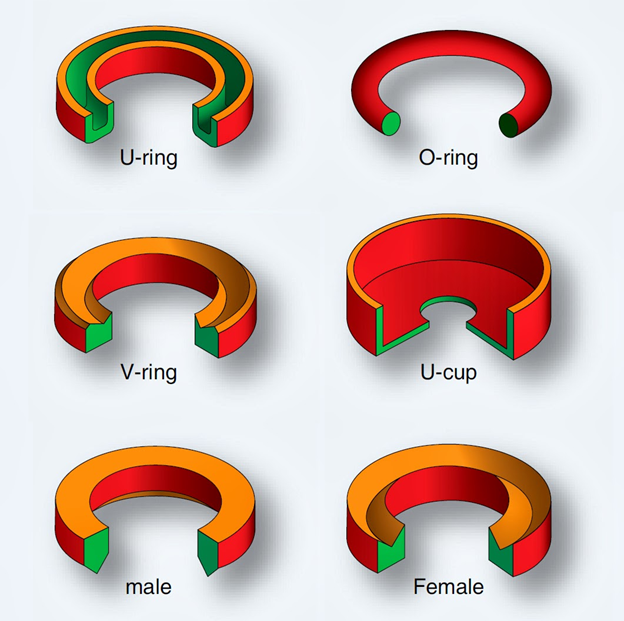

8 Types of O-Ring include:

- A Nitrile O-ring

- A VitonTM O-ring

- Silicone O-rings

- PFA O-rings

- FEP O-rings

- USP Class VI O-rings

- Vulc O-rings

- Large O-rings

There is undoubtedly an O-ring that is ideal for any application, whether it is in an industrial power plant, heavy-duty agricultural machinery, underwater in a maritime environment, or among the gears and pistons of the automobile sector. But it might be challenging to decide which material is best for you when there are so many options.

Here is a list of the numerous O-ring varieties that are available, along with information on their benefits and potential uses.

A Nitrile O-ring

Nitrile elastomers, usually referred to as Buna-N or NBR, are frequently used as all-purpose O-rings because they provide a decent temperature range of between -50°C and 120°C as well as outstanding resistance to rips and abrasive treatment. Although it is vulnerable to damage from automotive brake fluid, ketones, halogenated hydrocarbons, nitro hydrocarbons, or phosphate ester, nitrile also enjoys respectable resistance to water, oils, and some hydraulic liquids. As a result, it may be used for a limited number of applications in the fields of agriculture, the automobile sector, dairy, mining, plumbing, and railways.

A VitonTM O-ring

The fluorocarbon-based VitonTM O-rings, sometimes referred to as FKM O-rings, have excellent mechanical properties, are resistant to temperatures of -40°C to 250°C, have a low gas permeability, and have a low compression set. Acids, halogenated hydrocarbons, petroleum, and silicone fluids or gases can all be used with them with great success. However, they shouldn’t be used with Skydrol, heated hydrofluoric acids, amines, esters, or ethers with low molecular weight. They are well-liked in a variety of industries, including the automobile industry, aviation, chemical processing, and mechanical engineering companies, due to their extraordinary adaptability.

Silicone O-rings

Silicone O-rings have one of the broadest temperature tolerances of any O-ring material, withstanding temperatures of between -100°C and 300°C. This resilient material is a wonderful option for situations where extremely high or low temperatures are an issue because it has even been reported to withstand higher extremes (-115°C to 315°C) for a short period of time. Although it is very flexible and works fantastically with water, steam, or petroleum, it is vulnerable to ripping and abrasion damage. As a result, it’s better suited to static applications than dynamic ones.

PFA O-rings

Perfluoroalkoxy (PFA)-encapsulated O-rings are a desirable substitute for PTFE or FEP O-rings because they have a number of benefits over their rivals. PFA O-rings are a more affordable alternative to PTFE while offering stronger resilience to temperatures above 250°C than FEP. It is also better able to prevent various substances from penetrating its seal, making it perfect for usage in the food industry, pharmaceutical companies, and the chemical and petrochemical sectors.

FEP O-rings

FEP O-rings give consumers a number of significant benefits over a typical PTFE O-ring. They combine a silicone or fluorocarbon core with a covering of fluorinated ethylene propylene (FEP). First of all, they can withstand temperatures of -20°C to 204°C for fluorocarbon cores and -60°C to 260°C for silicone cores. Second, compared to their PTFE competitors, they also provide exceptional flexibility and low friction levels. They may be adapted to dynamic applications with slow, brief movements even if they are best suited to static ones. Because of this, they are well-liked in the petrochemical, chemical, food, and pharmaceutical sectors.

USP Class VI O-rings

USP, or United States Pharmacopeia, is used in this context, and rubber compounds that have earned a Class VI designation unquestionably have something special to offer. To guarantee that they are safe for use in circumstances where human life is at risk, all of the elastomers that get this accreditation must pass a battery of stringent testing processes. These methods evaluate the consistency, purity, quality, and strength of the elastomers. USP Class VI O-rings are therefore highly sought after in the healthcare and pharmaceutical sectors.

Vulc O-rings

Vulcanised O-rings (also known as Vulc O-rings) are formed by heating the parent material with sulfur at extremely high temperatures and fusing its ends together to form the donut shape. All of the O-rings mentioned above are made by molding procedures. With an average of 90% of the joint strength of the same molded item, this enables significantly quicker production generation on a more economical scale. Due to their adaptability and low compression values, Vulc O-rings are a desirable solution for a variety of sectors where the end user wishes to avoid the higher tooling costs of molded O-rings.

Large O-rings

O-rings may be made in any size because of the special manufacturing process used to make them, in addition to the financial benefits of vulcanization over molding. Although it is a very straightforward procedure to create a custom O-ring to whatever specifications necessary, standard bigger O-rings come in sizes up to 25.4mm. Like with normal Vulc O-rings, eliminating the need for molds and pricey manufacturing equipment not only lowers costs but also drastically shortens lead times, making them perfect for a variety of applications.

Factors to Consider When Picking O-rings

There are several things to take into account when selecting the best O-ring for your particular application. Operating circumstances, chemical compatibility, sealing pressure, temperature, durometer, size, and cost are only a few of them. You may also consider a material’s abrasion, tear, ozone, and electrical resistance capabilities, depending on the circumstances. To make sure the fluid, temperature, pressure, and climatic conditions are suitable for the O-ring of your choice, you may also carry out the necessary field tests.

Choosing O-ring Materials

Manufacturers create O-rings and seals using a variety of elastomers with diverse physical and chemical qualities to fit a wide range of applications. Here are a few of them to consider:

Rubber Butadiene Nitrile (NBR)

Water, petroleum oils & fluids, and hydraulic fluids are all resistant to it.

Ketones, ozone, strong acids, halogenated hydrocarbons, freons, automotive braking fluids, and methanol are all not advised for use.

Temperature Range: -40° to +250°F; nevertheless, this is an average of the lower and higher tolerances for the different nitrile butadiene rubber (NBR) compounds produced by Parker. Parker’s Buna-N compound, which contains compounds N0674, is a 70 to 90 durometer hardness nitrile that can tolerate temperatures as low as -30°F and as high as 250°F.

Hardness: 40 to 90 durometers of Shore A

Nitrile Buna

The most often used elastomer for O rings. The majority of the basic O-rings provided by Parker Hannifin are made of hard nitrile (Buna-N) in 70 durometer, with 90 durometer being an option for tube fittings and adapters. Buna-Nitrile elastomer is highly regarded by seal experts for its affordable pricing and superior resistance to petroleum-based lubricants and fuels, silicone greases, hydraulic fluids, water, and alcohol.

Ethylene-Propylene (EPDM)

Because of its outstanding resistance to heat, water and steam, alkali, mild acidic and oxygenated solvents, ozone, and sunshine, EPDM enjoys a flawless reputation in the sealing industry (UV). Nevertheless, experts advise against using EPDM chemicals in settings including hydrocarbons, oil, or gasoline.

Extreme cold, steam, boiling water, sunshine and UV rays, weak acids, ketones, and alkalis are all resistant to it.

Not advised for Di-ester base lubricants and petroleum base oils

Range of temperatures: -65 to +450°F

40 to 90 durometers of Shore A hardness

Neoprene (CR)

Neoprene is a versatile elastomer with mediocre resistance to weather and petroleum fluids (ozone, sunlight, UV, and oxygen). Neoprene O-rings are resistant to flex breaking, have strong durability, and have a relatively low compression set.

Resistant to: Silicate ester lubricants, high aniline point petroleum oils, mild acids, and refrigerants (freons, ammonia).

Ketones and phosphate ester fluids are not advised.

Range of temperatures: -45 to +250°F

50 to 80 Shore A durometers of hardness

Fluorocarbon (Viton)

Viton is a well-known brand name that may spring to mind when we discuss fluorocarbon O-rings. Compounds made of fluorocarbon (FKM) have strong chemical resistance as well as high thermal resistance. They are a popular choice for a variety of applications, including those in the automobile and aerospace sectors.

Resistant to acids, halogenated hydrocarbons, certain phosphate ester base fluids, silicone and silicate ester base lubricants, and petroleum-based oils and fluids.

Standard temperature range: -15°F to +400°F; however, certain Parker FKM Viton compounds may withstand temperatures as low as -65°F and as high as +450°F.

50-95 Durometer Shore A Hardness

FFKM, or perfluoroelastomers (Parfluor)

Perfluoroelastomers (FFKM) is an expansion of the Fluorocarbon FKM elastomers that increase the FKM’s compatibility while also raising the materials’ upper temperature limitations at the expense of their lower temperature limits. The cleanest and purest substances on the market are FFKMs. They are the top option for clean applications and are incredibly well-liked in the semiconductor sector.

Silicone

O-rings made of silicone offer a number of exceptional qualities, such as high ozone and UV radiation resistance, good flexibility, and long fatigue life. Despite the qualities listed above, experts advise against using silicone O-rings in dynamic applications. The majority of petroleum fluids, water, ketones, and steam are not compatible with them due to their low strength, poor abrasion resistance, and high gas permeability.

High aniline point oils and dry heat (air to 400°F) resistance

Not advised for: The majority of petroleum fluids, ketone bodies, water, and steam

Range of temperatures: -175°F to +450°F

40–80 Durometer Shore A hardness

Polytetrafluoroethylene (PTFE)

O-rings made of polytetrafluoroethylene (PTFE) are intended to be utilized in extreme conditions where the temperature ranges from -450°F to 600°F. The greatest variety of solvents, including acetone, isopropyl, methyl, etc., are compatible with PTFE O-rings. Additionally, they absorb little and have little gas permeability. Unfortunately, pure PTFE O-rings are stiff and challenging to apply because of the qualities of the polytetrafluoroethylene substance. In order to provide consumers with greater options, manufacturers like Parker resolve this issue by combining PTFE material with different fillers. Food, pharmaceutical, and medical sectors frequently employ PTFE seals.

Most chemicals, with the exception of fluorine, alkali metals, and a few fluorochemicals like chlorine trifluoride and oxygen difluoride.

Applications requiring O-Ring strain and compression are not advised.

Range of temperatures: -260°F to 300°F

55 to 60 Shore D durometers of hardness

Application of O-Rings

O-rings for Sealing at High Pressure

Industrial o-rings frequently need to be high-pressure resistant and durable in situations with high temperatures and dynamic conditions. O-ring design and fabrication again focus on selecting certain materials for improved performance under specified situations for a high-pressure seal to function at optimal levels.

O-rings work on the premise that even pressure applied to the (more or less incompressible) o-ring material results in predictable deformation patterns all the way around the gasket’s perimeter in its groove. This indicates that an o-contacting ring’s surfaces are under reasonably consistent mechanical stress.

It is essentially impossible for leaks to happen, even at high pressure, as long as the internal pressure from the fluids being held stays below a specific O-contact ring’s stress value. However, mechanical failure under high pressure can easily result in the o-ring being extruded or destroyed, therefore it’s crucial to pick the proper material for the specific environment you want to utilize it in.

Engines with O-ring Seals

An engine o-ring is an excellent example of a product that has to be tough enough in design and material construction to handle many hard criteria of temperature, pressure, and chemical compatibility, especially one used in high-performance or turbo engines.

Many common rubbers and polymers shouldn’t be used with substances based on solvents, fuels, or oils. An oil o-ring must be specially made for use in engines out of compatible hybrid materials that enable it to maintain essential o-ring characteristics (flexibility, incompressibility) while providing more robust resistance to heat, pressure, o-ring leaking, and chemical attack than a standard elastomer typically could.

Please feel free to get in touch with our customer service staff through the help sections on our website for more guidance and details on appropriate goods to use as engine o-rings.

O-Ring Plumbing Seals

Given the variety of materials, sizes, and gauges available for use in ducting and piping applications, as well as to form tight, watertight seals around taps and other fittings, plumbing o-ring options are widely accessible. Finding the right size and form for the particular purpose you have in mind is key to selecting the finest product for the job.

O-Ring Seals Made of Food Grade

O-rings that have been designated as “food safe” for use in the manufacture and preparation of meals, drinks, and dining goods have been produced to higher criteria of material composition.

O-Rings for CO2 Seals

For many different types of o-rings, carbon dioxide frequently causes problems because softer materials have a propensity to absorb the gas over time and swell. In the near term, this might result in an inconsistent seal, and over time, the CO2 will actually start to cause the o-ring to degrade inside.

Polyurethane, PTFE, nitrile, and fluoroelastomers are some common materials to utilize in situations where the o-ring will have prolonged CO2 interaction. However, taking into account other environmental or application aspects will always help you make the right decision.

O-Ring Seals for Use in Aviation

In order to keep the powertrain of an aerospace craft operating cleanly, efficiently, and smoothly, aircraft o-rings and aerospace o-rings often need to be extremely chemically resistant, able to work within a broad range of temperatures, and able to withstand high pressures. Fuel cap gaskets, fuel system o-rings, and valve cover seals are examples of typical uses.

Nitriles, ethylene-propylene, fluorosilicones, and other common elastomers are employed in aerospace-related applications. The majority of sales for aerospace and aeronautics are made through bulk purchases of multi-size o-ring kits since there are so many various sizes and gauges of o-rings spread throughout most aircraft engines and systems.

Download Types of O-Ring PDF

You can download the PDF format of this post from here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The 10 Best Circular Saws in the USA

- 5 Different Types of Drill Bits for Wood: A Comprehensive Guide

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- The 10 Best Hammers

- The 10 Best Mini/Benchtop Milling Machine

- The 8 Best Pressure Washers

- The 8 Best Rust Converter (Review Guide)

- 8 Best Soldering Iron for Electronics & The Like + Buying Guide

- The 10 Best Fertilizer Spreader

- The 7 Best Portable Band Saws + Tips for Choosing

- The 9 Best Cordless Impact Wrenches

- The 10 Best Electric Space Heater + Buying Guide

- The 8 Best Engine Hoists & Accessories + Buying Guide

- Top 10 Irrigation Equipment Suppliers

- Top 10 Railroad Equipment Suppliers in USA & Worldwide

- The 10 Best Steel Toe Boots for Women

- Top Brick Manufacturers in USA & Globally

- Top Water Filter Supplier & Companies

- Top Foam Rubber Suppliers in USA & Worldwide

- Top Crushed Stone Suppliers in USA

- The 4 Best Ceramic Coatings

- Types of Drill Bits for Metal: Comprehensive Guide

- All 24 Types of Drill Bits + Video: Clear Guide

Informative blog! Thanks for sharing well-explained information about O Ring Seals, which describes its types, features, & applications. I found this information very useful and beneficial for those who work in the same field.

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various O-rings based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals.

we want 72 Bar withstand pressure O-RING. static condition,using in underwater purpose

dia X Cross Sec

390.4 X 6.8

638.4 X 6.8

370.4 X 3

610 X 3.9

SWARAN

+91-8891866520

I know that “AS-” Orings are designed to Aero-Space specifications, “G-” are just general, but what does “”MVP-” stand for?