Efficiency of Diesel Generators- When buying a generator set, fuel efficiency should be one of your top priorities, regardless of the use. Fuel-efficient generators offer numerous advantages to the end-user, ranging from fuel savings to a lower cost of ownership. In this post, we’ll look at what you should consider when selecting a generator based on fuel efficiency, including which fuel to use and which items to consider.

Linquip’s website contains all of the information you would ever need to know about diesel generator equipment and devices. You can always turn to our team of experts at Linquip at any time with any questions you might have about generators. Linquip’s article “What Is A Diesel Engine?” would be a good starting point if you wish to gain a better understanding of diesel generators.

You can also sign up as a Linquip Expert if you would like to discover and make use of all the features available through the Linquip website. By doing so, you will be able to demonstrate your skills to potential employers exactly depending on the industrial equipment you work with. Have you ever thought about writing as a Guest Posting? As a Guest Posting contributor, you can submit your content on the Linquip platform.

Importance of the Efficiency of Diesel Generators

Diesel generators are extremely important appliances that use diesel fuel to generate power. To create power, these machines combine an electric generator with a diesel engine. Diesel generators use combustion to transform some of the chemical energy in diesel fuel into mechanical energy. This mechanical energy is then used to turn a crank, which generates electricity.

Moving the wire through a magnetic field induces electric charges in it. The magnetic field is commonly produced by two polarized magnets in an electric generator application. After that, a wire is coiled multiple times around the diesel generator’s crankshaft and positioned between the magnets and in the magnetic field. The wires are moved throughout the magnetic field when the diesel engine rotates the crankshaft, which might produce electric charges in the circuit.

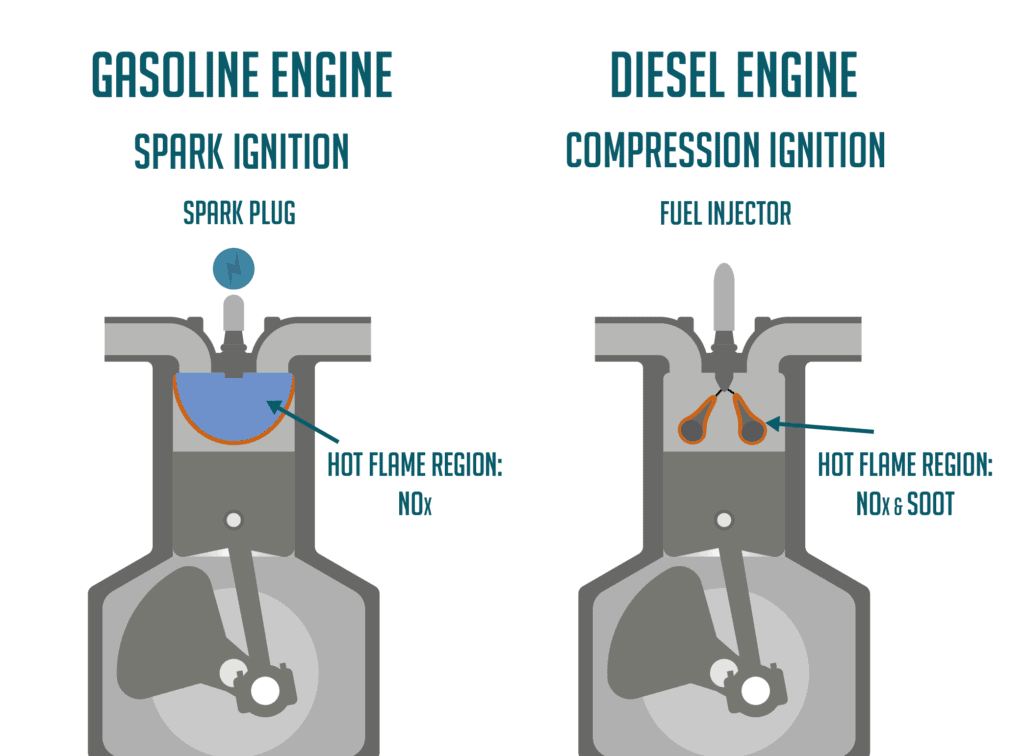

A diesel generator will use 0.4 L of diesel per kWh produced as a rough rule of thumb. Fundamentally, the diesel engine is an internal combustion engine. The diesel engine, unlike a gasoline engine, relies on the heat of compression to ignite and burn the fuel pumped into the injection chamber. Diesel engines, in general, have the best thermal efficiency of any internal combustion engine, allowing them to achieve a percentage of Carnot efficiency. Many crude oil derivatives can be used in diesel engines. Natural gas, alcohols, gasoline, wood gas, and diesel are all possible fuels for a diesel engine. You can find more information about the definition and importance of the efficiency of diesel generators here.

The Efficiency of Diesel Generators Specifications

Versatility

Diesel generators are employed in a wide range of applications all around the world. They are typically installed in rural areas where they are connected to the power grid and can be utilized as the primary power source or as a backup. Diesel generators can also be used to offset the grid’s peaking power needs because they can be turned on and off fast and without causing any lag.

Generators for household usage range from 8 to 30 kW, whereas generators for commercial use range from 8 KW to 2,000 KW. Auxiliary power, which can range from lights, fans, and switches to supplementing power to the propulsion system, is provided by diesel generators on large ships.

Emissions

Exhaust fumes are produced when diesel or other fuels are burned. Carbon dioxide (CO2), nitrogen oxide (NOx), and particulate matter are all produced by diesel generators. These generators discharge this into the environment, significantly lowering air quality in the surrounding areas. Every liter of gasoline contains 0.73 kilograms of pure carbon, while diesel fuel releases 2.6 kg of carbon dioxide.

Why Are Industrial Diesel Engines So Efficient?

For more than a century, industrial diesel engines have been utilized in a variety of applications, including power generation for the oil and gas industry. The internal combustion process, which enhances engine efficiency and reduces fuel consumption, is one of the key reasons for this engine’s success.

No Spark – Efficiency Comes from Compressed Air

The injection of atomized fuel into a combustion chamber ignites the internal combustion diesel engine. Because the compressed air in the cylinder is at a high temperature, immediate combustion occurs without the use of a spark-ignition source.

The thermal efficiency of a diesel engine is the highest of any internal combustion engine. Diesel generates greater power than gasoline because of its high energy content (high energy density). Diesel fuel has a lower carbon footprint than gasoline.

The high compression ratios of diesel engines allow them to extract more power from the fuel when the hot exhaust expands. This higher expansion or compression ratio boosts the engine’s performance while also lowering its fuel consumption.

The cost of fuel per kW produced by diesel engines is significantly lower than that of other engine fuel types. Smaller amounts of fuel are consumed due to the higher energy density. As a result, diesel engines typically have a fuel efficiency of thirty to fifty percent lower than gasoline engines.

Advantages of Industrial Diesel Engines

Diesel engines have improved their operational efficiency and overcome the disadvantages of higher noise and maintenance costs since their beginnings in industrial use.

The maintenance costs of diesel engines utilized in electric gensets are frequently lower. They are often easier to maintain because of their lower operating temperatures and lack of a spark ignition mechanism. Their dependability is improved due to the removal of the electronic ignition system, which reduces the parasitic load on the engine and allows it to run reliably in damper or colder regions.

Diesel engines can run for lengthy periods with no problems. An 1800 rpm water-cooled diesel plant, for example, can run for 12,000 to 30,000 hours before requiring extensive repair. The same rpm water-cooled gas unit only lasts 6000-10,000 hours before it needs to be serviced.

Because of the high amount of compression and the higher creation of torque, diesel engines are typically manufactured with stronger parts. Diesel fuel, which is distilled from petroleum as light oil, gives the cylinders and unit injectors more lubricity, extending their life.

FAQs about the Efficiency of Diesel Generators

If a Diesel Engine Is More Efficient, Isn’t It the Right Choice for Everyone?

While diesel engine design and operational features have improved significantly, natural gas and gasoline engines have also increased markedly, allowing them to compete with gallons of diesel for use in tough and remote environments.

Diesel engines can be limited by high fuel costs and a scarcity of fuel. Natural gas is less expensive in distant places or everywhere there is access to a natural gas source. Otherwise, diesel fuel must be trucked at a premium to the site. The cost of fuel storage, the risk of leaks, and the chance of shortages can all be disadvantages of relying on diesel.

Diesel engines are noisier than gasoline engines, despite significant advances over time. This renders them unsuitable for some environments that require backup power generation. Hospitals, libraries, fire and police stations, and other usage in crowded locations are examples.

Diesel generators are larger and less mobile due to their robust structure, which necessitates the use of massive and heavy components. As a result, diesel generators may not be the most portable device when compared to smaller and lighter generators.

While diesel generators are extensively utilized due to their numerous benefits, natural gas generators are narrowing the gap: with the development of new technologies in engines, enclosures, and other components, the distinctions between diesel and natural gas generators are becoming less evident.

Need Help Deciding Which Engine Type Is Right for Your Generator Set?

The benefits and downsides of using a diesel engine and generator combination over a similar-performing natural gas unit must be understood before making a decision. Worldwide Power Products provides the expertise and experience to help you make that selection. Please contact us with your needs, and we will give you the finest advice and solutions possible.

Diesel Vs. Gaseous Generators: Which Is Best for Fuel Efficiency?

When comparing the amount of fuel required to run a generator, diesel generators outperform their gaseous counterparts. That isn’t to say that diesel is the best solution in every circumstance.

In oil and gas applications, for example, using a diesel generator makes no sense because there is a virtually endless source of free gas on site. However, because there is already so much diesel-fueled equipment on a building site, a diesel generator would be the superior option.

When deciding between diesel and gaseous generators, consider fuel expenses as well as possible fuel efficiency gains during the equipment’s lifetime. Natural gas is often less expensive than diesel as a fuel source, although being less efficient. You should check the fuel market at the time of purchase because fuel costs fluctuate. A gaseous generator set may be more enticing if diesel fuel prices are high. If diesel fuel prices fall, diesel may become the most cost-effective choice throughout the lifetime of the generator set.

In general, when it comes to efficiency, diesel generators are the preferable option. As a result, all of the fuel-efficient generator sets we recommend in this post are Tier 4 Final-certified diesel generator sets.

Nonetheless, you should consult with your generator distributor to determine which choice will provide the best long-term value for your application. Read our thorough analysis of the advantages and disadvantages of diesel and gaseous generators for additional information.

Three Fuel-Efficient Generators Suitable for Almost Any Application

We take pride in the fact that all of Power’s diesel generators are Tier 4 Final solutions that lower end-user running costs. But, out of all the alternatives, one line of generators has proven to be more fuel-efficient than the others: Our Tier 4 solutions are driven by the Volvo Penta D13 engine, which is one of the best in the world. The characteristics of three of these generators are mentioned below, but first, let’s talk about why we think this line is the best for fuel efficiency.

About the Volvo D13 Engine Platform

The Volvo D13 engine platform is one of the most popular in the world and for a good reason. It outperforms the competition in terms of fuel efficiency, conformity to Tier 4 emission requirements, and application diversity. It offers a wide range of on- and off-highway uses, including construction, shipping, mining, and more, and its cutting-edge system boosts fuel efficiency by up to 5%.

The advanced combustion technology (V-ACT) developed by Volvo is optimized for fuel economy. Its cutting-edge engine management technology adjusts to different load levels and improves engine performance as needed. The V-ACT system also aims to increase power production by turning more fuel into mechanical energy while reducing heat rejection. As a result, operational, maintenance, and downtime expenses are decreased.

Meeting Emission Standards

Volvo uses a simple two-part emission control system to meet Tier 4 Final standards: selective catalytic reduction (SCR) and modest exhaust gas recirculation (EGR). Tier 4 Final regulations limit two types of hazardous pollutants produced by diesel combustion: nitric oxides (NOx) and particulate matter (PM). The engine architecture of the D13 produces low levels of PM but significant levels of NOx.

Through a chemical process with a urea solution called AdBlue, their strong SCR technology turns harmful NOx into nitrogen and water, which are naturally occurring chemicals in our environment.

The mild EGR recirculates some exhaust gas back into the combustion chamber, replacing some oxygen with CO2, resulting in less NOx formation during combustion. The EGR system not only reduces nitric oxide emissions but also lowers peak combustion temperatures and lowers the unit’s cooling requirements. EGR also has further fuel economy benefits because it repurposes gas that would otherwise be squandered.

We offer a variety of generator designs based on the D13 Tier 4 Final engine architecture, ranging from mobile to stationary. The CK300VM-T4 Final model, which is the standard unit in this kW range, comes with a 300-gallon sub-base fuel tank, allowing for 19 hours of operation duration at full load.

In this section, three ideal types for improving fuel efficiency in practically any application are presented:

- CK300VM-T4 Final

Rating level: 60 HZ (3 phase / .8 power factor)

Standby rating: 250 kW / 300 kVA

Prime rating: 225 kW / 280 kVA

Specifications:

Volvo Penta: CARB certified, TAD1371 Tier 4 Final

300 gallon, 19 hours run time at 100% load

Does not require regeneration

- CK375VM-T4 Final

Rating level: 60 HZ (3 phase / .8 power factor)

Standby rating: 300 kW / 375 kVA

Prime rating: 275 kW / 343 kVA

Specifications:

Volvo Penta: CARB certified, TAD1372 Tier 4 Final

300 gallon, 17 hours run time at 100% load

Does not require regeneration

- CK430-T4 Final

Rating level: 60 HZ (3 phase / .8 power factor)

Standby rating: 350 kW / 430 kVA

Prime rating: 325 kW / 406 kVA

Specifications:

Volvo Penta: CARB certified, TAD1375 Tier 4 Final

300-gallon, 16 hours run time at 100% load

Does not require regeneration

The Volvo Penta D13’s simplicity not only improves fuel efficiency and reduces dangerous pollution emissions, but also makes it easier to maintain. The D13, which serves as the foundation for this line of Power Tier 4 generators, saves you money on fuel, maintenance, and time.

What Is a GenSet?

An engine generator is a piece of equipment composed of a generator and an engine attached. It can also be referred to as a GenSet or an engine-generator set. It is often assumed that the engine will always be there, and the combined unit will be known as a generator.

Download Efficiency of Diesel Generators PDF

You can download this PDF document to your computer if you would like to keep it for future reference in case you need it. Download it by clicking the link below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The Difference Between Generator and Inverter: All You Need to Know

- Types of Generators: Learn the Basics, Get the Most Out f it!

- What is the Working Principle of a DC Generator?

- Generator Efficiency

- Working Principle of Diesel Generator + Diagram

- The Best Diesel Generator of 2022

- Diesel Generator Parts: A Complete Description

- Electric Generator Maintenance, Repair, and Services (2022 Guide)

- Gasoline Generator Repair and Maintenance (2022 Guide)

- How Much Does It Cost to Install a 22kW Generac Generator?

- How Long Can A Standby Generator Run Continuously?

- What is the Difference Between a Whole House and Standby Generator?

- The Difference Between Prime & Standby Generators

- Can I install a Standby Generator Myself? (An All-In-One Guide)

- Portable vs. Standby Generator (Best Choose for Home in 2022)

- DC Generator Repair, Maintenance & Testing 2022 (Full Guide)

- Pros and Cons of Inverter Generators in 2022

- The 5 Best Propane Generators in 2022

- The 9 Best RV Generators in 2022 (Clear Guide)

- The 10 Best Ozone Generators in 2022 (Ultimate Guide)

- How to Connect a Generator to Your Home? (Best Guide in 2022)

- The 3 Best Portable Power Station Generators in 2022 +Pros & Cons

It sure was interesting when you said that the operational efficiency of diesel engines has improved. This is something that I will share with my mother who is looking to find the best heating oil for her generator at home before this month ends. She wants to save money in the long run, so I will ask her to consider visiting a diesel depot to grab some offers.

Thanks for sharing your experience with us! You can also visit our industrial directories, where you can find thousands of various industrial equipment based on your application and demand.